Abstract

The study aimed to evaluate the effects of selected protein isolates and concentrates on quality and staling of gluten-free bread, in the absence of other structure-forming agents such as guar gum and pectin. The applied preparations included albumin, collagen, pea, lupine and soy. Their addition had various effects on rheological properties of the dough and volume of the bread. Volumes of the loaves baked with soy and pea protein were smaller, while those with albumin significantly larger than control. Presence of non-gluten protein caused changes in crumb structure (higher porosity, decrease in cell density, higher number of pores with a diameter above 5 mm) and its color, which was usually darker than of unsupplemented starch-based bread. The least consumer’s acceptance was found for bread baked with soy protein. The presence of pea and lupine preparations improved sensory parameters of the final product, providing more acceptable color and smell in comparison to control, while soy caused a decrease of all analyzed consumer’s scores. The addition of protein caused an increase in bread hardness and in enthalpy of retrograded amylopectin, during bread storage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Commercial mixes for gluten-free dough contain mostly carbohydrates, which have a negative influence on the quantity of protein present in the diet of celiacs, because bakery products are an important source of amino – acids in a diet of healthy people (Matos Segura and Rosell 2011). The lack of gluten protein in this type of food has negative consequences on bread structure, as gluten normally provides a viscoelastic matrix in traditional products. Its absence decreases gas retaining properties of the dough and has negative impact on crumb texture. Therefore sensory properties of gluten-free bread are usually worse in comparison to wheat based products, and staling is usually much faster (Matos and Rosell 2015). Gluten-free bread in general has also unsatisfactory nutritional value, which is why the number of studies on its fortification with proteins, fibre and/or bioactive compounds, mineral salts and so on have dramatically increased in recent years (Capriles and Arêas 2014; Diowksz et al. 2009; Korus et al. 2009; Krupa-Kozak et al. 2014; Martínez et al. 2014; Ronda et al. 2014; Tsatsaragkou et al. 2014). The key objective in gluten-free bread production is to imitate gluten viscoelastic matrix, responsible for product’s structure by proper composition of the recipe. To this end various hydrocolloids could be used, most of them of polysaccharide and protein origin. In order to improve texture and sensory properties other processing aids are added, including emulsifiers, stabilizers and enzymes acting on proteins (transglutaminase) or starch (amylases) (Capriles and Arêas 2014).

Addition of non gluten proteins in the production of gluten-free bread is especially interesting, as those substances have both nutritional and technological role. Their addition reduces amino acid deficits, and impact structure and texture forming properties of the dough, as well as the color and sensory properties of the final product, in this way affecting its consumer acceptance. Their presence may influence storage of gluten-free products, and decrease bread staling. Protein could be added in various forms, as components of gluten-free flours (e.g., rice, soy, pea) or in the form of concentrates and isolates (Deora et al. 2015). The formation of dough and bread structure by protein addition is often assisted by the introduction of other supplements such as polysaccharide hydrocolloids, enzymes or surfactants. Among cereal proteins zein and kaffirin have been applied for gluten-free bread supplementation (Deora et al. 2015; Pontieri et al. 2013; Schober et al. 2011). Andersson et al. (2011) observed that the addition of corn protein in the presence of hydrocolloids positively influences dough rheology, improves bread structure and increase its volume. Also Schober et al. (2010) registered a positive influence of zein on viscoelastic properties of the dough, if it was mixed at 40 °C, resulting in better gas retention and increased bread volume. Another important source of amino-acids in gluten-free products are diary proteins, which positively influence nutritional value and quality of gluten-free bread. They are a good source of calcium and essential amino acids, such as lysine, methionine and tryptophan (Krupa-Kozak et al. 2013). The addition of diary proteins strengthens structure, improves texture and color of bakery products and slows down its ageing. Caseins are most frequently applied, as they have emulsifying properties and stabilize other components of gluten-free dough. Other preparations include isolates and concentrates of whey proteins with an ability to form gel-like structures and skim milk powder, characterized by a high water binding capacity (Deora et al. 2015). An innovative idea to use meso-structured whey protein particles in the production of gluten-free bread was suggested by van Riemsdijk et al. (2011). The application of whey proteins is however restricted by a fact, that celiac disease might be accompanied by lactose intolerance, and that dairy proteins themselves could be allergens.

Egg proteins could also be used as a functional ingredient in gluten-free bread, in particular albumin could be added (Deora et al. 2015). High functionality of this ingredient is related to its foam stabilizing properties, which are important for gas retention, and structure stabilization of the crumb (Schoenlechner et al. 2010; Tsatsaragkou et al. 2014).

Another group of proteins applicable in gluten-free products is derived from legume seeds. They are nutritionally valuable, due to high lysine content, which is a limiting amino acid in cereal products (Marco and Rosell 2008b). Isolates and concentrates of these proteins are produced in high quantities, especially from soy and pea. Marco and Rosell (2008a) observed that the presence of legume proteins causes an increase in water absorption and modifies mechanical properties of the final product. In other studies an increase of specific volume and improvement of sensory quality were observed after an addition of pea protein, which was also accompanied by a decreased retrogradation (Miñarro et al. 2012). Matos et al. (2014) stated, that the addition of pea protein to gluten-free muffins makes them softer and more elastic. In these group of protein preparation a special attention should be paid to carob germ proteins. As it was demonstrated by Smith et al. (2012) they improve viscoelastic properties of the dough and allow obtaining gluten-free bread with a high quality. Other proteins tested in the production of gluten-free include collagen and lupine proteins (Ziobro et al. 2013).

In our earlier studies proteins of various origin were used as an ingredient improving nutritional value and structure of gluten-free bread based on starch and non-starch hydrocolloids (pectin and guar gum). A varying influence was observed for different preparations both for rheological properties of the dough, and for final bread quality. It was observed that lupine proteins and albumin resulted in an increase of the loaves, while pea proteins positively influence their sensory parameters. Protein preparations also significantly retarded bread staling (Ziobro et al. 2013). However the use of hydrocolloids such as guar gum, which have a status of allowed additives is not fully acceptable by the consumers (Rinaldi et al. 2014). Therefore it seems reasonable to eliminate such substances, and in this way obtain a “clean label” products, additionally enriched in protein. Protein preparations are classified as food constituents, and are not regarded as “chemical” or “artificial”, therefore they could be used instead of such hydrocolloids without a negative influence on consumer’s acceptance. The aim of this study was to check their influence on structure and properties of gluten-free dough based on starch, in the absence of other structure-forming agents such as guar gum and pectin.

Materials and methods

Materials

The material for dough and bread making consisted of corn starch, (Bezgluten, Poland), potato starch (Pepees S.A., Poland), guar gum (Lotus Gums & Chemicals, India), pectin (Pektowin, Poland), freeze dried yeast Saf-instant (S.I. Lesaffre, France). Sucrose, salt, and plant oil were obtained from local supermarkets. In addition the following high protein ingredients were used: albumin contained 82–86 % protein in d.b. according to producer’s declaration (Ovovita, Poland), Fralu-Con lupine protein – 59 % protein in d.b. (L.I. Frank, Netherlands), Arcon S IP DNGM soy protein concentrate – 72 % protein mfb (ADM Co., USA), Hewipro HP95 collagen – 90 % protein in d.b. (Brentag, Poland) and pea protein isolate Nutralys F85M – 85 % protein in d.b. (Roquette, France).

Methods

Rheological properties of dough

Dough preparation was done following the method described earlier (Korus et al. 2009). A detailed gluten free dough formulation used for control sample was as follows: corn starch (830 g), potato starch (207 g), pectin (17.2 g), guar gum (17.2 g), yeast (52 g), sugar (20.7 g), salt (17.2 g), oil (31 g) water (1072 g). Other samples were obtained by adding 10 % of protein (per total starch, i.e., 103.7 g), with parallel removal of pectin and guar gum (3.3 % of total starch) and 6.7 % of both starches, i.e., 55.5 g of original corn and 13.8 g of potato starch, so that the amount of dry substances would be the same as in control sample.

Preliminary rheological analyses indicated a strong influence of applied protein preparations on dough properties. Thus it seemed necessary to adjust the level of water used in baking experiments, to obtain the dough suitable for bread baking. To this end consistency of the control sample (which was found to be appropriate for baking in our previous studies) was checked on Brabender Farinograph E (Brabender, Duisburg, Germany), and water absorption of other dough mixes was determined taking into account the established value (i.e., 100 farinograph units).

Water addition to individual dough mixes ranged between 688 g per sample in the case of albumin and 1312 g in the case of collagen. Intermediate values were obtained from formulations with lupine (832 g), pea (944 g) and soy (1112 g).

In order to check the effect of protein addition on rheological properties of the dough, all dry samples (deprived of yeast) were mixed with the same amounts of water using mechanical stirrer RW20 (IKA-Werke, Staufen, Germany) until a uniform mass was obtained. Viscoelastic properties of the dough were measured at 25 °C with the use of rheometer MARS II (Thermo-Haake, Karlsruhe, Germany) equipped with a system of parallel plates (diameter 35 mm, gap 2 mm). Dough samples obtained as described above, were put between the plates and left for 15 min in order to obtain relaxation and stabilize temperature. Mechanical spectra were measured in the range of linear viscoelasticity, at constant strain amplitude (γ = 0.05 %) in the range of angular frequency 1–100 rad s−1 (Juszczak et al. 2012).

Bread making

After mixing for 8 min (Laboratory Spiral Mixer SP 12, Diosna, Osnabrück, Germany) the dough was fermented for 15 min (35 °C, 80 % moisture), re-mixed for 1 min and divided into 250 g pieces in greased metal pans. Final fermentation (35 °C, 80 % moisture) was performed for 20 min. Baking was done in an electric oven MIWE Condo type CO 2 0608 (MIWE GmbH, Arnstein, Germany) for 30 min at 230 °C. Seven loaves were baked in a single batch. Two independent batches were analysed. The loaves were removed from pans, and cooled at ambient temperature.

Bread analyses

Bread volume was measured using volume meter Volscan profiler 600 (Stable Micro Systems, Surrey, England).

Image analysis were performed for slices from the internal part of each loaf (thickness – 1 cm) were scanned by Plustek S-12 desktop scanner (Plustek, Taipei, Taiwan). The registered images were analysed with the help of ImageJ software v. 1.44c (NIH, Bethesda, USA), evaluating porosity, cell density and percentage of pores > 5 mm (Abramoff et al. 2004).

Analysis of crumb color in CIE L*a*b* system was performed by reflectance method using Color i5 spectrometer (X-Rite, Grand Rapids, USA) set for the following parameters: measuring geometry d/8, illuminant D65, observer 10°, slit width 25 mm.

Sensory analysis of bread was performed by the sensory panel consisting of 14 assessors with established sensory sensitivity (trained according to PN-ISO 8586–1:1996 PKN 1996). The methods of sensory evaluation was based on the acceptance analysis of encoded bread samples on the seven-point scale, where 1 means “extremely dislike” and 7 – “extremely like”. The analysis included the following quality attributes: overall appearance, structure and porosity, color, smell and taste.

Texture profile analysis (TPA) of bread crumb of one loaf from each batch was performed, using texture analyzer TA-XT2plus (Stable Micro Systems, Surrey, England), according to standard program, at the compression rate 5 mm s−1 (loaves used for analysis in the following days were stored in plastic bags at 22 ± 2 °C). Sample of bread crumb, taken from the centre of the loaf with a height 2 cm was pressed to reach 50 % deformation by a P/20 aluminium cylinder probe with a diameter 2 cm, in two cycles with a 5 s delay. The resulting hardness, springiness, cohesiveness and chewiness of the crumb were used as indicators of textural changes during storage. The calculations were performed using the attached software Texture Exponent (Stable Micro Systems, Surrey, England). The analysis were performed after 2, 24 and 48 h after baking.

Thermal properties of gluten-free bread crumb were characterised by means of differential scanning calorimeter DSC 204 F1 Phoenix (Netzsch-Gerätebau, Selb, Germany). The calorimeter was calibrated by Indium standard. Loaves after baking were cooled for 2 h at ambient temperature. After this time samples were taken for DSC analyses and the rest of loaves was packed in polyethylene bags and stored at 22 ± 2 °C for further analyses (after 24 and 48 h). Dry mass of the crumb was estimated in parallel. Crumb samples (approx 15 mg) in the following days of analyses were closed hermetically in aluminium pans and heated in the calorimeter from 25 to 100 °C at a rate of 10 °C min−1. Empty aluminium pan was used as reference. Temperatures and enthalpy of thermal transitions were determined with the use of instrument’s software Proteus Analysis (Netzsch-Gerätebau, Selb, Germany). Enthalpy values were expressed as g d.b.

Statistical analysis

In order to establish the statistical differences between means, the data were treated by one-factor analysis of variance, and the least significant difference (LSD) at significance level 0.05 was calculated using Fisher post hoc test. Two way analysis of variance was performed in order to establish the influence of protein component and storage time. Hierarchical cluster analysis was done in order to exhibit the similarities and differences between analysed samples. The calculations were performed using statistical software package Statistica 9.1 (StatSoft Inc., Tulsa, USA).

Results and discussion

Rheological properties of dough

Dough for gluten-free bakery products is usually based on starches and flours, which in the absence of viscoelastic gluten form a structure with a limited ability to retain air and gases produced during fermentation. In the effect the crumb of final products has compact structure, with poorly expanded cells, and the resulting bread has low volume and unacceptable texture properties (Capriles and Arêas 2014). To avoid this problem various strategies could be used together, which involve technological innovations and the use of appropriate ingredients and/or additives as well as processing aids. The analysis of dough rheology, especially its viscoelastic parameters, allows checking the influence of dough composition and preparation method on its structure. Gluten free dough exhibits non-linear viscoelasticity, however in the range of small deformations its properties could be described by a combination of viscous and elastic properties (Witczak et al. 2012). According to Hüttner et al. (2010) low viscosity of the dough positively influences quality of the final product, because it improves gas cell expansion during proofing, and in this way positively affects volume and allows to obtain well-aerated crumb. Nevertheless too low viscosity could lead to structure weakening, and thus decrease gas retention, negatively influencing bread quality. It is therefore difficult to predict the exact influence of rheological properties on product characteristics, and the optimum dough formulation should combine relatively low viscosity with the ability to form sufficiently strong and rigid structure, which would hold enough gas during proofing and provide crumb with appropriate structure and texture. Mechanical spectra of control dough and selected samples with added protein preparations are shown in Fig 1a. All analysed systems, under the applied conditions, exhibited the prevalence of elastic properties over viscous (storage modulus G’ > loss modulus G”). The replacement of structure forming hydrocolloids and part of the starch in formulation with protein significantly modified viscoelastic properties of the dough in a way depending on preparation type. The presence of soy protein had no significant influence on the values of G”, but caused a visible increase of G’ in comparison to control. Slight changes in the values of G” and significant in G’ signify strengthening of elastic structure of the dough, despite of its comparable ability to dissipate energy. An increase in storage modulus, accompanied with decreasing phase shift tangent (tan δ = G” / G’) mentioned above, was earlier observed by Crockett et al. (2011) in doughs containing soy protein isolate. The changes in rheological properties of gluten-free dough, corresponding to the application of soy protein were also reported by Marco and Rosell (2008a), who observed the increase of the development time and time necessary for hydrating the compounds. The presence of pea protein caused a significant rise of both moduli. The most pronounced drop in their values was observed for dough with lupine protein (Fig. 1a). It confirms earlier observations, that the addition of lupine protein to the dough weakens its structure and deteriorates viscoelastic properties, which results in impaired quality of the product (Kohajdová et al. 2011). Significant influence of protein addition on viscoelastic properties of the dough could be observed in the values of phase shift tangent (tan δ = G” / G’) represented on Fig. 1b. All analyzed samples behaved as weak gels (0.1 < tan δ < 1) which is in agreement with earlier observations of viscoelastic properties of gluten free dough (Pruska-Kędzior et al. 2008; Witczak et al. 2012). The addition of protein preparations caused a significant decrease of tan δ which corresponds to strengthening of dough structure in comparison to control. The smallest decrease of tan δ was observed for the dough with albumin. Although albumin had the smallest impact on the ratio between viscous and elastic properties of the dough, its ability to form foams and retain gases results in a significant improvement of bread volume (Schoenlechner et al. 2010; Storck et al. 2013; Ziobro et al. 2013). The lowest values of tan δ were found for the dough in which structure-forming hydrocolloids were replaced with collagen, which confirms our earlier observations about the role of specific structure of such protein in regulating properties of starch based systems (Ziobro et al. 2013). All other dough samples with protein preparations exhibited similar values of tan δ, which was significantly lower in comparison to control and dough with albumin. Only the presence of lupine protein resulted in an increase of tan δ at higher values of angular frequency, which indicates that the dough with lupine protein has weaker structure and deforms faster, directly after stress is applied. Various components have different influence on dough characteristics. The largest share of viscous properties could be observed for control and albumin samples. On the other hand, the dough with collagen is more elastic than all others in the whole analyzed range. A sharp decrease of tan δ accompanying the initial increase of angular frequency indicates rapid gaining of elastic properties, exhibited by much faster change of G’ (storage modulus) than G” (loss modulus). The most pronounced effect (largest change per cent) could be observed for the sample with alubmin. At higher values of angular frequency the values of tan δ cease to change, and finally rise, but to a very limited extent.

Mechanical spectra (top -(white diamond) Control, (white triangle) Lupine, (white square) Pea, (white circle) Soy; G’ – filled markers; G” – empty markers) and tangent of phase shift (bottom -(white triangle) Control, (asterisks) Albumin, (plus sign) Collagen, (white triangle) Lupine, (white square) Pea, (white circle) Soy) of control dough and samples structured with different proteins

Gluten-free bread characteristic

Volume and structure of the crumb

Ability of crumb structure to hold gas produced during fermentation has significant impact on bread volume. In the case of wheat dough it is mainly controlled by proteins, which form gluten network. The role of proteins in gluten-free dough is also important, as they can hold water and stabilize starch gel formed during gelatinization. Structure forming ability of proteins is related to their swelling and emulsifying properties. All applied preparations except lupine protein had significant influence on loaf volume (Table 1). Its increase observed in the case of albumin, could be explained by its foaming properties (ability to decrease surface tension, resulting in an increased stability of multiphase systems), which increase gas retention, as it was reported earlier (Schoenlechner et al. 2010; Storck et al. 2013; Ziobro et al. 2013). Egg albumins reveal relatively small molar masses, and high potential to absorb carbon dioxide (due to the presence of high amounts of mostly acidic amino acids and free sulphydryl groups, which promote foaming, heat setting and adhesion), which is decisive for its binding in bread crumb (Crockett et al. 2011; Mine 1995; Ziobro et al. 2013). Another important factor, which has a positive influence on loaf volume, is low denaturation temperature of albumin, which is responsible for structure formation and stabilization during baking. The presence of other protein preparations, especially soy and pea proteins, caused a decrease in bread volume (Table 1). Negative influence of soy protein on volume of gluten-free bread was earlier observed by Marco and Rosell (2008a). Similar observations were reported by Ribotta et al. (2004), together with crumb faults, and excessively compact structure. On the other hand a positive influence of pea protein on crumb structure was reported by Miñarro et al. (2012).

Table 1 represents other parameters characterizing crumb structure, obtained using digital image analysis (see also Online Resource 1). The lowest porosity was found for control bread. The application of albumin had insignificant influence on this parameter, while the addition of other types of protein preparations had a positive impact on its value, especially when collagen was used. Similar trend could also be observed for a number of large pores (with a diameter above 5 mm), and the opposite relation was noticed for cell density, which decreased in comparison to control. Except albumin, all applied protein preparations, had significant influence on these parameters. The most pronounced decrease in cell density could be found for bread with collagen, which also contained the highest percentage of large pores. The observed changes in porosity reflect differences in physico-chemical properties of analyzed proteins (structure, solubility, hydration etc.), which lead to modified gas retention capacity.

Color and sensory attributes

The application of protein preparations in bread baking had a significant influence on bread lightness (L* parameter) (Table 2). The presence of albumin increased the value, while other preparations caused its decrease. Bread with soy and collagen were darker than the standard but not statistically different from each other. The results are in agreement with our earlier report (Ziobro et al. 2013). Gluten free bread, especially based on starch, is usually light in appearance, often regarded by the consumers as highly purified, with decreased levels of fibre and minerals. Therefore the additions which reduce the lightness seem to be beneficial from marketing point of view. The value of a* characterizes balance between green (negative) and red (positive). Control sample, and the product with albumin revealed negative values of a*, while in other cases the parameter was positive, which indicates increased intensity of red and is correlated with decreased lightness (Table 2). Similar tendency was observed for b*, which was in all cases positive, because of a prevalence of yellow over blue. The lowest values were found for control sample, and the addition of individual preparations caused their increase, especially in the case of lupine proteins. A significant rise of yellowness in bread supplemented with lupine protein was observed by Kohajdová et al. (2011).

Sensory parameters and their acceptability are decisive for consumer’s acceptance. The results of sensory acceptance of the analysed bread are shown on Fig 2. The application of proteins in bread formulations had varying effects on consumer’s acceptance, depending on their source. The lowest scores were given to samples with soy protein, as it could be expected by its lowest volume (Table 1). Positive effects on bread appearance could be noticed after the use of pea and lupine proteins, while collagen and albumin had a negative impact on this parameter. Structure and porosity of the loaves with pea and lupine preparations were almost equally acceptable as control sample, although their porosity, and the percentage of large pores were higher (Table 1). The presence of other proteins caused a decrease in approbation of this feature. The acceptance of color was improved after the addition of pea and lupine proteins, which could be attributed to their darker, more yellow color (Table 2). Bread with albumin was also more accepted than control, despite of its lighter crumb (Table 2). The introduction of pea, lupine and collagen preparations caused a significant increase in acceptability of bread smell. Flavor of the product with lupine protein was comparably acceptable as the control sample. In other cases, despite of the elimination of gums, a slight decrease in Flavor acceptance could be observed. The exception was bread with soy protein, which received significantly poorer scores than all other samples.

Texture properties

Staling of gluten free bread, observed during its storage, could be attributed mainly to the loss of moisture and starch retrogradation. The interactions between structure forming components and starch could significantly modify their rate, in a similar way as in wheat bread, in which starch-gluten interactions are considered to be decisive for crumb hardening. The structure-forming role in GF bakery products is usually played by polysaccharide or protein hydrocolloids or their combination. The values of texture parameters during storage of bread with protein preparations are shown in Table 3. The applied two-way analysis of variance proved, that for all analysed parameters, type of the applied protein preparations and storage time, together with the interactions with both these factors, had a significant influence on their values. Bread ageing, including a visible increase of crumb hardness is a complex process, which could be modified by any of bread constituents, as well as the interactions between them. Texture changes are closely related to the migration of water to crust, and the changes caused by recrystallization of starch polymers (Fadda et al. 2014). Protein significantly affects this process. Crumb of starch based bread, in which there are no protein-starch interactions, and water is bound only by a carbohydrate fraction, hardens much faster than of standard wheat bread, containing gluten (Korus et al. 2015). The results of two-way anova confirmed a significant influence of protein type on crumb hardness (Table 3). On the day of baking, the samples with collagen and lupine revealed hardness comparable with control, while bread with albumin and pea protein was significantly firmer. Hardness increased during storage period, however the changes depended on type of protein preparation applied in the recipe. The smallest increase could be observed in the case of bread with collagen and control sample. Slightly more intensive staling could be found for bread with lupine protein. Significantly more pronounced rise of hardness, especially on the second day of storage, could be seen for samples with albumin and soy protein, and the highest change was measured in the case of bread with pea protein. Although the latter sample received best scores in a consumer survey, the analysis was performed on the day of baking, so fast rate of staling had no influence on the results. Basing on the data it could be observed, that all protein preparations except collagen have a negative influence on structural changes in bread crumb during storage, causing the rise of its hardness. In our earlier report (Ziobro et al. 2013) it was found that supplementation of gluten-free bread with protein significantly reduced bread hardness, especially in the case of lupine protein, and that their use diminished changes in bread hardness upon storage. It could be concluded, that this was due to the synergistic action of gums and proteins, which should be combined and not used separately.

Springiness varied to a lesser extent than hardness (Table 3), and generally diminished with increasing time of storage. The type of applied protein preparation was statistically significant, but less important.

On the day of baking all bread samples revealed comparable cohesiveness, but the replacement of gums with individual protein preparations had varying effects on the reduction of this parameter (Table 3). A decrease in cohesiveness was least pronounced for control sample, in which structure was formed by starch and gums. When the gums were replaced with protein preparations, a decrease in cohesiveness was more visible, especially when lupine or pea protein was used. The excessive loss of cohesiveness negatively influences consumer acceptance, because the product is more susceptible to crumbling.

Trends observed in the case of chewiness generally follow those reported for hardness, because both parameters are highly correlated. The least changes during storage were found for samples with collagen and lupine protein and control. The highest chewiness was found for bread with pea protein.

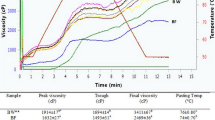

Thermal properties

Thermograms obtained during heating of bread crumb, reveal the presence of peak caused by disruption of retrograded amylopectin. Temperature range of this transition (data not shown) varied between 43.0 °C for control sample and 48.0 °C for bread with collagen to 71.3 °C for the sample with collagen and 79.7 °C for bread with pea protein. In all cases an increase in onset temperature during storage could be observed, which is probably the result of interactions between starch polymers and proteins in the system. Two-way ANOVA indicated a slight variability in the values of onset temperatures, depending on the type of applied preparation (p < 0.025), while endset temperature did not depend on time of storage in a statistically significant way (p < 0.095). No influence of interactions between preparation type and storage time could be found for onset and endset temperatures. More variability could be observed in values of the enthalpy of retrograded amylopectin (Fig. 3), although the interactions between type of protein and time of storage had no significant influence on its value. The smallest values of the enthalpy were measured for bread with collagen, both on the day of baking and during storage, and the values were significantly smaller than for control. It indicates the ability of collagen to retard amylopectin recrystallization, and in consequence bread staling. The results agree with those of crumb hardness (Table 3), which were the smallest for the sample with collagen. Other samples with protein preparations were not statistically different in terms of enthalpy of retrograded amylopectin. They significantly increased during storage and were in most cases higher than for control sample. It indicates a limited ability of these protein types to retard structural changes in crumb, and well agrees with the results of hardness. In our earlier report, it was observed that the supplementation of gluten-free bread based on pectin and guar gum, with soy and pea protein preparations significantly reduces enthalpy of retrograded amylopectin on the subsequent days of storage in comparison to control (Ziobro et al. 2013). It then seems that the effective reduction of amylopectin recrystallization, and thus bread staling, requires the combined use of gums and proteins. The interactions between those constituents and starch during baking and storage require further examination.

Cluster analysis

In order to find analogies in the effects of individual proteins on bread properties a hierarchical cluster analysis was done. As it is shown on Fig. 4, the properties of samples with pea and soy protein were most similar. Resemblance between control sample and bread with lupine protein could also be observed. Bread with collagen was comparable with those with soy and pea protein, but the variability was almost twice as before. Samples with pea protein, soy protein and collagen differed highly from those with lupine protein and control, as it is indicated by the distances between clusters. However the most pronounced changes in bread behaviour were caused by the addition of albumin, which is in agreement with earlier observations.

Conclusions

The use of protein preparations in recipes for gluten-free bread had varying effects on dough properties and bread characteristics. In general, the applied isolates and concentrates caused a firming of dough structure, which was reflected by a drop in phase shift tangent. Bread produced with the use of soy protein and collagen had lower volume, while albumin caused its increase in comparison to control. The replacement of gums with proteins influenced bread structure, and had positive effects on crumb color and its consumer acceptance. The presence of pea and lupine proteins positively influenced sensory parameters. However the replacement of gums with proteins caused an increase in bread hardness and enthalpy of retrograded amylopectin. These observations, together with earlier results, indicate that the application of protein preparations in the absence of guar gum and pectin negatively influences bread staling, but their combination with polysaccharide hydrocolloids could retard it. They also suggest, that the formulations deprived of plant gums, should be stabilized by some other means, such as structure-forming trans-glutaminases. Varying effects of individual proteins in the presence of polysaccharide hydrocolloids (Ziobro et al. 2013) and without them, gives an opportunity to obtain specific effects by proper combination of different protein sources. This could lead to production of bread with required quality parameters, which could be low or even completely free from structure forming additives and enriched in amino acids. However the optimization of such recipe is not an easy task and requires further studies.

References

Abramoff MD, Magelhaes PJ, Ram SJ (2004) Image processing with Image. J Biophoton Int 11:36–42

Andersson H, Öhgren C, Johansson D, Kniola M, Stading M (2011) Extensional flow, viscoelasticity and baking performance of gluten-free zein-starch doughs supplemented with hydrocolloids. Food Hydrocoll 25(6):1587–1595

Capriles VD, Arêas JA (2014) Novel approaches in gluten-free breadmaking: interface between food science, nutrition, and health. Compr Rev Food Sci F 13(5):871–890

Crockett R, Ie P, Vodovotz Y (2011) Effects of soy protein isolate and egg white solids on the physicochemical properties of gluten-free bread. Food Chem 129(1):84–91

Deora NS, Deswal A, Mishra HN (2015) Functionality of alternative protein in gluten-free product development. Food Sci Technol Int 21(5):364–379

Diowksz A, Sucharzewska D, Ambroziak W (2009) Function of dietary fibre in forming functional properties of gluten free dough and bread. Food Sci Technol Quality 16(2):83–93

Fadda C, Sanguinetti AM, Del Caro A, Collar C, Piga A (2014) Bread staling: updating the view. Compr Rev Food Sci F 13(4):473–492

Hüttner EK, Dal Bello F, Arendt EK (2010) Rheological properties and bread making performance of commercial wholegrain oat flours. J Cereal Sci 52(1):65–71

Juszczak L, Witczak T, Ziobro R, Korus J, Cieślik E, Witczak M (2012) Effect of inulin on rheological and thermal properties of gluten-free dough. Carbohyd Polym 90(1):353–360

Kohajdová Z, Karovičová J, Schmidt Š (2011) Lupin composition and possible use in bakery – a review. Czech J Food Sci 29(3):203–211

Korus J, Witczak M, Ziobro R, Juszczak L (2009) The impact of resistant starch on characteristics of gluten-free dough and bread. Food Hydrocoll 23(3):988–995

Korus J, Witczak M, Ziobro R, Juszczak L (2015) The influence of acorn flour on rheological properties of gluten-free dough and physical characteristics of the bread. Eur Food Res Technol 240(6):1135–1143

Krupa-Kozak U, Bączek N, Rosell C (2013) Application of dairy proteins as technological and nutritional improvers of calcium-supplemented gluten-free bread. Nutrients 5(11):4503–4520

Krupa-Kozak U, Bączek N, Adamowicz J (2014) Effect of calcium caseinate and calcium citrate on quality and technological parameters of gluten-free bread. Food Sci Technol Quality 94(3):136–150

Marco C, Rosell CM (2008a) Breadmaking performance of protein enriched, gluten-free breads. Eur Food Res Technol 227(4):1205–1213

Marco C, Rosell CM (2008b) Functional and rheological properties of protein enriched gluten free composite flours. J Food Eng 88(1):94–103

Martínez MM, Díaz Á, Gómez M (2014) Effect of different microstructural features of soluble and insoluble fibres on gluten-free dough rheology and bread-making. J Food Eng 142:49–56

Matos Segura ME, Rosell CM (2011) Chemical composition and starch digestibility of different gluten-free breads. Plant Foods Hum Nutr 66(3):224–230

Matos ME, Rosell CM (2015) Understanding gluten-free dough for reaching breads with physical quality and nutritional balance. J Sci Food Agric 95(4):653–661

Matos ME, Sanz T, Rosell CM (2014) Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll 35:150–158

Miñarro B, Albanell E, Aguilar N, Guamis B, Capellas M (2012) Effect of legume flours on baking characteristics of gluten-free bread. J Cereal Sci 56(2):476–481

Mine Y (1995) Recent advances in the understanding of egg white protein functionality. Trends Food Sci Tech 6(7):225–232

PKN (1996) Sensory analysis - General guidance for selection, training and monitoring of assessors - Part 1: Selected assessors. PKN, Warszawa

Pontieri P, Mamone G, de Caro S, Tuinstra MR, Roemer E, Okot J, de Vita P, Ficco DBM, Alifano P, Pignone D, Massardo DR, Del Giudice L (2013) Sorghum, a healthy and gluten-free food for celiac patients as demonstrated by genome, biochemical, and immunochemical analyses. J Agric Food Chem 61(10):2565–2571

Pruska-Kędzior A, Kędzior Z, Gorący M, Pietrowska K, Przybylska A, Spychalska K (2008) Comparison of rheological, fermentative and baking properties of gluten-free dough formulations. Eur Food Res Technol 227(5):1523–1536

Ribotta PD, Ausar SF, Morcillo MH, Pérez GT, Beltramo DM, León AE (2004) Production of gluten-free bread using soybean flour. J Sci Food Agric 84(14):1969–1974

Rinaldi M, Dall’Asta C, Paciulli M, Guizzetti S, Barbanto D, Chiavaro E (2014) Innovation in the Italian ice cream production: effect of different phospholipid emulsifiers. Dairy Sci Technol 94(1):33–49

Ronda F, Villanueva M, Collar C (2014) Influence of acidification on dough viscoelasticity of gluten-free rice starch-based dough matrices enriched with exogenous protein. LWT-Food Sci Technol 59(1):12–20

Schober TJ, Moreau RA, Bean SR, Boyle DL (2010) Removal of surface lipids improves the functionality of commercial zein in viscoelastic zein-starch dough for gluten-free breadmaking. J Cereal Sci 52(3):417–425

Schober TJ, Bean SR, Tilley M, Smith BM, Ioerger P (2011) Impact of different isolation procedures on the functionality of zein and kafirin. J Cereal Sci 54(2):241–249

Schoenlechner R, Mandala I, Kiskini A, Kostaropoulos A, Berghofer E (2010) Effect of water, albumen and fat on the quality of gluten-free bread containing amaranth. Int J Food Sci Tech 45(4):661–669

Smith BM, Bean SR, Herald TJ, Aramouni FM (2012) Effect of HPMC on the quality of wheat-free bread made from carob germ flour-starch mixtures. J Food Sci 77(6):684–689

Storck CR, da Rosa ZE, Gularte MA, Elias MC, Rosell CM, Guerra Dias AR (2013) Protein enrichment and its effects on gluten-free bread characteristics. LWT-Food Sci Technol 53(1):346–354

Tsatsaragkou K, Gounaropoulos G, Mandala I (2014) Development of gluten free bread containing carob flour and resistant starch. LWT-Food Sci Technol 58(1):124–129

van Riemsdijk LE, van der Goot AJ, Hamer RJ, Boom RM (2011) Preparation of gluten-free bread using a meso-structured whey protein particle system. J Cereal Sci 53(3):355–361

Witczak M, Juszczak L, Ziobro R, Korus J (2012) Influence of modified starches on properties of gluten-free dough and bread. Part I: Rheological and thermal properties of gluten-free dough. Food Hydrocoll 28(2):353–360

Ziobro R, Witczak T, Juszczak L, Korus J (2013) Supplementation of gluten-free bread with non-gluten proteins. Effect on dough rheological properties and bread characteristic. Food Hydrocoll 32(2):213–220

Acknowledgment

The authors thank Barentz Sp. z o.o. and Brenntag Polska Sp. z o.o. for donating protein preparations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Research highlights

• evaluated the effects of selected proteins on quality and staling of gluten-free bread

• bread containing the soy protein and collagen had lower volume, while albumin caused its increase

• replacement of gums with proteins had positive effects on crumb color and its consumer acceptance

• replacement of gums with proteins caused an increase in bread hardness

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 284 kb)

Rights and permissions

About this article

Cite this article

Ziobro, R., Juszczak, L., Witczak, M. et al. Non-gluten proteins as structure forming agents in gluten free bread. J Food Sci Technol 53, 571–580 (2016). https://doi.org/10.1007/s13197-015-2043-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2043-5