Abstract

Microencapsulation is an optimistic method for the delivery of live microbial cells through different food products. In this study, riboflavin-producing probiotic strain Lactiplantibacillus plantarum MTCC 25,432 was encapsulated using a spray drying technique with different wall materials including Inulin, maltodextrin (MD), and MD + Inulin (1:1). The obtained spray dried powder was investigated for probiotic viability, encapsulation efficiency, particle size, water activity, moisture content, hygroscopicity, bulk and tapped densities, storage stabilities, Fourier transform infrared spectroscopy (FTIR) and thermogravimetric analysis (TGA). Besides this, the viability of the free and encapsulated probiotic cells was tested under simulated gastric and intestinal fluid conditions. In the results, microcapsules produced with the combination of MD + Inulin showed higher dry powder yield (36.5%) and viability of L. plantarum MTCC 25,432 (7.4 log CFU / g) as compared with individual coating materials. Further characterization revealed that MD + Inulin microcapsules are spherical (3.50 ± 1.61 μm in diameter) in shape with concavities, showed the highest encapsulation efficiency (82%), low water activity (0.307), moisture content (3.67%) and good survival ability at low pH (pH 2.0 and 3.0), high bile salt concentrations (1.0% and 2.0%), and long storage conditions. No differences in FTIR spectra were observed among the tested samples. However, TGA showed enhanced thermal stability of probiotic-loaded microcapsules when MD + Inulin was used together. In conclusion, MD + Inulin could be a potential encapsulation material for riboflavin-producing probiotic bacteria L. plantarum MTCC 25,432.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The term “probiotics” is used for live microorganisms that confer health benefits to the host when administered in an adequate quantity [1]. In the past few decades, many strains of Lactiplantibacillus plantarum have been isolated from various sources and documented for their probiotic potential and nutritional values [2, 3]. Besides probiotics, prebiotics such as inulin, maltodextrin, and fructo-oligosaccharide (FOS) are known to increase the probiotic’s stability and survivability in the gastrointestinal tract (GIT) [4]. Studies suggested that prebiotics are more resistant to gastric pH and digestive enzymes present in the GIT and provide fermentable sugars to the probiotic bacteria [4]. Therefore, the combination of prebiotics and probiotics termed “synbiotics” has a functional target of the intestine and the combination may improve the effect on each other [5]. Consequently, compared to prebiotics or probiotics alone, the synergistic action of synbiotics increases the viable counts of Lactobacilli and Bifidobacteria [6].

To shield probiotic cells from harmful conditions in the GI system and lessen the unfavorable effects of food-borne probiotic cells, encapsulation is necessary [7]. The most common encapsulation method in the food, chemical, cosmetic, and pharmaceutical industries is spray drying [8]. In order to perform the spray drying process, feed slurry, solution, or emulsion with a combination of one or more required product components is atomized by spraying inside a hot-air chamber, where the spraying droplets quickly evaporate and turn into dry powder at a specific temperature and pressure [9]. The main benefits of spray drying include its great adaptability, high reproducibility, quick drying, ability to adjust particle size at various diameters, and high encapsulation efficiency [10]. It is also fully automated and continuous. Additionally, the probiotic cells (depending on strains) that have been encapsulated reduce the cost of shipping and storage, making this encapsulation process extremely cost-effective [11].

Maltodextrin, starch, and inulin are some of the common carbohydrates used for probiotic encapsulation by spray drying, whereas fructo-oligosaccharides, galacto-oligosaccharides, and trans-galacto-oligosaccharides are rarely used in microencapsulation because of their sticky nature or low glass transition temperature (Tg) [12]. Maltodextrin is an admirable wall material due to some specific properties including gelation, emulsification, and film formation [13]. Maltodextrin has a low water activity, which inhibits enzyme reactions and microbiological development. Maltodextrin lacks reducing sugars, which are primarily responsible for color formation via Maillard reactions [14]. Moreover, maltodextrin is stable at high temperatures and acidic environments, thus ideal for application in food and pharmaceuticals [15]. Besides this, inulin is an oligosaccharide, which belongs to the group of fructans and is involved in the selective stimulation of bifidogenic bacteria in the GIT [16]. The wall matrix has a significant influence in determining the core and core-to-wall ratio features, in addition to the viability and stability of the probiotic throughout the spray drying and storage period. To get the desired features of microcapsules, the core-to-wall ratio must be taken into consideration [17].

Studies have demonstrated that Lactiplantibacillus plantarum MTCC 25,432 possesses potential probiotic properties [18] and the ability to produce riboflavin during the fermentation of soy and cow’s milk [19,20,21]. However, the studies on the suitability of strain to various coating matrices in spray drying remained uninvestigated. This study aims to utilize maltodextrin, inulin, and maltodextrin + Inulin (1:1) as encapsulating materials for Lactiplantibacillus plantarum MTCC 25,432. The microparticles obtained with spray drying were evaluated for bacterial viability, encapsulation efficiency, morphology, moisture levels, water activity, densities, storage stability, and survival in simulated gastric, and intestinal fluid.

Materials and methods

Bacterial Strain and Preparation of Cell Mixture with Different Wall Materials

The probiotic strain Lactiplantibacillus plantarum MTCC 25,432 used in this study was previously isolated by our group [19], and maintained at Microbial Type Culture Collection (MTCC), Chandigarh, India under safe deposit regulations. The materials required for microencapsulation i.e. inulin, and maltodextrin (MD), were obtained from HiMedia, India. A 12–14 h old L. plantarum MTCC 25,432 cells (~ 8.8 log CFU / mL) were harvested (~ 20 g, wet weight) and mixed separately with encapsulating agents [i.e. inulin (20% w/v) or MD (20% w/v) or MD + inulin (each 10% w/v; 1:1) prepared in sterile ultrapure water] to obtain a 1:1 core-to-wall ratio. All solutions were mixed to homogeneity before spray drying using an overhead stirrer (100–120 rotations per min). The glassware used in the spray drying operation was autoclaved at 121 oC for 15 min.

Spray Drying

The spray drying was performed by using a laboratory-scale spray dryer (18 SMST, India). To provide a uniform temperature throughout the operation the spry dryer was started for 20–30 min at constant inlet and outlet temperatures of 120 ± 2 oC and 65 ± 2 oC respectively. The mixture of cells and encapsulating agents prepared as described earlier was kept under magnetic agitation in a feed bottle connected to a spray drier through a peristaltic pump with a feed rate of 6 mL /min at room temperature. The airflow rate and air pressure were constantly set at 30 m3/h and 0.275 Mpa respectively. The spray-dried microcapsules collected from the bottom of the dryer chamber were kept in laminated low-density polyethylene (LDPE) film pouches. The sealed pouches were stored at 4 oC and 25 oC for further analysis.

Enumeration of Bacteria

The cell viability was determined before and after spray drying by routine serial dilution method. In brief, for the enumeration of bacteria in feed solution before spry-drying, a sample was serially diluted 9 times in 0.85% saline (HiMedia, India). One milliliter of aliquots from different dilutions was pour-plated using molten-MRS agar (HiMedia, India). The plates were incubated anaerobically at 37 oC for 48 h. After incubation, the colonies were counted and expressed as log colony-forming units (CFU).

Encapsulation Efficiency

One gram of spray-dried powder was immersed in 9 mL saline (0.85%, pH 7.0 ± 2) and vortexed for 1 min. This mixture was kept at 28 oC for 30 min to rehydrate and vortexed for another 1 min. A 1 mL sample was serially diluted in saline and bacterial viability was enumerated as described earlier. All the enumerations were done in triplicates and the number of colonies was expressed in CFU / mL or CFU / g. The encapsulation efficiency was determined as follows,

Encapsulation Efficiency = N / N0 × 100.

Where, N0: viable cells before drying; N: viable cells after drying.

Physicochemical Properties of Microencapsulated Probiotic Powder

Moisture Content

The moisture content of the sample was estimated according to the method described by Sarabandi et al. [22], with slight modifications. In brief, an empty aluminum dish was weighed (W1) and 2 g of sample was added into the dish and the weight was noted as W2. The dish was placed into a hot air oven (MAC i-therm, AI-7782) at 105 oC ± 2 oC until the constant weight was reached. The dish was closed, cooled to 28 oC, and the final weight was taken as W3. The % moisture content was calculated according to the following equation:

Where, W1: weight of empty dish; W2: weight of dish with sample (before drying); W3: weight of dish with sample (after drying).

Water Activity (aw)

The water activity of the microencapsulated powder was determined by using a water activity meter (3TE, Aqua Labs, USA) at 25.5 oC. Immediately after switching the equipment, it was allowed for 15 min to get stabilized. Then the samples were placed and aw was determined.

Hygroscopicity

The hygroscopicity of encapsulated powder was determined by weighing 1 g of powder placed into a glass petri dish. Then after, it was placed in air-tight desiccators which contain saturated NaCl solution (75% relative humidity) for a week at 25 oC. The samples were weighed and % hygroscopicity was calculated from the equation below,

Where,

MC% = moisture content of the powder.

Bulk and Tapped Density

To calculate bulk density, 20 g powder was transferred to a 100 mL graduated cylinder as described previously [22]. The volume occupied by powder was noted. Bulk density was calculated by the ratio of the mass of powder to the volume occupied by powder inside the cylinder.

To determine tapped density, the cylinder was tapped 20–25 times and the volume occupied by powder was noted. Tapped density was calculated by the ratio of the mass of powder to the tapped volume occupied by powder.

Storage Stability

To determine the storage stability of microencapsulated L. plantarum MTCC 25,432, the spray-dried powder was packed into LDPE laminated bags and stored at 4 oC and 25 oC for 7 weeks. The samples were withdrawn weekly for up to 7 weeks and bacterial viability was determined as described earlier.

SEM Analysis

The samples were sputter coated and the morphology of microcapsules was examined using scanning electron microscopy (Leo 435 VP, Leo Electronic Systems, Cambridge, UK). ImageJ software (USA) was used for the measurement of particle size.

Fourier Transform Infrared Spectroscopy (FTIR) Analysis

The FTIR spectrum was determined using an FTIR spectrometer (Cary 630, Agilent Technologies, USA) at room temperature. The sample was placed on the clean crystal and scanned after applying enough force. The spectra were recorded between 4000 − 600 /cm. The background was taken after cleaning the crystal to get accurate analysis results.

Thermogravimetric Analysis (TGA)

Thermo gravimetric curves were obtained using a DTG-60 thermo balance (Shimadzu, Kyoto, Japan). Approximately 7 mg of the sample was placed in metal pans and heated from 30 oC to 300 oC at the rate of 10 oC / min under a dynamic synthetic air atmosphere. The instrument was calibrated with a standard reference calcium oxalate.

Survival in Simulated Gastric and Intestinal Fluid

The viability of free and encapsulated L. plantarum MTCC 25,432 cells in the simulated gastric and intestinal fluid was determined as described by Rajam et al. [10] with modifications. The pH of MRS broth was adjusted to 2.0 and 3.0 using 1 M HCL and sterilized by autoclaving at 121 oC for 15 min at 15 psi. After that, a filter sterilized 0.3% (v/v) pepsin (1:3000 µ/g, Himedia, India) was added to the media with different pH values. The resulting solutions were referred to as simulated gastric fluid (SGF). In order to develop simulated intestinal fluid (SIF), 0, 1.0, and 2.0% (w/v) bile salt was suspended separately in MRS broth and pH was adjusted to 7.5 using 1 N sodium bicarbonate. The solutions were sterilized by autoclaving. One milliliter free and 1 g microencapsulated cells of L. plantarum MTCC 25,432 were suspended in 10 mL SGFs and or SIFs and incubated shaking (150 rpm) at 37 oC. The 1 mL aliquots were analyzed for viability on a plate at interval of 0, 30, 60, and 120 min for SGF tolerance and 60 and 120 min for SIF tolerance.

Statistical Analysis

The experimental outcomes were calculated as the mean with standard deviation. Microsoft Office Excel 2007 was used to perform the statistical analysis. SPSS base 19.0 was used to conduct a one-way analysis of variance (ANOVA) on the differences between groups. All experiments were conducted in triplicate, and statistically significant differences were observed at p < 0.05.

Results and Discussion

Encapsulation of L. plantarumMTCC 25,432.

The probiotic strain L. plantarum MTCC 25,432 was microencapsulated successfully using different encapsulation matrices such as inulin, maltodextrin (MD), MD + inulin (1:1). After spray drying, MD + Inulin yield 73.0 g (36.5%) dry powder from 500 mL slurry, which was higher than that of MD (66.0 g; 33%), and Inulin (63.0 g; 31.5%). The powders were off-white could be due to the biomass and or spray drying conditions. The survival of strain in encapsulated matrices decreased significantly from their initial cell count due to spray drying. In the spray drying process, the outlet temperature has a more dominant effect on the formed microcapsules than the inlet temperature. As the particles go to the bottom of the spray drying chamber, the particle temperature increases away from the wet sample on the upper side of the chamber and approaches the outlet temperature [23]. The higher outlet temperature and rapid drying affect the viability of the cells. Hence, to retain maximum viability, a lower outlet temperature (55–60 oC) has been maintained. In this study, the microcapsules produced with MD + Inulin (7.4 log CFU / g) showed higher survival of L. plantarum MTCC 25,432 as compared to microcapsules produced with MD (6.04 log CFU / g) or inulin (7.1 log CFU/g). These results revealed that MD in combination with inulin has a more positive effect on bacterial protection (Fig. 1a). According to Fritzen-Freire et al. [24], inulin act as a protective agent against thermal stress during spray drying. The L. plantarum MTCC 25,432 count estimated before spry drying was 9.01 log CFU / g (wet weight) which was reduced by around 2 log CFU / g (dry weight) after spry drying.

Overall, the L. plantarum MTCC 25,432 with MD + Inulin had high encapsulation efficiency (82%) when compared to the inulin (78%) and MD (68%) (Fig. 1b) alone. The decrease in encapsulation efficiency may be due to cellular injuries from heat, the protection ability of coating material, higher residence time, etc. [25]. These findings were corroborated well with Xu et al. [26] that microencapsulated Lactobacillus casei in pea protein isolates + inulin produced a high yield of microencapsulation efficiency (85.69%), demonstrating the inulin suitability as an encapsulation material.

Characterization of Spry Dried Powder of Microencapsulated Probiotic

Water Activity and Moisture Content

The water activity of the sample is defined as the ratio between the vapor pressure of the sample to the vapor pressure of the pure water. The physiology of microbial growth is highly dependent on water activity. In this study, the water activity (aw) of microencapsulated L. plantarum MTCC 25,432 cells with different matrices is shown in Table 1. There was no significant (p > 0.05) difference in water activity among all three samples viz., L. plantarum MTCC 25,432 + MD (0.339 ± 0.05), L. plantarum MTCC 25,432 + Inulin (0.302 ± 0.02), and L. plantarum MTCC 25,432 + MD + Inulin (0.307 ± 0.02). However, all are within range and limit (less than 0.3) as per the standard water activity recommendations for probiotic formulations. Besides this, the free water (aw) less than 0.6 inhibit almost all microbial activity.

Moisture content is the most influential factor affecting the overall product stability and probiotic viability during storage. It generally includes free-, bound- and unbound water of the product [27]. The optimal moisture content for improved storage stability is between 4 and 7%. In this study, the probiotic powder obtained with spry drying had different levels of moisture (Table 1). The powders obtained from L. plantarum MTCC 25,432 + MD + Inulin (3.67 ± 0.10%) had significantly (p < 0.01) lower levels of moisture as compared with L. plantarum MTCC 25,432 + Inulin (4.58 ± 0.22%), and L. plantarum MTCC 25,432 + MD (6.50 ± 0.23%). These results suggest that the use of a double matrix is beneficial to minimize the space between atoms and thus reduce the water-holding capacity thereof [28]. All the evaluated microparticles showed moisture content values (%) less than 7% which is directly related to the temperature utilised for spray-drying. Moreover, high temperatures have a significant negative impact on the microorganism’s capacity to survive. These findings were coordinated well with Barro and co-workers that microencapsulated Lactobacillus helveticus with different matrices (chitosan, gelatin-bloom 189, gelatin-bloom 246, gum Arabic, and maltodextrin) and noted that all samples remained below 13% moisture content [29].

Hygroscopicity

Spry-dried or freeze-dried probiotic powders are prone to absorb moisture due to their composition, this further deteriorates the quality and viability of probiotics during the storage or shelf-life. In this study, L. plantarum MTCC 25,432 encapsulated with MD + Inulin showed significantly (p < 0.001) lower levels of hygroscopicity (10.95 ± 0.04%) as compared with MD (12.57 ± 0.31%) and Inulin (11.75 ± 0.01%) (Table 1). This could maybe be due to the hydrophobicity and hydrophilicity of the encapsulation matrices [30]. Besides this, large particles render lower absorption of water molecules due to less surface area to volume ratio [30]. Arepally and co-workers confirmed similar results of hygroscopicity from 12 to 21% for the encapsulated Lactobacillus acidophilus with encapsulating matrix maltodextrin and gum arabic [31].

Bulk and Tapped Density

In this study, L. plantarum MTCC 25,432 encapsulated with MD or Inulin and or MD + Inulin showed a similar trend for both bulk and tapped density readings (Table 1). The bulk and tapped density of strain encapsulated with inulin is significantly (p 0.0001) lower as compared with MD and MD + Inulin. These results suggest that L. plantarum MTCC 25,432 encapsulated with Inulin is more free-flowing as compared with MD and MD + Inulin. Looi et al. [32] recently showed that both bulk and tapped densities were increased with increasing maltodextrin concentrations. Our results corroborated well with this finding. Moreover, studies indicated that the bulk/tapped densities are mainly affected by air inlet temperature, atomization pressure, the density of the spray drying solution, and occluded and interstitial air. Higher inlet temperature can lead to faster evaporation, resulting in smaller particle size and higher bulk density and vice-versa. Similarly, higher atomization pressure generally produces smaller droplets, which can lead to higher bulk density. Lower atomization pressures, on the other hand, can result in large droplets and lower bulk density. Moreover, the density of the spray drying solution affects the concentration of the encapsulated probiotic material. Higher solution densities can lead to higher concentrations of probiotics in the droplets, which may result in higher bulk density. Lower solution densities may lead to lower concentrations and lower bulk density [32].

Storage stability of encapsulatedLactiplantibacillus plantarumMTCC 25,432.

Since a long, the preservation of probiotic viability during storage is the subject of numerous investigations. The temperature has a significant impact on the viability of the cells during the storage time. Most of the vegetative forms of probiotics are sensitive to the temperature higher than 4 oC [20]. In order to increase the viability, probiotic bacteria were coated in protective carriers to stabilize cellular structures, which in turn minimized environmental stresses by limiting molecular movement. Arepally et al. [31] found that probiotic cells enclosed in a gum arabic and maltodextrin had a higher viability than free cells. In this study, L. plantarum MTCC 25,432 encapsulated with MD + Inulin showed significantly (p < 0.0001) higher viability as compared with MD, Inulin, and free cells, when stored at 4 oC for 7 weeks (Fig. 2a, b, c). The estimated viable count was 106 log CFU/g, which is equivalent to the WHO/FAO minimum probiotic dose criteria [33]. Moreover, the difference observed for cell viability at 4 and 25 oC was significant (p < 0.001), indicating an effect of temperature on viability.

Morphology by SEM

A 0.64 ± 0.04 μm (wide) × 1.19 ± 0.08 μm (long) round-ended cells of L. plantarum MTCC 25,432 encapsulated with MD, Inulin, and MD + Inulin showed variable size (1 to 12 μm), spherical shape particles with concavities (Fig. 3). These characteristics are typical for spray dried material due to rapid evaporation of liquid drops [34]. Besides this, no fissures or disruptions were visible along with entrapped cells. The cells with MD had the highest 32% particles of average 3.51 ± 0.34 μm diameter (Fig. 4). Moreover, cells with Inulin and MD + Inulin had the highest 48 and 40% particles of average 2.51 ± 0.27 and 2.56 ± 0.33 μm diameters (Fig. 4). These results indicated that addition of Inulin to MD reduced the particle size. Similar findings were reported by Bustamante et al. [35] that Lactobacillus encapsulated with MD and chia seed mucilage produced spherical shape assorted size (1.77–15.5 μm) particles with concavities.

FTIR and TGA Analysis

The FTIR spectra of dry powder of microencapsulated Lactiplantibacillus plantarum MTCC 25,432 with MD, Inulin, and MD + Inulin showed identical vibration peaks, suggestive of no interactions among coating materials and cells (Fig. 5a). The broad absorption band was observed around 3300 cm− 1 represents O-H stretching corresponds to carboxylic acid while the band from 3000 − 2840 cm− 1 corresponds to C-H stretch of alkane. The absorption band of 2140 − 2100 cm− 1 represents C ≡ C stretch of alkyne and the stretch from 1648 − 1638 cm− 1 indicated C = C of alkene. The band of 2000 − 1650 cm− 1 is described to C-H bend of aromatic overtones which is present in all samples. The medium stretch from 1661 − 1626 cm− 1 represents C = C of distributed alkene. The stretch from 1550 − 1500 cm− 1 corresponds to N-O stretch which may be a nitro compound and 1420 − 1330 cm− 1 for O-H bending of alcohol. Stretches from 1225 − 1200 cm− 1 and 1075 − 1020 cm− 1 correspond to C-O stretch of vinyl ether. The area between 800 and 1200 cm− 1 is called the fingerprint region for carbohydrates.

The thermo-gravimetric analysis (TGA) curves showed typical 3 steps of mass loss for powder samples prepared with L. plantarum MTCC 25,432 with MD, Inulin, and MD + Inulin (Fig. 5b). The powder sample of Lp + MD and Lp + Inulin had a first mass loss in between 30 oC to 150 oC due to dehydration. However, the sample of Lp + MD + Inulin showed a first mass loss in between 30 oC to 110 oC could be due to the less sample moisture (Fig. 5b). These results were coordinated well with a % moisture content of samples. The decomposition of all samples takes place between 230 oC to 260 oC. At 800 oC, the bacteria with MD had no residues, however, Inulin and MD + Inulin had 20 to 22% residues. Overall, the addition of Inulin with maltodextrin could have enhanced the thermo-stability of Lp + MD + Inulin particles.

Survival in Simulated Gastric and Intestinal Fluid

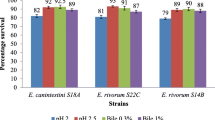

Probiotics must be able to withstand the adverse conditions of the stomach to provide beneficial effects on the host’s health. Therefore, enhancing probiotic’s ability to tolerate low pH is one of the key goals of encapsulation. In this study, L. plantarum MTCC 25,432 encapsulated with a double coating material (MD + Inulin) had significantly (p 0.0001) higher survival to pH 2.0 (6.8 log CFU) and pH 3.0 (7.1 log CFU) for 120 min of incubation as compared with free cells (2.01 log CFU and 2.2 log CFU) cells encapsulated with MD (5.1 log CFU and 5.4 log CFU) or Inulin (4.6 log CFU and 5.1 log CFU) (Fig. 6a, b). Besides this, no statistically significant viability differences were determined from 0 to 120 min of incubation in SGF of pH 2.0 and 3.0. Moreover, the survival of cells encapsulated with a single coating material (MD or Inulin) showed double viability as compared to free cells when incubated in SGF (pH 2.0 and 3.0) for 120 min (Fig. 6a,b). These results coordinated well with studies of Praepanitchai and co-workers that L. plantarum (TISTR 050) encapsulated in sodium alginate-soy protein isolate showed better survival at pH 2.0 and 3.0 as compared to free cells [36]. Overall, coating material could act as a barrier and protect cells from direct acid exposure, and prevent viability loss.

In another investigation, L. plantarum MTCC 25,432 cells encapsulated with Inulin and MD + Inulin had significantly (p 0.001) higher survival when incubated in SIF containing 1.0% (Inulin: 7.01 log CFU; MD + Inulin: 7.2 log CFU) and 2.0% (Inulin: 6.8 log CFU; MD + Inulin: 7.02 log CFU) bile salt up to 120 min as compared with free cells 2.08 log CFU, and cells encapsulated with MD 5.1 log CFU (Fig. 7). These results could be due to more resilient structure of MD + Inulin and Inulin microparticles. Besides this, the comparison of these results with others was challenging due to variations in the source and concentrations of bile salt. Moreover, encapsulated probiotic bacteria were found to be more resistant to bile salts ranging from 1.0 to 3.0% than free probiotic cells as indicated by previous studies [37] and [38].

Conclusion

Lactobacillus plantarum MTCC 25,432 was successfully encapsulated in maltodextrin (MD), Inulin, and MD + Inulin by using a spray drying technique. The microcapsules produced with MD + Inulin are spherical, 3.50 ± 1.61 μm in diameter with concavities. These particles showed the highest encapsulation efficiency (82%), low water activity (0.307), and moisture content (3.67%). The survival of L. plantarum cells was higher (7.4 log CFU / g) in MD + Inulin microparticles as compared to particles produced with MD (6.04 log CFU / g) or inulin (7.1 log CFU/g). Besides this, L. plantarum- MD + Inulin microparticles showed good survival ability than that of free cells at low pH (pH 2.0 and 3.0), high bile salt concentrations (1.0% and 2.0%), and long storage conditions. Moreover, MD + Inulin could be a potential encapsulation material for riboflavin-producing probiotic bacteria L. plantarum MTCC 25,432.

References

Hill C, Guarner F, Reid G et al (2014) Expert consensus document: the international scientific association for probiotics and prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat Rev Gastroenterol Hepatol 11:506–514. https://doi.org/10.1038/nrgastro.2014.66

Plaza-Diaz J, Ruiz-Ojeda FJ, Gil-Campos M, Gil A (2019) Mechanisms of action of Probiotics. Adv Nutr 10:S49–S66. https://doi.org/10.1093/advances/nmy063

Ahire JJ, Jakkamsetty C, Kashikar MS et al (2021) In vitro evaluation of probiotic properties of Lactobacillus plantarum UBLP40 isolated from traditional indigenous fermented food. Probiotics Antimicrob Proteins 13:1413–1424. https://doi.org/10.1007/s12602-021-09775-7

Guarino MPL, Altomare A, Emerenziani S et al (2020) Mechanisms of action of prebiotics and their effects on gastro-intestinal disorders in adults. Nutrients 12:1–24. https://doi.org/10.3390/nu12041037

De Vrese M, Schrezenmeir J (2008) Probiotics, prebiotics and synbiotics. Adv Biochem Eng Biotechnol 111:1–66. https://doi.org/10.1201/b15561-2

Hamasalim HJ (2016) Synbiotic as feed additives relating to animal health and performance. Adv Microbiol 06:288–302. https://doi.org/10.4236/aim.2016.64028

Nezamdoost-Sani N, Khaledabad MA, Amiri S, Mousavi Khaneghah A (2023) Alginate and derivatives hydrogels in encapsulation of probiotic bacteria: an updated review. Food Biosci 52:102433. https://doi.org/10.1016/j.fbio.2023.102433

Rodrigues FJ, Cedran MF, Bicas JL, Sato HH (2020) Encapsulated probiotic cells: relevant techniques, natural sources as encapsulating materials and food applications – A narrative review. Food Res Int 137. https://doi.org/10.1016/j.foodres.2020.109682

Ray S, Raychaudhuri U, Chakraborty R (2016) An overview of encapsulation of active compounds used in food products by drying technology. Food Biosci 13:76–83. https://doi.org/10.1016/j.fbio.2015.12.009

Rajam R, Anandharamakrishnan C (2015) Microencapsulation of Lactobacillus plantarum (MTCC 5422) with fructooligosaccharide as wall material by spray drying. Lwt 60:773–780. https://doi.org/10.1016/j.lwt.2014.09.062

Koh WY, Lim XX, Tan TC et al (2022) Encapsulated probiotics: potential techniques and coating materials for non-dairy food applications. Appl Sci 12. https://doi.org/10.3390/app121910005

Hadzieva J, Mladenovska K, Crcarevska MS et al (2017) Lactobacillus casei encapsulated in soy protein isolate and alginate microparticles prepared by spray drying. Food Technol Biotechnol 55:173–186. https://doi.org/10.17113/ftb.55.02.17.4991

Arepally D, Reddy RS, Goswami TK (2020) Encapsulation of Lactobacillus acidophilus NCDC 016 cells by spray drying, characterization, survival after in vitro digestion, and storage stability. Food Funct 11:8694–8706. https://doi.org/10.1039/d0fo01394c

Shams R, Singh J, Dash KK et al (2022) Effect of maltodextrin and soy protein isolate on the Physicochemical and Flow Properties of Button mushroom powder. Front Nutr 9:1–14. https://doi.org/10.3389/fnut.2022.908570

Ozcelik M, Kulozik U (2023) The role of maltodextrin concentration in maintaining storage stability of dried fruit foams texturized using plant protein–polysaccharide blends. Foods 12 https://doi.org/10.3390/foods12081673

Rodríguez-Huezo ME, Durán-Lugo R, Prado-Barragán LA et al (2007) Pre-selection of protective colloids for enhanced viability of Bifidobacterium bifidum following spray-drying and storage, and evaluation of aguamiel as thermoprotective prebiotic. Food Res Int 40:1299–1306. https://doi.org/10.1016/j.foodres.2007.09.001

Favaro-Trindade CS, de Matos Junior FE, Okuro PK et al (2021) Encapsulation of active pharmaceutical ingredients in lipid micro/nanoparticles for oral administration by spray-cooling. Pharmaceutics 13:1–14. https://doi.org/10.3390/pharmaceutics13081186

Bhushan B, Sakhare SM, Narayan KS et al (2021) Characterization of riboflavin-producing strains of Lactobacillus plantarum as potential probiotic candidate through in vitro assessment and principal component analysis. Probiotics Antimicrob Proteins 13(2):453–467. https://doi.org/10.1007/s12602-020-09696-x

Bhushan B, Kumkum CR, Kumari M et al (2020) Soymilk bio-enrichment by indigenously isolated riboflavin-producing strains of Lactobacillus plantarum. Lwt Food Sci Technol 119:108871. https://doi.org/10.1016/j.lwt.2019.108871

Narayan KS, Gaurkhede S, Sharma V et al (2021) Technological and functional assessment of riboflavin enriched probiotic soycurd. Fermentation 7. https://doi.org/10.3390/fermentation7020047

Kumar V, Amrutha R, Ahire JJ, Taneja NK (2022) Techno-functional assessment of riboflavin-enriched yogurt-based fermented milk prepared by supplementing riboflavin-producing probiotic strains of lactiplantibacillus plantarum. Probiotics Antimicrob Proteins. https://doi.org/10.1007/s12602-022-10026-6

Sarabandi K, Peighambardoust SH, Sadeghi Mahoonak AR, Samaei SP (2018) Effect of different carriers on microstructure and physical characteristics of spray dried apple juice concentrate. J Food Sci Technol 55:3098–3109. https://doi.org/10.1007/s13197-018-3235-6

Tirta GD, Martin L, Bani MD et al (2023) Spray drying encapsulation of Pediococcus acidilactici at different inlet air temperatures and wall material ratios. Foods 12. https://doi.org/10.3390/foods12010165

Fritzen-Freire CB, Prudêncio ES, Pinto SS et al (2013) Effect of microencapsulation on survival of Bifidobacterium BB-12 exposed to simulated gastrointestinal conditions and heat treatments. LWT - Food Sci Technol 50:39–44. https://doi.org/10.1016/j.lwt.2012.07.037

Bhagwat A, Bhushette P, Annapure US (2020) Spray drying studies of probiotic Enterococcus strains encapsulated with whey protein and maltodextrin. Beni-Suef Univ J Basic Appl Sci 9. https://doi.org/10.1186/s43088-020-00061-z

Xu M, Gagné-Bourque F, Dumont MJ, Jabaji S (2016) Encapsulation of Lactobacillus casei ATCC 393 cells and evaluation of their survival after freeze-drying, storage and under gastrointestinal conditions. J Food Eng 168:52–59. https://doi.org/10.1016/j.jfoodeng.2015.07.021

Rajam R, Subramanian P (2022) Encapsulation of probiotics: past, present and future. Beni-Suef Univ J Basic Appl Sci 11:46. https://doi.org/10.1186/s43088-022-00228-w

Baer DR, Engelhard MH, Johnson GE et al (2013) Surface characterization of nanomaterials and nanoparticles: important needs and challenging opportunities. J Vac Sci Technol A Vacuum Surfaces Film 31:050820. https://doi.org/10.1116/1.4818423

Barro NPR, da Silva LM, de Hassemer G S, et al (2021) Microencapsulation of probiotic Lactobacillus helveticus with different wall materials by spray drying. Biointerface Res Appl Chem 11:11221–11232. https://doi.org/10.33263/BRIAC114.1122111232

Fritzen-Freire CB, Prudêncio ES, Amboni RDMC et al (2012) Microencapsulation of bifidobacteria by spray drying in the presence of prebiotics. Food Res Int 45:306–312. https://doi.org/10.1016/j.foodres.2011.09.020

Arepally D, Reddy RS, Goswami TK (2020) Studies on survivability, storage stability of encapsulated spray dried probiotic powder. Curr Res Food Sci 3:235–242. https://doi.org/10.1016/j.crfs.2020.09.001

Looi YF, Ong SP, Julkifle A, Alias MS (2019) Effects of pretreatment and spray drying on the physicochemical properties and probiotics viability of Moringa (Moringa oleifera Lam) leaf juice powder. J Food Process Preserv 43:1–15. https://doi.org/10.1111/jfpp.13915

FAO/WHO (2002) Guidelines for the evaluation of probiotics in food. 1–11. https://www.fao.org/3/a0512e/a0512e.pdf. Assesed 19 April 2023

Saénz C, Tapia S, Chávez J, Robert P (2009) Microencapsulation by spray drying of bioactive compounds from cactus pear (Opuntia ficus-indica). Food Chem 114:616–622. https://doi.org/10.1016/j.foodchem.2008.09.095

Bustamante M, Laurie-Martínez L, Vergara D et al (2020) Effect of three polysaccharides (inulin, and mucilage from chia and flax seeds) on the survival of probiotic bacteria encapsulated by spray drying. Appl Sci 10:1–17. https://doi.org/10.3390/app10134623

Praepanitchai OA, Noomhorm A, Anal AK, Potes ME (2019) Survival and behavior of encapsulated probiotics (Lactobacillus plantarum) in calcium-alginate-soy protein isolate-based hydrogel beads in different processing conditions (pH and temperature) and in pasteurized mango juice. Biomed Res Int 2019. https://doi.org/10.1155/2019/9768152

Chandramouli V, Kailasapathy K, Peiris P, Jones M (2004) An improved method of microencapsulation and its evaluation to protect Lactobacillus spp. in simulated gastric conditions. J Microbiol Methods 56:27–35. https://doi.org/10.1016/j.mimet.2003.09.002

Kailasapathy K (2006) Survival of free and encapsulated probiotic bacteria and their effect on the sensory properties of yoghurt. Lwt Food Sci Technol 39:1221–1227. https://doi.org/10.1016/j.lwt.2005.07.013

Funding

The work was funded by the National Institute of Food Technology Entrepreneurship and Management (NIFTEM), Sonepat, India.

Author information

Authors and Affiliations

Contributions

Taneja NK and Vikram contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by Vikram, Amrutha and Sahil Nain. The first draft of the manuscript was written by Vikram. Ahire JJ edited the manuscript extensively and wrote the final draft. Taneja NK reviewed and approved the draft. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

Ahire JJ was employed by Dr. Reddy’s Laboratories Limited. Dr. Reddy’s Laboratories had no direct and indirect role in the study design/analysis/writing of this article. Other authors have no conflict of interest to declare.

Ethics Approval

This study does not contain any work related to the participation of humans and/or animals.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, V., Ahire, J.J., R., A. et al. Microencapsulation of riboflavin-producing Lactiplantibacillus Plantarum MTCC 25,432 and Evaluation of its Survival in Simulated Gastric and Intestinal Fluid. Probiotics & Antimicro. Prot. 16, 1365–1375 (2024). https://doi.org/10.1007/s12602-023-10115-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12602-023-10115-0