Abstract

Drying of apple pomace representing by-products from apple juice processing was studied. The results obtained show that moisture content of the pomace decreases with time and temperature. The Midilli et al. model was selected as the best mathematical model for describing the drying kinetics of the apple pomace. The effective moisture diffusivity varied from 1.73 × 10−10 to 4.40 × 10−10 m2/s and the activation energy was calculated to be 29.65 kJ/mol.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Apple is the pomaceaus fruit of the apple tree, species Malus domestica in the rose family (Rosaceae). Apple plantations are cultivated all over the world in many countries. Apple has a World-wide production of apples is 75.5 million tonnes in 2011 and the major producers include China, United States of America, India, Turkey, Poland and Italy. Apple production in Turkey was about 2.68 million tonnes in 2011 [1]. The apples are consumed either fresh or in the form of various processed such as juice, jam and marmalade, dried apples, etc. [2].

Apple juice concentrate represents the major processed product, with a total recovery of 70–75 % in the industrial process. Therefore, 25–30 % of apple pomace remains as a side-stream [3]. Being a rich source of carbohydrate, pectin, crude fibre and minerals, apple pomace is the good source of nutrients [4]. The apple pomace has generally high moisture content, and need to removal of moisture before the production of high value-added products [5]. Also, the by-products do not only cause disposal costs, but also are a major environmental problem. Drying has always been of great importance to the preservation of agricultural products and their by-products.

Drying is the most widely used commercial process to preserve foods because, compared to other long-term preservation methods, it is less costly and easier to operate. The main purpose of drying products is to allow longer periods of storage, minimize packaging requirements, and reduce shipping weights [6]. There are many drying methods, of which sun drying is the most traditional and economical one. However, sun drying has some significant disadvantages, such as the fact that it is time-consuming, weather-dependent, results in nutrient loss, is labor-intensive, and may result in possible environmental contamination [7]. In order to improve the quality of products, the sun drying technique should be replaced with industrial drying methods such as hot air drying [8, 9].

The most relevant aspects of drying technology are the mathematical modeling of the process and the experimental setup. The modeling is basically based on the design of a set of equations to describe the system as accurately as possible. Drying characteristics of the particular products being dried and mathematical models are needed in the design, construction and operation of drying systems [10]. Many mathematical models have proposed to describe the drying process, of them, thin-layer drying models have been widely in use. These models can be categorized as theoretical, semi-theoretical, and empirical [11]. Several mathematical modelling and experimental studies have been revealed concerning the drying characteristics of fruit and vegetable pomaces, such as grape pomace [12], tomato pomace [10, 13], carrot pomace [14], and olive pomace [15, 16]. So far, there a little information available about modelling, effective diffusivity and activation energy of drying of apple pomace [5, 17]. The objectives of this present study were to study the effect of drying air temperature on the drying time and drying rate, to fit the experimental data to ten mathematical models, and to compute effective moisture diffusivity and activation energy of apple pomace.

2 Material and method

2.1 Material

The apple pomace, which is a waste material of apple juice processing, was provided by Döhler Natural Food and Beverage Ingredients Factory located in Denizli (Turkey). The pomace was collected just after the pressing operation and immediately packaged and stored at 4 °C. The initial moisture content of apple pomace was determined by using the oven method at 110 °C for 24 h. Triplicate samples were used for the determination of moisture content and the average values were reported as 69.32 %, w.b. (2.259 kg water/kg dry matter, d.b.).

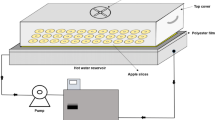

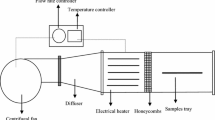

2.2 Experimental apparatus

The drying experiments were conducted in a laboratory scale cabinet dryer that is described previously by Doymaz [18]. The dryer basically consists of a centrifugal fan to supply the air-flow, an electric heater, an air filter and an electronic proportional controller. The air temperature was controlled by means of a proportional controller. Air velocity was regulated by a centrifugal fan and fan speed control unit. The velocity was measured with TESTO 440 Vane Probe Anemometer (AM-4201, Lutron, Taipei, Taiwan), and flowed horizontal to the bed. The air passed from heating unit and heated to the desired temperature and channeled to the drying chamber. The samples were dried in the square chamber, which had a flow cross-section of 30 cm × 30 cm. Weight loss of samples was recorded by using a digital balance (model BB3000, Mettler-Toledo AG, Grefensee, Switzerland) with a sensitivity of 0.1 g.

2.3 Experimental procedure

Drying experiments were performed at drying temperatures varying from 50 to 80 °C, with 10 °C increments, and a constant air velocity of 2 ± 0.1 m/s for all circumstances. After the dryer reached steady-state conditions for the set points (at least 30 min), the samples were distributed uniformly into the square chamber as a thin-layer (layer thickness: 0.8 cm). Hot-air orientation was horizontal over the surface and square chamber bottom of the drying material. Each experiment utilised in the experiment weighed 200 ± 0.5 g. Sample weight was recorded at regular time intervals (15 min). The experiments ended when the content of moisture in the samples was reduced from 2.259 to 0.005 kg water/kg dry matter approximately. Triplicate runs were performed for experimental conditions investigated in this work.

2.4 Mathematical modeling of drying curves

Moisture content was calculated using the equation:

where M is the moisture content (kg water/kg dry matter), W 0 is initial weight of sample (kg), W is the amount of evaporated moisture (kg) and W 1 is dry matter content of sample (kg). Experimental data from the different drying runs were expressed as moisture ratio versus drying time and drying rate versus moisture content.

The moisture ratio (MR) were calculated from weight loss data of the samples during drying. Equation (2) was used to calculate the moisture ratio:

where M, M 0 and M e are moisture content at any time of drying (kg water/kg dry matter), initial moisture content (kg water/kg dry matter) and equilibrium moisture content (kg water/kg dry matter), respectively. As M e is much lower than M 0 and M, it is negligible in the study.

The drying rate (DR) of apple pomace was calculated using Eq. (3):

where M t and M t+dt is moisture contents at t and t + dt (kg water/kg dry matter), respectively, and t is time (min).

2.5 Data analysis

The drying data obtained were fitted to ten mathematical models detailed in Table 1 using the non-linear regression analysis. Statistical analyses of the experimental data were performed by using the software package (Statistica 6.0, Statsoft Inc., Tulsa, OK). The coefficient of determination (R 2), reduced Chi square (χ 2) and root mean square error (RMSE) were used as criteria to assess the fit of mathematical models to experimental data, according to Eqs. (4) and (5):

where MR exp,i is experimental dimensionless moisture ratio; MR pre,i is predicted dimensionless moisture ratio; N is number of observations; z is number of constants. The best model describing the drying characteristics of samples was chosen as the one with the highest R 2, χ 2 and RMSE [10, 19].

2.6 Determination of effective moisture diffusivity

Drying occurs mostly in the falling rate period, and moisture transfer during drying is controlled by internal diffusion. Fick’s second law of unsteady state diffusion given in Eq. (6) can be used to determine the moisture ratio in Eq. (7). The solution of diffusion equation for infinite slab given by Crank [20], and supposed uniform initial moisture distribution, negligible external resistance, constant diffusivity and negligible shrinkage, is:

where D eff is the effective moisture diffusivity (m2/s), t is the time (s), L is the half-thickness of samples (m) and n is a positive integer. With increasing drying time, all terms except the first are negligible. By limiting Eq. (7) equation only to the first term and after excluding the values at t = 0 and its vicinity, it would be possible to calculate D eff as follows [21]:

From Eq. (8), a plot of ln MR versus drying time gave a straight line with a slope (K) of:

2.7 Computation of activation energy

The relationship between the effective moisture diffusivity and drying temperature was described using the Arrhenius-type equation:

Here D 0 is the pre-exponential factor (m2/s), E a is the activation energy (kJ/mol), R is the universal gas constant (kJ/mol K), and T is drying air temperature (°C).

3 Results and discussions

3.1 Drying curves

Figure 1 shows the experimental drying curves of apple pomace at 50, 60, 70 and 80 °C, expressed by moisture content as a function of drying time. The moisture content decreased exponentially with elapsed duration of drying. As shown in this curves, increasing the temperature caused to decrease in drying time since both the thermal gradient inside the object and the evaporation rate of product increase. The drying time required to reach the final moisture content of samples were 660, 405, 315 and 255 min at the air temperatures of 50, 60, 70 and 80 °C, respectively. The average drying rate increased 2.59 times as air temperature increased from 50 to 80 °C. These experimental results are similar to other results published in the literature of the drying process of agricultural by-product, pomace and bagasse [10, 17, 22, 23].

3.2 Drying rate

The drying rate curves of apple pomace are shown in Fig. 2. It is clear that the drying rate decrease continuously with moisture content. As can be seen in Fig. 2, a constant-rate period was not observed in drying of the apple pomace. The drying process occurred entirely in the falling-rate period. This shows that diffusion in dominant physical mechanism governing moisture movement in the samples. During drying, the drying rates were higher in the beginning of the process, and after that decreased with decrease of moisture content in the samples. The results were consistent with observations made by different authors on drying various agricultural products [17, 22].

3.3 Fitting of drying curves

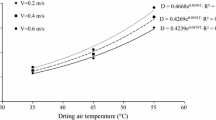

The moisture content data obtained at different air temperatures were converted to dimensionless moisture ratio (Eq. 2) and then fitted to the ten thin-layer drying models (Table 1). Non-linear regression analysis was used to estimate the parameters of those ten models. The statistical results from models are summarised in Tables 2, 3, 4 and 5. The best model describing the thin-layer drying characteristics of apple pomace was chosen as the one with the highest R2 values and the lowest χ2 and RMSE values. The statistical parameter estimations showed that R2, χ2 and RMSE values were ranged from 0.9845–0.9995, 0.000043–0.001579 to 0.029365–0.194165, respectively. Of all the models tested, the Midilli et al. model gives the highest value of R2 and the lowest values of χ2 and RMSE. Generally R2, χ2 and RMSE values of the selected model in all experiments were varied between 0.9992–0.9995, 0.000043–0.000100 and 0.029365–0.033716, respectively. Accordingly, the Midilli et al. model was selected as the suitable model to represent the thin layer drying characteristics of the apple pomace. Figure 3 compares experimental data with those predicted with the Midilli et al. model for apple pomace at 50, 60, 70 and 80 °C. The prediction using the model showed MR values banded along the straight line, which showed the suitability of this model in describing drying characteristics of apple pomace.

3.4 Effective moisture diffusivity

The values of effective moisture diffusivity were calculated using Eq. (9) and is shown in Fig. 4. The D eff values of dried samples at 50–80 °C were varied in the range of 1.73 × 10−10–4.40 × 10−10 m2/s. As expected, the values of D eff increased notably with increasing temperature. When samples were dried at higher temperature, increased heating energy would increase the activity of water molecules leading to higher moisture diffusivity [24]. The values of D eff obtained from this study meet the standard range for food and agricultural products (from 10−12 to 10−8 m2/s) and can be compared to 1.91–3.93 × 10−9 m2/s for apple pomace in temperature range 75–105 °C [17], 1.57–8.03 × 10−10 m2/s for grape seed in temperature range 40–60 °C [25], 3.18–4.36 × 10−10 m2/s for pomegranate seed in temperature range 40–60 °C [26], 2.74–4.64 × 10−9 m2/s for carrot pomace in temperature range 60–75 °C [14], and 3.24–5.80 × 10−9 m2/s for tomato by-product in temperature range 25–45 °C [10]. These values are consistent with the present estimated D eff values for apple pomace.

3.5 Activation energy

The activation energy can be determined from the slope of Arrhenius plot, ln D eff versus 1/(T + 273.15) (Eq. 10). The ln D eff as a function of the reciprocal of absolute temperature was plotted in Fig. 5. The slope of the line is (−E a /R) and the intercept equals ln (D 0). The results show a linear relationship due to Arrhenius type dependence. Equation (11) shows the effect of temperature on D eff of samples with the following coefficients:

The value of E a found 29.65 kJ/mol and was within the general range of 12.7–110 kJ/mol for various food and agricultural products [27]. This value is similar to those proposed in the literature by several authors for different fruit and vegetable by-products, pomaces and wastes in Table 6.

4 Conclusions

The effect of air temperature on drying characteristics of apple pomace was investigated in the cabinet dryer. Constant drying rate period was not observed, the drying process took place in the falling-rate period. Drying data obtained were fitted to ten thin-layer drying models and goodness of fit determined using R2, χ2 and RMSE. The Midilli et al. model gave the best representation of drying data under all experimental conditions. The effective moisture diffusivity was computed from Fick’s second law, the values of which varied between 1.22 × 10−10 and 4.29 × 10−10 m2/s, over the temperature range. The effective moisture diffusivity increases as temperature increases. The relationship between the effective moisture diffusivity and temperature can be described by Arrhenius-type relationship, which displays activation energy of 29.65 kJ/mol for apple pomace.

References

FAO (2013) http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor. Updated: August 08, 2013

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 43:1233–1238

Bosse AK, Fraatz MA, Zorn H (2013) Formation of complex natural flavours by biotransformation of apple pomace with basidiomycetes. Food Chem 141:2952–2959

Shalini R, Gupta DK (2010) Utilization of pomace from apple processing industries: a review. J Food Sci Technol 47:365–371

Sun J, Hu X, Zhao G, Wu J, Wang Z, Chen F, Liao X (2007) Characteristics of thin-layer infrared drying of apple pomace with and without hot air pre-drying. Food Sci Technol Int 13:91–97

Zielinska M, Markowski M (2010) Air drying characteristics and moisture diffusivity of carrots. Chem Eng Process 49:212–218

Chen H, Zhang M, Fang Z, Wang Y (2013) Effects of different drying methods on the quality of squid cubes. Dry Technol 31:1911–1918

Kingsly RP, Goyal RK, Manikantan MR, Ilyas SM (2007) Effects of pretreatments and drying air temperature on drying behavior of peach slice. Int J Food Sci Technol 42:65–69

Adedeji AA, Gachovska TK, Ngadi MO, Raghavan GSV (2008) Effect of pretreatments on drying characteristics of okra. Dry Technol 26:1251–1256

Celma AR, Francisco C, Fernando LR, Aida R (2013) Thin layer drying behaviour of industrial tomato bye-products in a convective dryer at low temperatures. Res J Biotechnol 8(2):50–60

McMinn WAM (2006) Thin-layer modelling of the convective, microwave, microwave-convective and microwave-vacuum drying of lactose powder. J Food Eng 72:113–123

Celma AR, López-Rodríguez F, Cuadros Blázquez F (2009) Experimental modelling of infrared drying of industrial grape by-product. Food Bioprod Process 87:247–253

Al-Muhtaseb AH, Al-Harahsheh M, Hararah M, Magee TRA (2010) Drying characteristics and quality change of unutilized-protein rich-tomato pomace with and without osmotic pre-treatment. Ind Crop Prod 31:171–177

Kumar N, Sarkar BC, Sharma HK (2012) Mathematical modelling of thin layer hot air drying of carrot pomace. J Food Sci Technol 49:33–41

Meziane S (2011) Drying kinetics of olive pomace in a fluidized bed dryer. Energ Conv Manag 52:1644–1649

Vega-Gálvez A, Miranda M, Díaz LP, Lopez L, Rodriguez K, Di Scala K (2010) Effective moisture diffusivity determination and mathematical modelling of the drying curves of the olive-waste cake. Bioresour Technol 101:7265–7270

Wang Z, Sun J, Liao X, Chen F, Zhao G, Wu J, Hu X (2007) Mathematical modelling on hot air drying of thin layer apple pomace. Food Res Int 40:39–46

Doymaz I (2004) Effect of pre-treatments using potassium metabisulphide and alkaline ethyl oleate on the drying kinetics of apricots. Biosyst Eng 89:281–287

Karaaslan S, Erdem T, Oztekin S (2013) Mathematical modelling and color characteristics of purslane (Portulace oleraceae L.) leaves using different drying methods. Philip Agric Sci 96:267–274

Crank J (1975) The mathematics of diffusion, 2nd edn. Clarendon Press, Oxford

Chayjan RA, Kaveh M (2014) Physical parameters and kinetic modeling of fix and fluid bed drying of terebinth seeds. J Food Process Preserva 38:1307–1320

da Costa SantosD, de Melo QueirozJ, de Figueiredo RMF, de Oliveira ENA (2013) Mathematical modeling for the annatto (Bixa orellana L.) seed drying process. Chil J Agric Res 73:320–326

Mazutti MA, Zabot G, Boni G, Skovronski A, de Oliveira D, Di Luccio M, Oliveira JV, Rodrigues MI, Treichal H, Maugeri F (2010) Mathematical modeling of thin-layer drying of fermented and non-fermented sugarcane bagasse. Biomass Bioenerg 34:780–786

Xiao HW, Pang CL, Wang LH, Bai JW, Yang WX, Gao ZJ (2010) Drying kinetics and quality of Monukka seedless grapes dried in an air-impingement jet dryer. Biosyst Eng 105:233–240

Roberts JS, Kidd DR, Padilla-Zakour O (2008) Drying kinetics of grape seeds. J Food Eng 89:460–465

Sharma SR, Arora S, Chand T (2011) Air drying kinetics of pomegranate seeds. Int J Food Eng 7(2):Article 7

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1996) Moisture diffusivity data compilation in foodstuffs. Dry Technol 14:2225–2253

Ghodake HM, Goswami TK, Chakraverty A (2006) Mathematical modeling of withering characteristics of tea leaves. Dry Technol 24:159–164

Verma LR, Bucklin RA, Endan JB, Wratten FT (1985) Effects of drying air parameters on rice drying models. Trans ASAE 28:296–301

Sobukola OP, Dairo OU, Odunewu VA (2008) Convective hot air drying of blanched yam slices. Int J Food Sci Technol 43:1233–1238

Wang CY, Singh RP (1978) A single layer drying equation for rough rice. ASAE, St. Joseph

Corzo O, Bracho N, Pereira A, Vásquez A (2008) Weibull distribution for modelling air drying of coroba slices. LWT-Food Sci Technol 41:2023–2028

Celma AR, Rojas S, López F, Montero I, Miranda T (2007) Thin-layer drying behaviour of sludge of olive oil extraction. J Food Eng 80:1261–1271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kara, C., Doymaz, İ. Effective moisture diffusivity determination and mathematical modelling of drying curves of apple pomace. Heat Mass Transfer 51, 983–989 (2015). https://doi.org/10.1007/s00231-014-1470-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1470-6