Abstract

The use of composite materials has increased lately and the need to know the behavior of these materials is very important once these devices are subject to suffer from damage such as cracks and delamination. Normally, to analyze failure problems in composite materials, the following steps are necessary: (1) structure geometry design, (2) numerical and/or experimental analysis and (3) use of failure criteria (e.g., Tsai–Wu failure criterion). If the used composite material has a non-expected failure criterion, the procedure must be repeated. In order to eliminate the procedure above, this study proposes the use of an artificial neural networks (ANN) inversion which can be used to determine an adequate configuration for the layers of the composite material from the desired failure criteria value. Numerical simulations, based on the finite element method, were made in order to create a database for ANN training and validation. After the inversion of the ANN, satisfactory results were obtained and this procedure could be used to minimize the high number of numerical simulations normally used in the design of a composite device.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Composite material has numerous benefits as low weight, high strength and rigidity. There are many industries using this type of material, and there are important previous studies on the behavior of this material mainly about the possible failures that can occur due to the conditions in which these types of materials are submitted.

About failure analysis, there are some criteria that are used to verify whether the material has or not failure. One of the most used is the Tsai–Wu failure criterion for anisotropic materials which can distinguish the tensile and compression strength using the concept of strength tensor [5].

The use of neural networks for analysis of composite materials has been applied over the last years with good results encouraging further study on this important topic [9].

As examples of use of artificial neural networks (ANN) in composite materials analysis, Brito Jr. et al. [1] used the technique of neural networks to predict the dynamic-mechanical behavior in a composite material used in the aviation industry and compared the numerical results with experimental ones. In the study presented by Selva et al. [17], the researches created a structural integrity monitoring method of composite plates reinforced with carbon fibers using the technique of neural networks to locate damage. In the study proposed by Velmurugan et al. [18], the technique of artificial neural networks to predict the loss of volume in the heat treatment of a metal matrix composite material is shown. The research presented by Fenza et al. [7] shows the use of artificial neural networks together with methods probability for detecting damage in composite plates using lamb waves. Mallela and Upadhyay [14] developed neural networks to predict the shear buckling load of laminated composite stiffened panels. Gomes et al. [8] used the technique of neural networks together with the genetic algorithm to analyze the failures in the carbon/epoxy composite material searching minimizes the maximum value of Tsai–Wu failure criterion.

In order to contribute with researches in the composite materials technology, this study presents numerical simulations, using finite element method (FEM), for a hollow tubular structure formed from a carbon/epoxy composite material. After the simulations, it was created a database, used in the ANN training and validation, which relates the layers orientation of the structure with the Tsai–Wu failure criterion. Using the database, an ANN inversion was proposed which relates the desired inputs (Tsai–Wu failure criteria) with calculated outputs from ANN that inform the final configuration of the laminate which can resist the load applied. Using this procedure, an ANN inversion, we hope to reduce the time when projecting an anisotropic material as a carbon/epoxy composite material with adequate safety margin.

Materials and Method

Tsai–Wu Failure Criterion for Composite Materials

The occurrence of a failure, due to various factors such as load, type of material, fibers orientation, etc., is sometimes dangerous, and a diagnose of the composite material before its production can generate many benefits.

Since the composite materials are anisotropic and their property depends on the fiber orientation, the Tsai–Wu failure criterion is totally applied to analyze this material. According to Voyiadjis and Kattan [19], this failure criterion is based on the total strain energy failure theory, where the failure occurs in the material if the following equation is violated:

where \(F_{11} ,F_{22} ,F_{66} ,F_{1} ,F_{2} ,F_{12}\) are the strength tensors and \(\sigma_{1} ,\sigma_{2} ,\tau_{12}\) are the normal stresses. According to Voyiadjis and Kattan [19], the strength tensors are obtained as follows:

Thus, an important characteristic of this failure theory, is that Tsai-Wu is able to distinguish the tensile and compressive strengths [10].

The Tsai–Wu failure criterion is one of the most used in research because of its simple computational implementation. According to Costa [4], it is considered as a relatively easy method of calculating the loads on the composite material structure.

Debski and Jonak [6] developed a study comparing the experimental and numerical results of thin-walled composite materials in relation to the problems of stability and the capacity to nonlinear loads. In numerical analysis were considered the Tsai–Wu failure criterion and the finite elements method. The results proved the efficiency of the Tsai–Wu failure criterion for failure analysis of a composite material.

In the search proposed by Koc et al. [11], an investigation about the behavior of the composite material under four-point bending was analyzed. In their study, some experiments and numerical analysis using the finite element method were made looking for a comparison in between supported rupture load in the simulations and the generated ones in the experiments. The authors report that the Tsai–Wu failure criterion demonstrated success in predicting the failure of the structure.

A composite structure is designed to support a given load, and the safety margin is considered the capacity of the structure that must support a given additional loading. When the structure is able to support this additional load, its safety margin is positive [2].

The safety margin used for the Tsai–Wu failure criterion according to Kolios and Proia [12] is obtained by the equation:

The SR as failure rate of the composite material is obtained by Tsai–Wu failure criteria using the following equation [12].

where a and b are calculated according to the strength tensors, and the normal stresses are obtained through calculating Tsai–Wu failure criterion. A negative safety margin indicates that the material will suffer failure. A positive number indicates that material proves to be safe and reliable.

Artificial Neural Networks

Since ANN are well fitted to reproduce causal relations, we can use these devices to map the desired output with the inputs of the system. Then, an ANN is developed to perform an inversion in the composite material design where the input of the neural network is the desired failure criterion, in this case the Tsai–Wu criterion, and its output is an adequate configuration for the layers of the composite material. According to Fig. 1, check a sketching of the ANN inversion.

The theory of neural network was firstly presented in 1940 by McCulloch and Pitts, and over the years this theory has been refined and began to gain prominence due to the advancement of technology [13]. According to Chong and Zak [3], artificial neural networks resemble the human brain, and they are formed by simple circuits constituted of interconnected neurons layers to each other by synaptic connections that have the function of spread information. Normally, the neural network consists of input layer that has the function of receiving information from the external environment, hidden layers that are responsible for extract the information provided by the input layers and do the processing and the output layer that transmits the processed response the hidden layers. The neurons in those layers have several inputs and only one output. The neurons are housed in groups according to the learning algorithm that has the function to identify the appropriate weights and make the necessary adjustment for the network to behave appropriately and can learn from examples [20].

In this study, we used a multilayer feedforward network with backpropagation training algorithm that has a supervised learning. The network is trained, and generated errors are transmitted to the previous layers until reach negligible values [9]. In addition, levenberg-marquardt and gradient descent (GDX) algorithm were used in the ANN architecture to promove the training phase correctly, as well a fast convergence rate.

Numerical Simulation

As there is the possibility of the appearance of failures in composite materials, it is essential to have some mechanism to predict these drawbacks before the material is produced. Normally, some tries are required in order to determine the final composition (e.g., layers orientations) in a composite material that determines the security requirements and reliability of the material.

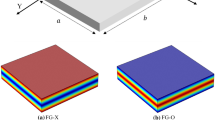

In this study, was used the finite element method (FEM) as a tool in the numerical simulations. The analyzed composite system is a hollow tubular cross section beam used in transtibial prostheses built of prepreg carbon/epoxy composite material. According to Table 1, check the beam dimensions.

In the structural analysis, we used the following properties of carbon/epoxy composite as is provided to Table 2.

In order to analyze the failure criterion by FEM, it is necessary to have other important properties of the composite material. The average values used were obtained by Martins [15] according to Table 3.

Using the data above, a free-clamped tubular beam was created using finite elements as shown in Fig. 2. We used a shell element type, and the beam was exposed to distributed compressive loads. The following intensity loads were applied (3000 N, 4480 N, 7500 N, 9000 N and 12,000 N), the fibers orientation in each layer varied in three values (0°, 45° and 90°), and it was considered laminates with three and six layers.

After the structural analyses were selected, the maximum value of failure criteria to each orientation and databases were created for artificial neural network training and validation.

Using the database, an ANN inversion was done allowing a fast and sensible analysis of the behavior of the composite material in a certain environment with adjustment in the laminate configuration.

Results and Discussion

In this study was separated approximately 5% of the values of each database for network validation, and the remaining data were used for training and simulation.

Equally important, backpropagation network was used as training architecture method. The stopping criterion was defined about the proposed number of steps when the algorithm reaches the desired minimum error or when the minimum gradient recommended is found.

After a few tries, the consistent neural network parameters (number of layers, number of neurons, etc.) were found and used in the numerical simulations.

Composite Material with Three Layers

In this first numerical simulation, we use an ANN with one input and one output. The input data were the value of the failure criterion, and output the orientation for a three-layer laminate. The general configuration of neural network is shown in Table 4.

After the training, the neural network presented a good consistence in the results and a small error in the failure criteria was analyzed. These good results are seen in Table 5.

According to Table 5, the orientations generated by the ANN were close to proposed ones (0°, 45° and 90°) and the obtained Tsai–Wu failure criterion from neural network was validated from a commercial finite element program shown consistency in the neural network results.

Figure 3 shows the maximum value of Tsai–Wu failure criterion for a material composite with three layers using numerical simulation.

The next application is about the use as input in the neural network both failure criteria and variable applied strength (3000 N, 4480 N, 7500 N, 9000 N and 12000 N). As neural network output was considered the layers orientation. The general configuration of neural network is seen in Table 6.

The results generated by the ANN are shown in Table 7. As shown in the last simulation, the results from neural network with two inputs were very consistent with values so close to ones obtained from commercial finite element program.

Figure 4 shows the maximum value of Tsai–Wu failure criterion for a material composite with three layers and strength 7500 N using numerical simulation (Table 7).

Composite Material with Six Layers

Neural networks for six layers were made considering one input and one output. The ANN had as input the value of the failure criterion and as output the orientation for a six-layer laminate. It is configured as follows.

Table 8 shows the results of simulations. We can see that the results from neural network were close to the expected Tsai–Wu failure criteria values, obtained from a commercial finite element program, showing the robustness of the adopted methodology.

Figure 5 shows the maximum value of Tsai–Wu failure criterion for a material composite with six layers using numerical simulation.

It is possible to see in Table 9 that the layers orientations obtained from neural network were very close to the expected values (0°, 45° and 90°).

Studies were performed about linear regression analysis of the data used in ANN in order to explore the relationship between the responses generated by the neural network with the data used for training and validation. Linear regression analysis is detailed in “Appendix.”

Conclusion

In this study, the artificial neural network was used in order to generate the appropriate hollow tubular structure formed from a carbon/epoxy composite material according to Tsai–Wu failure criterion. This failure criterion was used as input of the neural network, and the orientations of the final laminate were the output of the neural network. In this sense, the artificial neural network is developed to perform an inversion in the composite material design where the input of the neural network is the desired failure criterion.

The final orientations generated by neural networks were validated using a commercial finite element program in order to certify the robustness of the adopted methodology. Then, comparing these values of the failure criterion generated by the commercial finite element program with ones used as input in the neural network, it was possible to see that the values are shown very close generating a similar safety margin.

This study showed the feasibility of using neural networks for the study of composite materials. In addition, the study presented satisfactory and coherent results of the layup the CFRP laminated tube that comply with the desired safety factor.

Knowing which orientation of the composite material layers must have to provide certain safety margin becomes possible to produce more reliable and accurate structures. The procedure adopted here can reduce the number of experiments in the laminated composite material production and consequently save the time and materials.

References

C.A.R. Brito Jr., E.M. Bezerra, L.C. Pardini, A.C. Ancelotti Jr., M.S. Pereira, E. De Barros, L.R. De Carmargo, Redes neurais artificiais aplicadas para a predição do comportamento dinâmico-mecânico de compósitos de matriz epóxi reforçados com fibras de carbono. Mag. Mater. 12(2), 346–357 (2007)

F.C. Campbell, Structural Composite Materials (ASM International, Novelty, 2010)

E.K.P. Chong, S.H. Zak, An Introduction to Optimization (Wiley, Hoboken, 2001)

D.I.G. Costa, Análise numérica de falhas em materiais compósitos laminados usando um critério baseado em fenômenos físicos, Dissertations (Master in Engineering), State University of Campinas, Campinas, 2011

I.M. Daniel, O. Ishai, Engineering Mechanics of Composite Materials (Oxford University Press, New York, 1994)

H. Debski, J. Jonak, Failure analysis of thin-walled composite channel section columms. Compos. Struct. 132, 567–574 (2015)

A. Fenza, A. Sorrentino, P. Vitiello, Application of artificial neural networks and probability ellipse methods for damage detection using Lamb waves. Compos. Struct. 133, 390–403 (2015)

G.F. Gomes, C.A. Diniz, S.S. Cunha, A.C. Ancelotti, Design optimization of composite prosthetic tubes using GA-ANN algorithm considering Tsai–Wu failure criteria. J. Fail. Anal. Prev. 17(4), 740–749 (2017)

S. Haykin, Neural Networks and Learning Machines (Pearson, Hoboken, 2009)

A.K. Kaw, Mechanics of Composite Materials (CRC Press, Boca Raton, 2006)

M. Koc, F.O. Sonmez, N. Ersoy, K. Cinar, Failure behavior of composite laminates under four-point bending. J. Compos. Mater. 50(2), 1–19 (2016)

A.J. Kolios, S. Proia, Evaluation of the reliability performance of failure criteria for composite structures. World J. Mech. 2, 162–170 (2012)

Z.L. Kovács, Redes Neurais Artificiais: Fundamentos e Applicações (Academic, Sao Paulo, 1996)

U.K. Mallela, A. Upadhyay, Buckling load prediction of laminated composite stiffened panels subjected to in-plane shear using artificial neural networks. Thin Walled Struct. 102, 158–164 (2016)

A.T.D. Martins, Projeto e fabricação de tubos compósitos em fibras de carbono/epóxi pata próteses transtibiais por moldagem com bladder, Dissertations (Master in Engineering), Federal University of Itajubá, Itajubá, 2015

D.C. Montgomery, E.A. Peck, G.G. Vining, Introduction to Linear Regression Analysis (Wiley, Hoboken, 2012)

P. Selva, O. Cherrier, V. Budinger, F. Lachaud, J. Morlier, Smart monitoring of aeronautical composites plates based on electromechanical impedance measurements and artificial neural networks. Eng. Struct. 56, 794–804 (2013)

C. Velmurugan, V. Muthukumakan, K. Ragupathy, S. Ragunath, Modeling volume loss of heat treated AL 6061 composites using an artificial neural networks. Proc. Mater. Sci. 5, 31–40 (2014)

G.Z. Voyiadjis, P.I. Kattan, Mechanics of Composite Materials with Matlab (Springer, Berlin, 2005)

B. Yegnanarayana, Artificial Neural Networks (Prentice-Hall of India Private Limited, New Delhi, 2005)

Acknowledgments

The authors would like to acknowledge the financial support from the Brazilian agency CAPES – Coordenação de Aperfeiçoamento de Pessoal de Nível Superior.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

In order to verify the correlation between the data used in the ANN training and validation, a linear regression analysis was proposed. In this study were considered independent variables that are known orientations and the dependent variables that are the orientation generated by the network. The fit is measured by coefficient of determination (R2), that has its values \(0 \le R^{2} \le 1\), nearer on one the coefficient demonstrates that the variables clarify the regression model [16].

Regression analysis was made for the neural network with three layers and an input, three layers and two inputs and six layers and one input (Fig. 6).

Rights and permissions

About this article

Cite this article

Diniz, C.A., Cunha, S.S., Gomes, G.F. et al. Optimization of the Layers of Composite Materials from Neural Networks with Tsai–Wu Failure Criterion. J Fail. Anal. and Preven. 19, 709–715 (2019). https://doi.org/10.1007/s11668-019-00650-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00650-w