Abstract

This study evaluated the effects of superheated steam treatment (SST) on rice starch and changes in vitro digestibility, morphostructural, thermal, and functional characteristics were investigated. SST was applied at 150 °C for 3 min (SS150/3) and 5 min (SS150/5) and for the same times at 190 °C (SS190/3 and SS190/5), followed by drying and storage. SST affected the structural order, favoring gelatinization and exposing more of the double helix structure. Results indicated increased mobility of starch chains and disrupted ordered structures. The control shown a higher amount of long branches (DP ≥ 37), whereas thermally treated starches by SST exhibited a higher proportion of small amilopectin molecules, with SS190/5 being particularly noteworthy. Longer treatment times and higher temperatures caused pronounced morphological changes, including gelatinization, agglomeration, granule destruction, and surface roughness. SST also increased water and oil absorption, reduced syneresis index, and altered crystallinity. Crystallinity experienced a significant reduction for all starches subjected to SS, with SS190/5 standing out with a maximum reduction of 55.07%, as confirmed by the IR (1047/1022) cm−1. The results demonstrated the feasibility of structural and morphological modification of starch with superheated steam, mainly SS150/5 and SS190/5, obtaining properties distinct from native starch.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The largest fraction of the rice grain is the endosperm (70%), rich in starch and containing some protein bodies, with approximately 20% of amylose, featuring distinct molecular masses, degrees of branching, and physicochemical properties [1]. Starch plays a fundamental role as an energy source in staple foods, and its digestibility directly impacts human health and nutrition. Various intrinsic factors such as thermal properties, crystalline structure, molecular order, and surface characteristics, along with extrinsic factors including physical, chemical, and enzymatic modifications, influence starch digestibility [2, 3].

It can be used in its natural state after extraction, referred to as "native starch," or undergo one or more modifications (physical, mechanical, biological, and/or chemical) to attain desired properties and become "modified starch". Several thermal techniques for starch modification have been investigated in previous studies, such as hydrothermal methods (autoclaving and cooking), and heat-moisture treatments [4].

In most cases, starch modification methods are time-consuming and can lead to increased production costs and energy consumption, especially in large-scale production.

Superheated steam treatment (SST) has emerged as a promising technology for food processing, particularly in food drying, due to its enhanced heat transfer coefficients and efficient use of latent heat of evaporation [5]. Zhong et al. [6] describe SST as an innovative method offering high thermal efficiency, low pollution, and reduced energy waste compared to conventional techniques like thermal-moisture treatment. Operating in shorter time intervals, SST involves heating saturated steam beyond its saturation point, making it capable of overcoming the limitations of traditional approaches by maximizing heat transfer coefficients and reusing evaporative heat [7]. These advantages encompass superior energy efficiency, rapid treatment, and the ability to achieve high temperatures owing to its high enthalpy and heat transfer capacity. Moreover, Koc et al. [8] highlight SST's potential for inducing structural and morphological changes in materials, alongside increased water retention capacity, compared to other industrial processes.

Zhong et al. [6] applied SST to produce resistant starch, converting slowly digestible starch (SDS) into resistant starch (RS) at 120 °C. Hu et al. [9] demonstrated the impact of SST on starch digestibility in wheat flour, while Hu et al. [10] examined its effects on potato starch's structural and rheological properties. Among the various starch modification techniques, superheated steam proves to be viable due to its short processing time and the potential for operation on heating belts, where only the moisture content needs to be controlled at the beginning. The heat used in the process can come from steam produced by the industry's boilers. Additionally, it is an environmentally friendly technique that does not harm the consumer's health, as it does not involve the use of acids or harmful chemical reagents. In addition to establishing a relationship between what happens in the structure of starch granules after SST with digestibility and affinity with water, oil, and retrogradation behavior after gelatinization. Therefore, the objective of this study is to evaluate the influence of SST at different times and temperatures on the in vitro digestibility and morphostructural, thermal, and functional characteristics of rice starch.

Materials and methods

Materials

Basmati rice (Urbano, Brazil), sunflower oil (Soya, Brazil), sodium hydroxide (Neon, Brazil), α-amylase from human salivary Type XIII-A (EC 232-565-6), 3,5-dinitrosalicylic acid (DNS), ethyl alcohol, isoamylase from Pseudomonas sp. sodium metabisulfite, sodium acetate, acetic acid was purchased from Sigma Aldrich (Sigma Aldrich, USA). Anhydrous dimethyl sulfoxide (DMSO) (99.9%) from Synth (São Paulo, Brazil).

Starch extraction and superheated steam treatment (SST)

Rice grains were soaked in a 0.5% sodium metabisulfite solution at a ratio of 1:2 (w/v) at 7 °C for 72 h. After rinsing with running water for 3 min, the grains underwent grinding in an industrial blender (KOHLBACH, KM42A) with distilled water at a ratio of 1:2 (w/v) for 5 min. The resulting suspension was filtered through an organza mesh, with the process repeated four times. The liquid collected during filtration was stored at 7 °C, with the supernatant discarded every 12 h, repeated five times with 200 mL of distilled water added each interval. At the end of the process, the starch has a moisture content of 70–75% moisture and needs to be adjusted by adding distilled water to 80% as a form of standardization before it can be inserted into the superheated steam equipment.

For SST, rice starch (300 g) with 80% moisture was treated using an SST equipment (NINGBO, DCZF-F30-T300) at 150 °C and 190 °C for 3 min and 5 min, respectively (SS150/3, SS150/5, SS190/3 and SS190/5). Untreated starch served as the control, following parameters extrapolated from Ma et al. [11]. The flow speed was adjusted to 1.00 m s−1 and the steam was produced by a mini boiler coupled to the equipment with a pressure of 2 bar. After cooling, samples were dried at 50 °C with an air velocity of 1.0 m s−1 until reaching 14% water content. Starch pastes were spread onto aluminum plates (15 × 2 cm, 5.0 mm thickness), then dried in a circulating oven (MARCONI, MA048) at 50 °C and 1.0 m s−1 for 630 min, as determined in previous analyses. Subsequently, they underwent grinding three times using a disk mill (BOTINI, B55) [12].

In vitro digestion

In the salivary digestion phase, a solution of α-amylase (10 mg of α-amylase dissolved in 10 mL of 100 mmol/L sodium acetate buffer at pH 6.8) was added to 2 g of starch, and the mixture was agitated for 2 min at 37 °C. Subsequently, gastrointestinal digestion occurred, wherein supernatants from the simulated digestion (0.5 mL) were collected at various time intervals during small intestine digestion (5, 30, 60, 90, 120, 150, 190, and 200 min) and promptly diluted with 2.5 mL of 95% ethanol to deactivate the enzymes. Maltose concentrations were determined using the reducing sugar method proposed by Miller [13]. The starch digestion curve at different maltose concentrations was constructed according to Eq. 1. Then, the area under the curve (AUC) was calculated (Eq. 2). The glycemic index (GI) was calculated using Eq. 3 [14].

where C∞ is the estimated percentage of final starch digestion; Ct is the starch digestibility in t (min) and k is the starch digestion rate coefficient, AUC is the area of the curve; tf is the final time (min), t0 is initial time (min) and HI is hydrolysis index.

X-ray diffraction (XRD)

XRD measurements (SHIMADZU, XRD-7000) were conducted with a 0.01º/s step in the 5–35° range at room temperature, operating at 80 mA and 40 kV. The relative crystallinity was calculated using the amorphous (Aa) and crystalline areas (Ac), as shown in Eq. (4) [7].

Fourier transform infrared Spectroscopy (FTIR)

The FTIR (Agilent, Cary 630) was conducted with 32 scans and a resolution of 4 cm-1 in the ranges of 600–1500 cm−1 and 1500–3900 cm−1. The ratio between the bands at 1047/1022 cm−1 and 1022/995 cm−1 was calculated to relate to the degree of order and double helix, respectively [15].

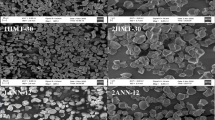

Scanning electron microscopy (SEM)

Images captured by a Superscan SSX-550 scanning electron microscope (SEM) were used to observe native (Control) and modified starch samples (SS150/3, SS150/5, SS190/3, and SS190/5). The samples were coated with a thin layer of gold, and SEM images were captured at a magnification of 1000 × using a 10 kV potential [16].

Differential Scanning Calorimetry (DSC)

The starch (2 mg, dry basis) was weighed and mixed with distilled water (6 µL), then left to equilibrate at 25 °C, for 12 h. Subsequently, it was subjected to heating from 20 to 180 °C, at a rate of 10 °C,/min using a DSC (2920 Modulated DSC), where the onset temperature (To), conclusion temperature (Tc), and transition enthalpy (ΔH) were calculated [17].

Amylopectin branch chain-length distribution

The processing began with the addition of 10 mg of starch to 3 mL of 90% DMSO, followed by heating in a water bath (CAP LAB, CAP-BMD) until boiling for 20 min. Then, 6 mL of anhydrous ethanol were added to the mixture, which was centrifuged at 5000 rpm for 15 min. The resulting precipitate was dissolved in 2 mL of 50 mM sodium acetate buffer (pH 4) in a water bath for 20 min. After cooling the dispersion to 40 °C, it was treated with isoamylase (5 μL) for 24 h. The reaction was stopped in a boiling water bath for 20 min, and then 400 μL of the hydrolysate were extracted and diluted in 2 mL of NaOH (120 mmol/L), filtered through a 0.45 μm nylon filter. Next, 25 μL of the sample were injected into the Dionex™ CarboPac™ PA200 system to determine the average length of the amylopectin chain. The elution of the sample occurred at a rate of 1 mL/minute with a sodium acetate gradient, prepared by adding eluent B (150 mM sodium hydroxide containing 500 mM sodium acetate) to eluent A (150 mM sodium hydroxide) [18].

Water absorption capacity (WAC) and oil absorption capacity (OAC)

Starch (1 g) was added to 10 mL of distilled water or sunflower oil, then the suspension was vortexed for 30 s (KASVI, K45-2810) and allowed to stand for 30 min. Subsequently, the samples were centrifuged (SOLAB, SL706) for 15 min at 2000 rpm, the supernatant was discarded, and the calculation was performed by weight difference to determine the amount of water or oil retained by the starch [19].

Syneresis index

Starch pastes were formulated at a concentration of 10% (starch/water) (w/v) and heated at 80 °C for 12 min using a thermostatic water bath (Laborglas, Alpha A12). Subsequently, they were stored for 72 h at 7 °C and then centrifuged (SOLAB, SL706) at 2000 rpm for 10 min. Syneresis was determined by calculating the ratio of the mass of water separated from the paste to the initial sample mass.

[20].

Solubility and swelling power

Starch (0.5 g) was added to 50 mL of distilled water and vortexed for 20 s (KASVI, K45-2810). The mixture was subjected to temperatures of 40, 60, and 80 °C in a thermostatic water bath (LaborgLas, Alpha A12) for 30 min. Subsequently, it was cooled to 20 °C and centrifuged at 3000 rpm for 20 min, then dried at 120 °C in an oven (Marconi, MA048). The dry weights of the supernatant (P1), post-centrifugation pellet (P2), and initial starch weight (P) were used to calculate the solubility and swelling power (Eqs. 8 and 9) [21].

Analysis statistical

The statistical analysis was conducted using Statistica 7.0 software (Statsoft, USA) with three repetitions (n = 3). Statistical significance (p < 0.05) was determined through one-way ANOVA with Tukey's post hoc test. For the analysis of the distribution of the branched chain length of amylopectin, the online software ASTRA 6.1 (Wyatt Technology, USA) was employed. The graphs were generated using OriginPro 8.5 software.

Results and discussion

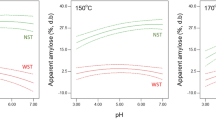

Impact of treatment conditions on the in vitro digestion of rice starch

The catalytic reaction of α-amylase was evaluated, and the graph depicting starch digestion over time is shown in Fig. 1. It was observed that starch digestibility increased rapidly at the beginning of the process and then gradually reached stability. For the control and SS150/3 (Fig. 1), the time to stabilization was 150 min, with the increase in exposure time and temperature, the digestion stabilization time was reduced to 120 min. This indicates that the SST process facilitates the entry of α-amylase into starch granules, reducing digestion time. According to Kumar et al. [22], starch molecules become more complex and harder to be decomposed by α-amylase after a certain digestion time, leading to a deceleration in the digestion rate and a gradual attainment of the digestibility peak.

In vitro digestibility of rice starch treated by superheated steam adjusted to the general first-order model: Control: native (untreated) rice starch; SS150/3: rice starch steamed at 150 °C for 3 min; SS150/5: rice starch steamed at 150 °C for 5 min; SS190/3: rice starch treated at 190 °C for 3 min and SS190/5: rice starch treated at 190 °C for 5 min

The statistical parameters used to measure the degree of fit to the experimental data were summarized in Table 1. For all treatment conditions, the model provided an accurate description with a coefficient of determination (R2) greater than 0.94 and ϰ2 less than 1.798, indicating a satisfactory fit to the experimental data for all conditions evaluated in this study. When evaluating the kinetic parameters C∞ and k (Table 1), a significant difference (p < 0.05) between the control and SST-treated samples is evident, with SS150/5 and SS190/5 standing out, showing the highest hydrolysis percentages with rates of 2.94 × 10–2 min−1 and 3.14 × 10–2 min−1, respectively.

The results showed that rice starch treated with SST resulted in higher rates of enzymatic reaction. This can be observed for the samples treated for longer periods, SS190/5 and SS150/5 (Fig. 1), which exhibited more pronounced digestion curves, indicating higher digestibility rates. This occurs because SST promotes partial gelatinization of starch, breaking down crystalline structures and making starch molecules more soluble and available for the action of digestive enzymes [10]. Starch treated with SST for a longer period may lead to the fragmentation of starch granules, increasing their available surface area for the action of digestive enzymes [11].

As observed in Table 1, the control sample exhibited the smallest area (2416.15) and consequently the lowest hydrolysis Index (HI) (17.76), in contrast to the treated samples which showed larger areas ranging from 4628.68 (SS150/3) to 9192.61 (SS190/5), and HI ranging from 34.06 to 67.59%, contributing to a more efficient starch hydrolysis during the digestion process. The control sample had a GI of 49.46, while the modified starches' GI values were significantly higher (p < 0.05) and above 50. According to the classification proposed by Osman et al. [23], SS150/3, SS150/5, and SS190/3 belonged to medium GI foods (56–70), while SS190/5 was considered a high GI food (> 70), with a GI of 76.82. According to Dadi et al. [24], the increase in GI with the application of SST treatment can be attributed to starch gelatinization, as gelatinized starch is more easily digested and absorbed by the body, leading to a faster increase in blood glucose levels and consequently a higher glycemic index.

After 210 min of reaction, the fraction that remains unchanged in the starch is called resistant starch (RS), as the enzyme did not have access to the internal structure of the granules. Only SS150/3 (4.55%) showed a lower RS value than the control (5.16%), indicating that at prolonged times and temperatures, the clusters of amorphous rice starch particles formed by SST hinder the complete breakdown of the molecules. This can also be explained by the rearrangement of internal molecules forming more complex structures and the saturation of the active sites of α-amylase after extended hydrolysis times [10].

X-ray diffraction (XRD) and relative crystallinity

In Fig. 2, the main peaks in the rice starch diffractogram are presented. It was found that the control, SS150/3, and SS190/3 exhibited characteristic peaks of type A pattern at 14.85°, 16.84°, 17.83°, 19.66°, and 22.81°, indicative of cereal starch. These results suggest that SST at shorter times did not alter the crystalline pattern of rice starch. However, with prolonged treatment (SS150/5 and SS190/5), a flattening of the doublet between 17–18° was observed, with a shift to 19.86°. The peak intensity decreased with longer heat application, possibly due to structural rearrangements within the starch granule's crystalline domain, leading to the displacement of double helices between the crystals. Guo et al. [25] found a more pronounced peak at 20°, indicating the formation of the amylose–lipid complex due to the type V pattern formation. This confirms that the type and crystallinity index of these formulations were significantly affected, especially for SS190/5, where an elevation of the peak at 19.86° and a large amorphous area were observed.

X-ray diffraction of rice starch treated by superheated steam. Control: native (untreated) rice starch; SS150/3: rice starch steamed at 150 °C for 3 min; SS150/5: rice starch steamed at 150 °C for 5 min; SS190/3: rice starch treated at 190 °C for 3 min and SS190/5: rice starch treated at 190 °C for 5 min

The variation in crystallinity index from 21.77 to 9.78% can be observed in Table 2, with the lowest value for SS190/5. It is possible to verify that the crystallinity index decreased as the time and temperature of SST treatment increased, showing significant differences for all formulations. The SST increased the mobility of starch chains, fragmenting unstable crystalline areas and altering the arrangement of ordered helical structures, resulting in structural changes in the starch granules [26].

Fourier transform infrared spectroscopy (FTIR)

The FTIR spectra of the starches treated by SST are presented in Fig. 3A and B. The ratio between the bands corresponding to amylose and amylopectin chains was chosen to quantify the structural changes in the granules after SST treatment. The short-range structure of starch was characterized by absorbance at 1047 cm−1 (crystalline area) and 1022 cm−1 (amorphous area), while the range at 995 cm−1 represented the hydrated starch structure [11]. The IR 1047/1022 cm−1 ratio decreased for the SST-treated samples, indicating a reduction in short-range molecular ordering. In contrast, the IR 1047/995 cm−1 ratio increased, suggesting partial gelatinization due to limited water availability during SST. Formulations with the same processing time showed no significant differences for the IR 1047/1022 cm−1 ratio, while differences were observed for the IR 1022/995 cm−1 ratio only between SS150/5 and SS190/5. A decrease in peak intensity around 3300 cm−1 (OH and hydrogen), 2931 cm−1 (CH), and 1625 cm−1 (H–O) was observed for samples treated for 5 min and SS190/3, indicating the disruption of hydrogen bonds and exposure of double helices during SST, as observed by Ma et al. [27]. It is noticeable that a consistent band pattern was maintained for all formulations, with no new functional groups found, only differences in intensities.

Rice starch FTIR: A Total FTIR spectrogram 600–1500 cm−1 and B 1500-3900 cm−1 magnification. Control: native (untreated) rice starch; SS150/3: rice starch steamed at 150 °C for 3 min; SS150/5: rice starch steamed at 150 °C for 5 min; SS190/3: rice starch treated at 190 °C for 3 min and SS190/5: rice starch treated at 190 °C for 5 min

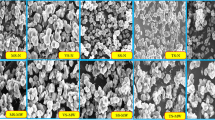

Scanning electron microscopy (SEM)

SST was also evaluated on the morphology and surface characteristics of rice starch particles (Fig. 4). In Fig. 4A, the control starch granules with intact surface can be observed, characterized by an ovoid geometry with some multifaceted parts due to the extraction and grinding method. As the treatment time and temperature in the SST processing of rice starch increased, more pronounced morphological changes were observed. For SS150/3 (Fig. 4B), it can be observed that the granules began to partially gelatinize and form a single agglomerate, while the geometry of the granules is still visible. In Fig. 4C, with the increase in treatment time from 3 to 5 min, gelatinization becomes more pronounced and a significant portion of the granules is destroyed, forming large agglomerates with irregularities and roughness on the surface. With the increase in temperature to 190 °C (Fig. 4C and D), the granules appear to be dissolved due to complete gelatinization, and the geometry of the granules can no longer be defined. In SS190/5, porosity and roughness of the starch are observed, being the formulation where the action of SST treatment was most efficient. According to Ma et al. [28], after SST, some starch granules showed partial fragmentation, with irregular shapes and rough surfaces, due to partial gelatinization under conditions of low water availability.

SEM image of the starch rice surface: A Control, B SS150/3, C SS150/5, D SS190/3 and E SS190/5. Control: native (untreated) rice starch; SS150/3: rice starch steamed at 150 °C for 3 min; SS150/5: rice starch steamed at 150 °C for 5 min; SS190/3: rice starch treated at 190 °C for 3 min and SS190/5: rice starch treated at 190 °C for 5 min

Thermal properties

The values of onset gelatinization temperature (To) and peak temperature (Tc) are presented in Table 2 and Fig. 5. Higher values of To and Tc were observed for starches modified by SST compared to the control. When comparing SS150/3 and SS190/3, it was observed that increasing the temperature from 150 to 190 °C at a fixed time of 3 min did not significantly modify the thermal parameters of rice starch. However, when comparing SS150/5 and SS190/5, there was a significant difference (p < 0.05) between the formulations, with the latter showing even higher temperatures (To: 64.09 °C and Tc: 73.02 °C), indicating greater resistance to hydration and intermolecular bond breaking. Chen et al. [29] reported that during SST, the interaction between starch granules and water resulted in partial breakage of intermolecular hydrogen bonds and a decrease in double helix content, leading to partial gelatinization of starch granules.

DSC thermograms for rice starch treated under different conditions of temperature and superheated steam treatment time. Control: native (untreated) rice starch; SS150/3: rice starch steamed at 150 °C for 3 min; SS150/5: rice starch steamed at 150 °C for 5 min; SS190/3: rice starch treated at 190 °C for 3 min and SS190/5: rice starch treated at 190 °C for 5 min

SS190/5 showed a 28.81% reduction in ΔH values compared to the control, indicating that even with high To and Tc, the time required for complete gelatinization is low, resulting in less energy for this process. This can be justified because the broken molecules could reorganize, leading to increased interaction between starch chains, resulting in improved double helix formation and reduction of starch granule destabilization [30]. The positive enthalpy of gelatinization reflects the starch crystallinity and the energy required to disrupt its ordered organization. During the initial stages of gelatinization, starch double helices begin to unwind, with this process being intensified with increasing time and temperature [31].

Length of the branched chain of amylopectin

This parameter could be related to the crystallinity index, where according to 32), a decrease in crystallinity corresponds to an increase in the branching degree of amylopectin, especially for shorter chains (Table 3). The proportions of (DP 6–12) and (DP 13–24) were lower for the control, while (DP 25–36) remained constant for all formulations. The control presented higher proportions of intact amylopectin with larger branches (DP ≥ 37), due to non-covalent bonds or co-crystallization with other large amylopectin molecules [33]. However, these bonds may break as heating disrupts the crystalline structure, making them easily removable from the surface through heat treatment [34]. This is why starches treated with SST exhibited a higher proportion of smaller amylopectin molecules.

Water absorption capacity (WAC), oil absorption capacity (OAC) and syneresis index

As the temperature and treatment time increased, the WAC values of all samples increased, with SS190/5 showing the highest WAC, reaching 63.69 g 100 g−1 (Fig. 6A). These results indicate that higher heating temperatures are required to increase the WAC of rice starch. This increase is attributed to the decrease in water content and reduction in hydrogen bonds caused by SST.

Functional analysis: A Absorption capacity of water, B oil and C syneresis of rice starch. Control: native (untreated) rice starch; SS150/3: rice starch steamed at 150 °C for 3 min; SS150/5: rice starch steamed at 150 °C for 5 min; SS190/3: rice starch treated at 190 °C for 3 min and SS190/5: rice starch treated at 190 °C for 5 min

Keppler et al. [35] found that SST increased WAC due to water interaction with polar carbohydrate groups.

The results indicate that SST application led to an improvement of up to 10.37% in oil absorption capacity (OAC) compared to control starch (Fig. 6B). However, starches subjected to 190ºC showed no significant differences for the studied times (3 and 5 min), with values of 64.99% (SS190/3) and 65.86% (SS190/5), respectively. This suggests that our strategy is promising as an alternative to increase OAC levels. Almeida et al. [36] obtained OAC values ranging from 47 to 71% for enzymatically modified red rice starch.

The study revealed that water release is influenced not only by the treatment temperature but also by the treatment duration (p < 0.05). All treated formulations showed lower syneresis index (Fig. 6C) values compared to control starch, which recorded a value of 24.33 g 100 g−1. SS190/5 exhibited the most significant reduction in the syneresis index (22.07%), due to the increased concentration of the gel-forming polymer, effectively minimizing syneresis.

Swelling power and solubility of rice starch

SST significantly increased swelling power values but decreased solubility values for all formulations. Swelling power values ranged from 9.37 to 16.35 g/g, with the highest value observed for SS190/5 (Fig. 7A), while solubility values ranged from 10.13 to 14.97%, with the highest value for the control. 32) observed that a higher number of short branches in amylopectin chains resulted in greater swelling capacity, while longer and more branched chains had the opposite effect. The increase in swelling power can be justified as SST caused starch granules to break down due to partial gelatinization, enhancing the interaction between starch and water [37]. Meanwhile, the rearrangement and strengthening of the molecular order of functional groups may be responsible for the decrease in solubility [38].

Swelling power (A) and solubility (B) of rice starch subjected to superheated steam: Control: native (untreated) rice starch; SS150/3: rice starch steamed at 150 °C for 3 min; SS150/5: rice starch steamed at 150 °C for 5 min; SS190/3: rice starch treated at 190 °C for 3 min and SS190/5: rice starch treated at 190 °C for 5 min

Conclusion

In conclusion, the results of this study demonstrate the feasibility of modifying rice starch using the SST treatment, which rapidly altered properties, employing a low-cost and environmentally friendly technique. This opens up the possibility of expanding the application of starch in large-scale food industries. Rice starch treated with SST showed increased water and oil absorption, reduced syneresis, and a higher glycemic index. These modifications were attributed to changes in crystalline structure, porosity, and availability of amylose and amylopectin for enzymatic digestion. The formulation SS190/5 stood out, with a significant reduction in crystallinity index (55.07%) and the appearance of the amylose–lipid complex, leading to a change in crystallinity type to type V. The control showed a higher quantity of long branches (DP ≥ 37), while starches treated thermally with SST showed a higher proportion of small amylopectin molecules (DP 6–12 and DP 13–24). Modified rice starch also exhibited higher To and Tc values and lower ΔH values, with a maximum reduction of 28.81% for SS190/5. The results demonstrated the feasibility of structural and morphological modification of rice starch with SST, especially at SS150/5 and SS190/5, obtaining distinct properties from native starch.

Finally, this methodology can be applied to various starch sources and even expand the range of time and temperature to evaluate the limits of modification with SST without significant nutritional losses. As shown, the morphostructural changes are related to the time–temperature combination used in the process. Therefore, the focus now is to study how SST influences the textural, rheological, and viscosity parameters in paste formation and when applied to foods that require further thermal treatment. This study has some limitations, as one concern in thermal modification processes of starch is developing new methods to cool the starch quickly, aiming for starch recovery after the process. Therefore, new techniques such as forced ventilation with cold air, direct and indirect cooling, and freezing can be employed.

Data availability

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

References

G.H. Lang, D.H. Kringel, T. dos Santos Acunha, C.D. Ferreira, Á.R.G. Dias, E. da Rosa Zavareze, M. de Oliveira, Cake of brown, black and red rice: Influence of transglutaminase on technological properties, in vitro starch digestibility and phenolic compounds. Food Chem. 318, 126480 (2020). https://doi.org/10.1016/j.foodchem.2020.126480

B. Li, Y. Zhang, F. Xu, M.R. Khan, Y. Zhang, C. Huang, A. Liu, Supramolecular structure of Artocarpus heterophyllus Lam seed starch prepared by improved extrusion cooking technology and its relationship with in vitro digestibility. Food Chem. 336, 127716 (2021). https://doi.org/10.1016/j.foodchem.2020.127716

M.R. Toutounji, A. Farahnaky, A.B. Santhakumar, P. Oli, V.M. Butardo Jr., C.L. Blanchard, Intrinsic and extrinsic factors affecting rice starch digestibility. Trends Food Sci. Technol. 88, 10–22 (2019). https://doi.org/10.1016/j.tifs.2019.02.012

R.L.J. Almeida, N.C. Santos, G.M. da Silva, J.V.F. Feitoza, V.M. de Alcântara Silva, V.H. de Alcântara Ribeiro, C.E. de Sousa Muniz, Effects of hydrothermal pretreatments on thermodynamic and technological properties of red bean starch. J. Food Process Eng 45(4), e13994 (2022). https://doi.org/10.1111/jfpe.13994

A. Alfy, B.V. Kiran, G.C. Jeevitha, H.U. Hebbar, Recent developments in superheated steam processing of foods—a review. Crit. Rev. Food Sci. Nutr. 56(13), 2191–2208 (2016). https://doi.org/10.1080/10408398.2012.740641

C. Zhong, Y. Xiong, H. Lu, S. Luo, J. Wu, J. Ye, C. Liu, Preparation and characterization of rice starch citrates by superheated steam: A new strategy of producing resistant starch. LWT 154, 112890 (2022). https://doi.org/10.1016/j.lwt.2021.112890

J. Wu, S. Xu, Y. Huang, X. Zhang, Y. Liu, H. Wang, C. Liu, Prevents kudzu starch from agglomeration during rapid pasting with hot water by a non-destructive superheated steam treatment. Food Chem. 386, 132819 (2022). https://doi.org/10.1016/j.foodchem.2022.132819

F. Koc, I. Sugrue, K. Murphy, S. Renzetti, M. Noort, R.P. Ross, C. Stanton, The microbiome modulating potential of superheated steam (SHS) treatment of dietary fibres. Innov. Food Sci. Emerg. Technol. 80, 103082 (2022). https://doi.org/10.1016/j.ifset.2022.103082

Y. Hu, L. Wang, H. Zhu, Z. Li, Modification of physicochemical properties and in vitro digestibility of wheat flour through superheated steam processing. J. Cereal Sci. 74, 231–237 (2017). https://doi.org/10.1016/j.jcs.2017.02.012

X. Hu, B. Guo, C. Liu, X. Yan, J. Chen, S. Luo, Modification of potato starch by using superheated steam. Carbohyd. Polym. 198, 375–384 (2018). https://doi.org/10.1016/j.carbpol.2018.06.110

Y. Ma, S. Sang, D. Xu, Y. Jin, Y. Chen, X. Xu, The contribution of superheated steam treatment of wheat flour to the cake quality. LWT 141, 110958 (2021). https://doi.org/10.1016/j.lwt.2021.110958

R.L.J. Almeida, N.C. Santos, I.L.D.S. Ferreira, M.D.S. Pedro, J.R.F. Morais, A.P. de Oliveira, R.D.A. Silva, Impact of treatment with superheated steam on the structural, thermal, and functional characteristics of quinoa starch. Starch-Stärke 75(11–12), 2300013 (2023). https://doi.org/10.1002/star.202300013

G.L. Miller, Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31(3), 426–428 (1959). https://doi.org/10.1021/ac60147a030

J. Tian, Y. Cai, W. Qin, Y. Matsushita, X. Ye, Y. Ogawa, Parboiling reduced the crystallinity and in vitro digestibility of non-waxy short grain rice. Food Chem. 257, 23–28 (2018). https://doi.org/10.1016/j.foodchem.2018.03.005

J.E. Dominguez-Ayala, M.T. Ayala-Ayala, G. Velazquez, D.G. Espinosa-Arbelaez, G. Mendez-Montealvo, Crystal structure changes of native and retrograded starches modified by high hydrostatic pressure: physical dual modification. Food Hydrocolloids 140, 108630 (2023). https://doi.org/10.1016/j.foodhyd.2023.108630

N.C. Santos, R.L.J. Almeida, E.W.V. de Andrade, M. de Medeiros, M.R. da Silva Pedrini, Effects of drying conditions and ethanol pretreatment on the techno-functional and morpho-structural properties of avocado powder produced by foam-mat drying. J. Food Measur. Charact. (2023). https://doi.org/10.1007/s11694-023-01857-0

J. Hong, X. Zeng, R. Buckow, Z. Han, M. Wang, Nanostructure, morphology and functionality of cassava starch after pulsed electric fields assisted acetylation. Food Hydrocoll. 54, 139–150 (2016). https://doi.org/10.1016/j.foodhyd.2015.09.025

Z.A. Syahariza, S. Sar, J. Hasjim, M.J. Tizzotti, R.G. Gilbert, The importance of amylose and amylopectin fine structures for starch digestibility in cooked rice grains. Food Chem. 136(2), 742–749 (2013). https://doi.org/10.1016/j.foodchem.2012.08.053

N. Singh, K.S. Sandhu, M. Kaur, Characterization of starches separated from Indian chickpea (Cicer arietinum L.) cultivars. J. Food Eng. 63(4), 441–449 (2004). https://doi.org/10.1016/j.jfoodeng.2003.09.003

N.S. Sodhi, N. Singh, Morphological, thermal and rheological properties of starches separated from rice cultivars grown in India. Food Chem. 80(1), 99–108 (2003). https://doi.org/10.1016/S0308-8146(02)00246-7

K.N. Jan, P.S. Panesar, J.C. Rana, S. Singh, Structural, thermal and rheological properties of starches isolated from Indian quinoa varieties. Int. J. Biol. Macromol. 102, 315–322 (2017). https://doi.org/10.1016/j.ijbiomac.2017.04.027

S.R. Kumar, N. Tangsrianugul, M. Suphantharika, A Review on isolation, characterization, modification, and applications of proso millet starch. Foods 12(12), 2413 (2023). https://doi.org/10.3390/foods12122413

N.M.H. Osman, B.N. Mohd-Yusof, A. Ismail, Estimating glycemic index of rice-based mixed meals by using predicted and adjusted formulae. Rice Sci. 24(5), 274–282 (2017). https://doi.org/10.1016/j.rsci.2017.06.001

S. Dadi, M.H. Cardoso, A.K. Mandal, O.L. Franco, N. Ildiz, I. Ocsoy, Natural molecule‐incorporated magnetic organic‐inorganic nanoflower: investigation of its dual fenton reaction‐dependent enzyme‐like catalytic activities with cyclic use. ChemistrySelect 8(13), e202300404 (2023). https://doi.org/10.1002/slct.202300404

P. Guo, J. Yu, S. Wang, S. Wang, L. Copeland, Effects of particle size and water content during cooking on the physicochemical properties and in vitro starch digestibility of milled durum wheat grains. Food Hydrocoll. 77, 445–453 (2018). https://doi.org/10.1016/j.foodhyd.2017.10.021

L. Wang, L. Wang, A. Wang, J. Qiu, Z. Li, Effects of superheated steam on starch structure and physicochemical properties of buckwheat flour during storage. J. Cereal Sci. 99, 103221 (2021). https://doi.org/10.1016/j.jcs.2021.103221

Y. Ma, H. Zhang, Y. Jin, D. Xu, X. Xu, Impact of superheated steam on the moisture transfer, structural characteristics and rheological properties of wheat starch. Food Hydrocoll. 122, 107089 (2021). https://doi.org/10.1016/j.foodhyd.2021.107089

Y. Ma, W. Zhang, Y. Pan, B. Ali, D. Xu, X. Xu, Physicochemical, crystalline characterization and digestibility of wheat starch under superheated steam treatment. Food Hydrocoll. 118, 106720 (2021). https://doi.org/10.1016/j.foodhyd.2021.106720

Y. Chen, Q. Yang, X. Xu, L. Qi, Z. Dong, Z. Luo, X. Peng, Structural changes of waxy and normal maize starches modified by heat moisture treatment and their relationship with starch digestibility. Carbohyd. Polym. 177, 232–240 (2017). https://doi.org/10.1016/j.carbpol.2017.08.121

X. Tan, X. Li, L. Chen, F. Xie, L. Li, J. Huang, Effect of heat-moisture treatment on multi-scale structures and physicochemical properties of breadfruit starch. Carbohyd. Polym. 161, 286–294 (2017). https://doi.org/10.1016/j.carbpol.2017.01.029

D. LeCorre, J. Bras, A. Dufresne, Influence of native starch’s properties on starch nanocrystals thermal properties. Carbohyd. Polym. 87(1), 658–666 (2012). https://doi.org/10.1016/j.carbpol.2011.08.042

L. Gao, H. Wang, C. Wan, J. Leng, P. Wang, P. Yang, J. Gao, Structural, pasting and thermal properties of common buckwheat (Fagopyrum esculentum Moench) starches affected by molecular structure. Int. J. Biol. Macromol. 156, 120–126 (2020). https://doi.org/10.1016/j.ijbiomac.2020.04.064

L. Guo, Y. Zhu, J. Li, Y. Gui, H. Tao, F. Zou, B. Cui, The effects of wheat amylose ratios on the structural and physicochemical properties of waxy rice starch using branching enzyme and glucoamylase. Food Hydrocoll. 113, 106410 (2021). https://doi.org/10.1016/j.foodhyd.2020.106410

H. Li, M.A. Fitzgerald, S. Prakash, T.M. Nicholson, R.G. Gilbert, The molecular structural features controlling stickiness in cooked rice, a major palatability determinant. Sci. Rep. 7(1), 43713 (2017). https://doi.org/10.1038/srep43713

S. Keppler, S. Bakalis, C.E. Leadley, S.S. Sahi, P.J. Fryer, Evaluation of dry heat treatment of soft wheat flour for the production of high ratio cakes. Food Res. Int. 107, 360–370 (2018). https://doi.org/10.1016/j.foodres.2018.02.041

R.L.J. Almeida, T. dos Santos Pereira, R.D. Almeida, Â.M. Santiago, W.I.M. de Lima Marsiglia, E.H. Nabeshima, R.P. de Gusmão, Rheological and technological characterization of red rice modified starch and jaboticaba peel powder mixtures. Sci. Rep. 11(1), 1–11 (2021). https://doi.org/10.1038/s41598-021-88627-4

S. Delatte, L. Doran, C. Blecker, G. De Mol, O. Roiseux, S. Gofflot, P. Malumba, Effect of pilot-scale steam treatment and endogenous alpha-amylase activity on wheat flour functional properties. J. Cereal Sci. 88, 38–46 (2019). https://doi.org/10.1016/j.jcs.2019.05.002

O.E. Dudu, L. Li, A.B. Oyedeji, S.A. Oyeyinka, Y. Ma, Structural and functional characteristics of optimised dry-heat-moisture treated cassava flour and starch. Int. J. Biol. Macromol. 133, 1219–1227 (2019). https://doi.org/10.1016/j.ijbiomac.2019.04.202

Acknowledgements

The authors would like to thank CNPq (National Council for Scientific and Technological Development) for supporting this study and for its research grant.

Author information

Authors and Affiliations

Contributions

Raphael Almeida: Formal Analysis, methodology and writing (draft and review). Newton Santos: Writing (draft and review). João Feitoza: Conceptualization. Cecília Muniz: Investigation. Raphael Eduardo: Visualization. Mércia Mélo: Validation and Visualization. Josilene Cavalvante: Data Curation. Rebeca Silva: Resources. Bárbara Oliveira: Visualization. Jessica Negreiros: Visualization. Mateus Ferreira: Validation. Sinara Fragoso: Data Curation. Gilsandro Costa: Supervision. Celene Ribeiro: Funding acquisition and Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Ethical approval

Ethics approval was not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Almeida, R.L.J., Santos, N.C., Feitoza, J.V.F. et al. Effect of superheated steam treatment on rice starch: study on in vitro digestibility and morphostructural, thermal and functional changes. Food Measure 18, 7495–7506 (2024). https://doi.org/10.1007/s11694-024-02743-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02743-z