Abstract

Physical and textural properties of mayonnaise prepared using virgin coconut oil (VCO)/fish oil (FO) blends at different ratios were examined in comparison with that prepared using soybean oil (SO) as affected by storage time (30 days). At day 0, sample prepared with SO showed the highest L*, a*, and b* values among all the samples, whereas the lowest values were noticeable for VCO containing sample. At day 30 of storage, decreases in L*, and b* values of all mayonnaise samples were observed (p < 0.05). However, a* values were increased at day 30 of storage (p < 0.05). For texture analysis, highest firmness, consistency and cohesiveness were obtained for the sample containing SO. Increasing levels of FO in VCO/FO samples increased the firmness, consistency and cohesiveness. For all the samples, loss modulus (G″) values were lower than G′. After 30 days of storage, all samples demonstrated slight decreases in G′ and viscosity than freshly prepared mayonnaise (day 0). When the sample containing VCO/FO (90:10) blend was further characterized, slight difference was observed in microscopic structure and droplet size distribution before and after storage of 30 days. Increase in droplet size was noticeable because of coalescence after the storage. Overall, type of oil used for preparation of mayonnaise as well as storage time affected the physical properties including textural and rheological properties of mayonnaise.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Virgin coconut oil (VCO) comprises medium chain fatty acids (MCFAs), mainly lauric acid [1]. On account of high oxidative stability as well as numerous health benefits, VCO has drawn attention from consumers and food manufacturers [2]. MCFAs are digested instantly after consumption and thus the body utilizes it promptly to produce energy, rather than depositing it as body fat [1]. Lauric acid is changed into monolaurin, which possesses antibacterial and antiviral activity [3]. Therefore, it is presumed that intake of VCO could support immune system. VCO is highly stable against lipid oxidation and hydrolytic activity ascertained by low free peroxide value and fatty acid content [1, 4].

Fish oil (FO) has been well known for health-promoting benefits. Therefore, health experts recommend a higher intake of fish oil rich in polyunsaturated fatty acids (PUFAs), mainly docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA) [5]. Dietary recommendations for EPA and DHA based on cardiovascular risk considerations for European adults are between 250 and 500 mg/day [6]. However, the current mean intake of EPA and DHA by adults is estimated to be about 244 mg/day [7]. Incorporation of PUFAs into foods can be of consumers’ health benefit [8]. Numerous studies have been done on incorporation of FO in mayonnaise. Hsieh and Regenstein [9] investigated the effect of temperature on the oxidation of FO mayonnaise. FO mayonnaise was more stable at refrigerated temperature (2 °C) than at higher temperature (30 °C). Hsieh and Regenstein [10] prepared mayonnaise containing 70% by weight of FO, corn oil or soya oil and found that storage stability of mayonnaise varied with oils used. Highest oxidation was found in FO containing mayonnaise after 4 week of storage and still increased up to week 8 at 30 °C. Since fish oil rich in PUFAs, antioxidant is still required to prevent oxidation. Nielsen et al. [11] prepared mayonnaise samples with 16% FO and 64% rapeseed oil (w/w) with addition of either lactoferrin (8–32 μM), phytic acid (16–124 μM), or EDTA (16–64 μM) and were stored at 20 °C for up to 4 weeks. EDTA was an effective metal chelator even at 16 μM, whereas phytic acid did not exert a distinct protective effect against oxidation. Mayonnaise is a widely consumed as desirable salad dressing due to its desired texture and flavor [12]. Therefore, incorporation of VCO in combination with FO could be a means to produce a functional mayonnaise for health benefits. The balance between saturated and unsaturated oil would achieve health promoting target. Different types of oil in mayonnaise may give different physical characteristics and rheological property, which might be changed over the storage time. Therefore, the present work was undertaken to incorporate VCO or VCO/FO blends at various ratios into mayonnaise. Physical properties including textural and rheological properties of resulting mayonnaises were examined in comparison with those prepared using soybean oil (SO) before and after 30 days of storage.

Materials and Methods

Chemicals

Nile blue A was procured from Sigma (St. Louis. MO, USA). Sodium dodecyl sulfate was purchased from Merck (Darmstadt, Germany). Soybean oil, salt, vinegar, sugar and eggs were bought from a local supermarket in Hat Yai, Songkhla, Thailand.

Preparation of VCO

For production of VCO, coconut milk was firstly hydrolyzed with partially purified seabass protease (10 units/ g protein) at 60 °C for 60 min followed by low speed centrifugation (3585 xg) to obtain cream. The cream was frozen at −20 °C for 6 h and then thawed at room temperature (30 ± 2 °C) for 1 h. Five freeze-thawing cycles were applied. Finally, cream was centrifuged at high speed (8000 xg) to obtain VCO.

Preparation of Depot Fat from Seabass Viscera

Whole viscera of seabass purchased from a local market in Hat Yai were placed in polyethylene bag. Ice was used to store the sample using an ice/sample ratio of 2:1 (w/w). Thereafter, samples were carried to the Department of Food Technology, Prince of Songkla University within 30 min. After arrival, depot fat from viscera was separated immediately from other internal organs such as stomach, liver, intestine and pyloric caeca. The depot fat was chopped with knife and ground with a blender (National, MX-T2GN, Taipei, Taiwan). The ground sample was subjected to oil extraction.

Extraction of Oil from Depot Fat

Visceral depot fat (100 g) was transferred into a round bottom flask equipped with a rotary evaporator (EYELA, N-1000, Tokyo Rikakikai, Co., Ltd., Tokyo, Japan). The extraction was performed at 70 °C for 20 min under vacuum. After extraction, oil was mixed with anhydrous sodium sulfate (approximately 3–4 g). The mixture was decanted into a centrifuge tube through a Whatman No. 4 filter paper. The filtrate was centrifuged at 10,000 xg for 20 min at 4 °C using a refrigerated centrifuge (CR22N, Hitachi, Hitachi Koki Co., Ltd., Tokyo, Japan). Pasteur pipette was used to collect oil. The oil sample was transferred to the amber bottles and purged with N2 gas. The amber bottles were capped tightly and stored at −40 °C until further use.

Preparation and Storage of Mayonnaise

Mayonnaise was produced following the method of Chotphruethipong [13]. Formulation (% on weight basis) included 8% fresh egg yolk, 4% vinegar, 1% salt, 14% sugar, 3% distilled water and 70% oil. For oil samples, VCO or VCO/FO blends with various VCO: FO ratios (95:5, 90:10, 85:15, v/v) were used. Soybean oil (SO) was used as the reference. Mayonnaise samples were designated as S: soybean oil (100%), V: VCO (100%), V-F5: VCO (95%) + FO (5%), V-F10: VCO (90%) + FO (10%), V-F15: VCO (85%) + FO (15%). All mayonnaise samples were kept in zip-lock bag and stored at 30 ± 2 °C in the incubator (Memmert, Schwabach, Germany).

Study on Physical and Textural Properties of Mayonnaise Containing Different Oils before and after 30 Days of Storage

All the mayonnaise samples were subjected to analyses after preparation. Another portion was kept at 30 ± 2 °C for 30 days and analyzed.

Color Determination

Color of oil samples (VCO, SO and FO) and mayonnaise samples was determined by a colorimeter (HunterLab, Model colourFlex, VA, USA). L*, a*, b* values, indicating lightness, redness/greenness, and yellowness/blueness, respectively, were recorded. Total difference in color (ΔE*) and the difference in chroma (ΔC*) were also calculated using following equations:

where ΔL*, Δa* and Δb* are the differences between the corresponding color parameter of the sample at day 0 and that of day 30.

(where) \( {\mathsf{C}}^{\ast }=\sqrt{{\left({\mathit{\mathsf{a}}}^{\ast}\right)}^{\mathsf{2}}+{\left({\mathit{\mathsf{b}}}^{\ast}\right)}^{\mathsf{2}}} \)

Texture Analysis

Firmness, consistency and cohesiveness of samples were evaluated using a texture analyzer TA-XT2 (Stable Micro Systems, UK) at 30 °C by back extrusion method according to the method of Fernandesa and de las Mercedes Salas-Mellado [14]. The samples were gently transferred into 150 mL cylindrical containers (80 mm height and 60 mm internal diameter) up to the 125 mL mark. A 35-mm diameter disc was applied for compression (Stable Micro Systems, UK). The applied cycle consisted of constant speed (1 mm/s), till reaching the 40 mm depth. From the force-time curve, firmness, consistency and cohesiveness were calculated. The ‘peak’ or maximum force is taken as a measurement of firmness. The area of the curve is taken as a measurement of consistency. The negative region of the graph, produced on probe return, considered as the maximum negative force is taken as an indication of the cohesiveness of the sample.

Measurement of Rheological Properties

The rheological property of mayonnaise samples was determined using a controlled stress rheometer (RheoStress RS 1, HAAKE, Karlsruhe, Germany) with parallel geometry (60 mm diameter, and 1 mm gap) as per the method of Huang, Wang, Han, Meng and Lu [15]. Strain sweep from 0.1 to 100% at 1.0 Hz fixed frequency was set to determine the linear viscoelastic range. A constant strain (0.5%), within the linear region and over a frequency range between 0.1 and 100 Hz, was applied to conduct frequency sweep. Samples were analyzed at temperature of 30 °C. The loss modulus (G′′) and storage modulus (G′) as a function of frequency were obtained [15]. Flow curves were determined using an increasing shear rate i.e., 1–100 s−1 within 2 min.

Characterization of Mayonnaise Containing VCO/FO (90:10) Blend before and after 30 Days of Storage

Mayonnaise was prepared using VCO/FO blend (90:10), named ‘V-F10’, which showed the sensorial property equivalent to S sample. The prepared sample was kept at 30 ± 2 °C for 30 days. Both samples, freshly prepared and stored for 30 days were subjected to the determination of microstructural, particle size, coalescence and flocculation.

Microstructure Analysis

The microstructures were determined with a confocal laser scanning microscope (CLSM) (Model FV300; Olympus, Tokyo, Japan.). Nile blue A solution was used to mix the samples and uniformity was obtained by manually stirring. The mixture was smeared on the microscopy slide. The CLMS in the fluorescence mode (emission wavelength: 630 nm; excitation wavelength: 533 nm) was used. For lipid analysis, a Helium Neon Red laser (HeNe-R) was applied.

Determination of Particle Size

Particle size distributions were determined using a laser particle size analyzer (LPSA) (Model LS 230, Beckman Coulter®, Fullerton, CA, USA) according to the method of Patil and Benjakul [16]. Prior to analysis, 1% (v/v) sodium dodecyl sulfate (SDS) solution (20 mL) was used to dilute the samples (1 g) and to dissociate the flocculated droplets. The volume-weighted mean particle diameter (d43) and the surface-weighted mean particle diameter (d32) of the emulsion droplets were measured.

Determination of Coalescence and Flocculation

Samples were firstly diluted with distilled water in the presence and absence of 1% SDS. The coalescence index (Ci) and flocculation index (Fi) were calculated using the following equations [17]:

where d43 + SDS and d43-SDS are the volume-weighted mean particle diameter of the emulsion droplets in the presence and absence of 1% SDS, respectively; d43 + SDS,in and d43 + SDS,t are the volume-weighted mean particle diameter of the emulsion droplets in the presence of 1% SDS at day 0 and the designated storage time (30 day).

Statistical Analysis

Experiments were carried out in triplicate using three different lots of samples. Analysis of variance (ANOVA) of data was done. Duncan’s multiple range test was used for mean comparison. For pair comparison, T-test was used [18]. Statistical analysis was performed using the Statistical Package for Social Science (SPSS 11.0 for windows, SPSS Inc., Chicago, IL, USA).

Results and Discussion

Physical and Textural Properties of Mayonnaise Containing Different Oils before and after 30 Days of Storage

Color

Lightness (L*), redness (a*), yellowness (b*), total color difference (ΔE*) and total chroma difference (ΔC*) of mayonnaises prepared using SO, VCO and VCO/FO blends at day 0 and day 30 of storage are presented in Table 1. At day 0, all mayonnaise samples showed different values for L* and b* (P < 0.05). S sample showed the highest L*, a* and b* value, whereas the lowest values were noticeable for V sample (p < 0.05). Differences in lightness might be due to varying light scattering among samples. Light absorption and scattering rely on the refractive index, concentration, size and dispersion of the droplets, also the presence of chromophoric materials [19]. Absorption is mainly responsible for chromaticness (redness, greenness, blueness, etc.), while scattering is mostly accountable for the turbidity, lightness, or opacity of an emulsion [19]. It was hypothesized that different lightness among mayonnaise samples at day 0 was most likely due to the differences in particles size and dispersion of droplets, which alter the light segregation. Egg yolk color was ascribed to yellowish fat-soluble carotenoids [20]. VCO is generally colorless and clear like water [1] and had L* 97.45, a* -1.31 and b* 0.90, whereas SO (L* 75.5, a* -1.66 and b* 7.90) and FO (L* 74.4, a* 1.08 and b* 9.60) had pale yellow color. SO and FO possessed some indigenous chromophores as indicated by higher b* value (yellowness) for mayonnaise prepared from SO and FO, compared to VCO containing mayonnaise sample. The difference was observed in b* values, when comparing among the samples containing VCO/FO blends (p < 0.05). The b* values were increased with increasing FO level in the blends. The results suggested that the presence of colorants in the SO, FO and egg yolk had the impact on the color of all mayonnaise samples.

After 30 days of storage, all mayonnaise samples showed the decreases in L* and b* values. On the other hand, a* values were increased after the storage. It was hypothesized that decreases in lightness (L*) values were probably owing to the increase in droplet sizes of the mayonnaise samples after the storage of 30 days. As a result, the scattering capability of the droplets was decreased. The beam of light possibly penetrate more inside the emulsion and was absorbed at a larger amount [21]. The b* values (yellowness) for all the mayonnaise samples were decreased, probably because of the oxidation of pigments, mainly carotenoids. This led to the paler color. Lennersten and Lingnert [22] reported that light at different wavelengths from 410 nm to 450 nm was able to degrade β-carotene in low-fat mayonnaise. Similar results were reported by Kupongsak and Sathitvorapojjana [23], in which L* and b* values of mayonnaise prepared using rice bran oil/coconut oil blend were decreased throughout the storage of 4 weeks at 30 °C. On the other hand, the increase in a* values (redness) plausibly was associated with lipid oxidation products generated during storage, which might serve as the source of carbonyl compounds for non-enzymatic browning [24]. These led to the development of the browner color. The presence of secondary oxidation products (e.g., aldehydes) has been proposed as index of browning [24]. Total differences in color (ΔE*) and the difference in chroma (ΔC*) after the storage of 30 days in all the mayonnaise samples are reported in Table 1. Coloring compounds were possibly degraded or generated during the storage of 30 days. Lowest ΔE* values were observed for VCO containing mayonnaise sample (p < 0.05). For ΔC*, no difference was observed between mayonnaise samples containing VCO and VCO/FO blends (p > 0.05). The results indicated that type of oil used for preparation of mayonnaise could affect the color before and after storage of 30 days at 30 °C.

Textural Property

Textural properties of mayonnaise prepared using SO, VCO and VCO/FO blends at day 0 and day 30 of storage are presented in Table 2. At day 0, mayonnaise containing VCO showed lowest firmness value when compared with other samples (p < 0.05). Firmness is an index of resistance to penetration by a probe and higher value is obtained as the force required for penetration increases [14]. Firmness values were increased with increasing levels of FO in VCO/FO blends. V-F15 showed higher value, compared to V-F5 and V-F10 (p < 0.05). Kupongsak and Sathitvorapojjana [23] also reported that firmness values were increased with increasing level of rice bran oil (unsaturated fatty acids) in mayonnaise prepared using various ratios of rice bran oil/ coconut oil blends (0:100, 10:90, 20:80, 30:70 and 40:60, v/v). No difference was observed between the S and V-F15 samples (p > 0.05). Oil droplets surrounded by proteins became linked together in a network-structure. This probably increased the firmness of mayonnaise. Physicochemical properties and composition of oil in the dispersed phase generally affect the size of droplet generated during homogenization [25]. The consistency showed the similar tendencies to the firmness. Highest consistency was observed for S samples, when compared to all mayonnaise samples. S sample exhibited the highest negative value, compared with other samples (p < 0.05). More negative cohesiveness value indicated more sticky sample [26]. Generally, different oil types can change the ratio of viscosity between continuous and dispersed phase, that further governs the minimum size of droplet. However, the viscosity of the samples can partially but not totally reflects the texture parameters [26].

The firmness and consistency of all mayonnaise samples decreased after storage of 30 days (p < 0.05) (Table 2). Cohesiveness had the less negative value. The oil droplets more likely coalesced and turned to the larger droplets, as the storage time was extended. An increase in the size of droplet was related to a decrease in droplets number per unit volume of the emulsion [27]. As a result, the droplets become less resistant to flow and more mobile [23]. Different types of oil used for preparation of mayonnaise could therefore affect the overall textural properties of resulting mayonnaise.

Viscoelastic Properties

Viscoelastic properties of the mayonnaises prepared using SO, VCO and VCO/FO blends with various ratios expressed as loss modulus (G′′) and storage modulus (G′) are depicted in Fig. 1. A linear viscoelastic response was observed in all mayonnaise samples. For all the samples, loss modulus (G″) values were lower than G′, indicating a dominant elastic behavior than viscous behavior. The experimental linearity of the moduli indicated that mayonnaise may be considered as gel-like network in the frequency range of 0.1–100 Hz [28]. This is a general behavior for concentrated emulsion as previously documented for commercial mayonnaise [29, 30]. Mayonnaise is protein-stabilized emulsion and a small region where a plateau is observed is generally ascribed to the development of a pseudo-gel network because of entanglements between protein segments adsorbed at the oil–water interface of the neighboring droplets [31]. The G′ values for all mayonnaise samples were increased with increasing frequency. The G′ values are increased at high frequency because of strong interactions between the droplets that contribute to the elastic modulus, which needs a long time to relax [31]. At day 0, slight differences in G′ values were observed among all mayonnaise samples (Fig. 1 A). S sample showed slightly higher G′ than the others. Higher G′ indicated that higher stresses are required to cause the emulsion to flow [31]. This might be owing to strong interactions of droplets in mayonnaise. G′ values were increased in VCO/FO blends samples with increasing level of FO in mayonnaise. Generally, saturation degree and the chain length of the oil can change the ratio of viscosity between continuous and dispersed phase, that further governs the minimum size of droplet. Decrease in droplet size reduces the interfacial tension. Therefore, the saturation degree and the chain length of the oil phase partially affected the interfacial tension [32]. The ability to produce an emulsion containing small droplets might be dependent on the nature of the oil used such as FO or VCO. As a result, the size and dispersion of oil droplets could affect a network or structure of mayonnaise.

Storage modulus (G′) (a, c) and loss modulus (G′′) (b, d) values (in log) of frequency sweep of mayonnaise containing different oils before (a, b) and after (c, d) 30 days of storage. S: mayonnaise containing soybean oil, V: mayonnaise containing virgin coconut oil, V-F5: mayonnaise containing VCO (95%) + fish oil (5%), V-F10: mayonnaise containing VCO (90%) + fish oil (10%), V-F15: mayonnaise containing VCO (85%) + fish oil (15%)

After 30 days of storage, all mayonnaise samples showed a slight decrease in G′ value than freshly prepared mayonnaise (day 0) (Fig. 1 c). This suggested that the mayonnaise samples were less elastic after storage of 30 days at 30 °C. Generally, low G′ indicates that low stresses are required for the sample to flow, suggesting a more liquid-like behavior plausibly due to less compact structure [33]. The decrease in rheological properties was more likely due to structural rearrangement of oil droplets after 30 days of storage. Therefore, a weaker network between the droplets was formed. The characteristic flocculated network of a dense emulsion (i.e., high volume fraction of the oil phase) results in eventual coalescence which results in larger particles with more voids, a less tight network after 30 days of storage. Long time contact between droplets could lead to coalescence [25]. The results were in agreement with texture properties, where the firmness and consistency were decreased. S sample showed the highest G′ with the highest textural properties. Oil used affected rheological property of all mayonnaise samples before and after storage of 30 days.

Flow Behaviour

Viscosity

Viscosity of mayonnaise samples as a function of the shear rate is shown in Fig. 2. The viscosity of all samples decreased as the applied shear rate increased, representing a similar shear-thinning behavior. Flocculation of adjacent oil droplets forms a gel network in mayonnaise [34]. The flocs are disrupted during shearing. As a result, viscosity was reduced. After a sharp reduction, the viscosity became flattened at high shear rates. All samples showed similar pattern.

Viscosity versus shear rate rheograms of mayonnaise containing different oils before (a) and after (b) 30 days of storage. S: mayonnaise containing soybean oil, V: mayonnaise containing virgin coconut oil, V-F5: mayonnaise containing VCO (95%) + fish oil (5%), V-F10: mayonnaise containing VCO (90%) + fish oil (10%), V-F15: mayonnaise containing VCO (85%) + fish oil (15%)

At day 0, slight difference was observed in viscosity properties of all mayonnaise samples (Fig. 2a). Higher viscosity was observed for S sample, whereas V sample showed the lower value. Viscosity of mayonnaises is mainly associated with close droplets packing, as they are connected in the matrix [34]. The closer the droplets, the higher the viscosity is attained as a results of the more interaction between droplets [35]. The results coincided with textural and viscoelastic properties, in which S sample had the highest firmness, consistency, cohesiveness and storage modulus (G′). Conversely, the lowest values were observed for V sample. Viscosity of mayonnaise prepared using palm kernel olein/soybean oil (PKO) blends was reported by Hayati, Man, Tan and Aini [31]. Higher concentration of saturated PKO yielded the resulting mayonnaise with the lower viscosity.

At day 30, the viscosity of all mayonnaise samples was decreased when compared to that found at day 0 (Fig. 2b). The degree of polydispersity and size of droplets mainly influenced the viscosity of concentrated emulsions [36]. The increase in size of droplets resulted in the decrease in droplet number per unit volume of the emulsion and the average droplets dispersion increases. Consequently, the droplets become less resistant to flow and more mobile as evidenced by the decreased viscosity.

Flow Curve

The flow curves of mayonnaise prepared using SO, VCO and VCO/FO blends at day 0 and day 30 are depicted in Fig. 3. Shear stress was increased with increasing shear rate for all the mayonnaise samples. Shear stress was dependent on shear rate. Thus, all mayonnaise samples exhibited non-Newtonian behavior. The results were in agreement with flow curve of mayonnaise prepared with soybean oil reported by Liu, Xu and Guo [26]. At day 0, the difference was observed in all mayonnaise samples (Fig. 3a). S sample showed higher shear stress, compared to other samples, regardless of shear rate. Viscosity is a ratio between shear stress and shear rate [37]. The higher shear stress of S sample might be due to the higher viscosity (Fig. 2a). Increase in shear stress was observed with increasing level of FO in VCO/FO blend. On the other hand, V sample showed the lowest shear stress associated with low viscosity of sample.

Flow curve of mayonnaise containing different oils before (a) and after (b) 30 days of storage. S: mayonnaise containing soybean oil, V: mayonnaise containing virgin coconut oil, V-F5: mayonnaise containing VCO (95%) + fish oil (5%), V-F10: mayonnaise containing VCO (90%) + fish oil (10%), V-F15: mayonnaise containing VCO (85%) + fish oil (15%)

At day 30, flow curves of all mayonnaise samples were decreased when compared to those found at the day 0 (Fig. 3b). The results indicated that the viscosity of all mayonnaise sample might be decreased after storage of 30 days. The high viscosity during chewing gives a desirable mouth feel, while the reduction in viscosity gives advantage during high-shear processing operations for example filling and pumping [38]. Thus, flow properties of all mayonnaise samples were affected by the storage time.

Characteristics of Mayonnaise Prepared Using VCO/FO (90:10) Blend before and after 30 Days of Storage

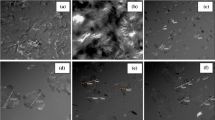

Microstructure

Microstructures of mayonnaise V-F10 sample were visualized by confocal laser scanning microscopy at day 0 and day 30 of storage at 30 °C (Fig. 4). Mayonnaise comprises oil droplets dispersed in an continuous phase [39]. Samples at day 0 and day 30 showed similar microstructure, in which uniform dispersion with close packing of oil droplets was observed. However, for both samples, slight difference was noted in the size of droplets. Smaller oil droplets were observed at day 0, whereas the slightly larger oil droplets were found after 30 days of storage. In a highly concentrated close packing emulsion such as the mayonnaise, an increase in size of droplet was plausibly due to coalescence of oil droplet [25]. Microstructure of mayonnaise prepared using soybean oil/palm kernel olein blends was not different in droplet size after storage for 30 days [31]. The results indicated that microstructure of mayonnaise V-F10 sample was altered with increasing storage time.

Particle Size

Particle size distribution of V-F10 mayonnaise sample at day 0 and day 30 is shown in Table 3. At day 0, V-F10 sample showed d32 of 3.56 ± 0.04 μm and d43 of 5.87 ± 0.09 μm. In mayonnaise, the stability of the oil–water interface is mostly because of the granular micro-particles generated from coalesced low-density lipoprotein and the phosphoprotein constituents of egg yolk. In high-fat product, the granules were able to separate the droplets and prevent them against coalescence [33]. d32 and d43 were increased after 30 days of storage from 3.56 ± 0.04 μm to 3.74 ± 0.15 μm and 5.87 ± 0.09 μm to 6.48 ± 0.15 μm, respectively. Droplet size was changed after the storage of 30 days. The obtained results were in line with microstructure (Fig. 4). The larger size of oil droplet was observed after 30 days of storage. Droplets surrounded by a film of emulsifier give physical stability to mayonnaise.

Coalescence and Flocculation

Coalescence index (Ci) and flocculation index (Fi) of V-F10 at day 0 and day 30 are shown in Table 3. After the storage of 30 days, Ci was 10.08 ± 1.50, suggesting that the coalescence happened in the sample to some extent. On the other hand, Fi was decreased after the 30 days of storage, indicating that individual droplets joined together to form larger droplet. The results were in accordance with droplet size distribution (Table 3), where d32 and d43 were increased as the storage time extended. In emulsion, the protective film formed by proteins around oil droplets gives stabilizing effect. As a result, the repulsive interactions (for example, electrostatic and steric) among the droplets are developed and prevent their coalescence [16]. With increasing storage time, coalescence was augmented, leading to the larger oil droplet. This was related with the changes in viscosity and rheological property of mayonnaise after the storage of 30 days.

Conclusion

Mayonnaise prepared using different types of oil showed differences in color and textural properties at storage day 0 and day 30. It was concluded that the presence of colorants in the SO and FO had the impact on the color of mayonnaise samples. Sample containing SO showed highest textural properties such as firmness, consistency and cohesiveness. Type of oil used to prepare mayonnaise also affected the rheological properties of all samples at storage day 0 and day 30. However, mayonnaise containing VCO/FO (90:10) blend also showed the property equivalent to that prepared using SO. The droplets size was slightly increased after 30 days of storage, associated with coalescence. Therefore, mayonnaise prepared using VCO/FO (90:10) blend could be prepared and had slight change after storage of 30 days at 30 °C.

References

U. Patil, S. Benjakul, T. Prodpran, T. Senphan, N. Cheetangdee, Carpath. J. Food Sci. Technol 8(4), 103–115 (2016)

E. Carandang, Indian Coconut J. Chochin 38(9), 8–12 (2008)

M. DebMandal, S. Mandal, Asian Pac J Trop Med 4(3), 241–247 (2011)

T. Senphan, S. Benjakul, Eur. J. Lipid Sci. Technol. 118(5), 761–769 (2015)

K. Hartvigsen, P. Lund, L.F. Hansen, G. Hølmer, J. Agric. Food Chem. 48(10), 4858–4867 (2000)

N. EFSA Panel on Dietetic Products and Allergies, EFSA J. 10(7), 2815 (2012)

D. Givens, R. Gibbs, Nutr. Bull. 31(2), 104–110 (2006)

S.G. Gorji, H.E. Smyth, M. Sharma, M. Fitzgerald, Trends Food Sci. Technol. 56, 88–102 (2016)

Y.T. Li Hsieh, J.M. Regenstein, J. Food Sci. 56(5), 1298–1301 (1991)

Y.-T.L. Hsieh, J.M. Regenstein, J. Aquat. Food Prod. T. 1(1), 97–106 (1992)

N.S. Nielsen, A. Petersen, A.S. Meyer, M. Timm-Heinrich, C. Jacobsen, J. Agric. Food Chem. 52(25), 7690–7699 (2004)

N.F. Rahmati, M.M. Tehrani, K. Daneshvar, A. Koocheki, Food Biophys. 10(1), 39–50 (2015)

L. Chotphruethipong, Prince of Songkla University, 2017

S.S. Fernandesa, M. de las Mercedes Salas-Mellado, Integr. Food. Nutr. Metab. 5(3), 1–4 (2018)

L. Huang, T. Wang, Z. Han, Y. Meng, X. Lu, Food Hydrocoll. 56, 311–317 (2016)

U. Patil, S. Benjakul, Food Hydrocoll. 69, 220–228 (2017)

M. Cermeño, M. Felix, A. Connolly, E. Brennan, B. Coffey, E. Ryan, R.J. FitzGerald, Food Hydrocoll. 88, 170–179 (2019)

R. Steel, J. Torrie, Principles and Practices of Statistics (McGraw Book Coy Inc, New York, USA, 1980)

D.J. McClements, Curr. Opin. Colloid Interface Sci. 7(5–6), 451–455 (2002)

E.C. Li-Chan, H.-O. Kim, In Egg bioscience and biotechnology (John Wiley and Sons Inc., New Jersey, 2008) pp. 1-96

W. Chantrapornchai, F. Clydesdale, D.J. McClements, Colloids Surf. A Physicochem. Eng. Asp. 155(2–3), 373–382 (1999)

M. Lennersten, H. Lingnert, LWT-Food Sci. Technol. 33(4), 253–260 (2000)

S. Kupongsak, S. Sathitvorapojjana, Pol. J. Food Nutr. Sci. 67(2), 107–116 (2017)

S.S. Bharate, S.B. Bharate, J. Food Sci. Tech. 51(10), 2271–2288 (2014)

D.J. McClements, Food emulsions: principles, practices, and techniques (CRC press, 2015)

H. Liu, X. Xu, S.D. Guo, LWT-Food Sci. Technol. 40(6), 946–954 (2007)

D.J. McClements, Langmuir 21(21), 9777–9785 (2005)

F. Mancini, L. Montanari, D. Peressini, P. Fantozzi, LWT-Food Sci. Technol. 35(6), 517–525 (2002)

L.B. Fomuso, M. Corredig, C.C. Akoh, J. Am. Oil Chem. Soc. 78(7), 771–774 (2001)

J. Moros, J. Franco, C. Gallegos, J. Am. Oil Chem. Soc. 79(8), 837–843 (2002)

I.N. Hayati, Y.B.C. Man, C.P. Tan, I.N. Aini, Food Res. Int. 40(8), 1051–1061 (2007)

C. Granger, P. Barey, N. Combe, P. Veschambre, M. Cansell, Colloids Surf. B Biointerfaces 32(4), 353–363 (2003)

M. Langton, E. Jordansson, A. Altskär, C. Sørensen, A.-M. Hermansson, Food Hydrocoll. 13(2), 113–125 (1999)

J. Depree, G. Savage, Trends Food Sci. Technol. 12(5–6), 157–163 (2001)

E. Dickinson, J. Chem. Soc. Faraday Trans. 94(12), 1657–1669 (1998)

R. Pal, Chem. Eng. J. 67(1), 37–44 (1997)

D. Izidoro, M.-R. Sierakowski, N. Waszczynskyj, C.W. Haminiuk, A. de Paula Scheer, Int. J. Food Eng. 3(1), 1–15 (2007)

D.L. Pyle, P.J. Fryer, C.D. Reilly, Chemical Engineering for the Food Industry (Springer Science & Business Media, Cambridge, UK, 2012)

S. Mun, Y.-L. Kim, C.-G. Kang, K.-H. Park, J.-Y. Shim, Y.-R. Kim, Int. J. Biol. Macromol. 44(5), 400–407 (2009)

Acknowledgements

This work was supported by the Thailand’s Education Hub for Southern Region of ASEAN Countries (TEH-AC, 2015) scholarship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patil, U., Benjakul, S. Physical and Textural Properties of Mayonnaise Prepared Using Virgin Coconut Oil/Fish Oil Blend. Food Biophysics 14, 260–268 (2019). https://doi.org/10.1007/s11483-019-09579-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-019-09579-x