Abstract

This work was to correlate physical properties with adhesion properties of soy protein-based adhesives. By building such a correlation, the adhesion properties can be predicted by measuring physical properties of soy protein-based adhesives. In this context, three important physical properties, viscosity, tacky force, and water resistance, were selected to correlate with adhesion strength of enzymatically modified soy protein-based adhesives (ESP). Response surface methodology, specifically central composite design, was used with three independent variables to prepare ESP: trypsin concentration (X 1), incubation time (X 2), and glutaraldehyde (GA) concentration (X 3). The three physical properties measured were all greatly affected by our three independent variables with significance at the 95 % confidence level. The responses were then correlated with the adhesion properties of ESP. In conclusion, viscosity can be used to predict the dry adhesion strength of ESP based on the coefficient of determination (R 2) of 0.8558. In addition, tacky force and water resistance can be used to represent wet adhesion strength of ESP based on R 2 of 0.7082 and 0.6930, respectively (P < 0.05). This work preliminarily identified the significant physical properties that can predict the adhesion strength of the ESP system crosslinked with GA, but the results need to be further confirmed by another protein modification system to give a generic conclusion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soy proteins have shown strong potential as wood adhesives, and much research has been dedicated to improving the adhesion performance of soy protein-based adhesives. High adhesive strength, water resistance, and low viscosity are the basic requirements for wood glue. To meet these requirements, adhesive strength and water resistance have been improved by modifying soy protein-based adhesives using denaturation reagents, reducing agents, crosslinking agents, and enzyme hydrolysis [1–7]. Application of modifiers to enhance the adhesion properties of soy protein should greatly affect the resulting physicochemical properties, such as thermal, spectroscopic, and rheological properties. Many works have shown improvement in adhesion strength and changes in physiochemical properties to support this conclusion [8–13]. Industries are seeking time-efficient methods for both quality control and screening in soy protein-based adhesive product development; however, research has not determined the correlation between physicochemical properties and shear adhesion performance, and knowing such correlations would help reduce testing cycle length and expenses.

The objective of this study was to investigate the physical properties of soy protein-based adhesives that can explain and predict adhesion performance and their relationship with shear adhesion strength. Viscosity, tackiness, and water resistance were measured to correlate the shear adhesion strength of soy protein-based adhesives. Viscosity is one of the most critical factors that affects the flow property and penetration of soy protein molecules through wood materials, which directly influence adhesion strength [14]. Tackiness can represent the degree of mechanical interlocking between soy protein molecules and a metal substrate, and can be an indirect indicator of adhesion performance. Also, water resistance is an important parameter of soy protein-based adhesives and can be obtained by measuring the solubility of soy protein molecules in water. These three properties were used to establish reliable and representative methodologies to correlate with adhesion strength. Our previous studies successfully accomplished a new modified soy protein-based adhesive (MSP) using NaHSO3 with a high solid content of 38 %, good flowability and good water resistance [15, 16]. The MSP is in viscous and cohesive phase with latex texture. In this work, MSP was used as a base polymer for further treatment to prepare enzymatically modified soy protein-based adhesives (ESP) with three independent variables [X 1: trypsin concentration; X 2: incubation time; and X 3: glutaraldehyde (GA) concentration as a crosslinker] using response surface methodology (RSM) called central composite design (CCD) [17–19]. A series of treatments was applied to MSP, and the important physical properties of viscosity (Y 1), tacky force (Y 2), and water resistance (Y 3) were measured and their relationship with shear adhesion strength was investigated.

Experimental Procedures

Materials

Defatted soy flour with a protein dispersion index of 90 was provided by Cargill (Cedar Rapids, IA, USA). Trypsin was purchased from MP biochemical (Santa Anna, CA, USA), and GA (Glutaraldehyde solution, 50 wt% in the water) was purchased from Fisher Scientific (Hampton, NH, USA). Cherry wood samples with dimensions of 50 mm (width) × 127 mm (length) × 5 mm (thickness) were obtained from Veneer One (Oceanside, NY, USA).

Experimental Design

Three variables, trypsin concentration (X 1), incubation time (X 2), and GA concentration (X 3), were chosen as parameter variables, and the corresponding viscosity (Y 1), tacky force (Y 2), and water resistance (Y 3) were the responses. The ranges of each variable were selected based on preliminary experiments and the coded and un-coded variables are summarized in Table 1.

A standard RSM design called central composite design (CCD) was applied to study the effects and interactions of the parameter variables (X 1, X 2, and X 3) on the responses (Y 1, Y 2, and Y 3). A set of 20 experiments, including 8 factorial experiments, 6 star points, and 6 center points, were carried out. The distance of the star points from the center point is given by α = 2n/4, where n is the number of factors (for three factors, α = 23/4 = 1.682). The system behavior is described by a second-order polynomial regression model carried out using Design Expert software (trial version 9.0.0; Static-Made Easy, Minneapolis, MN, USA) and given by:

where Y is the response variable; α 0 is a constant; α i , α ij , and α ii are the linear, quadratic and interactive coefficients, respectively, X i and X j are the levels of the parameter variables, and ε is the random error. The responses obtained from the experimental design were subjected to multiple non-linear regressions using Design Expert. The quality of the fit of the polynomial model equation was evaluated by the R-squared (R 2), Predicted R-squared (Pred R 2), adequate precision (AP), and standard deviation (SD). The significance of the regression coefficient was determined using an F test and p value. Furthermore, the models were further justified through an analysis of variance (ANOVA).

MSP and ESP Sample Preparation

MSP was extracted from soy flour slurry modified with sodium bisulfate using the acid precipitation method described by Qi et al. [13, 15]. Defatted soy protein flour was dispersed in water (1:16 ratio) at pH 9.5 using 3 N NaOH. The NaHSO3 (6 g/L) was added to the soy protein slurry and stirred for 2 h. The pH of the slurry was then adjusted to pH 5.4 with 2 N HCl to remove carbohydrates by centrifugation at 12,000g relative centrifugal force (RCF). After centrifugation, the supernatant liquid was carefully decanted from the container and then collected. Then, the pH of the collected supernatant was adjusted to 4.8 with 2 N HCl and centrifuged at 8000g RCF. After discarding the supernatant, the precipitate that gathered on the bottom of the container was collected with spatula. The precipitate, MSP, was collected. As noted in Table 2, a variation of treatments was applied to MSP to prepare ESP. A specific amount of trypsin was added to the MSP, and the mixture was incubated at room temperature (25 ± 1 °C) for corresponding incubation time (1.0–12.0 h) while gently stirring. Immediately after the enzyme reaction had taken place, the trypsin was inactivated by heating at 90 °C for 3 min [20]. Then, the corresponding GA concentration (0.0–1.0 wt% based on total adhesive weight) was added to ESP and stirred thoroughly for complete mixing. The experiments in Table 2 were sequentially conducted.

Physicochemical Properties Measurement

Viscosity Measurement

A Bohlin CVOR 150 rheometer (Malvern Instruments, Southborough, MA, USA) was used to measure viscosity of ESP. A parallel plate head with 20-mm plate diameter and a 500-μm gap was used. The measurements were performed with the single shear rate of 40 s−1. The testing temperature was 25 °C. A thin layer of silicon oil was spread around the circumference of the sample to prevent dehydration. Viscosities were recorded for 120 s, and all measurements were triplicated and averaged.

Tacky Force

The standard test method for a loop tack test for pressure-sensitive adhesives (ASTM D 6195-03) was followed to measure the tackiness of ESP. This test method involved a loop of ESP applied on papers (LaserJet printing paper; Hewlett-Packard, Palo Alto, CA, USA) to be brought into controlled contact with a 1-in.2 (c.2.52-mm) stainless steel surface. To ensure that the same amount of ESP was applied to the paper, a brass mold was built with a square hole (25.4 × 25.4 × 0.25 mm) in the middle of the rectangular bass plate (60.0 × 40.0 × 0.25 mm). The sample amount was controlled by the thickness of the mold. The mold was placed on the middle of the paper (1 × 7 in.), the sample was placed inside the hole of the mold, and excess sample was removed by scraping a stainless steel stick across the surface of the brass mold. The paper with a sample was bent to form a teardrop-shaped loop with the sample surface facing out. The ends of the loop were fastened into the upper grips of the tensile tester (Imada tensile tester; DS2-11, Northbrook, IL, USA). Moving the tensile tester down meant the specimen loop completely covered the 1-in.2 area of the stainless steel portion of the test fixture. After waiting for 30 s (dwell time), the maximum force required to remove the specimen loop from the stainless steel was recorded. All measurements were in triplicate.

Water Resistance

Water resistance of ESP was determined by measuring the protein loss after soaking the cured soy protein film in water. The adhesive samples were spread on a glass slide using a spatula to make a thin film, and the specimen was cured in an oven at 100 °C for 1 h. The specimen was soaked in water (tap water, temperature 21 °C) for 30 min to observe the loss or dissolution of the cured protein film. The average of the loaded adhesive was 0.7061 g and 30 min was adequate to observe the diffusion of the protein molecules into water. The wet specimens were dried in the oven at 100 °C for 1 h. Water resistance (%) was calculated based on the weight difference of protein film before and after soaking using Eq. (2);

where W b and W a are weights of sample before and after water soaking, respectively.

Mechanical Plywood Properties

Two-Ply Plywood Specimen Preparation

Cherry wood veneers with dimensions of 50 × 127 × 5 mm were preconditioned in a chamber (Electro-Tech Systems, Glenside, PA, USA) for 7 days at 23 °C and 50 % relative humidity. The adhesives were brushed onto one end of a piece of cherry wood with dimensions of 127 × 20 mm (length × width) until the entire area was completely wet. The consumed average amount of the adhesive was 0.70 g. Two brushed wood pieces were assembled immediately and conditioned for 10 min at room temperature. Then the assembled wood specimens were pressed with a hot press (Model 3890 Auto M; Carver, Wabash, IN, USA) at 1.4 MPa and 170 °C for 10 min.

Shear Strength Measurement

For two-ply plywood samples, the assembled wood samples were cooled, conditioned at 23 °C and 50 % relative humidity for 48 h, and cut into five pieces with dimensions of 80 × 20 mm (glued area of 20 × 20 mm). The cut wood specimens were conditioned for another 2 days before measurements were taken. Wood specimens were tested with an Instron Tester (Model 4465; Canton, MA, USA) according to ASTM Standard Method D2339-98 [21] at a crosshead speed of 1.6 mm/min. Shear adhesion strength at maximum load was recorded; reported values are the average of four specimen measurements. Water resistance of the wood assemblies was measured following ASTM Standard Methods D1183-96 [22] and D1151-00 [23]. Six preconditioned specimens were soaked in tap water at 23 °C for 48 h, and wet strength was tested immediately after soaking.

Results and Discussion

Adhesion between soy protein and wood is attributed to a combination of three mechanisms: mechanical interlocking, physical interaction, and covalent chemical bonding [24]. When applied to wood, protein adhesives spread, wet, and penetrate the wood surface, forming mechanical interlocking, physical interaction, and covalent bonding upon thermal curing to achieve a strong bond. Soy protein is composed of an array of polypeptides with different molecular sizes and could be partially cleaved or degraded by trypsin, which specifically hydrolyses carbonyl bonds formed by basic amino acids such as lysine and arginine [25]. In this work, trypsin was used to degrade the soy protein into smaller molecular size and expose more hydrophobic groups to the surface [3, 26]. GA was subsequently applied as a crosslinking agent to rebuild or reconstruct the structure of soy protein by increasing crosslinking density with large and interwoven polymers [27]. To navigate the effect of each variable (X 1, X 2, and X 3) on three important responses (Y 1, Y 2, and Y 3) of ESP, CCD was employed to build a regression model between the preparation variables and the three responses of ESP; results obtained from the experiments are listed in Table 2.

Model Fitting

For viscosity (Y 1), a quadratic model was build and reduced with only statistically significant terms using backward elimination approach provided by Design Expert software. The coefficients of the parameter variables (X 1, X 2, and X 3) for the viscosity (Y 1) can be expressed by the following second-order polynomial equation in terms of coded values:

A positive or negative coefficient indicates a synergistic and antagonistic effect, respectively. The coefficient of the model for viscosity was estimated using the multiple regression analysis technique included in RSM. Adequate precision (AP) represents the signal-to-noise ratio, where a ratio greater than 4 is desirable. For Eq. (3), the R-squared (R 2), predicted R-squared (Pred R 2), adequate precision (AP), and standard deviation (SD) were 0.719, 0.664, 12.399, and 0.34, respectively. These indicate that 71.9 % of the total variation in viscosity is attributed to the experimental variables. The adequacy of the models was further justified through an ANOVA. Results from the ANOVA for the quadratic model for viscosity are listed in Table 3a. Corresponding variables are more significant at greater F and smaller p values. As shown in Table 3a, the F value of 13.65 and p value of 0.0001 (less than 0.05) of the model suggest that model terms are significant. Also, trypsin concentration (X 1) and the interaction with incubation time (X 1 X 2) significantly affected the viscosity, whereas the other term was insignificant to the response.

For tacky force (Y 2), a quadratic model was built using the backward elimination approach provided by Design Expert software. The second-order polynomial equation of the parameter variables (X 1, X 2, and X 3) for the tacky force (Y 2) can be expressed by the following in terms of coded values:

For the tacky force model, the R 2, Pred R 2, AP, and SD were 0.662, 0.541, 6.275, and 0.15, respectively. As the results from ANOVA analysis summarized in Table 3b, an F value of 5.47 and a p value less than 0.0054 indicate that model terms are significant. In this case, trypsin concentration (X 21 ) and GA concentration (X 3) are significant model terms.

In addition, a quadratic model was built for water resistance (Y 3) based on the second-order polynomial equation of the parameter variables (X 1, X 2, and X 3):

For the water resistance model, the R 2, Pred R 2, AP, and SD were 0.739, 0.587, 7.325, and 1.25, respectively. The model F value of 4.85 and p value less than 0.0500 mean that model terms are significant; in particular, incubation time (X 2) significantly affected the water resistance of ESP. The regression models of three responses (Y 1, Y 2, and Y 3) were greatly affected by three variable parameters (X 1, X 2, and X 3), resulting from high R 2. Despite the complexity of the system to be tested, three variables successfully reflected the three responses based on statistical explanation.

Interpretation of Response Surface Model

To further investigate the effects of the three variables on the responses, the relationships between the variable parameters and responses are shown in Figs. 1, 3, and 4. To simplify the effects of variables on responses, three levels (−1, 0, and +1) of one variable are presented with another variable while maintaining the other variable at zero.

The effects of three variables on viscosity. Three levels (−1, 0, and +1) of a incubation times (X 2) are presented with trypsin concentrations (X 1), b trypsin concentrations (X 1) are presented with GA concentrations (X3), and c GA concentrations (X 3) were presented with incubation times (X 2). The other variable was maintained at zero

The effects of trypsin concentration (X 1) and incubation time (X 2) on viscosity (Y 1) are shown in Fig. 1a. Viscosities increased with increased trypsin concentration (X 1) at the early stage of hydrolysis (X 2 = 3.23 h); however, at 6.50 h of incubation time (X 2), viscosities increased up to trypsin concentration (X 1) of 1.30 wt% but started to decrease with higher trypsin concentration (X 1), and viscosities seemed to decrease with concentrations of whole trypsin (X 1) after 9.77 h of incubation time (X 2). In general, reduced viscosity can provide evidence of proteolytic hydrolysis by confirming weaker intermolecular interaction and smaller polypeptide chains. The increased viscosities at a low concentration of trypsin (X 1) and with short incubation time (X 2) did not agree with previous findings [20].

For further investigation, reducing SDS-PAGE was performed to study the effects of low trypsin concentration and short incubation time on MSP hydrolysis, as shown in Fig. 2. For this purpose, only qualitative analysis of SDS-PAGE was performed. At low trypsin concentration (0.50 wt%), some molecular bands became darker and thicker after 3 h of incubation (Lane D), but became gradually lighter and disappeared after 6 h of incubation (Lanes E and F), particularly the bands of acidic and basic polypeptides. We believe this might be strongly related to the trypsin activity, depending on hydrolysis conditions. The reaction conditions of MSP were pH 4.6 and ambient temperature, which were far from the optimum conditions for trypsin activity of pH 8 and 37 °C [28, 29]. Adverse reaction conditions and low enzyme concentrations might cause low trypsin activity during the early stages of incubation. MSP is in continuous and viscous phase with a latex texture and this may block the access of trypsin to the hydrolysis site especially at the early incubation stages. We assume that the increased surface area of soy protein due to enzyme hydrolysis might lead to intermolecular interactions at certain solid contents, thus increasing viscosity. Trypsin concentration (X 1) above 1.30 wt% could start to hydrolyse soy protein in the early stages of incubation, providing reduced viscosity due to low molecular weight and cleaved molecular bands; however, the detailed hydrolysis mechanism needs to be investigated.

Viscosities increased as GA concentration (X 3) increased at all trypsin concentrations (X 1), as shown in Fig. 1b. The effects of GA concentration (X 3) and incubation time (X 2) on viscosity are shown in Fig. 1c. With different GA concentrations (X 3), viscosities tended to increase up to 9.77 h of incubation time (X 2), then decrease. Increased viscosities could be explained by the hydrolysis mechanism of trypsin on MSP, as mentioned earlier. At long incubation times (X 2 > 9.77 h), however, viscosities decreased with GA concentration (X 3). GA generally increases the crosslinking density of the protein polymeric matrix, and subsequently viscosity, but enzymatic degradation would lower viscosity. The crosslinking function of GA marginally affects viscosity, which could be advantageous for adhesives in wetting and spreading on the wood surface.

The relationship of each variable to tacky force (Y 2) is presented in Fig. 3. Tacky force decreased at low trypsin concentration (X 1), but increased gradually at higher trypsin concentrations (X 1) as shown in Fig. 3a. With higher trypsin concentration (X 1) and longer incubation time (X 2), cleaved soy proteins could expose more functional groups and contribute to increased cohesion and adhesion at the interface between paper and the stainless steel substrate.

The effects of three variables on tacky force. Three levels (−1, 0, and +1) of a incubation times (X 2) are presented with trypsin concentrations (X 1), b trypsin concentrations (X 1) are presented with GA concentrations (X 3), and c GA concentrations (X 3) are presented with incubation time (X 2). The other variable was maintained at zero

Tacky force increased with GA concentration (X 3) as shown in Fig. 3b. Additional protein functional groups could interact with GA to form the entangled structure at the interface, leading to enhanced tacky force. Furthermore, GA concentration (X 3) was significant, and incubation time (X 2) had only a minor effect on tacky force as shown in Fig. 3c. Because tacky force indicates the ability of an adhesive to adhere to the substrate, it is highly dependent on the polymer chains and the extent of crosslinking [30]. The enzymatic hydrolysis and subsequent crosslinking by GA led to a structure with free protein polymers which were converted to larger constructions with the help of additional GA. Therefore, tacky force can be explained by a function of GA which is further expected to correlate with the shear adhesion performance.

The last response, water resistance (Y 3), is presented in Fig. 4. Water resistance increased with incubation time (X 2) and trypsin concentration (X 1), as illustrated in Fig. 4a. Also, as trypsin concentration (X 1) increased, we found slightly higher water resistance. As incubation time (X 2) and trypsin concentration (X 1) increased, hydrolyzed soy protein would have more functional groups available to form a higher degree of entanglement, which could contribute to better water resistance. As shown in Fig. 4b, water resistance improved with increased trypsin concentration (X 1) and GA concentration (X 3); furthermore, Fig. 4c shows that water resistance decrease at the beginning of hydrolysis but started to increase after 9.77 h of incubation time (X 2). This result occurred because of the complex hydrolysis mechanism of trypsin on MSP as mentioned above.

The effects of three variables on water resistance. Three levels (−1, 0, and +1) of a incubation times (X 2) are presented with trypsin concentrations (X 1), b trypsin concentrations (X 1) are presented with GA concentrations (X 3), and c GA concentrations (X 3) are presented with incubation times (X 2). The other variable was maintained at zero

Relationship between Three Responses and Shear Adhesion Properties

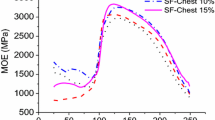

Based on the response value (low, medium, and high), nine experimental treatments of each response from Table 3 were selected for adhesion strength measurement. Correlations between each response (i.e. viscosity, tacky force, and water resistance) and adhesion strength were then established using a linear regression model (Table 4); the coefficients of determination (R 2) are presented in Figs. 5, 6 and 7.

Viscosity

Viscosity can be dramatically affected by protein structure. For soy protein-based adhesives, viscosity is a result of intermolecular interactions, such as electrostatic interaction and disulfide bonding among protein molecules. Because viscosity, or flow property, governs the penetration and wetting of soy protein through the wood material, it could directly affect adhesion strength [31, 32]. To achieve strong adhesion, an appropriate penetration depth into wood cells or capillary pores is necessary to form a strong bond to the adherend.

The linear regression between viscosity and dry shear adhesion strength had an R 2 value of 0.7678 and adjusted R 2 value of 0.6880 with significance at the 95 % confidence level (as indicated by the filled circles in Fig. 5), which suggests that viscosity has a good correlation with dry strength. Adhesion decreased as viscosity increased up to 10.5 Pa s. As explained in the previous section, viscosity was significantly affected by trypsin concentration (X 1) and the interaction between trypsin concentration and incubation time (X 1 X 2). Enzymatic hydrolysis causes a reduction in molecular size and intermolecular interactions, resulting in lower viscosity, which could play an important role in wettability and penetration of protein molecules to an appropriate depth in the wood surface. For adhesives with higher viscosity, molecular attractions among protein molecules would be stronger, which would result in a shallower penetration due to the greater restriction caused by molecular attraction. Also, adhesives with too low viscosity would lead to poor adhesion quality due to excessive absorption into the wood substrate and further cause bond line starvation. Cheng et al. demonstrated the different penetration depths for adhesives with different viscosities by collecting scanning electron microscopy (SEM) images [32]. They showed that the one with low viscosity can penetrate deeper due to less restriction of protein molecules and that this could cause the lack of protein molecules on the wood surface, resulting in poor adhesion strength. On the other hand, adhesives with moderate viscosity from progressive proteolytic hydrolysis could penetrate deeper than those with a higher viscosity and eventually develop a much stronger three-dimensional zone at the interface. Upon curing, the soy protein molecules were entangled and cured in this three-dimensional zone, contributing to mechanical interlocking.

To determine the optimum viscosity range for processing parameters, the ESP with low viscosity were prepared with higher trypsin concentrations (3 %) and longer incubation times (12, 24, 48, and 72 h). The viscosities (3.486, 2.865, 2.249, and 2.127 Pa s, respectively) were decreased due to prolonged hydrolysis time as presented with empty circles in Fig. 5a, and had a R 2 of 0.8847 using linear regression. The overall R 2 value was also calculated using all viscosities with cubic nonlinear regression and is presented in Fig. 5a. The dry strength seemed consistent with the viscosity range from 2.80 to 6.10 Pa s, which can lead to fairly stable and good adhesion performance with wood substrates. On the other hand, the linear regression model between viscosity and wet strength was very low, with a R 2 value of 0.0011 and an adjusted R 2 value of 0.0007, as shown in Fig. 5b. Crosslinking agents play an important role in the formation of interwoven and entangled structure, which could be used as a water barrier to improve the wet adhesion of the soy protein [24, 33, 34]. Because GA increases the crosslinking density in this soy protein system, it would be more related to wet adhesion strength, but viscosity was statistically reflected by the interaction between trypsin concentration and incubation time (X 1 X 2) and the trypsin concentration (X 1) rather than GA concentration (X 3). Therefore, GA may not significantly affect viscosity compared with trypsin concentration (X 1) and incubation time (X 2).

Tacky Force

The bonding mechanism involves comprehensive understanding of simultaneous cohesion (the internal strength among protein molecules) and adhesion (the tendency of the protein molecule to stick to a wood surface) [35]. The loop tack test could be an easy way to evaluate the cohesion and adhesion properties of polymer adhesives, particularly pressure-sensitive adhesives. Although this method is generally limited to bonding strength at the interface, in this study it is used as a simple method to predict the adhesion strength of soy protein-based adhesives. The thickness of protein-based adhesives on paper was thin enough to be cured on a stainless steel substrate surface with a short dwelling time (30 s), and all the failure occurred at the paper–protein interface. Thus, we could expect similar adhesion and cohesion between protein molecules and wood materials. Paper is a cellulosic material like wood. The bonding mechanism, including wetting, penetration, and mechanical interlocking, could occur at the interface between paper and a stainless steel substrate surface.

As presented in Fig. 6, the linear regression model between tack force and dry and wet strength was built with R 2 values of 0.3660 and 0.7082 and adjusted R 2 values of 0.2754 and 0.6082, with significance at the 95 % confidence level, respectively. Tacky force is positively related to wet strength based on R 2 values. The tacky force was significantly affected by GA concentration (X 3), as confirmed by ANOVA analysis in Table 3c. As discussed earlier, GA plays an important role in determining the wet strength by building an entangled structure as a water barrier. Accordingly, the tacky force could be an indicator to explain wet strength. Soy protein is a thermosetting polymer and becomes harder with crosslinking reactions and drying at elevated temperatures. Curing conditions in this loop tack test differed in temperature and pressure from wood tests, which might lead to different adhesion phenomena of protein molecules between paper and stainless steel substrate; however, the loop tack test can be used as a good predictor of adhesion strength based on results of the high correlation between tacky force and dry/wet strength.

Water Resistance

Upon curing at high temperatures, soy protein could make an entangled three-dimensional zone between protein molecules and glass surface. Measuring the protein solubility into water of the cured protein film allows water resistance to be used to predict wet adhesion strength. Wet adhesion performance is an important property to determine the resistance to moisture of the soy protein-based adhesive, which will help expand its applications in the wood product market for structural and exterior wood products. As shown in Fig. 7, dry and wet strength were well correlated to the water resistance of thin protein film, with R 2 values of 0.5257 and 0.6930 and adjusted R 2 values of 0.4759 and 0.6491, with significance at the 95 % confidence level, respectively. This method of determining water resistance can be used to predict wet adhesion strength because it directly measures the soluble protein molecules which are not highly crosslinked in the protein network. A less crosslinked state in the protein network would be easily loosened and dissolved in the water leading to poorer wet adhesion strength.

Conclusion

This work has shown the potential to correlate important physical properties and shear adhesion strengths of protein-based adhesives. Viscosity was successfully reflected by parameter variables and showed a good correlation with dry shear strength. Tacky force was a good indicator of wet shear adhesion strength, which was significantly reflected by cohesion and adhesion phenomena between the paper and stainless steel substrates. Water resistance can be used to predict wet adhesion strength based on its good relationship with wet adhesion strength. The crosslinking degree plays an important role in developing entangled three-dimensional zones, which can be used as a water barrier then as a predictor of wet adhesion strength. This work preliminarily identified the most significant physical properties that can explain and predict the shear adhesion strength of an enzymatically modified soy protein-based adhesive system, but the results need to be further confirmed by another protein modification system in order to give a generic conclusion. Different modifiers such as denaturing reagents and crosslinking chemicals will be further investigated to identify the correlation between physical and adhesion properties.

References

Kato A (1991) Significance of macromolecular interaction and stability in functional-properties of food proteins. ACS Symp Ser 454:13–24

Lambuth AL (1977) Soybean glues. In: Skeist I (ed) Handbook of adhesives. Van Nostrand Reinhold, New York, pp 172–180

Hettiarachchy NS, Kalapathy U, Myers DJ (1995) Alkali-modified soy protein with improved adhesive and hydrophobic properties. J Am Oil Chem Soc 72:1461–1464. doi:10.1007/BF02577838

Wu YV, Inglett GE (1974) Denaturation of plant proteins related to functionality and food applications—review. J Food Sci 39:218–225. doi:10.1111/j.1365-2621.1974.tb02861.x

Mackay CD (1998) Good adhesive bonding starts with surface preparation. Adhes Age 41:30–32

Huang W, Sun X (2000) Adhesive properties of soy proteins modified by sodium dodecyl sulfate and sodium dodecylbenzene sulfonate. J Am Oil Chem Soc 77:705–708. doi:10.1007/s11746-000-0113-6

Markley KS (1951) Soybeans and soybean products, vol II. Interscience, New York

Huang WN, Sun XZ (2000) Adhesive properties of soy proteins modified by sodium dodecyl sulfate and sodium dodecylbenzene sulfonate. J Am Oil Chem Soc 77:705–708. doi:10.1007/s11746-000-0113-6

Huang WN, Sun XZ (2000) Adhesive properties of soy proteins modified by urea and guanidine hydrochloride. J Am Oil Chem Soc 77:101–104. doi:10.1007/s11746-000-0016-6

Singha AS, Thakur VK (2009) Study of mechanical properties of urea-formaldehyde thermosets reinforced by pine needle powder. Bioresources 4:292–308

Hettiarachchy NS, Kalapathy U, Myers DJ (1995) Alkali-modified soy protein with improved adhesive and hydrophobic properties. J Am Oil Chem Soc 72:1461–1464. doi:10.1007/BF02577838

Kalapathy U, Hettiarachchy NS, Myers D, Rhee KC (1996) Alkali-modified soy proteins: effect of salts and disulfide bond cleavage on adhesion and viscosity. J Am Oil Chem Soc 73:1063–1066. doi:10.1007/BF02523417

Qi G, Li N, Wang D, Sun XS (2013) Physicochemical properties of soy protein adhesives modified by 2-octen-1-ylsuccinic anhydride. Ind Crops Prod 46:165–172. doi:10.1016/j.indcrop.2013.01.024

Nordqvist P, Thedjil D, Khosravi S, Lawther M, Malmstrom E, Khabbaz F (2012) Wheat gluten fractions as wood adhesives-glutenins versus gliadins. J Appl Polym Sci 123:1530–1538. doi:10.1002/app.34312

Qi G, Li N, Wang D, Sun XS (2012) Physicochemical properties of soy protein adhesives obtained by in situ sodium bisulfite modification during acid precipitation. J Am Oil Chem Soc 89:301–312. doi:10.1007/s11746-011-1909-6

Sun X, Zhu L, Wang D (2006) Surface active and interactive soy protein polymers and making hydrophobic clusters and complexes of soybean globular proteins. Patent Application Country: Application: WO; WO; Priority Application Country: US Patent WO2006116560

Chen N, Lin Q, Zeng Q, Rao J (2013) Optimization of preparation conditions of soy flour adhesive for plywood by response surface methodology. Ind Crops Prod 51:267–273. doi:10.1016/j.indcrop.2013.09.031

Cao N, Yang X, Fu Y (2009) Effects of various plasticizers on mechanical and water vapor barrier properties of gelatin films. Food Hydrocoll 23:729–735. doi:10.1016/j.foodhyd.2008.07.017

Mo X, Sun XS (2013) Soy proteins as plywood adhesives: formulation and characterization. J Adhes Sci Technol 27:2014–2026. doi:10.1080/01694243.2012.696916

Kalapathy U, Hettiarachchy N, Myers D, Hanna MA (1995) Modification of soy proteins and their adhesive properties on woods. J Am Oil Chem Soc 72:507–510. doi:10.1007/BF02638849

ASTM (2002) Standard test method for strength properties of adhesives in two-ply wood construction in shear by tension loading. Anonymous annual book of ASTM standards. ASTM International, West Conshohocken, pp 158–160

ASTM (2002) Standard test methods for resistance of adhesives to cyclic laboratory aging conditions. Anonymous annual book of ASTM standards. ASTM International, West Conshohocken, pp 70–73

ASTM (2002) Standard practice for effect of moisture and temperature on adhesive bonds. Anonymous annual book of ASTM standards. ASTM International, West Conshohocken, pp 67–69

Sun XS (2011) Soy protein polymers and adhesion properties. J Biobased Mater Bioenergy 5:409–432. doi:10.1166/jbmb.2011.1183

Shutov AD, Pineda J, Senyuk VI, Reva VA, Vaintraub IA (1991) Action of trypsin on glycinin—mixed-type proteolysis and its kinetics—molecular mass of glycinin-T. Eur J Biochem 199:539–543. doi:10.1111/j.1432-1033.1991.tb16152.x

Kalapathy U, Hettiarachchy NS, Myers D, Rhee KC (1996) Alkali-modified soy proteins: effect of salts and disulfide bond cleavage on adhesion and viscosity. J Am Oil Chem Soc 73:1063–1066. doi:10.1007/BF02523417

Migneault I, Dartiguenave C, Bertrand MJ, Waldron KC (2004) Glutaraldehyde: behavior in aqueous solution, reaction with proteins, and application to enzyme crosslinking. Biotechniques 37:790–798

Barkia A, Bougatef A, Nasri R, Fetoui E, Balti R, Nasri M (2010) Trypsin from the viscera of Bogue (Boops boops): isolation and characterisation. Fish Physiol Biochem 36:893–902. doi:10.1007/s10695-009-9365-z

Sipos T, Merkel JR (1970) An effect of calcium ions on activity, heat stability, and structure of trypsin. Biochemistry (N Y) 9:2766–2775. doi:10.1021/bi00816a003

Pang B, Ryu C, Kim H (2013) Improvement in wettability of pressure-sensitive adhesive on silicon wafer using crosslinking agent with siloxane groups. J Appl Polym Sci 129:276–281. doi:10.1002/app.38737

Scheikl M, Dunky M (1998) Measurement of dynamic and static contact angles on wood for the determination of its surface tension and the penetration of liquids into the wood surface. Holzforschung 52:89–94. doi:10.1515/hfsg.1998.52.1.89

Cheng E, Sun X (2006) Effects of wood-surface roughness, adhesive viscosity and processing pressure on adhesion strength of protein adhesive. J Adhes Sci Technol 20:997–1017. doi:10.1163/156856106777657779

Frihart CR (2010) Soy protein adheisves. McGraw Hill Yearbook of Science and Technology 2010:354–356

Cheng E (2004) Adhesion mechanism of soybean protein adhesives with cellulosic materials. PhD dissertation, Kansas State University

Sowa D, Czech Z, Byczynski L (2014) Peel adhesion of acrylic pressure-sensitive adhesives on selected substrates versus their surface energies. Int J Adhes Adhes 49:38–43. doi:10.1016/j.ijadhadh.2013.12.013

Acknowledgment

This work was supported by the Kansas Agricultural Experimental Station (contribution no. 15-107-J).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Kim, M.J., Sun, X.S. Correlation between Physical Properties and Shear Adhesion Strength of Enzymatically Modified Soy Protein-Based Adhesives. J Am Oil Chem Soc 92, 1689–1700 (2015). https://doi.org/10.1007/s11746-015-2722-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2722-4