Abstract

The objective of the present study was to evaluate the effect of microbial exopolysaccharide (EPS) encapsulation of lactic acid bacteria on enhancing their viability during exposure to the simulated conditions of the gasterointestinal tract. Lactobacillus plantarum (NR_104573.1) and Pediococcus pentosaceus (NR_042058.1) isolated from wheat bran sourdough were encapsulated by spray-drying with various ratios of EPS, whey protein concentrate, carboxymethyl cellulose and pectin. The viability, kinetics and survival under stress conditions were compared between the samples after 120 min of incubation and over 28 days of storage. HPLC was used for compositional assessment in terms of monosaccharide constituents, revealing that glucose, arabinose and xylose were the major components of the EPS produced by L. plantarum and P. pentosaceus. ANOVA demonstrated a significantly reduced logarithmic cycle of bacterial population in the control samples and free cells compared to the encapsulated L. plantarum and P. pentosaceus after 2 h in simulated gastric fluid conditions and bile salt solution. Encapsulation yields in the presence of WPC, CMC and pectin with and without EPS were about 85 and 80% for L. plantarum, and it was 81 and 75% for P. pentosaceus, respectively. Also, the viability number of L. plantarum and P. pentosaceus free cells decreased over 28 days of storage from 12.41 to 7.28 and 12.11 to 6.96 log Cfu/mL, respectively. Finally, by assessing the kinetics of the bacteria with three mathematical models, the Ritger–Peppas kinetics model was found to be a suitable correlation model for the data.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A number of probiotic bacteria have the capability of producing extracellular biopolymers known as microbial exopolysaccharides (EPSs) [1, 2]. EPSs are functional compounds produced during the growth of bacteria, with potential functions of thickening, gel production, hygroscopy, encapsulation and emulsifier stabilization [3, 4]. Probiotic bacteria can be attributed to the production of EPSs, which improve the balance of gastrointestinal microorganisms, inhibit pathogen growth and prevent diarrhea [5]. However, the composition, structure and biological functions of EPSs may greatly depend on the EPS production capability of the microorganism and the environmental conditions [2]. Encapsulation of probiotic bacteria is considered as a protective technology of incorporating biomaterials (such as biopolymers) into diminutive microspheres with abillity to kinetics under specific conditions to provide long-term preservation to the cells and to enhance their resistance during exposure to adverse conditions of the gastero-intestinal tract. [6, 7]. Amidst all technologies for bacterial encapsulation, spray-drying is one of the best ways and least time consuming to microbial encapsulation according to Ananta et al. [8]. Encapsulating LAB with a physical obstruction has been examinated by many researchers while different milk proteins such as WPC and casein have been used as encapsulation material [5, 9]. WPC is widely used as a defensive factor in spray-drying and have many physicochemical characteristics that are suitable for the encapsulation of probiotics and complex-forming interactions with other polymers like microbial EPSs and carboxymethyl cellulose (CMC) [9,10,11], but little research have reported the use of EPSs in the coating of materials.

Corcoran et al. [12] advised that these EPSs, as prebiotics, may potentially be employed as carrier media for spray-drying, and may be useful for increasing LAB viability during storage. Chen et al. [5] investigated on a polysaccharide-protein complex for probiotic coating as a relatively novel technique that for probiotic encapsulation. Girad et al. [13] indicated that polysaccharide-protein complexes could improve the emulsifying properties of proteins by thickening the layer at the interface of the bacterial cell wall.

In our previous research we isolated and characterized L. plantarum (NR_104573.1) and P. pentosaceus (NR_042058.1) as the dominant strains of wheat bran sourdough (WBS), then the productivity of EPS by these two strains were investigated [4]. EPS as a functional component was then applied in encapsulation of the dominant strains. While many researches have been carried out on encapsulation of probiotics with improved viability under adverse conditions, few studies have focused on the EPSs protective role against environmental stresses. So far, to our knowledge, no studies have been carried out using the technique of microencapsulation by EPSs along with mixture of other coating materials in order to verify the possibility of increasing the viability of bacteria towards simulated human gastro-intestinal condition.Thus the goal of the present study was to enhance the survival as well as kinetics of bacteria in simulated gastric fluid (SGF) and bile salt solution tolerance by spray drying encapsulation using EPS. For this aim, we investigated the effect of EPSs along with mixture of WPC, CMC and pectin in comparison with samples encapsulated with all aforementioned components except EPS (control) and free bacterial cells.

Materials and methods

Materials

Pure cultures of L. plantarum (NR_104573.1) and P. pentosaceus (NR_042058.1) extracted from WBS were stored at -80 °C in MRS broth. The encapsulating agents used were commercial WPC containing 80% protein, CMC, pectin and EPSs isolated from the two strains. The chemicals [1-phenyl-3-methyl-5-pyrazolone (PMP), anthranilic acid (AA) and Trifluoroacetic acid (TFA) and microbial media (MRS Agar, MRS Broth and Nutrient Broth] used in this study were purchased from Sigma-Aldrich company (Oakville, ON, Canada) and Merck, all having purities of greater than or equal to 99%.

Preparation of bacterial suspension and conditions for EPS production

Pure cultures of L. plantarum and P. pentosaceus from WBS were inoculated in MRS broth, to which 10% glucose had previously been added, then incubated at 37 °C for 24 h to 108 Cfu/mL. The highest amount of biomass produced at the initial and middle of stationary phase was subjected to centrifugation (15,000×g, 4 °C, 30 min) (Hermle, Z36 HK, Germany) before being suspended in sterile water [4, 14]. The supernatants were added to the MRS broth, while the EPSs were isolated from the pellets [15]. Using criteria related to mucoid phenotype, the LAB strains that produced EPSs were screened initially via observation while being cultured in MRS agar at 37 °C for 48 h [16].

Monosaccharide composition analysis of EPS by HPLC analysis

EPSs (1 mg) of the strains isolated from WBS were subjected to hydrolysis at 120 °C for 2 h using 1 mL of 2 M trifluoroacetic acid (TFA). Next, derivatization was performed using 1-phenyl-3-methyl-5-pyrazolone (PMP) and anthranilic acid (AA). HPLC (Waters, Milford, MA, USA) was then used for monosaccharide composition analysis. The reverse phase column was a RP C-18 with 250 mm × 4.6 mm ID and 5 µm particle size. The mobile phase consisted of sodium phosphate (50 mM, pH 7.0)/acetonitrile (82:18 v/v) at a flow rate of 1.0 mL min−1, and the volume injected was 20 µl [17, 18].

Preparation of microbial encapsulation by spray-drying

Based on previous studies, the coating and biopolymer mixtures suitable for microcapsule formation were determined [19, 20]. In short, coatings agents were prepared by dispersing WPC, CMC, pectin and EPSs of L. plantarum and P. pentosaceus in a proportion of 4.33, 0.43, 0.61 and 0.50 g/100 mL, respectively, achieving a suspension concentration of 5.878% (w/w). The suspension was homogenized in sterile distilled water for 10 min and heat treated (digital water bath,WBD-22, Germany) at 80 °C and pH 8.0 for 30 min [20, 21]. The pure stocks of bacteria were developed in MRS medium with low oxygen tension (facultative anaerobic conditions). After growth, the bacteria were transferred to physiological 0.85% saline solution [8]. The suspension of the encapsulating agents was inoculated with approximately 1012 CFU/mL of the pure probiotic culture before spray-drying. The mixture was homogenized for 10 min at 25 °C and then dry powdered using the Buchi B-191 mini spray-dryer (Buchi, Flawil, Switzerland) at a constant air inlet temperature of 160 ± 3 °C and outlet temperature of 65 ± 2 °C, with a 0.7 MPa compressor air pressure, a drying air flow rate of 35 m3/h, and a feeding rate of 15 mL/min [15]. Encapsulation process is shown in Fig. 1.

Evaluation of free and encapsulated L. plantarum and P. pentosaceus viable cells

Microspheres (1 g) were dissolved in 9 mL of 0.1 N phosphate buffer (pH = 7.5) on a shaker at 30 °C until complete dissolution was achieved. The kinetics L. plantarum and P. pentosaceus were serially diluted 10 times with physiological saline solution (0.85%) and 100 µL aliquots were plated on MRS agar. Also, free bacterial cells were serially diluted 10 times with saline solution, and 100 µL aliquots were plated on MRS agar. After incubation at 37 °C for 24 h, colonies of L. plantarum and P. pentosaceus were enumerated according to the method of Shi et al. [9, 22].

Encapsulation efficiency of bacteria

Encapsulation yield was evaluated using Eq. 1 suggested by Picot and Lacroix [23]:

N is the number of viable cells (log Cfu/g) after drying and N0 is the number of viable cells (log Cfu/g) before drying.

Viability of free and encapsulated L. plantarum and P. pentosaceus in SGF

The survival of the control, EPS encapsulated and free cells of L. plantarum and P. pentosaceus in simulated gastric fluid ) made of 3.2 mg/mL pepsin in 2.0 mg/mL NaCl (pH = 1.5) [24, 25]. Matrix containing L. plantarum and P. pentosaceus (0.5 g) were added to the tubes containing 4.5 mL of SGF, which were then incubated at 37 °C for 10, 30, 60, 90 and 120 min [21, 23]. At the specified time intervals, samples were taken out for analysis. Free cells were serially diluted 10 times with saline solution, and 100 µL aliquots were plated on MRS agar plate. Microspheres containing L. plantarum and P. pentosaceus were recovered from SGF and dissolved in 4.5 mL of 0.1 N phosphate buffer (pH = 7.5). Microbial enumeration was then conducted according to the procedures described by Shi et al. [9, 22].

Bile salt solution tolerance of free and encapsulated bacteria

The viability of the control, EPS encapsulated and free cells of L. plantarum and P. pentosaceus was tested in porcine bile salt solution (sigma-aldrich, 48,305) in accordance to the procedures developed by Shi et al. [22]. Suspensions of free cells (0.5 mL) or matrix containing L. plantarum and P. pentosaceus (0.5 g) were placed in tubes containing 4.5 mL of bile salt solution (1% w/v) and incubated at 37 °C for 10, 30, 60, 90 and 120 min [26]. At the specified time intervals, samples were taken out and assayed according to the method described by Shi et al. [9, 22].

In vitro kinetics of free and encapsulated L. plantarum and P. pentosaceus in GI (SIF)

The kinetic of encapsulated bacteria was evaluated in accordance to the procedure developed by He et al. [27]. In short, 4.5 mL of SGF, bile salt, pre-warmed gastrointestinal (GI) solution, 1% porcine bile salt solution (pH = 8.5) and 10 mg/mL of pancreatin in 0.1 mol/L potassium phosphate (pH = 7.4) were each separately added to microcapsules (0.5 g) in conical plastic tubes and incubated at 37 °C with shaking at 150 rpm. At the specified time intervals, the samples at different time intervals were taken and the units of the kinetics bacteria were counted by the pour plate method [9, 22, 25]. The same volume of the fresh medium was used to replace the volume of the withdrawn samples. The bacterial kinetic over time was monitored [9, 28]. Cell kinetic were analyzed according to a model Eq. (2), Higuchi Eq. (3) and Ritger–Peppas Eq. (4) using MATLAB software version 8.1 R 29 (MathWorks Inc., Natick, MA). Also, the nonlinear least squares fitting method was used to determine the parameters in each equation [27, 29,30,31,32].

where M∞ is the total cumulative bacteria kinetic; Mt is bacteria accumulated kinetic percentage at time t; K1 is the first order model constant kinetics; KH is the Higuchi model constant kinetics; t is the kinetic time; C1, CH and K are constants. Also, Mt/M0 is the ratio of active ingredient kinetics at time t, and n in the Ritger–Peppas model, which is a parameter that is indicative of the transport mechanism.

Survival of free and encapsulated bacteria during storage

The storage stability of the control, EPS encapsulated and free L. plantarum and P. pentosaceus was evaluated for about 1 month at 4 °C. At pre-determined times of 1, 7, 14, 21, and 28 days, samples were harvested for survival assessment. Microbial enumeration was then conducted according to the procedures described in according to the method of Shi et al. [9, 22].

Statistical analysis

All experimental procedures were conducted three times. Statistical analysis of the data was done according to a completely randomized design. Analysis of variance (ANOVA) was used to compare the means in SAS (9.1) software.

Results and discussion

Identification of EPS monosaccharide composition by HPLC

Previously we studied on extraction and molecular weight evaluation of microbial EPS [4]. Under initial incubation conditions at 37 °C, in modified MRS medium, the amount of microbial EPS isolated from two strains of L. plantarum and P. pentosaceus from WBS were 408.443 mg/L and 263.629 mg/L respectively in the middle and late stationary phase of growth (during idiophase). The monosaccharide composition of the EPS of L. plantarum and P. pentosaceus were analyzed by HPLC; independent peaks at a retention time of 25.21 and 25.34 min both of them confirmed the presence of arabinose (Fig. 2a and b). Other monosaccharides of the EPSs were glucose and xylose are shown in Table 1. Ispirli and Dertli [33] showed that glucose and galactose as the sugar monomers of the EPS produced by L. bulgaricus Y39 and S. thermophilus Y102. Also, Ai et al. [34] reported that monosaccharides composition of the microbial EPS extracted from L. casei LC2W revealed the presence of glucose (57.8% mol%), rhamnose (27.7%, mol%) and galactose (14.5%, mol%), respectively. Monosaccharide composition of EPSs seems an important basis for their functional characteristics. The study of Tallon et al. (2003) showed that glucose, galactose and xylose are the major components of the EPS produced by L. plantarum EP56. Wang et al. [35] reported that the monosaccharide composition of the microbial EPS extracted from L. plantarum KF5 comprises mannose, glucose and galactose portion in a near ratio of 1, 4.99 and 6.90 (% w/w).

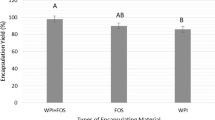

Encapsulation yield and cell viability after spray-drying

One of the necessary prerequisites for utilizing the encapsulation method is a high encapsulation efficiency. In this research, the spray-drying method was used to encapsulate L. plantarum and P. pentosaceus. The initial survival number of L. plantarum and P. pentosaceus in the aqueous suspension used to prepare the microspheres was about 12.414 and 12.113 log Cfu/mL. However, after encapsulation by spray-drying, the number of viable cells recovered from EPS encapsulated and control samples of L. plantarum was 10.59 and 9.86 log Cfu/g, with the numbers being 10.02 and 9.32 log Cfu/g for EPS encapsulated and control samples of P. pentosaceus. The encapsulation yields in the presence of WPC, CMC and pectin with and without EPS were about 85 and 80% for L. plantarum, and 81 and 75% for P. pentosaceus, respectively. The results of Hebrard et al. [36] demonstrated a high encapsulation yield for the coating of probiotic bacteria with WPC and biopolymer matrices. Complex of protein and polysaccharide may have a large number of applications in the food sector. Milk proteins have many physicochemical properties that are suitable for encapsulating probiotics, such as gelation properties, pH-responsive gel swelling behavior, interactions with other polymers such as alginate to form complexes, biocompatibility and biodegradability [6]. Dong et al. [10] reported that denatured WPC along with polysacharide such as alginate and CMC were suitable matrices for probiotics encapsulation, while native protein provided the weakest safeguard against thermal and acid stress.

Viability of free and encapsulated L. plantarum and P. pentosaceus in SGF

The effectiveness of probiotic consumption in human health is related to their survival; hence, probiotics must resist the stressful gastric environment [37]. The results of ANOVA showed that gastric simulation conditions had a reduced amount of cell desorption effect to decrease the viability of logarithmic cycle of the encapsulated L. plantarum population in the presence and absence of EPS compared to free cells (reduction ratio of 3:4:8 log CFU/mL, respectively), with similar results obtained for P. pentosaceus (reduction ratio of 3:3:8 log Cfu/mL). Encapsulation of L. plantarum and P. pentosaceus in biopolymer matrices that contain EPS (0.5%) could significantly improve the survival of L. plantarum and P. pentosaceus in SGF, as shown in Figs. 3 and 4. Many studies have reported that the stomach pH causes the destruction of most uncoating microorganisms [38]. Sohail et al. [39] reported more than 6 log Cfu/mL of L. acidophilus reduction after 120 min in pH 2.0 SGF. The results of Guerin et al. [40] showed that the buffering ability of WPC was contributed to the high survival rate of probiotics encapsulated in a matrix of alginate–pectin–WPC microspheres when exposed to pH 2.5 SGF. The results of Shi et al. [22] showed that the survivability of L. bulgaricus in SGF (pH = 2.0) was highly improved when placed within milk-alginate and hydrocolloid carrageenan matrices. The results of Feng et al. [41] showed that using double-layered encapsulation for probiotic cells fabricated by a simple coaxial electrospinning improved the survivability of the loaded cells in adverse conditions. This study also relates with the Afzal et al. [42] who reported that encapsulation with WPC improves the survival of probiotics in gastric conditions.

The viability of the control, EPS encapsulated and free cells of L. plantarum in the SGF conditions (different letters indicate significant differences with a confidence interval of 95%). Results are expressed as mean values of triplicates ± standard deviation. A.B.CDifferent superscript letters denote significant differences during 120 minutes (P < 0.05). a,b.cDifferent superscript letters denote significant differences at each time (P < 0.05)

The stability of the control, EPS encapsulated and free cells of P. pentosaceus in the SGF conditions (different letters indicate significant differences in a confidence interval of 95%). Results are expressed as mean values of triplicates ± standard deviation. A.B.CDifferent superscript letters denote significant differences during 120 minutes (P < 0.05). a,b.cDifferent superscript letters denote significant differences at each time (P < 0.05)

Viability of free and encapsulated cells in bile salt solution

One of the main purposes of encapsulating bacteria is to protect them from damage in the bile salt solution environment of the human intestine [21, 25]. In this research, the viability of free and encapsulated L. plantarum and P. pentosaceus was analyzed in bile salt solution incubated at 37 °C for 10, 30, 60, 90 and 120 min. The exposure to a series of condition that simulate the passage through the gastrointestinal tract showed that bile salt solution had a reduced effect on the viability of L. plantarum population in EPS encapsulated and control samples compared to free cells (reduction ratio 3:3:8 log CFU/mL, respectively), with the corresponding ratio being 4:4:9 log CFU/mL for P. pentosaceus. As reported in Table 2, free cells of L. plantarum and P. pentosaceus completely lost their viability in bile salt solution after 120 min. The reason for this might be that bile salts destroyed the cell wall integrity, resulting in the observed lethal action against some of the probiotic bacteria [9, 22, 43]. However, the presence of biopolymer matrices (EPS, WPC, CMC and pectin) around the cell wall can inhibit the diffusion of bile salt solution into the microsphere and thus provide effective protection compared to control matrices and free cells. The results of Afzaal et al. [42] showed that encapsulation has a shielding effect toward probiotics in simulated intestinal solution. The results presented in this study corroborate other researches that show the efficiency of microencapsulation in protecting probiotics during exposure to GI conditions, with emphasis on the protective role of EPSs.

Kinetics characterization of the encapsulated bacteria

Polymer compositions of the encapsulation matrices is another important factor which has a profound influence on the viability and kinetic of encapsulated bacteria [21, 44]. In order to allow health benefits to the human body, probiotic encapsulation materials should not only effectively protect L. plantarum and P. pentosaceus from adverse gastric conditions but also permit the survival of bacteria in host [9].

Release kinetics were evaluated based on empirical first-order, Higuchi, and Ritger–Peppas models. The original parameter values from various equations are summarized in Table 3 to explain the transport mechanism. Suitable correlations were identified between the kinetic profiles of 0.5% EPS encapsulated and control samples of P. pentosaceus across all three mathematical models (R2 = 0.920 and 0.950). The maximum regression correlation value for encapsulated L. plantarum and P. pentosaceus with the presence and absence of EPS signified that the most appropriate model for the data was the Ritger–Peppas kinetics model, which represented a swellable system. Argin et al. [32] reported that chain mobility is the main factor affecting cell kinetic rate from entrapping matrices. Shori [44] reported that the high kinetic rate of encapsulated probiotics can probably be described by the buffering capacity of the protein-based biopolymer matrices, compact structure, and low porosity on the surface of the microspheres.

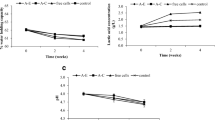

Storage stability of free and encapsulated cells

The evaluation of storage stability over 28 days at 4 °C demonstrated that the logarithmic cycle of the free L. plantarum and P. pentosaceus cell populations was significantly reduced compared to the encapsulated cells (EPS-containing and control). Also, results showed that encapsulated bacteria in the presence of 0.5% EPS, as a bioactive compound, had high stability and relative humidity that they could be preserved after 4 weeks of storage in comparison to control cells. The viability number of L. plantarum and P. pentosaceus free cells decreased over 28 days of storage from 12.41 to 7.28 and 12.11 to 6.96 log Cfu/mL, respectively (Fig. 5). A lot of research has proven that encapsulation can enhance the storage stability of LAB [45, 46]. Ismail and Nampoothiri [47] reported that encapsulation with the EPS extract of L. plantarum (about 0.2% concentration) was found to have a better influence on storage stability and the prevention of syneresis in wheat starch in comparison with the carboxymethyl cellulose polymer after 22 days of storage. Increasing the concentration of EPS may have a profound influence on the prevention of syneresis. Also, encapsulation showed protection effects to probiotic in hostile conditions. These results correspond with Afzaal et al. [48], also González-Ferrero et al. [49] have reported similar results. According to the reports of these researchers, the encapsulation with soybean protein concentrate enhanced significantly the stability of the lactic acid bacteria all along the probiotic food value chain, from production to the end of the food shelf-life.

Storage stability of the control, EPS encapsulated and free cells of L. plantarum and P. pentosaceus in 4 °C (different letters indicate significant differences with a confidence interval of 95%). Results are expressed as mean values of triplicates ± standard deviation. A,B,CDifferent superscript letters denote significant differences in storage stability of L. plantarum and P. pentosaceus at 1 month (P < 0.05). a,b,cDifferent superscript letters denote significant differences in storage stability of L. plantarum and P. pentosaceus at each time (P < 0.05)

Conclusions

The current research indicated that encapsulation of L. plantarum and P. pentosaceus with and without EPS not only provided protection to the cells but also enhanced the survival of probiotics in simulated gastrointestinal conditions. Bacteria encapsulated within EPS microspheres could be released at suitable rate on exposure to GI. Furthermore, the release kinetics based on three mathematical models showed a suitable correlation between the release profiles of EPS encapsulated and control samples. Overall, encapsulation with microbial EPSs, as bioactive compounds, along with WPC, CMC and pectin, proved to be a good method for protecting bacteria isolated from WBS in adverse environments.

References

I.W. Sutherland, Novel and established applications of microbial polysaccharides. Trends Biotechnol. 16, 41–46 (1998)

B. Vu, M. Chen, R.J. Crawford, E.P. Ivanova, Bacterial extracellular polysaccharides involved in biofilm formation. Molecules. 14, 2535–2554 (2009)

C. Liu, J. Lu, L. Lu, Y. Liu, F. Wang, M. Xiao, Isolation, structural characterization and immunological activity of an exopolysaccharide produced by Bacillus licheniformis 8-37-0-1. Bioresour. Technol. 101, 5528–5533 (2010)

A. Abedfar, M. Hossininezhad, A. Sadeghi, M. Raeisi, J. Feizy, Investigation on “spontaneous fermentation” and the productivity of microbial exopolysaccharides by Lactobacillus plantarum and Pediococcus pentosaceus isolated from wheat bran sourdough. LWT Food Sci. Technol. 96, 686–693 (2018)

M.Y. Chen, W. Zheng, Q.Y. Dong, Z.H. Li, L.E. Shi, Z.X. Ananta, Activity of encapsulated Lactobacillus bulgaricus in alginate-whey protein microspheres. Braz. Arch. Biol. Technol. 57, 736–741 (2014)

L.E. Shi, Z.H. Li, D.T. Li, M. Xu, H.Y. Chen, Z.L. Zhang, Z.X. Tang, Encapsulation of probiotic Lactobacillus bulgaricus in alginate–milk microspheres and evaluation of the survival in simulated gastrointestinal conditions. J. Food Eng. 117, 99–104 (2013)

A.K. Anal, W.F. Stevens, C. Remunan-Lopez, Ionotropic cross-linked chitosan microspheres for controlled release of ampicillin. Int. J. Pharm. 312, 166–173 (2006)

E. Ananta, M. Volkert, D. Knorr, Cellular injuries and storage stability of spray-dried Lactobacillus rhamnosus GG. Int. Dairy J. 15, 399–409 (2005)

L.E. Shi, W. Zheng, Y. Zhang, Z.X. Tang, Milk-alginate microspheres: Protection and delivery of Enterococcus faecalis HZNU P2. LWT Food Sci. Technol. 65, 840–844 (2016)

Q.Y. Dong, M.Y. Chen, Y. Xin, X.Y. Qin, Z. Cheng, L.E. Shi, Z.X. Tang, Alginate-based and protein‐based materials for probiotics encapsulation: a review. Int. J. Food Sci. Technol. 48, 1339–1351 (2013)

S. Rokka, P. Rantamaki, Protecting probiotic bacteria by microencapsulation: challenges for industrial applications. Eur. Food Res. Technol. 231, 1–12 (2010)

B.M. Corcoran, R.P. Ross, G.F. Fitzgerald, C. Stanton, Comparative survival of probiotic lactobacilli spray-dried in the presence of prebiotic substances. J. Appl. Microbiol. 96, 1024–1039 (2004)

M. Girard, S.L. Turgeon, S.F. Gauthier, Interbiopolymer complexing between β-lactoglobulin and low-and high-methylated pectin measured by potentiometric titration and ultrafiltration. Food Hydrocoll. 16, 585–591 (2002)

F. Dal Bello, C.I. Clarke, L.A.M. Ryan, H. Ulmer, T.J. Schober, K. Ström, J. Sjögren, D. Van Sinderen, J. Schnürer, E.K. Arendt, Improvement of the quality and shelf life of wheat bread by fermentation with the antifungal strain Lactobacillus plantarum FST 1.7. J Cereal Sci. 45, 309–318 (2007)

Y. Boza, L.P. Neto, F.A.A. Costa, A.R.P. Scamparini, Exopolysaccharide production by encapsulated Beijerinckia cultures. Process Biochem. 39, 1201–1209 (2004)

R. Tallon, P. Bressollier, M.C. Urdaci, Isolation and characterization of two exopolysaccharides produced by Lactobacillus plantarum EP56. Res. Microbiol. 154, 705–712 (2003)

Y. Lv, X. Yang, Y. Zhao, Y. Ruan, Y. Yang, Z. Wang, Separation and quantification of component monosaccharides of the tea polysaccharides from Gynostemma pentaphyllum by HPLC with indirect UV detection. Food Chem 112, 742–746 (2009)

H. Stepan, E. Staudacher, Optimization of monosaccharide determination using anthranilic acid and 1-phenyl-3-methyl-5-pyrazolone for gastropod analysis. Anal. Biochem. 418, 24–29 (2011)

M.E. Rodríguez-Huezo, R. Durán-Lugo, L.A. Prado-Barragán, F. Cruz-Sosa, C. Lobato-Calleros, J. Alvarez-Ramírez, E.J. Vernon-Carter, Pre-selection of protective colloids for enhanced viability of Bifidobacterium bifidum following spray-drying and storage, and evaluation of aguamiel as thermoprotective prebiotic. Food Res. Int. 40, 1299–1306 (2007)

R. Altamirano-Fortoul, R. Moreno-Terrazas, A. Quezada-Gallo, C.M. Rosell, Viability of some probiotic coatings in bread and its effect on the crust mechanical properties. Food Hydrocoll. 29, 166–174 (2012)

Z. Tang, X. Huang, P.M. Sabour, J.R. Chambers, Q. Wang, Preparation and characterization of dry powder bacteriophage K for intestinal delivery through oral administration. LWT Food Sci. Technol. 60, 263–270 (2015)

L.E. Shi, Z.H. Li, Z.L. Zhang, T.T. Zhang, W.M. Yu, M.L. Zhou, Z.X. Tang, Encapsulation of Lactobacillus bulgaricus in carrageenan-locust bean gum coated milk microspheres with double layer structure. LWT Food Sci. Technol. 54, 147–151 (2013)

A. Picot, C. Lacroix, Encapsulation of bifidobacteria in whey protein-based microcapsules and survival in simulated gastrointestinal conditions and in yoghurt. Int. Dairy J. 14, 505–515 (2004)

H. Michida, S. Tamalampudi, S.S. Pandiella, C. Webb, H. Fukuda, A. Kondo, Effect of cereal extracts and cereal fiber on viability of Lactobacillus plantarum under gastrointestinal tract conditions. Biochem. Eng. J. 28, 73–78 (2006)

Y. Ma, J.C. Pacan, Q. Wang, P.M. Sabour, X. Huang, Y. Xu, Enhanced alginate microspheres as means of oral delivery of bacteriophage for reducing Staphylococcus aureus intestinal carriage. Food Hydrocoll. 26, 434–440 (2012)

W.P. Charteris, P.M. Kelly, L. Morelli, J.K. Collins, Development and application of an in vitro methodology to determine the transit tolerance of potentially probiotic Lactobacillus and Bifidobacterium species in the upper human gastrointestinal tract. J. Appl. Microbiol. 84, 759–768 (1998)

Y. He, Z. Wu, L. Tu, Y. Han, G. Zhang, C. Li, Encapsulation and characterization of slow-release microbial fertilizer from the composites of bentonite and alginate. Appl Clay Sci. 109, 68–75 (2015)

L.X. Pan, X.J. Fang, Z. Yu, Y. Xin, X.Y. Liu, L.E. Shi, Z.X. Tang, Encapsulation in alginate–skim milk microspheres improves viability of Lactobacillus bulgaricus in stimulated gastrointestinal conditions. Int. J. Food Sci. Nutr. 64, 380–384 (2013)

S. Benita, Kinetic model identification of drug release from microcapsules using the nonlinear regression search procedure. Appl. Biochem. Biotechnol. 10, 255–258 (1984)

T. Higuchi, Mechanism of sustained-action medication. Theoretical analysis of rate of release of solid drugs dispersed in solid matrices. J. Pharm. Sci. 52, 1145–1149 (1963)

P.L. Ritger, N.A. Peppas, A simple equation for description of solute release I. Fickian and non-Fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs. J. Control. Release. 5, 23–36 (1987)

S. Argin, P. Kofinas, Y.M. Lo, The cell release kinetics and the swelling behavior of physically crosslinked xanthan–chitosan hydrogels in simulated gastrointestinal conditions. Food Hydrocoll. 40, 138–144 (2014)

H. İspirli, E. Dertli, Isolation and identification of exopolysaccharide producer lactic acid bacteria from Turkish yogurt. J Food Process. Preserv. 42, 13351 (2018)

L. Ai, Q. Guo, H. Ding, B. Guo, W. Chen, S.W. Cui, Structure characterization of exopolysaccharides from Lactobacillus casei LC2W from skim milk. Food Hydrocoll. 56, 134–143 (2016)

Y. Wang, C. Li, P. Liu, Z. Ahmed, P. Xiao, X. Bai, Physical characterization of exopolysaccharide produced by Lactobacillus plantarum KF5 isolated from Tibet Kefir. Carbohydr. Polym. 82, 895–903 (2010)

G. Hebrard, V. Hoffart, E. Beyssac, J.M. Cardot, M. Alric, M. Subirade, Coated whey protein/alginate microparticles as oral controlled delivery systems for probiotic yeast. J. Microencapsul. 27, 292–302 (2010)

M. Hosseini Nezhad, M.A. Hussain, M.L. Britz, Stress responses in probiotic Lactobacillus casei. Crit. Rev. Food Sci. Nutr. 55, 740–749 (2015)

K. Abdhul, M. Ganesh, S. Shanmughapriya, M. Kanagavel, K. Anbarasu, K. Natarajaseenivasan, Antioxidant activity of exopolysaccharide from probiotic strain Enterococcus faecium (BDU7) from Ngari. Int. J. Biol. Macromol. 70, 450–454 (2014)

A. Sohail, M.S. Turner, A. Coombes, T. Bostrom, B. Bhandari, Survivability of probiotics encapsulated in alginate gel microbeads using a novel impinging aerosols method. Int. J. Food Microbiol. 145, 162–168 (2011)

D. Guerin, J.C. Vuillemard, M. Subirade, Protection of bifidobacteria encapsulated in polysaccharide-protein gel beads against gastric juice and bile. J. Food Prot. 66, 2076–2084 (2003)

K. Feng, R.M. Huang, R.Q. Wu, Y.S. Wei, M.H. Zong, R.J. Linhardt, H. Wu, A novel route for double-layered encapsulation of probiotics with improved viability under adverse conditions. Food Chem. 310, 125977 (2020)

M. Afzaal, F. Saeed, M.U. Arshad, M.T. Nadeem, M. Saeed, T. Tufail, The effect of encapsulation on the stability of probiotic bacteria in ice cream and simulated gastrointestinal conditions. Probiotics Antimicrob Proteins. 11, 1348–1354 (2019)

W.K. Ding, N.P. Shah, Effect of various encapsulating materials on the stability of probiotic bacteria. J. Food Sci. 74, 100–107 (2009)

A.B. Shori, Microencapsulation improved probiotics survival during gastric transit. HAYATI J. Biosci. 24, 1–5 (2017)

P. Darjani, M.H. Nezhad, R. Kadkhodaee, E. Milani, Influence of prebiotic and coating materials on morphology and survival of a probiotic strain of Lactobacillus casei exposed to simulated gastrointestinal conditions. LWT Food Sci. Technol. 73, 162–167 (2016)

Q. Zou, J. Zhao, X. Liu, F. Tian, H. Zhang, H. Zhang, W. Chen, Microencapsulation of Bifidobacterium bifidum F-35 in reinforced alginate microspheres prepared by emulsification/internal gelation. Int. J. Food Sci. Technol. 46, 1672–1678 (2011)

B. Ismail, K.M. Nampoothiri, Exopolysaccharide production and prevention of syneresis in starch using encapsulated probiotic Lactobacillus plantarum. Food Technol. Biotechnol. 48, 484–489 (2010)

M. Afzaal, F. Saeed, H. Ateeq, A. Ahmed, A. Ahmad, T. Tufail, Z. Ismail, F.M. Anjum, Encapsulation of Bifidobacterium bifidum by internal gelation method to access the viability in cheddar cheese and under simulated gastrointestinal conditions. Food Sci. Nutr. 8, 1–9 (2020)

C. González-Ferrero, J.M. Irache, B. Marín-Calvo, L. Ortiz-Romero, R. Virto-Resano, C.J. González-Navarro, Encapsulation of probiotics in soybean protein-based microparticles preserves viable cell concentration in foods all along the production and storage processes. J. Microencapsul. 37, 242–253 (2020)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no relevant conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abedfar, A., Hosseininezhad, M., Sadeghi, A. et al. Comparative survival of exopolysaccharide encapsulated Lactobacillus plantarum and Pediococcus pentosaceus in simulated gastrointenstinal conditions and storage time. Food Measure 15, 594–603 (2021). https://doi.org/10.1007/s11694-020-00664-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00664-1