Abstract

In this research, a Wurster fluidized bed coater, was used to double-coat Lactobacillus acidophilus to enhance resistance to simulated gastric conditions and increase heat stability during bread baking. The first layer of coating was Xanthan (0.5, 1 and 1.5% w/v) and alginate (0.5, 1 and 1.5% w/v). The microcapsules coated by 1% alginate showed the highest relative survival in simulated gastric conditions and was, therefore, selected as the first layer of the microcapsules. Chitosan (0.5, 1 and 1.5% w/v), and gellan (0.5, 1 and 1.5% w/v) were used for the second layer. Encapsulation efficiency decreased with increasing the level of both alginate and xanthan and microcapsule containing 1% xanthan had significantly higher (p < 0.05) encapsulation yield. In the case of acid resistance, 1% alginate in the wall matrix made significantly (p < 0.05) higher viability of the probiotic. 0.5% chitosan in the outer layer of the microcapsules caused probiotic more resistant to the heat treatment of 90 °C for 15 min. Probiotics population was significantly decreased in 90 °C heat treatment for 30 min. Moreover, results from SEM indicated that chitosan represented the smoother surface that is an essential factor to protect cells against environmental condition. Evaluation of encapsulated probiotic viability in bread showed that 1% chitosan in outer layer caused higher survivability on fresh bread and 24 h after baking. These finding indicated that the application of alginate and chitosan in the microcapsules can protect the L. acidophillus and it is considered as an effective method in probiotic bread production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is a growing market for foods that contain probiotic bacteria, and a wide variety of probiotic strains are now being added to an array of food products. They play an important role in promoting and maintaining human health [1]. In order, to produce health benefits, probiotic cells should be present in a viable form at a suitable level during the processing, storage period until consumption, and maintain high viability throughout the gastrointestinal tract [2]. Bakery products are an emerging category within the probiotic food segment and have attracted increasing research interest [3]. Bread is staple food in many countries, since it constitutes an important source of complex carbohydrates, proteins, minerals and vitamins for human [4].

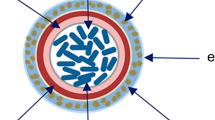

Currently, studies on the adding probiotics to bread are limited due to the adverse effects of processing, such as baking temperatures. The heat involved in baking can result in significant losses in viability during the manufacture and storage of breads. Many reports indicated that there is poor survival of probiotic bacteria in products containing free probiotic cells [5]. Providing probiotic cells with a physical barrier to resist adverse environmental conditions is therefore an approach currently receiving considerable interest. The encapsulation techniques for protection of bacterial cells have resulted in greater enhanced viability of these microorganisms in food products as well as in the gastrointestinal tract [6]. Various methods of microencapsulation for probiotics have been reported such as extrusion, emulsion and fluidized bed, spray, and freeze drying [7]. The choices of the method and materials are essential for an effective probiotic encapsulation strategy, and the use of gentle techniques, as well as the appropriate materials, such as gastro-resistant polymers, among others, are essential for efficient microencapsulation [8]. Fluid-bed micro-encapsulation is based on the use of fluidizing air to provide a uniform circulation of particles through an atomizing nozzle [9]. This nozzle is used to atomize selected coating material which solidifies in a low temperature. A proper circulation of the particles is recognized as the key to assure that all particles in the fluid-bed achieve a uniform coating. The most commonly used technique is bottom-spray (Wurster) fluid-bed process. Placement of the nozzle at the bottom of a fluid bed provides the most uniform film on small particles and minimizes agglomeration of such particles in the coating process compared with any other coating technique [9]. The term ‘‘probiotic’’ includes a large range of microorganisms, mainly bacteria but also yeasts. Because they can stay alive through the intestine and provide beneficial effects on host health, lactic acid bacteria (LAB), non-lactic acid bacteria and yeasts can be considered as probiotics. LAB is the most important probiotic known to have beneficial effects on the human gastro-intestinal (GI) tract [6, 7].

In the most of researches on microencapsulation of probiotics, bacteria are surrounded in a gel matrix made from natural compounds like alginate, gellan and carrageenan by using extrusion, emulsion and or transferring from organic solvents for encapsulation [6, 7].Main limitations of this methods are low relative survival of bacteria and inappropriate use of microcapsules for food formulations, specially, for scale up, so technologies such as spray drying, freeze drying and fluid-bed coating are used to enhance survival of encapsulated probiotics during storage. These technologies make glassy state for encapsulated matrix which are a sufficient replacement for gel matrix [6, 10].

There are many studies of microencapsulation of probiotics using fluidized bed coaters. Arabic gum, skim milk and sucrose are used for microencapsulation of Lactobacillus casei and L. acidophilus on microcrystalline cellulose (MCC) by fluidized bed coaters and determined the optimum parameters for prevention of agglomeration [11, 12]. L. reuteri with fluidized bed coater coated with shellac- sodium alginate has also been used. The survival of bacteria after acidic test at gastric simulated conditions was 0.14% [13]. In a similar study, microcapsules of Bifidobacterium were prepared by using sodium alginate and chitosan and the results showed significant increase in the survival of bacteria [14].

Fluid- bed coating method used for microencapsulation of L. paracasei; The optimum conditions of flow rate as 3.5 mL/min at 47 °C for prevention of agglomeration [15]. Survival bacteria after acidic condition increase by coating of probiotics with shellac and sweet whey protein [16].

This study aimed at developing a micro-encapsulation process for L. acidophilus by a two-step fluidized bed granulation in a Wurster coater system with a bottom spray coating technique to enhance resistance to acidic conditions and to increase heat stability during bread baking.

Materials and methods

Materials

The bacterial strain used in this study was a pure freeze-dried culture of L.acidophilus (PTCC 1643) from Persian Type Culture Collection (Tehran, Iran). These probiotic Gram-positive, rod shaped aerotolerant and heterofermentative lactic acid bacteria exhibit optimal growth at 37 °C. The inert carrier used to absorb the probiotic cells was microcrystalline cellulose (MCC) 200 m (Avicel Ph-200; FMC Bio Polymer, Brussels, Belgium). The following materials were used for coating from Sigma-Aldrich (Darmstadt, Germany): Aqueous alginate, xanthan gum, chitosan and gellan. Also, Pepsin for gastric simulation was purchased from Himedia.

Methods

Growing conditions and culture preparations

Freeze-dried L. acidophilus was added to 9 mL of MRS broth and incubated at 37 °C in anaerobic condition for 24 h. Then, the cultures were transferred into 200 mL MRS broth and incubated under the same conditions. The culture was harvested at early stationary phase, which corresponded to the fermentation time of 20 h. The culture was collected by centrifugation (Eppendorf, 5702 R, Germany) at 5000×g for 10 min at 4 °C. Harvested cells were re-suspended in 34 mL Ringer solution to a final concentration of approximately 109 CFU ml−1. Afterwards 10% (w/v) of inulin (Sigma-Aldrich, Darmstadt, Germany), was added to the cell suspension. The bacterial growth was monitored by plate counting on MRS broth incubated at 37 °C for 48 h and measuring the optical density at 600 nm (OD600) every two hours, in order to obtain the growth curve [8].

Microencapsulation

Pre-tests

According to the pre-tests, the optimal conditions for 15–20 min coating were an airflow of 300 mbar, temperature of 37 °C, and 0.25 mL/min of input solution. These parameters were constant for the microencapsulation in this study and showed high bacterial relative survival and no agglomeration.

Fluidized bed granulation

Ten gram of microcrystalline cellulose powder was sieved (350 μm) to eliminate existing agglomerates and to ensure a homogenous powder texture, before adding to the fluid bed granulator as a dry matrix. Distilled water was heated to at least 93 °C prior to addition of inulin to obtain complete dissolution. The solution was then cooled to room temperature. The probiotic cultures were dissolved in the formulation solution for at least 1 h in closed vials before being spray-coated in the air suspension process onto MCC powder. The drying temperature was 37 °C. According to the drying temperature, the spraying flow rate was adapted to 0.25 mL/min which resulted in a drying time of 15–20 min [17].

Coating

After granulation, to increase the resistance against simulated gastric acid condition and heat resistance, microcapsules were coated by button spray respectively with an aqueous sodium alginate (0.5,1 and 1.5% w/v) or xanthan gum solution (0.5,1 and 1.5% w/v) in the fluid bed granulator and chitosan or gellan [17]. Only granules containing inulin as thermo-resistant were used for coating. All parameters applied were the same as in the granulation step. Particles were coated for 15 to 20 min. The final chitosan or gellan coated beads were kept in 0.1% peptone solution at 4 °C.

Encapsulation efficiency (EE)

Encapsulated probiotics were disintegrated in phosphate buffer by using stomacher (Seward, UK), and afterward, the number of entrapped cells was calculated by the pour plate technique. Uncoated beads contain encapsulated L. acidophilus were disintegrated in sodium citrate 0.1 M for 10 min and stirred. Thereafter, samples respectively were diluted, pure plated in MRS agar, plates were incubated at 37 °C for 2 days and the encapsulated bacteria enumerated. Encapsulation efficiency was calculated by the following equation [17]:

where EY is the encapsulation efficiency, N the number of viable bacteria in CFU/g of microcapsules, and N0 the number of viable bacteria in CFU/mL of culture.

Survival under simulated gastrointestinal conditions

3.2 g pepsin was mixed with saline solution (0.5%) until its pH reached 1.2 ± 0.5 in hydrochloric acid (0.1 M). The acid solution was promoted to 1 L and sterilized at 121 °C for 15 min [17]. Afterward, 1 g of the microcapsules was submerged in 9 mL of the above acid solution (sterile conditions) and incubated at 37 °C for 2 h. Separation of cells was done in a centrifuge at 1000 rpm for 10 min, then 1 mL of the supernatant was taken. After serial dilutions, it was inoculated on MRS agar. Relative survival (%) before and after the acidic test was calculated [16, 17]. The percentage of surviving bacteria was calculated by the following equation [%]:

N2 = Number of viable cells (CFU/g) after exposure to simulated gastric juice. N1 = Number of viable cells (CFU/g) before exposure to simulated gastric juice.

Thermal stability of the microcapsules

One gram of the produced microcapsules was added to 10 mL of distilled water in sterile test tubes to study thermal stability of the microcapsules. The test tubes were exposed to 90 °C for 15 and 30 min, then rapidly cooled using chilled water and 0.5 g of the samples were mixed with 4.5 mL of phosphate buffer at a pH 7.2, which was stirred at 450 rpm after 10 min. This was followed by dilution the sample to 0.1 and inoculated on MRS agar. The colonies were incubated for two days at 37 °C and then counted [17, 18].

Scanning electron microscopy

Scanning electron microscopy (LEO 1450 VP, Germany) at an accelerating voltage of 17.13 kV was used to provide morphological information on microcapsules. All samples were fixed in stubs and coated with a fine layer of gold prior to observations [19].

Preparation of bread with encapsulated L. acidophilus

The bread dough was prepared following the procedure as described by Zhang et al. [3] having the following composition (based on % w/w of flour basis): wheat flour (100), instant baker’s yeast (1), crystalline sucrose (4), salt (1.5), non-salted butter (3) and UHT skimmed milk (65). 1 g microencapsulated probiotic was added and the ingredients were mixed for 10 min at the lowest speed using a lab scale mixer. The dough was bulk proved for 80 min at 40 °C, 85% RH, divided into individual samples of 60 g, shaped, placed in aluminum pans and proved under the same conditions for 30 min. Then, the samples were baked in a preheated oven at 180 °C for 35 min implementing a steaming step for the first 7 min of baking. The bread loaves were taken off the pans, placed on a metallic rack to cool for 30 min and then were packaged in the thermo-sealed polyethylene bags [3]. All bread samples were stored at room temperature and the percentage of surviving bacteria were calculated at 1 h and 24 h after the end of the baking process.

Statistical analysis

All the experiments were repeated three times, and the results were presented as average ± SD. Statistical analysis of the results was performed using Statistical Package for Social Sciences (SPSS) software v. 16 (SPSS Inc., Chicago, IL, USA). Data were analyzed by nonparametric one-way analysis of variance (ANOVA). When ANOVA indicated significant F values, multiple sample comparison was also performed by Duncan's multiple-range test (p ≤ 0.05) in order to detect significant differences.

Results and discussion

Growth kinetics

It is known that the stress responses of bacterial cultures vary depending on the growth phase. L.acidopillus that enter into stationary phase develop a general stress resistance and are thus more resistant to various types of stresses (including subsequent down-stream processing and storage) than bacteria in the log-phase [20, 21]. The time to reach stationary phase was 20 h (Fig. 1). This time for L.acidopillus was 14 h in the study of Kim et al., [20] and 16 h in the study of Mazzeo et al. (2016). The difference between the results may be attributed to several factors which limit bacterial growth such as the media acidity which is generated by cell growth itself, bacterial strain, the amount of oxygen and nutritional component.

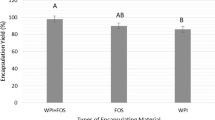

Encapsulation efficiency of carrier matrix with L. acidophilus

Encapsulation efficiency of L. acidophilus of different wall materials at different concentrations are shown in Table 1. The results indicated that both wall material and used concentrations have significant effect on encapsulation efficiency (p ≤ 0.05). Increasing the concentration of 0.5% to 1% results in both wall materials to have increased encapsulation efficiency. Increasing the concentration from 1 to 1.5% leads to a decrease in encapsulation efficiency of both wall materials (p ≤ 0.05). The encapsulation efficiency with 1% w/v xanthan was significantly highest (77.9%) and with 1.5% w/v Alginate and 0.5% Xanthan the encapsulation yields were the lowest.

Encapsulation efficiency of probiotics is necessary for considering in adding into probiotic products. The higher the efficiency, the higher the number of microorganisms in products, resulting in reducing the number of microcapsules needed to be added to the products, thereby reducing the sensory value of products with probiotic. A test on the encapsulation efficiency of L. plantarum with alginate at different concentrations (1%, 2% and 3% w/v) showed that 2% alginate concentration gave the best results [22].

Relative viability of L. acidophilus under simulated gastric conditions

Effect of different wall materials at different concentration on relative viability of L. acidophilus under simulated gastric conditions are shown in Table 1. The results indicated that both wall material and used concentrations have significant effect on relative viability of Lactobacillus acidophilus under simulated gastric conditions (p ≤ 0.05). Increasing the concentration of 0.5% to 1% results in both wall materials increased viability of bacteria. Increasing the concentration from 1 to 1.5% leads to a decrease in viability of bacteria of both wall materials (p ≤ 0.05). Xanthan and alginate at 1% concentration had the highest relative viability. The lowest relative viability has alginate at 0.5% concentration.

The results presented in this work corroborate other studies in literature that show the efficiency of microencapsulation in protecting probiotic microorganisms during exposure to gastrointestinal conditions [23,24,25,26].

Chandramouli et al. (2004) and Iyer et al. (2005) proved that only microencapsulated probiotics were able to tolerate the gastric acid condition. The results of our research were in line with Ding and Shah (2009) and Krasaekoopt et al. (2003) which stated that alginate beads improved the probiotics viability in simulated gastric condition [27, 28]. Chandramouli et al. (2004) stated that higher survivability of L. acidophilus in the presence of high acid condition acquired by Immobilization of bacteria in alginate beads. They also reported that higher concentration of sodium alginate capable of better protection of bacteria however, inordinate increasing may result to heterogeneous capsule followed by an increased viscosity [29]. An improved survivability of bifidobacterium longum encapsulated with calcium alginate in the gastric condition reported by Lee and Heo [30]. Moreover, only one logarithmic cycle reduction of immobilized L. acidophilus and B. lactis immediately and after 2 h exposure of high acid condition presented by Favaro-Trindade and Grosso (2002). They reported that the population of immobilized L. acidophilus and B. lactis at zero time and pH 1 was unaltered whereas in the same condition of pH the viability of free cells affected significantly [31]. On the contrary, Sultana et al. (2000) concluded that alginate beads will not be able to protect encapsulated probiotics in high acid condition [32].

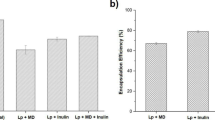

Thermal stability of double layered encapsulated L. acidophilus

Effect of wall materials at different concentration for the second layer on thermal stability of Lactobacillus acidophilus was carried out by exposing them to 90 °C for 15 and 30 min. As shown in Table 2, the encapsulated probiotics by the concentration of 0.5% of chitosan had the highest viability (24.3%) for 15 min under heat treatment. The probiotics viability decreases with increasing the chitosan concentration. Also, chitosan coated probiotics had the higher viability than the probiotics coated with the same concentration of gellan. Moreover, viability of encapsulated probiotics significantly decreased with duration of heating time. Fareez et al. (2015) reported that application of chitosan in the microencapsulation of L. plantarum LAB12 cause higher survival rate of probiotic in the lethal heat stress [33]. The dense matrices of the Chitosan coated beads probably considered the main reason [34]. In the research designed by Kim et al. (2008) and Sabikhi et al. (2010) it was found that encapsulated L. acidophilus had significantly higher heat stability than non-encapsulated ones [35, 36]. The results in this research were consistent with Ding and Shah (2007) which stated that in longer incubation, encapsulated probiotics behaved similar to non-encapsulated ones and survivability had a severe decline. Abbaszadeh et al. (2014) expressed that although chitosan improved heat stability of alginate-encapsulated L. rhamnosus however its protective effect is greater in the higher temperature than low temperature [37].

Morphological characterization of double-layered encapsulated L. acidophilus by scanning electron microscopy (SEM)

Alginate microcapsules incorporated with different level of gellan and chitosan captured under SEM are presented in Fig. 2. Morphological analysis showed that capsules could not be describe in a regular shape and size. Also, they appeared in a porous surface which attributed to the drying process followed by loss of water during the process. As same as Hadaegh et al. (2017), alginate microcapsule coated with gellan had no significant difference in the surface properties as compare with the chitosan coated microcapsule. However, the addition of chitosan made the external surface a slightly smoother with the smaller pores [38]. Fujiwara et al. (2013) had some reports about the chitosan ability of modifying shrinkage and bead permeability, making smooth the surface, improving stability and keeping the spherical shape of microcapsule [39]. Fritzen-Freire et al. (2013) stated that the Smooth surface has an important role for cells maintenance in adverse environmental conditions [40].

Relative viability of double-layered encapsulated Lactobacillus acidophilus in bread

The microbial count was determined after baking and 24 h storage to detect the microbial viability and also its stability during bread storage (Table 3). Viable microorganisms remained after the baking process in all the coatings. Therefore, those coatings could be used for obtaining viable microorganisms containing breads. However, the temperature reached during the full baking process of bread affected in different extent depending on the coatings studied. As shown in Table 3, the encapsulated probiotics by the concentration of 1% of chitosan had the highest viability in fresh and 24 h stored bread. The stability of the microorganism during short storage of the breads was investigated. The short-term storage caused a reduction in relative viability of microencapsulated L. acidophilus in all treatments. The reduction in the relative viability during the storage period was similar in all the treated breads, independently of the coating treatment. In the study by Arslan-Tontul et al. (2019) L. acidophilus encapsulated with different microcapsules, protected by heat transfer inhibition of microcapsules during the plain cake production but not protected the free cells [41]. Altamirano-Fortoul et al. (2012) indicated that although the short-term storage (24 h) caused a reduction in the total colony counts of microencapsulated L. acidophilus, the survival revealed that immobilization of probiotics may be an applied method to achieve functional breads [42]. Evaluation of encapsulated L. casei viability during 4 weeks storage of cream filled cake revealed that microencapsulation significantly influenced probiotics viability by protecting them in the microcapsule matrix [43].

Conclusion

Overall results show the positive effect of encapsulation in terms of probiotics survivability under environmental adverse condition. Encapsulated L. acidophilus in alginate (1%) microcapsule could better tolerate the simulated gastric acid condition as compared to other encapsulation materials and concentration. Moreover, incorporated chitosan (0.5%) as an outer layer improved probiotic survivability in the extreme heat treatment. Moreover, morphological analysis indicated the alginate (1%) microcapsule had the smoother external surface when integrated with chitosan as an outer layer. Therefore, microencapsulation is considered an effective protective method for maintenance of probiotics in the probiotic bread production.

References

L. Das, S. Roy, U. Raychaudhuri, R. Chakraborty, Int. J. Agric. Environ. Biotechnol. 6, 63–69 (2014)

K. Fenster, B. Freeburg, C. Hollard, C. Wong, R. Rønhave Laursen, A review of a practical approach. Microorganisms 7(3), 1–17 (2019)

L. Zhang, X.D. Chen, R.M. Boom, M.A.I. Schutyser, LWT - Food Sci. Technol. 93, 396–404 (2018)

C.M. Rosell, The Science of Doughs and Bread Quality in Flour and Breads and Their Fortification in Health and Disease Prevention (Elsevier Inc, Amsterdam, 2011), p. 3

T. Thang, L. Quyen, T. Hoang, H. Thuy, N. Luan, T. Dang, D. Lieu, Turk. J. Agric. Food Sci. Technol. 7(4), 588–592 (2019)

J. Burgain, C. Gaiani, M. Linder, J. Scher, J. Food Eng. 104(4), 467–483 (2011)

S. Misra, P. Pandey, H.N. Mishra, Trends Food Sci. Technol. 109, 340–351 (2021)

A.B. Shori, HAYATI J. Biosci. 24(1), 1–5 (2017)

C. Frey, Fluid Bed Coating-Based Microencapsulation in the Food Industry: A Practical Implementation Guide (Elsevier Inc, Amsterdam, 2014), p. 65

D. Semyonov, O. Ramon, Z. Kaplun, L. Levin-Brener, N. Gurevich, E. Shimoni, Food Res. Int. 43(1), 193–202 (2010)

E. Martins, D. Poncelet, R. Rodrigues, D. Renard, J. Microencapsul. 34(8), 1–18 (2017)

S. Saurabh, M. Garima, Int. J. Pharm. Sci. Drug. 2(4), 236–246 (2018)

S. Stummer, S. Salar-Behzadi, F. Unger, S. Oelzant, M. Penning, H. Viernstein, Food Res. Int. 43, 1312–1320 (2010)

M.T. Cook, G. Tzortzis, D. Charalampopoulos, V. Khutoryanskiy, Biomacromolecules 12, 2834–2840 (2011)

D. Semyonov, O. Ramon, A. Kovacs, L. Friedlander-Shani, E. Shimoni, Dry. Technol. 30, 1918–1930 (2012)

D. Schell, C. Beermann, Food Res. Int. 62, 308–314 (2014)

L. Zaghari, L. Basiri, S. Rahimi, Int J. Food Eng. (2020). https://doi.org/10.1515/ijfe-2019-0384

O.L. Pop, D.C. Vodnar, R. Suharoschi, E. Mudura, C. Socaciu, J. Food Process Eng. 39(5), 433–441 (2016)

R.R. Mokkarram, A. Mortazavi, M. Habbibi Najafi, F. Shahidi, M. Khorami, J. Food Sci. Technol. 7(2), 51–60 (1990). (In Persian)

W.S. Kim, L. Perl, J.H. Park, J.E. Tandianus, N.W. Dunn, LWT 43(5), 346–350 (2001)

M.F. Mazzeo, R. Lippolis, A. Sorrentino, S. Liberti, F. Fragnito, R.A. Siciliano, PLoS ONE 10(11), e0142376 (2015)

I. Trabelsi, D. Ayadi, W. Bejar, S. Bejar, H. Chouayekh, R. Ben Salah, Int J. Biol Macromol. 64, 84 (2013)

G.K. Gbassi, T. Vandamme, S. Ennahar, E. Marchioni, Int. J. Food Microbiol. 129(1), 103–105 (2009)

C.L. Gerez, G. Font de Valdez, M.L. Gigante, C.R.F. Grosso, Lett. Appl. Microbiol. 54(6), 552–556 (2012)

W. Krasaekoopt, B. Bhandari, H. Deeth, Int. Dairy J. 14, 737–743 (2004)

M. Rezaei, S.A. Mortazavi, M.B. Habibi Najafi, F. Shahidi, Food Res. Int. 42(8), 1040–1045 (2009)

W.K. Ding, N.P. Shah, J. Food Sci. 74, 100–107 (2009)

W. Krasaekoopt, B. Bhandari, H. Deeth, Int. Dairy J. 13(1), 3–13 (2003)

V. Chandramouli, K. Kailasapathy, P. Peiris, M. Jones, J. Microbiol. Methods. 56, 27–35 (2004)

K.Y. Lee, T.R. Heo, Appl. Environ. Microbiol. 66(2), 869–873 (2000)

C. Favaro-Trindade, C. Grosso, J. Microencapsul. 19, 485–494 (2002)

K. Sultana, G. Godward, N. Reynolds, R. Arumugaswamy, P. Peiris, K. Kailasapathy, Int. J. Food Microbiol. 62, 47–55 (2001)

I.M. Fareez, S.M. Lim, R.K. Mishra, K. Ramasamy, Int. J. Biol. Macromol. 72, 1419–1428 (2015)

P. Chitprasert, P. Sudsai, A. Rodklongtan, Carbohydr. Polym. 90(1), 78–86 (2012)

S. Kim, S. Cho, S. Kim, O. Song, S. Shin, D. Cha, H. Park, LWT - Food Sci. Technol. 41(3), 493–500 (2008)

L. Sabikhi, R. Babu, D. Thompkinson, S. Kapila, Food Bioprocess. Technol. 3(4), 586–593 (2010)

S. Abbaszadeh, H. Gandomi, A. Misaghi, S. Bokaei, N. Noori, J. Sci. Food Agric. 10, 2210 (2014)

H. Hadaegh, S.M. Ardabili, M. Ebrahimi, M. Chamani, R. Nezhad, J. Food Qual. 1, 1–11 (2017)

G. Fujiwara, R. Campos, C. Costa, J. Dias, O. Miguel, M. Miguel, F. Marques, S. Zanin, Braz. J. Pharm. Sci. 49(3), 537–547 (2013)

C. Fritzen-Freire, E. Prudêncio, I. Pinto, S. Muñoz, R. Amboni, LWT - Food Sci. Technol. 50, 39–44 (2013)

S. Arslan-Tontul, M. Erbas, A. Gorgulu, Probiot. Antimicrob Proteins 11(3), 840–849 (2019)

R. Altamirano-Fortoul, R. Moreno-Terrazas, A. Quezada-Gallo, C. Rosell, Food Hydrocoll. 29, 166–174 (2012)

M. Zanjani, B. Tarzi, A. Sharifan, N. Mohammadi, H. Bakhoda, M. Madanipour, Afr. J. Microbiol. Res. 6(26), 5511–5517 (2012)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mirzamani, S.S., Bassiri, A.R., Tavakolipour, H. et al. Survival of fluidized bed encapsulated Lactobacillus acidophilus under simulated gastro-intestinal conditions and heat treatment during bread baking. Food Measure 15, 5477–5484 (2021). https://doi.org/10.1007/s11694-021-01108-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-01108-0