Abstract

We aimed to investigate the effect of high-oxygen modified atmosphere packaging (MAP) on cooked meat products with respect to tenderness, lipid oxidation, and microbial growth. Pork meat was boiled and packaged using air packaging, vacuum packaging, and high-oxygen MAP (80% O2 + 20% CO2, 80% O2 + 20% N2, and 80% O2 + 10% CO2 + 10% N2). The acid value, peroxide value, thiobarbituric acid value, and aerobic bacterial counts were monitored during a 15-day storage period at 4 °C. Among the five different types of packaging, MAP (80% O2 + 20% N2) showed the smallest increase in shear force (from 14.01 to 20.52 N) and the lowest aerobic bacterial count (3.68 lg CFU/g). Acid values were the lowest for MAP with 80% O2 + 20% N2 and air packaging after 15 days of storage. High-oxygen MAP with 80% O2 + 20% N2 is, therefore, recommended for packaging cooked meat.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

High-oxygen modified atmosphere packaging (MAP) can be defined as packaging of a perishable product in a modified atmosphere with a high-oxygen component (i.e., > 70% O2). High-oxygen MAP successfully enhances the shelf life of products, preserving their visual appearance and inhibiting anaerobic microbial growth [1, 2]. High-oxygen MAP has been used for packaging fresh fruits and vegetables as an alternative to low O2 (< 3%) packaging [3,4,5,6]. Because of consumer preference, a great deal of interest has been shown in the use of high-oxygen MAP for meat to prolong its shelf life and enhance the quality of products [7,8,9,10,11].

Pork is the most common meat consumed by the Chinese. There is an urgent need for improvement in product storage in the pork industry. Many researchers have studied effects of high-oxygen MAP on beef [7,8,9, 12, 13] and chilled as well as fresh pork [14,15,16]. High concentration of O2 can promote lipid oxidation [8] and affect tenderness and juiciness of meat [9, 15, 17]. Although high-oxygen MAP increases meat protein oxidation and crosslinking, it also inhibits the growth of fungi and anaerobic microorganisms [4]. Previous evidence has shown that meat color can be well maintained by high-oxygen MAP with 55 and 80% O2 [18, 19]. Currently, high-oxygen MAP has been widely studied for preserving fresh fruits, vegetables, and raw meat. However, reports on the effect of high-oxygen MAP on cooked pork are rare. Whether high-oxygen MAP is a preferable type of packaging for pork products in the Chinese meat industry needs to be determined.

Therefore, the purpose of this study was to determine the effect of high-oxygen MAP with 80% O2 on cooked meat products with respect to lipid oxidation and microbial growth and compare it with air and vacuum packaging. We anticipate that the results will provide a basis for the use of high-oxygen MAP in the Chinese meat industry.

Materials and methods

Raw materials and package

Pork meat was purchased from a local market. The raw meat was cut into pieces weighing 100 g followed by boiling in deionized water. Then, the pieces of meat were placed in a thermoforming propene polymer (PP) box for packaging with polyamide/polyethylene (PA/PE) composite films. The pieces of meat were classified into five batches and packaged under different conditions: air packaging, vacuum packaging, and high-oxygen MAP under three conditions [80% O2 + 20% CO2, 80% O2 + 20% nitrogen (N2), and 80% O2 + 10% CO2 + 10% N2]. High-oxygen MAP was performed using a DT-6DMAP machine (Wenzhou DaJiang Machinery Equipment Co., LTD, Wenzhou, China). All packaging was performed in accordance with commercial practices. The gas headspace to meat volume ratio was 3:1 (mL/g). After packaging, all samples were stored for 15 days in a refrigerator at 4 ± 1 °C and shear force, acid value, thiobarbituric acid (TBA), peroxide value and aerobic bacterial count of each samples were measured at 0, 3, 6, 9, 12, 15 days respectively. The same experiments were repeated for three times.

Determination of shear force

Shear force was determined using a digital meat tenderness meter (C-LM3B, Northeast Agricultural University, Harbin, China). A 3-cm-thick cutter with a 60° cutting edge was used for cutting meat with a shearing rate of 1 mm/s. Shear force was read from the screen. A lower shear force indicated higher tenderness.

Evaluation of the acid value

Meat was homogenized using a ZW-800G homogenizer (Wenzhou Vico Biological Equipment Co., LTD, Wenzhou, China). The homogenate (3 g) was collected in a conical flask and 50 mL of ethanol–ether reagent was added. After shaking for 1 h, 2–4 drops of 1% phenolphthalein in ethanol were added. The samples were titrated with potassium hydroxide solution (NaOH, 0.1 mol/L) till the color turned red for more than 30 s. The acid value was calculated using the following formula

where V represens the volume of NaOH in mL, C represents the concentration of NaOH in mol/L, and m represents the weight of the sample g.

Assessment of the peroxide value

The peroxide value was measured according to the national standard of People’s Republic of China (GB/T 5538-2005/ISO 3960: 2001): animal and vegetable fats and oils-determination of the peroxide value [20]. Briefly, 2 g of homogenized meat was mixed with 10 mL of trichloromethane in a conical flask. Then, 15 mL of acetic acid and 1 mL of saturated solution of potassium iodide were added followed by blending for 1 min. The flask was placed in the dark for 5 min, and then diluted with 75 mL of distilled water. Oxidation–reduction titration was performed with 0.05% starch solution as the titration indicator and 0.01 mol/L sodium thiosulfate solution as the standard. The peroxide value was calculated according to the following formula:

where V is the volume of sodium thiosulfate solution in mL, c is the concentration calibration of sodium thiosulfate in mol/L, and m is the weight of the sample in g.

Assay of thiobarbituric acid (TBA) values

TBA values were determined using a previously reported method [21]. Briefly, 10 g of meat sample was homogenized and transferred to a flask. A volume of 50 mL of 7.5% trichloroacetic acid (containing 0.1% ethylene diamine tetraacetic acid) was added and mixed for 30 min. The supernatant was filtered through a filter paper. Then, 5 mL of the supernatant was collected in a tube and 5 mL of 0.02 mol/L TBA solution was added. The tube was sealed using a plastic wrap and incubated at 90 °C for 40 min. After cooling for 1 h, the mixture was centrifuged at 1600 rpm/min for 5 min. The supernatant was mixed with 5 mL of chloroform. After standing for layering, the supernatant was used for determination of the absorbance at 532 and 600 nm using a spectrophotometer (T9, Beijing General Co., LTD, Beijing, China). The TBA value was calculated according to the following equation:

A 532 : absorbance at 532 nm, A 600 : absorbance at 600 nm.

Microbiological examination

Aerobic bacterial count was examined according to the national standard of People’s Republic of China (GB/T 5538-2005/ISO 3960: 2001): animal and vegetable fats and oils-determination of the peroxide value.

Statistical analysis

All the data were expressed as mean ± standard error of the mean (SEM). Analysis of variance was performed using the Origin 8.0 software (Origin Lab, Northampton, USA). Significance was tested using the least significant difference (LSD) method.

Results

Changes in tenderness during storage after different types of packaging

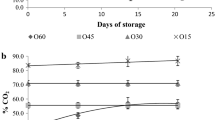

Tenderness of cooked meat after high-oxygen MAP was measured based on the shear force. The effect of high-oxygen MAP with different air components is shown in Fig. 1. After 15-day storage, shear force of all meat samples significantly increased compared with the samples at day 0 (P < 0.001). All meat samples had a significantly different shear force after different types of packaging at 3, 6, 9, 12, 15 days, separately (P < 0.001). After 15-day storage, all the packaging showed significantly higher shear force, compared with high oxygen MAP with 80% O2 + 20% N2 packaging (all P < 0.001). Aging after high-oxygen MAP with 80% O2 + 20% N2 caused the lowest increase in shear force (from 14.01 ± 1.12 to 20.52 ± 1.37 N), while aging after air packaging caused a significant increase in shear force (from 14.55 ± 1.21 to 38.21 ± 1.03 N) (P < 0.001). All meat samples showed a rapid increase in shear force at day 9 following storage.

Changes in the peroxide value during storage after different types of packaging

To investigate the degree of oxidation and rancidity of cooked meat after different types of packaging, we evaluated the peroxide value of meat samples. Changes in the peroxide value of meat samples after different types of packaging are illustrated in Fig. 2. All meat samples had a significant increase in the peroxide value after 15 days of storage (P < 0.001). Meat samples in various packaging showed significantly different peroxide values at day 3, 6, 9, 12, 15, respectively (P < 0.001). Meat samples after vacuum packaging (5.26 ± 0.36 meq/kg) and high-oxygen MAP with 20% CO2 (6.31 ± 0.37 meq/kg) showed the lowest peroxide value (P < 0.001), with a slight increase in the peroxide value at day 6 of storage, whereas meat samples after high-oxygen MAP with 20% N2 had a rapid increase in the peroxide value.

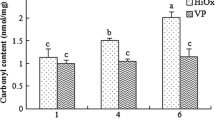

Changes in the acid value during storage after different types of packaging

As shown in Fig. 3, all meat samples showed a similar increasing trend in the acid value after different types of packaging. The meat samples showed significantly different acid values among various packaging at day 6, 9, 12, 15 storage (all P < 0.01). After 6 days of storage, the lowest increase in the acid value was observed in meat after air packaging (from 1.65 ± 0.18 to 4.33 ± 0.16 mg/g). There was a slight increase in the acid value of meat samples after MAP with 80% O2 + 20% CO2, MAP with 80% O2 + 10% CO2 + 10% N2, and MAP with 80% O2 + 20% N2 within 6 days, whereas a remarkable increase was observed after 9 days of storage. At 15-day storage, high oxygen MAPs with 80% O2 + 20% CO2, 80% O2 + 10% CO2 + 10% N2 and vacuum packaging showed significantly higher acid values than air packaging (all P < 0.01), while there was no significant difference between 80% O2 + 20% N2 and air packaging (P = 0.104). Meat after high-oxygen MAP with 80% O2 + 20% CO2 showed the highest acid value (5.53 ± 0.13 mg/g) compared with meat after other high-oxygen MAPs after 15 days of storage (P < 0.001).

Changes in TBA values during storage after different types of packaging

All meat samples showed a significant increase in the TBA value after different types of packaging (Fig. 4). TBA values were significantly different among different packaging types at 3, 6, 9, 12, 15 days, separately. At the end of storage, the TBA value of meat after vacuum package was the lowest among all packaging (1.38 ± 0.14 mg/kg, P < 0.001). Among all types of packaging, high-oxygen MAP and air packaging caused a prominent increase in the TBA value. Meat after MAP with 80% O2 + 10% CO2 + 10% N2 had the highest TBA value (3.54 ± 0.15 mg/kg).

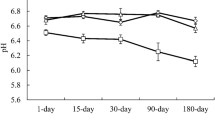

Changes in aerobic bacterial counts during storage after different types of packaging

Aerobic bacterial count is an indicator of food spoilage, and thus, we analyzed the bacterial count in the packaged meat samples at different time points. The aerobic bacterial count showed a similar increasing trend with a longer storage time (Fig. 5). Meat samples after high-oxygen MAP with different air components had a relatively low aerobic bacterial count. Air packaging resulted in the highest aerobic bacterial count (5.16 ± 0.043 lg CFU/g) in cooked meat (P < 0.001), whereas MAP with 80% O2 + 20% N2 showed the lowest aerobic bacterial count (3.68 ± 0.047 lg CFU/g) after 15 days of storage.

Discussion

High-oxygen MAP has been proposed to be a promising alternative for packaging fresh vegetables, fruits, and raw beef. However, the effect of high-oxygen MAP on cooked meat products has not been clearly investigated. In the present study, we varied air components of high-oxygen MAP, except for 80% O2, and investigated the effect on tenderness, lipid oxidation, and microbial growth of packaged meat.

Meat packaging has been widely studied for maintaining the quality of meat. Bouma et al. identified extractable substances from rubber nettings for meat product packaging [22]. However, several extracted substances are not allowed to come into contact with food because they may pose a risk to public health. Thus, this packaging method has not been widely developed. Recently, MAP has been extensively studied for meat product packaging. The modified atmosphere system includes a vacuum for cured or cooked meat, a gaseous atmosphere (anoxic) for raw and processed meat, and a gaseous atmosphere (with > 50% O2) for raw meat. Compared with the purple color of meat in low O2, vacuum or anoxic MAP with high O2 (> 40%) retained the pink–red color of meat. Microbial growth was low after low O2, vacuum, or anoxic MAP, whereas high microbial growth was observed after MAP with ambient O2 (15–20%) and medium microbial growth was observed after MAP with high O2 (> 40%) [1]. Consistent findings were reported by Jakobsen et al. who suggested that, during a 10-day storage, fresh beef muscle maintained a good color after MAP with 55–80% O2 [19]. Meat color is one of the main concerns in the meat industry. However, the effect of high-oxygen MAP on cooked meat has not been clearly studied.

Tenderness of meat refers to the state of being easily masticated, broken, or cut and can be measured by shear force [23]. It is closely correlated with the sensory quality of cooked meat products [24]. Figure 1 shows the increase in shear force with the time of storage for all types of packaging. This tendency was less pronounced after MAP with N2 component, which suggested that tenderness decreased in a time-dependent manner and MAP with N2 component maintained tenderness. Among the high-oxygen MAP groups, MAP with 80% O2 + 20% N2 showed the lowest increase in shear force, which suggests that a higher concentration of N2 in MAP is advantageous for maintaining tenderness of cooked meat. A previous study suggested that compared with vacuum packaging, high-oxygen MAP reduced tenderness of beef steaks [25]. This may be attributed to the fact that protein oxidation and protein cross-linking under high-oxygen atmosphere affects tenderness of meat under storage [15]. Thus, we speculated that high concentration of N2 under storage balances the effect of high-oxygen on meat.

The peroxide value is used to indicate the degree of oxidation and rancidity of cooked meat [26], serving as an index of change in the food quality of cooked meat products during storage. The peroxide value increased with the period of storage for different types of packaging. The peroxide value serves as a marker for primary lipid peroxidation [27]. Previous evidences has shown that high concentration of oxygen can increase lipid oxidation and rancidity in meat products [28, 29]. This is in accordance with our results, where a slight increase in the peroxide value was observed after a 15-day storage after air packaging compared with that after high-oxygen MAP with a N2 atmosphere. However, vacuum packaging and MAP with 80% O2 + 20% CO2 groups showed a relatively lower increase in the peroxide value than other groups and there was no significant difference between these two groups. We can speculate that the CO2 atmosphere in high-oxygen MAP shows an inhibitory effect on lipid oxidation.

The acid value is another indicator of the degree of rancidity of food [30]. The acid value is closely related to the concentration of free fatty acids during hydrolysis of cooked meat products. As shown in Fig. 3, there was a slight increase in the acid value (< 3 mg/g) for the air packaging and MAP with 80% O2 + 20% CO2, MAP with 80% O2 + 10% CO2 + 10% N2, and MAP with 80% O2 + 20% N2 groups at day 6 of storage, whereas the acid value markedly increased after 9 days of storage. The possible explanation for this phenomenon is that increased amount of free fatty acids, generated during hydrolysis of meat, contributes to the development of an acidic environment, which in turn promotes the process of hydrolysis and increase in the acid value. This hypothesis can be proven by the changes in the acid value after MAP with 80% O2 + 20% CO2 group. Our data showed that the MAP with 80% O2 + 20% CO2 group had a higher acid value after 15 days of storage than the MAP with 80% O2 + 10% CO2 + 10% N2 and MAP with 80% O2 + 20% N2 groups, indicating that a higher concentration of CO2 may contribute to the development of an acidic environment and promote an increase in the acid value. In addition, there was a linear increase in the acid value after vacuum packaging during the 15 days of storage and this increase was higher than that for other groups. However, the acid value in the air packaging group was relatively lower than that in other groups. There was no direct relationship between the acid value and oxygen content.

TBA is the second breakdown product of lipid oxidation, and the TBA value indicates the degree of lipid oxidation [31]. Our data showed that there is a significant increase in the TBA value in all packaging groups with a longer storage period. There was a similar increasing trend in the TBA value for high-oxygen MAP groups. MAP with 80% O2 + 10% CO2 + 10% N2 group showed a higher TBA value than MAP with 80% O2 + 20% N2 and MAP with 80% O2 + 20% CO2 groups. There was no obvious difference among air packaging, MAP with 80% O2 + 20% N2, and MAP with 80% O2 + 20% CO2 groups. The vacuum packaging group showed the lowest TBA value among different types of packaging groups. Thus, vacuum packaging may be the optimal type of storage with a respect to the TBA value.

Microbial spoilage is one of the primary parameters for evaluating the quality of food [32]. The remaining bacterial load in meat after incomplete processing can contribute to the meat spoilage. At the same time, processing and storage will eventually introduce microbial contamination [32]. Microorganisms consume nutrients in cooked meat products and produce adverse metabolic products, leading to a decline in the nutritional quality of cooked meat products. In addition, microbial metabolic processes may also affect the acid value and sensory quality of cooked meat products. Therefore, microorganisms play a critical role in the preservation of meat products.

Our data also indicated that the aerobic bacterial count increases with the longer storage period for all groups. The air packaging group showed the highest bacterial count, reaching 5.16 log (CFU/g) at day 15 of storage. The MAP groups had a lower aerobic bacterial count than air and vacuum packaging groups, and the MAP with 80% O2 + 20% N2 group showed the lowest aerobic bacterial count, which suggests that the high-oxygen MAP inhibits the growth of microorganisms. It is possible that the high-oxygen environment suppresses the growth of anaerobic bacteria in cooked meat. In addition, aerobic bacterial count increased with an increase in the CO2 concentration in the MAP system, but it was still lower than that in the air packaging group. These results indicate that high-oxygen MAP has a more inhibitory effect on microbial growth than vacuum and air packaging, and MAP with 80% O2 + 20% N2 shows the optimum effect.

The calculation methods for the acid value [33, 34] and TBA value [35, 36] have been widely applied for measuring food quality. All data were measured repetitively, and data for the same index were found to be similar. The above-mentioned results showed the repeatability and reproducibility of the methods used in this study. However, here we simply measured the aerobic bacterial count but did not determine the kind of bacteria that had a higher influence on the quality of the sample. This is a limitation of this study, and further research is warranted in the near future.

In this paper, we just measured the changes in shear force, acid value, TBA, peroxide value and aerobic bacterial count of meat samples under different types of packaging. In order to improve the MAPs in cooked meat packaging, the following aspects should be further studied. The dominant spoilage bacteria in MAPs should be identified and the changes in microbial community structure in meat packaging should be monitored, which could contribute to understanding the color changes of meat samples. Whether antioxidant can be used in the high oxygen MAP to prevent protein and fat oxidation should be solved in the future. A large number of studies about the application of high oxygen MAP in cooked meat package are warranted in the near future.

Conclusions

Compared with air and vacuum packaging, high-oxygen MAP with 80% O2 + 20% N2 shows obvious advantages in preserving tenderness and inhibiting microbial contamination of cooked meat. Although high-oxygen MAP has not shown a significant advantage with respect to preventing lipid oxidation, it has a comparable effect on peroxide and acid values. High-oxygen MAP with 80% O2 and 20% N2 may be more appropriate for cooked pork storage. However, the use of high-oxygen MAP in the meat industry still has a long way to go.

References

K.W. McMillin, Where is MAP going? A review and future potential of modified atmosphere packaging for meat. Meat Sci. 80(1), 43–65 (2008)

S. Eilert, New packaging technologies for the 21st century. Meat Sci. 71(1), 122–127 (2005)

B. Day, High oxygen modified atmosphere packaging for fresh prepared produce. (Postharvest News and Information, UK, 1996)

L. Jacxsens, F. Devlieghere, C. Van der Steen, J. Debevere, Effect of high oxygen modified atmosphere packaging on microbial growth and sensorial qualities of fresh-cut produce. Int. J. Food Microbiol. 71(2), 197–210 (2001)

D. Zagory, A.A. Kader, Modified atmosphere packaging of fresh produce. Food Technol. 42(9), 70–77 (1988)

O.J. Caleb, P.V. Mahajan, FA-J Al-Said, U.L. Opara, Modified atmosphere packaging technology of fresh and fresh-cut produce and the microbial consequences—a review. Food Bioprocess Tech. 6(2), 303–329 (2013)

K. Murphy, M. O’Grady, J. Kerry, Effect of varying the gas headspace to meat ratio on the quality and shelf-life of beef steaks packaged in high oxygen modified atmosphere packs. Meat Sci. 94(4), 447–454 (2013)

V.C. Resconi, A. Escudero, J.A. Beltrán, J.L. Olleta, C. Sañudo, M. Campo, Color, lipid oxidation, sensory quality, and aroma compounds of beef steaks displayed under different levels of oxygen in a modified atmosphere package. J. Food Sci. 77(1), S10–S18 (2012)

M. Vitale, M. Pérez-Juan, E. Lloret, J. Arnau, C. Realini, Effect of aging time in vacuum on tenderness, and color and lipid stability of beef from mature cows during display in high oxygen atmosphere package. Meat Sci. 96(1), 270–277 (2014)

X. Li, G. Lindahl, G. Zamaratskaia, K. Lundström, Influence of vacuum skin packaging on color stability of beef longissimus lumborum compared with vacuum and high-oxygen modified atmosphere packaging. Meat Sci. 92(4), 604–609 (2012)

J. Stoops, S. Ruyters, P. Busschaert, R. Spaepen, C. Verreth, J. Claes, B. Lievens, L. Van Campenhout, Bacterial community dynamics during cold storage of minced meat packaged under modified atmosphere and supplemented with different preservatives. Food Microbiol. 48, 192–199 (2015)

J.M. Lyte, J.F. Legako, J.N. Martin, L. Thompson, K. Surowiec, J. Brooks, Volatile compound characterization of modified atmosphere packaged ground beef held under temperature abuse. Food Control 59, 1–6 (2016)

M.G. O’Sullivan, S. Le Floch, J.P. Kerry, Resting of MAP (modified atmosphere packed) beef steaks prior to cooking and effects on consumer quality. Meat Sci. 101, 13–18 (2015)

E. Jääskeläinen, J. Hultman, J. Parshintsev, M.-L. Riekkola, J. Björkroth, Development of spoilage bacterial community and volatile compounds in chilled beef under vacuum or high oxygen atmospheres. Int. J. Food Microbiol. 223, 25–32 (2016)

P. Zakrys-Waliwander, M. O’sullivan, E. O’neill, J. Kerry, The effects of high oxygen modified atmosphere packaging on protein oxidation of bovine M. longissimus dorsi muscle during chilled storage. Food. Chem. 131(2), 527–532 (2012)

S. Jongberg, J. Wen, M.A. Tørngren, M.N. Lund, Effect of high-oxygen atmosphere packaging on oxidative stability and sensory quality of two chicken muscles during chill storage. Food Packag. Shelf Life 1(1), 38–48 (2014)

Y. Bao, P. Ertbjerg, Relationship between oxygen concentration, shear force and protein oxidation in modified atmosphere packaged pork. Meat Sci. 110, 174–179 (2015)

J.M. Behrends, W.B. Mikel, C.L. Armstrong, M.C. Newman, Color stability of semitendinosus, semimembranosus, and biceps femoris steaks packaged in a high-oxygen modified atmosphere. J. Anim. Sci. 81(9), 2230 (2003)

M. Jakobsen, G. Bertelsen, Colour stability and lipid oxidation of fresh beef. Development of a response surface model for predicting the effects of temperature, storage time, and modified atmosphere composition. Meat Sci. 54(1), 49 (2000)

General Administration of Quality Supervision IaQotPsRoCA, Standardization Administration of China Animal and vegetable fats and oils-determination of peroxide value. vol GB/T 5538–2005/ISO 3960: 2001. (Standardpress of China, Chinese, 2005)

V.C. Witte, G.F. Krause, M.E. Bailey, A new extraction method for determining 2-thiobarbituric acid values of pork and beef during storage. J Food Sci 35(5), 582–585 (1970)

K. Bouma, R.C. Schothorst, Identification of extractable substances from rubber nettings used to package meat products. Food Addit. Contam. 20(3), 300 (2003)

L.J. Bratzler, Measuring the tenderness of meat by means of a mechanical shear. An Acad. Bras Cienc 86(2), 633–648 (2010)

L. Vermeiren, F. Devlieghere, I. Vandekinderen, U. Rajtak, J. Debevere, The sensory acceptability of cooked meat products treated with a protective culture depends on glucose content and buffering capacity: A case study with Lactobacillus sakei 10A. Meat Sci. 74(3), 532–545 (2006)

P. Zakrys-Waliwander, M. O’sullivan, P. Allen, E. O’Neill, J. Kerry, Investigation of the effects of commercial carcass suspension (24 and 48 h) on meat quality in high oxygen modified atmosphere packed beef steaks during chill storage. Food research international 43(1), 277–284 (2010)

F. Shahidi, U.N. Wanasundara, C.C. Akoh, D.B. Min, Methods for measuring oxidative rancidity in fats and oils. Food Lipids: Chemistry, Nutrition and Biotechnology, (2002)

C.M. Messina, G. Bono, G. Renda, L. La Barbera, A. Santulli, Effect of natural antioxidants and modified atmosphere packaging in preventing lipid oxidation and increasing the shelf-life of common dolphinfish (Coryphaena hippurus) fillets. LWT Food Sci. Technol. 62(1), 271–277 (2015)

J.M. Cayuela, M.D. Gil, S. Bañón, M.D. Garrido, Effect of vacuum and modified atmosphere packaging on the quality of pork loin. Eur. Food Res. Technol. 219(4), 316–320 (2004)

F. Monahan, Oxidation of lipids in muscle foods: fundamental and applied concerns. Antioxidants in muscle foods. Nutritional strategies to improve quality. (Wiley, New York, 2000)

W. Vyncke, Direct determination of the thiobarbituric acid value in trichloracetic acid extracts of fish as a measure of oxidative rancidity. Chemische Revue über die Fett- und Harz-Industrie. 72(12), pp. 1084–1087 1969

R. Guillén-Sans, M. Guzmán-Chozas, The thiobarbituric acid (TBA) reaction in foods: a review. Crit. Rev. Food Sci. Nutr. 38(4), 315–350 (1998)

E. Caplice, G.F. Fitzgerald, Food fermentations: role of microorganisms in food production and preservation. Int. J. Food Microbiol. 50(1–2), 131–149 (1999)

Y. Rao, B. Xiang, X. Zhou, Z. Wang, S. Xie, J. Xu, Quantitative and qualitative determination of acid value of peanut oil using near-infrared spectrometry. J. Food Eng. 93(2), 249–252 (2009)

Z. Ying, Y. Lei, Y. Zu, X. Chen, F. Wang, L. Fang, Oxidative stability of sunflower oil supplemented with carnosic acid compared with synthetic antioxidants during accelerated storage. Food. Chem. 118(3), 656–662 (2010)

F. Liu, Q. Xu, R.T. Dai, Y.Y. Ni, Effects of natural antioxidants on colour stability, lipid oxidation and metmyoglobin reducing activity in raw beef patties. Acta Scientiarum Polonorum Technologia Alimentaria 14(1), 37 (2015)

W.J. Yan, J.Y. Cui, R.T. Dai, H.F. Wang, X.M. Li, Effects of dense phase carbon dioxide on quality and physical-chemical properties of chilled pork. Trans. Chin. Soc. Agric. Eng. 26(7), 346–350 (2010)

Funding

This study was supported by Major projects of natural science research in Universities of Jiangsu Province (13KJA550002) and sponsored by the Qing Lan Project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, W., Sun, Ye. & Ma, L. Effect of high-oxygen modified atmosphere packaging on the tenderness, lipid oxidation and microbial growth of cooked pork. Food Measure 12, 395–402 (2018). https://doi.org/10.1007/s11694-017-9652-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-017-9652-9