Abstract

Nowadays, celiac disease is known as an autoimmune disorder, the only cure for whom is consuming gluten-free foods. In this study, potato flour (Konbak variety) was used as a gluten-free resource in bread baking and texture improvement. Nevertheless, industrial challenges and strategies to facilitate formulation development still exist in terms of gluten-free bread characteristics such as texture, flavor, and extension of the products shelf life. As additives, guar gum, sodium caseinate and microbial transglutaminase enzyme at four levels (0.0, 0.5, 1.0 and 1.5) were used. Principal component analysis (PCA) was applied to evaluate type and level of additives in three bread formulations. The multivariate analysis allowed us to recognize different effect of additives from each other. The results showed that these additives increased the porosity, adhesion and elongation of the treatments and reduced the amount of a*, L* and b* dye component in the bread crust. Moreover, they reduced the specific volume, firmness of the tissue, adhesion and wrinkle of the final product. Besides that, all optimal formulation showed an acceptability quality level, indicating the potential to be used on an industrial scale.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As one of the basic sources of energy and protein in food baskets of people around the world, bread plays a key role in promoting a healthy life. In World Food Organization (FAO) report, in the Near East, nearly 70% of daily energy is supplied from bread [1]. Today, improving bread quality has vastly been studied along the cereals and its various products in order to improve individual healthy diet and well-being [2]. As a chronic disease, celiac disorder is one of the most common food allergies that the patient cannot sustain prolamin of cereal with oligopeptide sequences [3]. Wheat gliadins and glutenins, rye secalins, barley hordeins and avenins of oats proteins are major ingredients involved in celiac disorder. Basically, taking gluten protein by celiac patients causes invasive intestinal lymphoma and the stimulant response in their intestines. Meanwhile, intestinal villi become short, broad and smooth by gluten collisions. Therefore, using other flours in bakery products such as bread is of great importance [2].

Among different varieties of dicotyledonous plants, Solaman Tuberostan, known as potatoes, are from the Solanacea family and of 100 species, among which only 8 species are cultivated [4]. Its origin is from South America, mostly in Peru and Chile. Potatoes are great nutritional assets as they have invaluable nutrients such as protein (2%), carbohydrates (60–80%), minerals 1% (such as potassium, calcium, chlorine, magnesium, sodium), fibers (5%), vitamins (soluble in water B12, B6, B2, B1, C and soluble in fat A, D, E, K), enzymes, phenolic compounds and ascorbic acid. Therefore, potato flour is commonly seen in the formulation of various types of snacks, soups, sauces and baby food [5].

Research shows that since potatoes are gluten-free, they can be used in many bakery products made for celiac patients [6]. In a research conducted on potato bread, it was found that potato fibers can increase the hardness of the bread tissue and water holding capacity, and improving the texture of the baked product [2]. In another study on a mixed flour, containing sweet potato, soybean meal, corn starch and xanthan gum, it was reported that the specific volume and strength of the final product significantly decreased. In the same vein, researchers reported that adding hydrocolloids to various flours would enhance the water holding capacity in the final product and improve their physicochemical properties [7, 8]. In pastry and confectionery industries, potato flour can improve the sensory function and the shelf-life of the finished product. Likewise, potato flour would increase the stability of the dough, the water absorption rate, while the extensibility of the dough decreases [9]. In the same vein, the purpose of this study was to investigate the effect of guar gum, sodium caseinate and microbial transglutaminase enzyme on baking semi-volume bread made of potato flour (Konbak variety), as well as to examine the physicochemical properties. The evidence is the fact that Konbak variety is valuable for storage, due to its suitable properties such as high dry matter, proper specific gravity, and low reducing sugar content.

Materials and methods

Preparation of treatments

Solanum tuberosum (potato; Konbak variety) samples were obtained from the farms in Gorgan, Golestan province, Iran, and they were kept in a cool and dark place to preserve their quality. Guar gum and microbial transglutaminase enzyme (Elidt USA Modernist Pantry, USA), sodium caseinate (Alborz province, Iran), as well as yeast (Saccharomyces cerevisiae), in the form of dry active yeast powder in vacuum packed by Razavi Dough Company (Mashhad, Iran) were purchased. This research was carried out at the Research Center of Chemistry and Chemical Engineering of Iran, Tehran. First, the percentage of potato moisture was evaluated, then some potatoes were peeled off by abrasion and immersed in water at room temperature to prevent color variation. The tubers were peeled, grated by crushing machine before a hot water enzymatic treatment (90 ± 2 °C) was conducted for 3 m. Next, the rinsing operations were carried out to evaporate surface water. The samples were placed in the oven to decrease the moisture content to 5%. Then the dried samples were grinded by a homemade mixer [6]. To prepare the bread, dry ingredients including flour, yeast, transglutaminase enzyme, guar gum and sodium caseinate (at four levels of 0.0, 0.5, 1.0 and 1.5) were mixed with water. After passing 5–8 min from the formation of the dough, it was stored for 15 min at 25 °C and relative humidity of 75%. After fermentation, the dough was shaped manually with 2 cm thickness. The baking process was conducted in a deck oven (25 min, 160 °C, 75% relative humidity) to prepare the semi-volume bread. Abrasion peeling machine (manufactured by Isfahan Industrial Complex, Iran), Shredder (Myson, China), Hand gripping machine, Hot Air oven (Memmert 400ULM, Germany), Instron texture analyzer (USA), Sieve with mesh 30, Mill (Pars Khazar, Iran), Bain-marie (Memmert WB14, Germany), Spectrophotometer (Schimatso UV, Japan) Advanced Stirrer (Artisan, USA) are the equipment used in this research.

Tests

Specific volume

A 2 × 2 cm2 piece of bread was separated from its geometric center and specific volume was determined [10]. To measure the specific volume, the rapeseed displacement method was used after baking the bread.

Porosity

In order to evaluate the porosity of the processed bread, the image processing method was used and the images were taken from a 2 × 2 cm2 bread cut by a scanner (HP Scanjet G Model 3010) with a resolution of 300 pixels. Using Image software, the researchers calculated the porosity of the tissue samples.

Texture analysis

Tissue measurement was performed using a Texture Analyzer to determine the firmness and hardness of the tissue according to AACC No.10-74 at room temperature. The bread was cut from the margins and middle part into 5 × 5 cm pieces with a thickness of 25 mm. The pieces were evaluated by AACC method using a cylindrical probe with 36 mm radius at 1 mm/s and 5 g force using 5 kg load cell in 3 replications [10].

Color

In measuring the bread crust color, the a*, L* and b* values were determined with the Hanterlab apparatus in 1 h intervals. L* indicated the brightness of the treatments in the range of 0–100 (100 lighter and 0 darker), a* indicated the pure green-red color in treatments, within the range of 120 + to 120− pure green to pure red, and b* indicated the approximate color of the treatment to blue within the range 120 + to 120− from pure blue to pure yellow. After seeing the colors by Hanterlab, the treatments were imaged by the HP Scanjet G Scanner 3010 with a resolution of 300 pixels. Then, the images were calculated with the Image 7 software.

Statistical analysis

All tests were related the quality parameters of the produced bread. The factorial design was performed in completely randomized tests with three reiterations. Then, the data were analyzed by ANOVA and Duncan’s multiple range tests. Excel 2010 and SPSS were used to analyze and plot the Figures. For a better understanding of physicochemical properties of semi-volume gluten-free bread, the Principal Component Analysis (PCA) multivariate technique was performed by the SPSS software (Version 18.0; Illinois, USA). Multivariate techniques were applied to evaluate the correlation between the type and amount of additives and products properties [11, 12].

Results and discussion

Variations in specific volume of the bread

Analysis of variances (ANOVA) showed that increasing the agents’ level (1.5%) caused a significant reduction of about 10% in the specific volume of the bread. The addition of transglutaminase enzyme, guar gum, and sodium caseinate (1.5%) is responsible for high viscosity of the dough and preventing dough expansion, resulting in a significant reduction of the specific volume. The comparison of the means showed that the highest amount of volume was for the treatment of 1% (4.45 ml/g) (Fig. 1). The addition of sodium caseinate in bakery products develops calcium, protein, taste and texture properties, as well as the shelf-life of the products. The effectiveness of these compounds depends on the number of bubbles in the dough, the expansion of the air cells in the baking process and evaporation of the water in the pastry [5]. Hydrocolloids are able to strengthen the walls of gaseous cells and prevent tearing of the wall [13]. Therefore, the use of guar gum in the formulation of potato-based cereal products as a polymer composition causes swelling power. As a result, it produces the viscoelastic property such as the gluten in wheat-based dough. Such increase in the viscosity of the dough stores the gas in the dough [2]. Therefore, in gluten-free products, the final product viscoelasticity increases. Gluten-free bread is not capable of retaining carbon dioxide due to the lack of a coherent and consistent gluten-free network, resulting in low-volume and compact crumb [14]. Today, the use of the microbial transglutaminase enzyme in bread increases the quality of the product, creates a cross-linking between the lysine and glutamine amino acids and prevents the growth of gaseous cells during fermentation, which as a result decreases the specific volume of the bread. These results are supported by Moore et al. and Pourafshar et al., who stated that different levels of transglutaminase enzyme in formation of gluten-free bread protein network would increase the dosage rate significantly, so subsequently decrease the bread specific volume [15, 16]. Likewise, Renzetti et al. examined the specific volume of the bread containing brown rice and buckwheat and concluded that the microbial transglutaminase enzyme in bread would decrease its specific volume [17].

Variations in bread porosity

The results confirmed that increasing the of variables would increase the porosity of the bread, which can be related to the increasing number of gas cells and their uniform distribution in the product [14]. In this experiment, the comparison of the means showed that the highest porosity was seen in the treatment with 1.5% guar gum (35.88) (Fig. 1). The presence of microbial transglutaminase enzyme in bread formulation increased the cross-linking in the protein network, air bubble expansion and porosity. Likewise, sodium caseinate increased the final volume of the product. Therefore, it could be concluded that the presence of all three compounds and the interaction among them increased the porosity in treatments and improved bread quality [18]. These results of the study are supported by Lazaridou et al. who suggested the positive effects of adding pectin, carboxymethyl cellulose, xanthan gum, and beta-glucan in gluten-free rice or corn-based bread on increasing the porosity in the final product [19]. Similarly, Haghayegh et al. stated that the replacement of quinoa, amaranth and buckwheat flour with rice flour would increase the porosity in the treatments relative to the control treatment [20].

Variations in bread texture

The results of data analysis showed that increasing the level of agents would cause storing the gaseous cells in the starch network, which improved porosity and hardness of the tissue and increased the extensibility. Comparison of the mean showed that the highest hardness of tissues occurred in the treatment containing microbial transglutaminase 0.5% (8.83) and the highest extensibility in the treatments containing 1% sodium caseinate and 1.5% microbial transglutaminase (1.94) (Fig. 1). The hardness variation was dependent on such factors as the dough moisture, the moisture content of the product, the viscosity of the dough and its specific volume. Gums increase the viscosity of the dough due to their effect on increasing the water absorption in the product [2]. By increasing microbial transglutaminase concentration, the protein content was enriched and resulted in formation of a fine-pore protein network, which itself reduced the specific volume of the bread [15]. This event could also be attributed to the improved saving of the gaseous cells in the starch composition of the product. Since in the presence of water, amylose and amylopectin cause crystallization and polymer formation, they lead to tissue hardness in the product [21]. It was evident in this study that guar gum was effective in reducing the rate of staling and hardness of the bread containing potato power. These results of the study are supported by Hadian et al. who reported that in the gluten-free rice-based bread, containing quinoa flour in a period of 2–72 h after cooking, the hardness was gradually diminished while such phenomenon was dramatically reversed during 7 days of storage [22].

Variations in bread staling

Analysis of variances exhibited that the variables of cohesiveness and adhesiveness in this study had respective increasing and decreasing effects on bread staling rate in the treatments with concentrations of 0.5, 1 and 1.5% relative to the control treatment. The staling did not happen in the treatments as they had a higher and more favorable score in terms of peculiarity [9]. In this experiment, the comparison of the means showed that the highest cohesiveness (0.75) occurred in treatments containing sodium caseinate 1% and microbial transglutaminase enzyme 0.5%, and the lowest cohesiveness (0.40) existed in treatment containing guar gum 1.5% (Fig. 2). In the treatment with guar gum 1.5% concentration, due to its excessive moisture accumulation, bread staling occurred faster than other treatments.

As hydrocolloids compete with starch in for water absorption, they reduce water absorption in bread dough and accelerate staling. The results of tissue adhesiveness also showed that by increasing the amount of additive concentration, the final product adhesiveness rate was reduced. In the Instron texture analyzer, the control treatment was less cohesive and completely staled after baking due to the lack of proper tissue, which indicated that gums played an effective role in reducing the staling process. The presence of such compounds also helped to store more gas in the dough, increasing the consistency of the dough, strengthening the bread wall, forming a solid gelatinous network and decreasing the hardness of the breadcrumb [9]. The presence of the microbial transglutaminase enzyme in the bread formulation to network formation and protein polymers is responsible for water absorption in the bread tissue and preventing dehydration in the breadcrumb, which can slow down the bread staling process. It also increased the physicochemical and nutritional properties of the product [14]. In the storage time, the starch retrogradation is slowed down, so is the staling process [23]. Therefore, due to higher starch content and longer amylopectin side-chains than other cereals, potato powder can maintain the moisture content of the product during storage. On the other hand, in the treatment of 1.5%, of all additives, the moisture content was more preserved in the storage time, which reduced the hardness of the tissue and delayed the staling.

These results are supported by Movahed et al. who reported that adding xanthan hydrocolloid to the potato-based toast bread after 72 h in the storage period would cause the highest hardness of the tissue in the treatment with 1% xanthan gum, and 1.5% potato flour, relative to the treatment containing 0.5% xanthan gum and 0.5% potato flour, which had the lowest hardness of the tissue [24].

Variations in the bread color

Our results (Fig. 3) showed that by increasing the microbial transglutaminase enzyme concentration in formulation of the bread containing potato powder, the a* component would decrease, while by increasing sodium caseinate concentration and guar gum, the a* increased. Besides, by increasing sodium caseinate and microbial transglutaminase enzyme concentrations the L* component would increase and by increasing guar gum concentration, L* would decrease. It was also reported that b* parameter had a decreasing trend by increasing transglutaminase and sodium caseinate and growing trend as guar increased.

The comparison of means showed that the highest amount of a* was observed in sodium caseinate 0.5% and guar gum 1% (8.76), and the highest amount of L* was observed in sodium caseinate 1.5% (57.63), and the highest amount of b* was observed in guar gum 1.5% (21.81); It was observed that a* was optimal in the presence of the microbial transglutaminase enzyme which caused the appearance of dark red in the final product.

After increasing the accumulation of produced pigments and hardness of the tissues, a* value increased. By increasing the guar gum content, the b* increased, while in presence of microbial transglutaminase enzyme 1.5%, b* in the final product decreased. On the other hand, the more the guar gum content, the less transparency was reported in the treatments. The reason for decreasing L* in the presence of guar gum in bread formulation can be attributed to the high water holding capacity by this hydrocolloid, which by maintaining moisture and cooking time, usually reduces the changes in bread crust and consistency in the final product.

These findings are supported by Haghayegh et al. who studied the gluten-free rice-based bread containing pseudocereal flour reported that the buckwheat and amaranth flours would increase the color component a* and b* in the gluten-free bread crust [20]. Similarly, Purlis et al. stated that changes in the bread crust are responsible for the brightness of the products so that the event and smooth crust compared to the wrinkled crust is more capable of light reflection and an increase in the L* [25]. In addition, Shalini et al. added that the increase in carrageenan gum levels from 0.25 to 0.75% would increase the L* product, resulting in a dark color of the final product. Moreover, and increasing carrageenan gum from 0.1 to 0.5, would reduce L*. They acknowledged that increasing the L* by gums would cause a slight increase in bread color [26].

The influence of variable levels in semi-volume bread on the responses showed that the porosity, adhesion as well as elongation of products was more influenced by the guar gum content (Fig. 4). These surface plots showed that the changes of properties of semi-volume gluten-free bread have a nonlinear behavior based on the relationships between the guar gum content and porosity, adhesion. Application of these three agents at adequate levels can promote the holding water,increasing number of gas cells, interfacial activity and their uniform distribution in the dough system during the dough-making process.The decrease in the bread volume at high concentrations of these agents may be due to the high viscosity of the dough, which reduce dough expansion during fermentation and baking. Generally, the experimental results demonstrated that adding guar gum, transglutaminase and sodium caseinate to semi-volume bread formulation can enhance its quality.

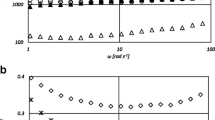

Principal component analysis (PCA)

Principal component analysis is a dimensionality-reduction statistical scheme, which cans classification original variables to explain the variance-covariance structure of the data [27, 28]. The data of porosity, adhesion, elongation, specific volume, firmness of the tissue and wrinkle mean values obtained from the semi-volume bread were evaluated using principal components analysis. In the treatment containing guar gum, the first two principal components explained 69.9% and 23.6% of the total variability and thus, were adequate to extract of classification accuracy. The contribution of variables to the outcome quality of products is shown in Fig. 5. Texture Springiness and gum levels were the closest, indicating that these variables had similar behavior. The L* color, indicator b*, texture, porosity percentage, texture continuity and gum levels had a high positive correlation with PC1, but they had a significant and negative correlation with specific volume and tissue adhesion.

In the treatment containing microbial transglutaminase, the first, second and third components compute 46.1%, 36.3% and 17.5% of the total variability. The contribution of each of the parameters in three factors and distribution of outcome quality of products in Biplot is shown in Fig. 5. Porosity percentage and transglutaminase levels were the closest, indicating that these variables had similar behavior. The L* color, texture springiness, porosity percentage, texture continuity, transglutaminase level had a high positive correlation with PC1.

The results showed that the L* color, specific volume and texture continuity had a positive correlation with PC2, while had negative correlation with porosity percentage and transglutaminase level.

In the treatment containing sodium caseinate, the first, second and third components compute 53.9%, 26.3% and 19.6% of the total variability. The contribution of each parameters in three factors and distribution of outcome quality of products in Biplot is shown in Fig. 5. L* color and sodium caseinate levels were the closest, indicating that these variables had similar behavior. Porosity percentage and transglutaminase levels were the closest, indicating that their treatments had similar properties. The texture, texture springiness, porosity percentage, texture continuity, sodium caseinate level and L* color had a high positive correlation with PC1. The results showed that the porosity percentage and a* color had a positive correlation with PC2, while had a negative correlation with specific volume and tissue adhesion.

Conclusions

In this study, the effect of addition of guar gum, transglutaminase and sodium caseinate on semi-bulk bread from potato flour was investigated. The results of porosity and physicochemical properties showed that the best texture was observed in the treatment containing 1% additives. It was also observed that the addition of microbial transglutaminase enzyme, sodium caseinate and guar gum in the semi-bulk bread containing potato flour increased the resistance of the dough and created gluten network and improved dough texture. It should be noted that the addition of microbial transglutaminase enzyme at 1% level improved the texture of breadcrumbs and delayed the staling process of the bread in the final product. The multivariate analysis showed the gum levels were highly negatively correlated with specific volume and tissue adhesion, and positively correlated with texture springiness, texture continuity and b* color. Furthermore, transglutaminase levels were highly negatively correlated with L* color and specific volume and positively correlated with porosity percentage. The results of colorimetric of the final product also showed that by increasing the concentration of additives, all color components of the final product were reduced. Above all, and based on the results of physicochemical and colorimetric tests, the addition of 1% guar gum, transglutaminase and sodium caseinate to the semi-bulk bread formulation of potato flour is recommended to achieve the desired characteristics.

References

Agriculture Organisation (FAO). The state of food security and nutrition in the world 2017. Building resilience for peace and food. Cairo (2018)

D. Bender, R. Schönlechner, J. Cereal Sci. 91, 102904 (2020)

M. Schumann, et al, Cell. Mol. Gastroenterol. Hepatol. 3, 150 (2017)

I. Rasul, F. Zafar, M.A. Ali, H. Nadeem, M.H. Siddique, M. Shahid, U.A. Ashfaq, F. Azeem, Int. J. Agric. Biol. 22, 178 (2019)

P. Fradinho, A. Oliveira, H. Domínguez, M. Torres, I. Sousa, A. Raymundo, Innov. Food Sci. Emerg. Technol 63, 102374 (2020)

M. Moradi, M. Bolandi, M. Karimi, F. Nahidi, H. Baghaei, J. Food Meas. Charact. 14, 2282 (2020)

F. Salehi, Food Sci. Nutr. 7, 3391 (2019)

A. Abdolshahi, F. Tabatabaei Yazdi, A. Shabani, S. Mortazavi, Int. Food Res. J. 26, 1803 (2019)

J. Xu, Y. Zhang, W. Wang, Y. Li, Trends Food Sci. Technol. 103, 200 (2020)

AACC, Approved methods of the American Association of Cereal Chemists (American Association of Cereal Chemists, Incorporated, St Paul, Minnesota, 2000)

A. Heydarieh, M. Arabameri, A. Ebrahimi, A. Ashabi, L. Monjazeb Marvdashti, B. Shokrollahi, Yancheshmeh, A. Abdolshahi, J. Chem. Health Risks 10, 93 (2020). https://doi.org/10.22034/jchr.2020.1883343.1067

N. Shariatifar, M. Rezaei, M.A. Sani, M. Alimohammadi, M. Arabameri, Biol. Trace Element Res. 198, 721 (2020). https://doi.org/10.1007/s12011-020-02110-1

A. Abdolshahi, M. Abdollahi, L. Monjazeb Marvdashti, B. Salehi, F. Maggi, j. Sharifi-Rad, J. Chem. Health Risks 10, 261 (2020). https://doi.org/10.22034/jchr.2020.1890915.1091

H. Yano, NPJ Sci. Food 3, 1 (2019)

M.M. Moore, M. Heinbockel, P. Dockery, H. Ulmer, E.K. Arendt, Cereal Chem. 83, 28 (2006)

S. Pourafshar, K.A. Rosentrater, P.G. Krishnan, J. Food Sci. Technol. 52, 5691 (2015)

S. Renzetti, F. Dal, Bello, E.K. Arendt, J. Cereal Sci. 48, 33 (2008)

S.A. Mir, M.A. Shah, H.R. Naik, I.A. Zargar, Trends Food Sci. Technol. 51, 49 (2016)

A. Lazaridou, D. Duta, M. Papageorgiou, N. Belc, C.G. Biliaderis, J. Food Eng. 79, 1033 (2007)

G. Haghayegh, S.S. Ataye, Iranian j. Food Sci. Technol. 14, 47 (2017)

A. Guarda, C. Rosell, C. Benedito, M. Galotto, Food Hydrocolloids. 18, 241 (2004)

M. Hadian, M. Ghiafeh Davoodi, Food Sci. Technol. 14, 95 (2017)

I. Mandala, K. Sotirakoglou, Food Hydrocoll. 19, 709 (2005)

S. Movahed, G.K. Mohseni, Int. J. Bio-Inorg. Hybd. Nanomat. 3, 43 (2014)

E. Purlis, V.O. Salvadori, Food Res. Int. 42, 865 (2009)

K.G. Shalini, A. Laxmi, Food Hydrocoll. 21, 110 (2007)

G. Ghelichkhani, M.H. Modaresi, L. Rashidi, N. Shariatifar, M. Homapour, M. Arabameri, J. Food Meas. Charact. 13, 2751 (2019). https://doi.org/10.1007/s11694-019-00196-3

M. Arabameri, R.R. Nazari, A. Abdolshahi, M. Abdollahzadeh, S. Mirzamohammadi, N. Shariatifar, F.J. Barba, A. Mousavi Khaneghah, J. Sci. Food Agric. 99, 5358 (2019). https://doi.org/10.1002/jsfa.9777

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moradi, M., Bolandi, M., Arabameri, M. et al. Semi‐volume gluten‐free bread: effect of guar gum, sodium caseinate and transglutaminase enzyme on the quality parameters. Food Measure 15, 2344–2351 (2021). https://doi.org/10.1007/s11694-021-00823-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-00823-y