Abstract

The aim of this research was to study the behaviour of the drying kinetics of pepino fruit (Solanum muricatum Ait.) at five temperatures (50, 60, 70, 80 and 90 °C). In addition, desorption isotherms were determined at 20, 40 and 60 °C over a water activity range from 0.10 to 0.90. The Guggenheim, Anderson and de Boer model was suitable to depict the desorption data. A monolayer moisture content from 0.10 to 0.14 g water g−1 d.m. was reported. The equations of Newton, Henderson–Pabis, Modified Page, Wang–Singh, Modified Henderson–Pabis, Logarithmic as well as standardised Weibull were tested for modelling drying kinetics. Besides, Fick’s second law model was used to calculate the water diffusion coefficient which increased with temperature from 2.55 to 7.29 × 10−10 m2 s−1, with estimated activation energy of 27.11 kJ mol−1. The goodness of fit of the models was evaluated using sum squared error and chi-square statistical tests. The comparison of the experimental moisture values with respect to the calculated values showed that the standardised Weibull model presented the best goodness of fit, showing that this equation is very accurate for simulating drying kinetics for further optimisation of drying times.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The pepino fruit (Solanum muricatum Ait.), which is an exotic fruit, is also known as melon pear and sweet cucumber. Although it is native to South America, it is also grown in Australia, New Zealand and USA (Huyskens-Keil et al. 2006). It is an herbaceous plant with great variation in size, shape and colour depending on the cultivar, very aromatic and juicy (Martínez-Romero et al. 2003). Furthermore, it is low in calories, very rich in minerals such as calcium, phosphorus and potassium and contains vitamins such as thiamin, niacin, riboflavin and ascorbic acid (vitamin C), ideal for a number of metabolic and antioxidant reactions (Diaz 2006). Besides, pepino fruit contains a high percentage of their fresh weight as water (approximately 92%). When pepino fruit ripens, it can be consumed as a dessert fruit, as an ingredient of fruit salads, in juices or in ice cream (Martínez-Romero et al. 2003).

One of methods to improve the shelf life of fruits is to reduce their moisture content to such extent that the microorganism cannot grow. Drying is a classical method of food preservation and it is a complex food processing operation mainly due to undesirable changes in the quality of the dried product. The basic objective in the drying of agricultural products is the removal of water in the solids up to certain level, at which microbial spoilage and chemical reactions deterioration are greatly minimised (Sacilik and Elicin 2006). Moreover, it brings about substantial reduction in weight and volume, minimising packing, storage and transportation costs and enabling storability of the product under ambient temperatures (Doymaz 2008). The drying process takes place in two stages. The first stage happens at the surface of the drying material at a constant drying rate and is similar to the vaporisation of water into the ambient. The second stage of the drying process takes place with decreasing drying rate. The conditions of the second stage are determined by the properties of the material being dried (Midilli and Kucuk 2003).

Dehydrated fruits have a rapid growing market and consumers are more demanding for higher quality dry products. Thus, in order to control and optimise the drying process, it is necessary to use mathematical equations to simulate water transport phenomena, particularly diffusion and external resistance which are the fundamental mechanisms governing food dehydration (Giner 2009; Kaya et al. 2007). Some empirical equations are used to model the drying kinetics of food including: Newton, Henderson–Pabis, Modified Page, Logarithmic, Two-terms exponential, Thompson, Diffusion approach, Wang–Singh, Modified Henderson–Pabis and others (Akpinar et al. 2003; Toğrul and Pehlivan 2003; Simal et al. 2005; Doymaz et al. 2006). Although most of the models are empirical, they are mainly derived from the diffusion model based on Fick’s second law for different geometries (Akpinar et al. 2003; Babalis and Belessiotis 2004; Akpinar 2006). In particular, the standardised Weibull model can be applied in many biological systems, and it was found valuable in the modelling of dehydration–rehydration phenomena mainly for differentiating between diffusion and external resistance processes (Marabi et al. 2003; Corzo et al. 2008).

Prior to the drying study, a sorption analysis must be performed to know the moisture content of the product at equilibrium, because drying behaviour is influenced by adsorption–desorption characteristics. This state of equilibrium results from multiple interactions on a microscopic scale, which is described by a relationship between the equilibrium water content of the product to be dried and the relative humidity of the atmosphere which surrounds it at a constant air temperature (Azzouz et al. 2002). Furthermore, determination of the moisture sorption behaviour of foods can be used to solve food-processing design problems, to predict energy requirements and to determine proper storage conditions (Arslan and Toğrul 2005).

Therefore, the aim of the present research was to study and to model the desorption isotherms and the drying kinetics of water mass transfer occurring during the process of hot-air drying of pepino fruit using empirical equations to evaluate the influence of temperature on the parameters related to the proposed models.

Materials and Methods

Preparation of Raw Material

Pepino fruits were acquired in a local market in the region of Coquimbo, Chile. The pepino fruits were selected by colour, size and state of ripeness according to a visual analysis, with no signs of mechanical damage. The pepino fruits were cut in slabs of 4.0 ± 0.2 mm in thickness. The moisture content was determined following the AOAC methodology no. 934.06 (AOAC 1990), using an analytical balance (CHYO, Jex-120, Kyoto, Japan) with an accuracy of ±0.0001 g and a vacuum drying oven (Gallenkamp, OVL570, Leicester, UK).

Determination of Desorption Isotherms

Desorption isotherms were determined following the methodology recommended by the European Project COST 90 (Spiess and Wolf 1983) at three working temperatures including 20, 40 and 60 °C. For this purpose, a known mass of sample, prepared in triplicate, was allowed to come into equilibrium with an atmosphere produced from a saturated salt solution having a known a w including LiCl, KC2H3O2, MgCl2, K2CO3, MgNO3, KI, NaCl, KCl and KNO2 (all reagents were purchased from Merck KgaA, Darmstadt, Germany) (Kaymak-Ertekin and Gedik 2004). The sample and the salt solution were maintained separately within a sealed container, and the sample weight was taken every 15 days from the beginning of the test until it reached equilibrium (constant weight). Sealed containers comprising salt solutions which generated a relative humidity greater than 75% were added Thymol in a Petri dish separated from the sample and the salt solution in order to prevent microbial growth in the sample, particularly moulding (Vega et al. 2007). Then, moisture content reached in the desorption experiment was determined (AOAC 1990).

The GAB (Guggenheim, Anderson and de Boer) equation is usually used to model food sorption behaviour, Eq. (1), as in the case of tomato and onions (Viswanathan et al. 2003), sweet potato (Chen 2002), peppers (Vega-Gálvez et al. 2007; Di Scala and Crapiste 2008), allig, kentichi and deglet nour (Bellagha et al. 2008). Besides, the model is considered to have parameters based on physicochemical phenomena, such as monolayer moisture content (X m) and the constants C and K (Goula et al. 2008). The constant C is related to the first layer heat of sorption and K is a factor correcting properties of the multi-layer molecules with respect to the bulk liquid (Arslan and Toğrul 2005).

Drying Process

The hot-air drying process was carried out in a convective dryer designed and built at the Department of Food Engineering of Universidad de La Serena, Chile (Vega et al. 2007). Dehydration was performed at five temperatures 50, 60, 70, 80 and 90 °C, with a constant air flow rate of 2.0 ± 0.1 m s−1 and a raw material load density of 10.2 kg m−2. Samples of 50.0 ± 0.1 g of pepino fruit slabs were placed as a thin layer in a stainless steel basket and weighed in a digital balance (OHAUS, model SP402, New Jersey, USA) with an accuracy of ±0.01 g. Hot air flowed perpendicularly through the samples. Dried samples were packed into polythene bags. All the drying experiments were done in triplicate.

Estimation of Water Diffusion Coefficient (D we)

Fick’s second diffusion law has been widely used to describe the drying process during the falling rate period for biological materials (Doymaz 2008). In this model, the dependent variable is the moisture ratio (MR) which relates the gradient of the sample moisture content in real time to both initial and equilibrium moisture contents (Eq. (2)). In the present experiment, the integrated equation of Fick’s second law was used for long time periods, and also slab geometry in one dimension (Eq. (3)), representing the first term in the development of the series in Eq. (4) (Crank 1975; Pardeshi and Chattopadhyay 2008). In this case, a linear relationship between logarithm of dimensionless moisture content and time is obtained, which can be used to determine water diffusion coefficients (D we) according to Eq. (4) (Vega-Gálvez et al. 2007; Babalis and Belessiotis 2004; Simal et al. 2005).

Modelling of Drying Kinetics

Numerous mathematical models have been proposed to describe the characteristics of agricultural products during drying (Doymaz 2008; Pardeshi and Chattopadhyay 2008). In this research, seven of the most known models were used to fit the drying experimental data, including Newton (Eq. 5), Henderson–Pabis (Eq. 6), Modified Page (Eq. 7), Modified Henderson–Pabis (Eq. 8), Logarithmic (Eq. 9), Wang–Singh (Eq. 10) and standardised Weibull (Eq. 11).

In particular, Eq. (11) was originally presented in 1939 by W. Weibull to describe the collapse of stressed materials. Since then, it has been successfully applied to describe kinetics of chemical, enzymatic and microbiological degradation processes as well as in the drying process (Marabi et al. 2003; Altenhofen da Silva et al. 2005; Corzo et al. 2008). The shape parameter (α) is related to the velocity of the mass transfer at the beginning, e.g. the lower the α value, the faster the drying rate at the beginning (Corzo et al. 2008). The parameter β can be interpreted as a kinetic reaction constant and represents the time when concentration, in this case, X wt − X we attains a value corresponding to 36.8% of X w0 − X we (Marfil et al. 2008).

In order to determine if there was an influence of the process temperature on the water diffusion coefficient (D we), kinetic parameters and monolayer moisture content (X m) were related to temperature through an Arrhenius-type equation (Eq. (12)).

Where Y is the parameter to be studied, Y o is the Arrhenius factor (m2 s−1). From Eq. (12), the activation energy (E a, kJ mol−1) can be estimated by plotting ln Y versus T −1 (Vega-Gálvez et al. 2007; Toğrul and Pehlivan 2003).

Statistical Evaluation of the Models

The statistical analysis of experimental data was determined using StatGraphics Plus 5.1® (Statistical Graphics Corp., Herndon, VA, USA), applying an analysis of variance (ANOVA) to estimate any statistically significant differences at a confidence level of 95% (p < 0.05). Goodness of fit of the proposed models for the desorption isotherm and drying kinetics data was evaluated by means of statistical tests including sum squared error (SSE) (Eq. 13) and chi-square (χ 2) (Eq. 14). It may be pointed out that the lower the value of SSE and chi-square, the better will be the goodness of fit (Pangavhane et al. 2000).

Results and Discussion

Desorption Isotherms

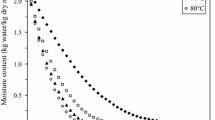

The average initial moisture content of pepino fruit samples was 0.910 ± 0.009 g water g−1 d.m. Figure 1 shows the experimental data as well as estimated equilibrium moisture content with the GAB equation at 20, 40 and 60 °C. This sorption model is very suitable to describe the desorption isotherms for a range of water activity between 0.10 and 0.95 which is the common a w range when analysing equilibrium moisture content of fresh fruits during dehydration (Arslan and Toğrul 2005). The moisture desorption behaviour of pepino fruit was temperature dependent, as indicated by a decrease in equilibrium moisture content, at all levels of a w, with increasing temperature (Fig. 1). Moreover, it can be observed that, for fixed water activities values, an increase in temperature leads to a decrease in equilibrium moisture content. This could be explained due to increasing temperature rendered to increase the kinetic energy associated with water molecules present in foods which, in turn, resulted in decreasing the attractive forces and consequently escape of water molecules. Therefore, it can desorb more moisture at lower temperatures than at higher temperatures at constant relative humidity environment (Lee and Lee 2008). This is probably due to an increase in the numbers of desorption sites (Arslan and Toğrul 2005). A similar behaviour was reported by other authors for different foods (Chua et al. 2002; Kaymak-Ertekin and Gedik 2004; Kaya et al. 2007; Di Scala and Crapiste 2008; Bellagha et al. 2008).

In addition, Fig. 1 shows that at a w >0.75 there is a crossing of the curves possibly due to the solubility of the polysaccharides and some protein, which make up almost 70% of the total weight in dry samples. Several researchers show a similar trend of curve crossing such as Fahrettin et al. (1998) with Turkish, Akanbi et al. (2006) with tomato, Lemus et al. (2007) with red alga Gracilaria and Vega-Gálvez et al. (2007) with red pepper var. Hungarian.

Table 1 shows the values of the parameters related to the GAB equation as well as the statistical parameters obtained when modelling the desorption isotherms at 20, 40 and 60 °C. It can be observed that the monolayer moisture content (X m) was in the range of 0.104–0.140 g water g−1 d.m., and C and K were in the range of 9.580–58.614 and 0.902–0.957, respectively. All the parameters mentioned presented a clear dependence on temperature. When the Arrhenius-type equation was performed, values of activation energies of 1.21, 35.5 and 6.17 kJ mol−1 for K, C and X m, respectively, were reported.

The average monolayer moisture contents found in this research were similar to those reported in other studies for similar temperature ranges, as in Di Scala and Crapiste (2008) for red pepper (0.127 g water g−1 d.m.), Babalis and Belessiotis (2004) for figs (0.117 g water g−1 d.m.), Goula et al. (2008) for tomatoes (0.138 g water g−1 d.m.) and Kaymak-Ertekin and Gedik 2004 for grapes (0.157 g water g−1 d.m.), apricots (0.105 g water g−1 d.m.) and potatoes (0.073 g water g−1 d.m.).

Determination of Water Diffusion Coefficient (D we)

Based on Fick’s equation, water diffusion coefficient (D we) can be calculated from the slope of the graphic representation of ln MR versus time, for each work temperature (Eq. (4)). Estimated D we values were 2.55, 3.04, 3.53, 6.08 and 7.29 × 10−10 m2 s-1 for 50, 60, 70, 80 and 90 °C, respectively. Similar values were reported by other researchers related to fruits and vegetables under analogous drying conditions. For example, D we: 1.28–2.91 × 10−9 m2 s−1 for Murici (Giraldo-Zuniga et al. 2006), 7.02–37.82 × 10−9 m2 s−1 for red pepper var. Hungarian (Vega-Gálvez et al. 2007), 1.33–3.36 × 10−9 m2 s−1 for figs (Babalis and Belessiotis 2004), 3.00–17.21 × 10−10 m2 s−1 for kiwi fruit (Simal et al. 2005), 1.17–4.80 × 10−10 m2 s−1 for fresh green beans (Abbasi and Mowla 2007), 3.91–6.65 × 10−10 m2 s−1 for tomato (Doymaz et al. 2006) and 1.89–3.3 × 10−10 m2 s−1 for cherry laurel (Kaya and Aydin 2007).

From the relationship of water diffusion coefficient and drying temperature (Eq. 12), activation energy from the inverse slope of the line plot of ln D we versus T −1 can be obtained. Activation energy can be interpreted as the energy barrier that must be overcome in order to activate moisture diffusion (Hii et al. 2009). In this research, an activation energy of 27.11 kJ mol−1 was obtained for D we (r 2 > 0.93). Comparable values for activation energy for fruits and vegetables has been reported by Vega-Gálvez et al. (2007) with 40.81 kJ mol−1 for red pepper var. Hungarian, Abbasi and Mowla (2007) with 57.67 (kJ mol−1) for fresh green beans and Kaya and Aydin (2007) with 15.81 kJ mol−1 for cherry laurel. To compare the goodness of fit of the standardised Weibull model, the activation energy was calculated from the mentioned distribution when plotting ln β −1 versus T −1 (Garcia-Pérez et al. 2005). A value of 21.84 kJ mol−1 was determined which is also in the range of activation energy of the products mentioned above. Thus, both diffusion and Weibull models can be used to predict such parameter.

Mathematical Modelling of Drying Curves

Figure 2 shows the clear exponential tendency of experimental drying curves for all working temperatures, and as expected, it is observed that drying time decreases as temperature is increased to reach a similar final moisture content. A drying constant rate period was not detected in the drying curves (Fig. 2). In fact, drying only occurred in the falling rate period for all the temperatures investigated in this study; this explains the use of the empirical models mentioned. The time required to achieve a moisture content lower than 0.2 g water g−1 d.m. at 50 °C was 600 min, approximately twice the time necessary to reach the same moisture content at a temperature of 70 °C (360 min), and three times for a temperature of 80 °C (180 min). Similar behaviours were reported by Akpinar et al. (2003), Toğrul and Pehlivan (2003), Simal et al. (2005) and Doymaz (2008) working with red pepper, apricot, kiwi and strawberry, respectively.

Table 2 shows the average values and standard errors of the kinetic and empirical parameters k i (i = 1, 2, …, 8), n i (i = 1, 2, …, 7), c, α and β, obtained for all the proposed models. As in the case of the water diffusion coefficient, a tendency with increasing temperature was observed for each of these kinetic parameters, since an increase in drying air temperature showed an increase in their values. Thus, it can be considered that these constants are directly proportional to this mass transfer coefficient. In particular, the values of scale (β) and shape (α) parameters of standardised Weibull model for fractional amount of moisture content (Eq. (11)) at different drying air temperatures are shown in Table 2. Values of β ranged from 98.88 to 244.37 min−1 and values of α ranged from 1.22 to 1.41. Similar values were reported by other authors when modelling water losses during osmotic dehydration of apple (Cunha et al. 2001), the rehydration of mushroom (García-Pascual et al. 2006) and air drying of coroba slices (Corzo et al. 2008).

For all kinetic parameters (Table 2), an ANOVA of 95% confidence level was performed. The analysis showed a p <0.05 for all cases, except for k 7 and α. This result indicated that there was statistically significant difference, and thus dependence, on the drying temperature for most of these kinetic parameters, except for the parameters mentioned. Thus, an Arrhenius-type equation (Eq. (12)) (r 2 > 0.83) was applied to the parameters that showed this dependence on temperature, reporting activation energy ranging from 21.87 to 32.70 kJ mol−1. The parameters k 7 and α probably depend on the characteristics of the tissue and/or the drying air rate as well as other external variables such as initial moisture content, shape and size of the product, presence of skin, pretreatments and others (Azzouz et al. 2002; Simal et al. 2005; Akpinar 2006; Vega et al. 2007).

Statistical Analysis of Models

Table 2 shows the average values of statistics test (SSE and χ 2) performed to the proposed models. These statistical tests evaluate the goodness of fit on the experimental data and they have been reported by other researchers during food drying analysis (Akpinar 2006; Doymaz 2008). All the proposed models showed a good fit with high values of r 2 (>0.90) and values close to zero for SSE and χ 2. According to these results, the models that best fitted the experimental data, considering the statistical test applied, were standardised Weibull model (SSE = 0.0005 and χ 2 = 0.0006), followed by Modified Page (SSE = 0.0006 and χ 2 = 0.0005) and Logarithmic (SSE = 0.0011 and χ 2 = 0.0015). The equation that best fitted the experimental moisture data was the standardised Weibull model. Similar observations were made by Cunha et al. (2001) modelling water losses during osmotic dehydration of apple, García-Pascual et al. (2006) for the rehydration of mushroom and Corzo et al. (2008) for air drying of coroba slices.

Figure 3 shows the experimental drying curves versus the corresponding estimate by the standardised Weibull model, which was the model that showed the best statistical fit of the experimental moisture values for all drying working temperatures. Generally, when drying products of biological origin, the constant rate period is not meaningful, but a marked falling rate period can be seen clearly, where molecular diffusion prevails as a mechanism of matter transfer (water exit). For this reason, a useful mathematical model is required for estimation of drying times, in which the entire drying process is ideally considered (Akpinar 2006; Simal et al. 2005).

Conclusions

Desorption isotherms and drying kinetics of pepino fruit (Solanum muricatum Ait.) were studied in this work. The desorption behaviour showed that the equilibrium moisture content increased with a decrease in the working temperature at a constant a w value. The GAB equation provided a good fit to the experimental data of desorption isotherm of pepino fruit at three temperatures (20, 40 and 60 °C). The parameters X m, C and K were dependent on temperature. The water diffusion coefficient showed positive dependence on temperature. D we value was increasing with temperature from 2.55 to 7.29 × 10−10 m2 s−1, for a range of temperatures between 50 and 90 °C, with an estimated activation energy of 27.11 kJ mol−1. Although all models used to describe the dehydration kinetics were useful, the standardised Weibull model gave the best goodness of fit on the experimental data at the five temperatures studied, based on the statistical tests performed (SSE = 0.0005 and χ 2 = 0.0006). From the results, it could be observed that the drying kinetics of pepino fruit presented a clear exponential tendency, showing that an increase of drying temperature from 50 to 90 °C led to a decrease in operation time. Therefore, the mathematical equations proposed to describe drying kinetics of pepino fruit could be applied to predict optimal drying conditions, in particular temperature, in order to achieve process efficiency minimising drying times.

Abbreviations

- a w :

-

Water activity (dimensionless)

- X we :

-

Equilibrium moisture content (g water g−1 d.m.)

- X wt :

-

Moisture content (g water g−1 d.m.)

- X wo :

-

Initial moisture content (g water g−1 d.m.)

- X m :

-

Monolayer moisture content (g water g−1 d.m.)

- C, K:

-

Parameters of GAB model

- D we :

-

Water diffusion coefficient (m2 s−1)

- L :

-

Half-thickness of the slab (m)

- k i :

-

Kinetic parameters (min−1)

- n i , c:

-

Empirical parameters (dimensionless)

- α :

-

Shape parameter (dimensionless) of the Weibull model

- β :

-

Scale parameter (min) of the Weibull model

- t :

-

Drying time (s, min)

- i :

-

Number of terms

- R :

-

Universal gas constant (8.314 J mol−1 K−1)

- T :

-

Absolute temperature (K)

- E a :

-

Activation energy (kJ mol−1)

- MRei :

-

Experimental moisture ratio (dimensionless)

- MRci :

-

calculated moisture ratio (dimensionless)

- z :

-

Number of constants of the model

- N :

-

Number of data values

- d.m.:

-

Dry matter

References

Association of Official Analytical Chemists (AOAC) (1990). Official method of analysis, Association of Official Analytical Chemists no. 934.06 (15th edition), Arlington, MA, Washington.

Abbasi, S. B., & Mowla, D. (2007). Drying behavior of fresh green beans in an inert medium fluidized bed. Journal of Food Processing and Preservation, 32(5), 697–718.

Akanbi, C. T., Adeyemi, R. S., & Ojo, A. (2006). Drying characteristics and sorption isotherm of tomato slices. Journal of Food Engineering, 73(2), 157–163.

Akpinar, E. K. (2006). Determination of suitable thin layer drying curve model for some vegetables and fruits. Journal of Food Engineering, 73(1), 75–84.

Akpinar, E. K., Bicer, Y., & Yildiz, C. (2003). Thin layer drying of red pepper. Journal of Food Engineering, 59(1), 99–104.

Altenhofen da Silva, M., Arévalo, R., & Guenter, T. (2005). Ascorbic acid thermal degradation during hot air drying of Camu-Camu (Myrciaria dubia [H.B.K.] McVaugh) slices at different air temperature. Drying Technology, 23, 2277–2287.

Arslan, N., & Toğrul, H. (2005). Moisture sorption isotherms for crushed chillies. Biosystems Engineering, 90(1), 47–61.

Azzouz, S., Guizani, A., Joma, W., & Belghith, A. (2002). Moisture diffusivity and drying kinetic equation of convective drying of grapes. Journal of Food Engineering, 55(4), 323–330.

Babalis, S. J., & Belessiotis, V. G. (2004). Influence of drying conditions on the drying constants and moisture diffusivity during the thin layer drying of figs. Journal of Food Engineering, 65(3), 449–458.

Bellagha, S., Sahli, A., & Farhat, A. (2008). Desorption isotherms and isosteric heat of three Tunisian date cultivars. Food and Bioprocess Technology, 1, 270–275.

Chen, C. (2002). Sorption isotherm of sweet potato slices. Biosystems Engineering, 83(1), 85–95.

Chua, K. J., Chou, M. N., Hawlader, A. S., Mujumdar, A. S., & Ho, J. C. (2002). Modelling the moisture and temperature distribution within an agricultural product undergoing time-varying drying schemes. Biosystems Engineering, 81(1), 99–111.

Corzo, O., Bracho, N., Pereira, A., & Vásquez, A. (2008). Weibull distribution for modeling air drying of coroba slices. LWT—Food Science and Technology, 41(10), 2023–2028.

Crank, J. (1975). The mathematics of diffusion (2nd edition). London: Oxford University Press.

Cunha, L. M., Oliveira, F. A. R., Aboim, A. P., & Frías, J. M. (2001). Stochastic approach to the modelling of water losses during osmotic dehydration and improved parameter estimation. International Journal of Food Science and Technology, 36, 253–262.

Diaz, L. (2006). Industrialización y aprovechamiento de productos y sub-productos derivados de materias primas agropecuarias de la región de Coquimbo (1st edition). Santiago: LOM ediciones Ltda.

Di Scala, K., & Crapiste, G. (2008). Drying kinetics and quality changes during drying of red pepper. LWT—Food Science and Technology, 41(5), 789–795.

Doymaz, I. (2008). Convective drying kinetics of strawberry. Chemical Engineering and Processing, 47(5), 914–919.

Doymaz, I., Tugrul, N., & Pala, M. (2006). Drying characteristics of dill and parsley leaves. Journal of Food Engineering, 77(3), 559–565.

Fahrettin, G., Medeni, M., & Ahmet, K. (1998). Sorption isotherms of Turkish delight. Journal of Food Processing and Preservation, 22, 345–357.

García-Pascual, P., Sanjuán, N., Melis, R., & Mulet, A. (2006). Morchella esculenta (morel) rehydration process modeling. Journal of Food Engineering, 72(4), 346–353.

Garcia-Pérez, J., Alves-Filho, O., Eikevik, T., Strommen, I., & Mulet, A. (2005). Effect of drying air temperature on heat pump fluidized bed drying of cód fish. Paris: Association Francaise de Sechage pou l’Industrie et l’Agriculture, AFSIA.

Giner, A. S. (2009). Influence of internal and external resistances to mass transfer on the constant drying rate period in high-moisture foods. Biosystems Engineering, 102, 90–94.

Giraldo-Zuniga, A., Arévalo-Pinedo, A., Rezende, J., Silva, C., & Monteiro, J. A. (2006). Drying kinetics for murici (Byrsonima crassifolia) fruit. Journal of Food Processing and Preservation, 30, 699–705.

Goula, A. M., Karapantsios, T. D., Achilias, D. S., & Adamopoulos, K. G. (2008). Water sorption isotherms and glass transition temperature of spray dried tomato pulp. Journal of Food Engineering, 85(1), 73–83.

Hii, C. L., Law, C. L., & Cloke, M. (2009). Modeling using a new thin layer drying model and product quality of cocoa. Journal of Food Engineering, 90(2), 191–198.

Huyskens-Keil, S., Prono-Widayat, H., Lüdders, P., & Schreiner, M. (2006). Postharvest quality of pepino (Solanum murcatum Ait) fruit in controlled atmosphere storage. Journal of Food Engineering, 77(3), 628–634.

Kaya, A., & Aydin, O. (2007). Experimental investigation of drying kinetics of cherry laurel. Journal of Food Processing Engineering, 31, 398–412.

Kaya, A., Aydin, O., & Demirtas, C. (2007). Drying kinetics of red delicious apple. Biosystems Engineering, 96(4), 517–524.

Kaymak-Ertekin, F., & Gedik, A. (2004). Sorption isotherms and isosteric heat of sorption for grapes, apricots, apples and potatoes. LWT—Food Science and Technology, 37(4), 429–438.

Lee, J. H., & Lee, M. J. (2008). Effect of drying method on the moisture sorption isotherms for Inonotus obliquus mushroom. LWT—Food Science and Technology, 41(8), 1478–1484.

Lemus, R., Pérez, M., Andrés, A., Roco, T., Tello, C., & Vega, A. (2007). Kinetic study dehydration and desorption isotherms of red alga Gracilaria. LWT—Food Science and Technology, 41(9), 1592–1599.

Marabi, A., Livings, S., Jacobsons, M., & Saguy, I. S. (2003). Normalized Weibull distribution for modeling rehydration of food particulates. European Food Research Technology, 217, 311–318.

Marfil, P. H. M., Santos, E. M., & Telis, V. R. N. (2008). Ascorbic acid degradation kinetics in tomatoes at different drying conditions. LWT—Food Science and Technology, 41(9), 1642–1647.

Martinez-Romero, D., Serrano, M., & Valero, D. (2003). Physiological changes in pepino (Solanum muricatum Ait) fruit stored at chilling and non-chilling temperatures. Postharvest Biology and Technology, 30, 117–186.

Midilli, A., & Kucuk, H. (2003). Mathematical modelling of thin layer drying of pistachio by using solar energy. Energy Conversion and Management, 44(7), 1111–1122.

Pangavhane, D. R., Sawhney, R. L., & Sarsavadia, P. N. (2000). Drying kinetic studies on single layer Thompson seedless grapes under controlled heated air conditions. Journal of Food Processing and Preservation, 24, 335–352.

Pardeshi IL & Chattopadhyay PK (2008). Hot air puffing kinetics for soy-fortified wheat-based ready-to-eat (RTE) snacks. Food and Bioprocess Technology, doi:10.1007/s11947-008-0100-z.

Sacilik, K., & Elicin, A. K. (2006). The thin layer drying characteristics of organic apple slices. Journal of Food Engineering, 73(3), 281–289.

Simal, S., Femenia, A., Garau, M., & Crosello, C. (2005). Use of exponential Page’s and diffusional models to simulate the drying kinetics of kiwi fruit. Journal of Food Engineering, 66(3), 323–328.

Spiess, W., & Wolf, W. (1983). The results of the COST 90 project on water activity. In R. Jowitt, et al. (Eds.), Physical properties of foods. London: Applied Science.

Toğrul, I. T., & Pehlivan, D. (2003). Modeling of drying kinetics of simple apricot. Journal of Food Engineering, 58(1), 23–32.

Vega, A., Uribe, E., Lemus, R., & Miranda, M. (2007). Hot-air drying characteristics of aloe vera (Aloe barbadensis Miller) and influence of temperature on kinetics parameters. LWT—Food Science and Technology, 40(10), 1698–1707.

Vega-Gálvez, A., Lemus-Mondaca, R., Bilbao-Sáinz, C., Yagnam, F., & Rojas, A. (2007). Mass transfer kinetics during convective drying of red pepper var.Hungarian (Capsicum annum L.): mathematical modeling and evaluations of kinetic parameters. Journal of Food Process Engineering, 31, 120–137.

Viswanathan, R., Jayas, D., & Hulasare, R. B. (2003). Sorption isotherms of tomato slices and onion shreds. Biosystems Engineering, 86(4), 465–472.

Acknowledgements

The authors thank the Research Office of Universidad de La Serena, Chile, for the support provided through Project DIULS No. 220-2-06 as well as the Research Fund of the Department of Food Engineering of Universidad Católica de Valparaiso, Chile.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uribe, E., Vega-Gálvez, A., Di Scala, K. et al. Characteristics of Convective Drying of Pepino Fruit (Solanum muricatum Ait.): Application of Weibull Distribution. Food Bioprocess Technol 4, 1349–1356 (2011). https://doi.org/10.1007/s11947-009-0230-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-009-0230-y