Abstract

This paper presents a groundbreaking strategy for optimizing composite laminate structures by integrating finite element modeling with a specialized multi-layer neural network. The neural network is trained on precise ground truth data obtained from rigorous finite element simulations, allowing it to discern intricate correlations among layer orientations, boundary conditions, and optimized designs. Tailored to the nuances of laminar composite optimization, the developed neural network emerges as a potent predictive tool, providing deep insights into the intricate interdependencies of design parameters. The study's findings hold immense promise for advancing materials design and structural engineering, highlighting the transformative potential of combining computational intelligence with traditional modeling approaches.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Engineered assemblages of composite laminates provide a flexible foundation for customizing mechanical properties according to specific requirements.[[1,2]] The design optimization of these laminates encompasses a multidimensional space involving considerations such as the number of layers, material selection for each layer, layer thickness, and stacking sequence.[[3,4]] While factors like the number of layers, material types, and thicknesses may be influenced by external constraints, the stacking sequence remains a critical parameter open to optimization. This study focuses on the systematic optimization of stacking sequences in composite laminates, aiming to minimize stresses within the structure under specified loading conditions. Additionally, by addressing the intricacies of stacking sequences, the research aims to pave the way for enhanced structural performance and durability in composite laminate.

Prior research has extensively addressed the optimization of composite laminates, often employing traditional optimization techniques like genetic algorithms and simulated annealing. These methodologies have been successful in exploring the design space, but their effectiveness can be limited when dealing with the intricate non-linearities inherent in composite materials.[[5,6]] Recent studies have begun incorporating computational intelligence, using metaheuristic algorithms and machine learning approaches to address these challenges. However, the specific application of generative deep-learning models for optimizing stacking sequences represents an innovative and promising frontier.[[7,8]] This paper builds upon this foundation, leveraging deep-learning capabilities to unlock new possibilities in optimizing stacking sequences for composite laminates and, consequently, advancing the field of material design for enhanced structural performance.[[9,10]] By embracing the cutting-edge realm of generative deep learning, the research aims to transcend the limitations of traditional optimization methods, offering a novel and effective approach to optimize stacking sequences for superior structural outcomes in composite laminates.

The presented example focuses on a laminate with a symmetric layup, using Carbon-Epoxy as the lamina material with orthotropic properties. The optimization analysis targets the determination of the optimal fiber orientation in each layer under specified loading conditions, with the primary objective of minimizing the maximum stress within the laminate. The optimization process employs the Bound Optimization BY Quadratic Approximations (BOBYQA) method, emphasizing the practicality and efficiency of the generative deep-learning approach in finding the optimum stacking sequence for enhanced structural performance.[[8,10]]

Materials and methods

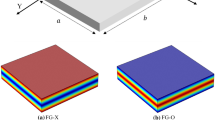

In this study, the ground truth data are generated through Finite Element Method (FEM) simulations, as depicted in Fig. 1. Figure 1(a) illustrates the model geometry of a composite laminate with a side length of 1 m and a thickness of 0.02 m. The simulation input encompasses boundary conditions, material properties, the number of layers, and the orientation of each layer. The simulation output is the optimized orientation of each layer, determined using the BOBYQA method. For illustration, Fig. 1(b), (c), and (d) presents von Mises stress, the initial orientation of fibers in each layer, and the optimized orientation in each layer, respectively. All boundary conditions are translated into a numerical vector using a preprocessor, achieved by representing them with digit numbers. The number of input nodes is fixed at 9. The input to the first node indicates the number of layers in the composite laminates (e.g., 6 for a laminar with 6 layers). The second to fifth nodes represent inputs of boundary conditions for each edge. Boundary conditions on the edge can be uniform distribution loads or bending moments, distinguished by adding an additional zero before the digits (e.g., 26 means \(26\,N/m\) uniform load while 260 means \(26N\cdot m\) bending moment). The sixth to ninth nodes denote the loads applied to the vertices. In this preliminary study, the value range of point loads or distribution loads is from − 50 to 50. The number of output nodes is adjusted based on the number of input layers which is a task easily accomplished in Python 3 by incorporating a loop to change the number of output nodes. Each ply of composite panel is assumed to be made of carbon fibers in an epoxy resin. The material properties for the given composite material are as follows: Young’s moduli (E1, E2, E3) are {134, 9.2, 9.2} GPa, shear moduli (G12, G23, G13) are {4.8, 4.8, 4.8} GPa, and Poisson's ratios (υ12, υ23, υ13) are {0.28, 0.28, 0.28}.

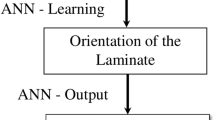

The flow chart of this study is detailed in Fig. 2(a). The adjustable MLP networks are demonstrated in Fig. 2(b). For the MLP, we employed a single input layer with 9 nodes, representing the number of layers and boundary conditions. The output of the MLP consists of orientation angle of layer in degrees. We adopted a straightforward architectural design, utilizing five layers with nine nodes in each layer. This simple architecture has proven effective in numerous studies and performed well during initial testing. In the training, we carefully tuned key parameters to ensure optimal model performance. The choice of an appropriate learning rate, often a critical factor in training deep-learning models, was set to 0.02, balancing the need for fast convergence with stability. A batch size of 500 was used, determining the number of data samples processed in each iteration, which played a significant role in optimizing training efficiency. The models were trained for 22 epochs, providing sufficient iterations to allow the model to learn the underlying patterns. Weight decay, set at 0.001, was employed to prevent overfitting. The rectified linear unit (ReLU) activation function was used in hidden layers, and the customized Mean-Squared Error (MSE) loss function was defined as follows:

where \(n\) represents the number of layers, \({\theta }_{i}\) indicates the predicted angle for each layer, and \(\widehat{{\theta }_{i}}\) represent the optimized angle for each layer from FEM simulation.

Results and discussion

Figure 3 depicts the average mean-squared errors (MSEs) for both training and validation graphs. The training loss exhibits a decreasing trend over epochs, suggesting the model's effective learning from the training data. Starting at approximately 0.5, it steadily declines and stabilizes around 0.05 after 12 training epochs. Similarly, the average validation loss initially decreases, reflecting the model's successful generalization to unseen data. It is common for the validation loss to be slightly higher than the training loss, as observed in the plot. Error bars in the graph represent the range of MSE curves for the 20 trials.

In Fig. 4, we randomly selected three sets of data from the test pool and performed a comparative analysis between the actual best design within each dataset and the optimized designs predicted by our trained models. The models demonstrate excellence in predicting orientation angles for each layer, with minimal differences between the ground truth data and predictions. The overall difference between the predicted and the angles form FEM is around 3%.

Conclusion

This paper presents an innovative approach to optimize composite laminate structures by integrating finite element modeling with a customized multi-layer neural network. The neural network is trained on ground truth data obtained from rigorous finite element simulations, enabling it to discern intricate correlations between layer orientations, boundary conditions, and resulting optimized designs. The study's outcomes offer significant promise for advancing materials design and structural engineering, highlighting the transformative potential of combining computational intelligence with traditional modeling techniques.

Data availability

The data will be available upon request from the corresponding author.

References

D. Liu, Y. Tang, W.L. Cong, A review of mechanical drilling for composite laminates. Compos. Struct. 94(4), 1265–1279 (2012)

L. Maio, P. Fromme, On ultrasound propagation in composite laminates: advances in numerical simulation. Prog. Aerosp. Sci. 129, 100791 (2022)

J. Cheng, Y. Xu, W. Zhang, W. Liu, A review on the multi-scale simulation of Z-pinned composite laminates. Compos. Struct. 295, 115834 (2022)

K. Kalita, S. Haldar, S. Chakraborty, A comprehensive review on high-fidelity and metamodel-based optimization of composite laminates. Arch. Comput. Methods Eng. 29(5), 3305–3340 (2022)

S. Li, W. Liu, Y. Mao, S. Hou, Numerical cross-scale optimization of homogenized composite laminates under impact loading. Int. J. Mech. Sci. 245, 108108 (2023)

K. Kalita, R.K. Ghadai, S. Chakraborty, A comparative study on the metaheuristic-based optimization of skew composite laminates. Eng. Comput. 38(4), 3549–3566 (2022)

S. Sang, Z. Wang, J. Fan, Particle swarm optimization for curved beams in multistable structures. J. Mech. Mater. Struct. 17(5), 441–453 (2023)

Q. Ren, X. Wang, S. Shi, Y. Ma, J. Wang, X. Ding, Structural static/fatigue/damage tolerance comprehensive design optimization of composite laminate. AIAA J. 60(2), 998–1012 (2022)

Y. Lu, L. Tong, Concurrent optimization of topologies and fiber orientations for laminated composite structures. Compos. Struct. 295, 115749 (2022)

J.B. Orsatelli, E. Paroissien, F. Lachaud, S. Schwartz, Bonded flush repairs for aerospace composite structures: A review on modelling strategies and application to repairs optimization, reliability and durability. Compos. Struct. 304, 116338 (2023)

Funding

No funding information available.

Author information

Authors and Affiliations

Contributions

XX: Writing—original draft, review & editing, Conceptualization, Formal analysis. JW: Writing—review & editing. Sheng Sang, Conceptualization.

Corresponding author

Ethics declarations

Conflict of interest

We hereby declare that we have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, X., Wei, J. & Sang, S. Enhancing composite laminate structures with tailored neural networks. MRS Communications 14, 345–349 (2024). https://doi.org/10.1557/s43579-024-00536-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-024-00536-5