Abstract

To investigate the effectiveness of different permeable bricks on the pollutants from urban rainfall runoff, three common used bricks (ceramic brick, cement brick, and steel slag brick) were selected and applied to study their decontamination performance. The influencing factors such as rainfall intensity and contaminant concentrations were investigated. Then the ultrapure water was used to wash the permeable brick to research the pollution status and cleaning characteristics by monitoring the water quality of the rinsing water. Suspended solids (SS), chemical oxygen demand (COD), ammonia nitrogen (NH4+-N), total nitrogen (TN), total phosphorus (TP), and heavy metals (Cu, Zn, Pb, and Cd) in the influent and effluent were measured. The results showed the following: (I) The upper layer of the brick may play a more critical role in purification process; the uniform and dense pore distribution of ceramic permeable brick was instrumental in the retention of particulates. (II) Contaminant concentration and rainfall intensity had a great influence on pollutants with lower removal rate and had little effect on pollutants with higher removal rate. (III) Non-sintered bricks containing a certain amount of cement increased the pH after filtration. (IV) The removal performance of permeable brick for dissolved pollutants such as COD, NH4-N, and TN was inferior to that for SS, TP, and heavy metals since the discrepancy in removal mechanism of pollutants. The study could offer a new perspective for the decontamination research of pervious bricks.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, permeable pavements have become one of the most frequently used low impact development (LID) techniques (Hernandez-Crespo et al. 2019; Liu et al. 2019; Rahman et al. 2015; Kia et al. 2019). This infiltration-based technology consists of structural layers with relatively high porosity to allow rainwater to pass through its surface and underlying layers, including a permeable pavement surface, aggregate subbases, and sometimes includes geotextiles and underdrains, and eventually infiltrate into the natural soil or discharge into a drainage system (Imran et al. 2013; Kuruppu et al. 2019; Chandrappa and Biligiri 2016).

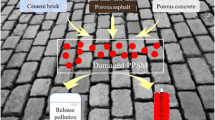

In addition to good hydrological effect in reducing runoff, delaying peak flow, increasing infiltration rate, and recharging the ground water (Rowe et al. 2010; Newman et al. 2014; Fassman and Blackbourn 2015; Collins et al. 2010; Brown and Borst 2014), permeable brick paving system (PPS) also exhibits a good decontamination potential in improving water quality (Boogaard and Lucke 2019; Chu and Fwa 2019; Drake et al. 2013; Jiang et al. 2015). Many scholars had researched the management performances of PPS. Fassman E A et al. found that the runoff reduction rate and flood peak reduction rate of PPS were 72% and 89% in the power clay circumstance, respectively (Fassman and Blackbourn 2015), while Collins K A et al. found that the runoff reduction rate and flood peak reduction rate of PPS were 38–66% and 60–77% in the clay circumstance (Collins et al. 2010). There were more researches on runoff rainwater quality for permeable pavement and showed that PPS were highly effective in the mitigation of pollutants in rainwater runoff; it not only removed suspended solids but also decreased total phosphorus and heavy metals (Boogaard and Lucke 2019; Chu and Fwa 2019; Drake et al. 2013; Jiang et al. 2015). For example, research has shown that suspended solids, total phosphorus, and lead can be decreased by up to 64%, 74.2%, and 79% (Legret et al. 1996).

At present, in China, except the bricks in which the infiltration of storm water is through open joints filled with clear aggregate, there are more and more applications of bricks that can infiltrate themselves (Lin et al. 2020; Lin et al. 2019; Yang et al. 2019). Obviously, the role of surface bricks is becoming more and more important. However, fewer researches focused on the surface layer of PPS, namely, the surface permeable brick. In fact, the effect of permeable brick on water purification was very significant. As the surface layer of PPS, the permeable brick was the first layer that contacts directly with the runoff. The characteristics of the brick would remarkably affect the runoff quality (Zhang et al. 2018; Li et al. 2017), especially for permeable bricks that can permeated. Li et al found the shale brick had a good removal effect on some pollutants in runoff (Li et al. 2017). Furthermore, the composition of the material in the brick itself would also directly affect the quality of the rainwater. Some permeable brick containing cement is alkaline in nature, and it released hydroxide ions and carbonate ion when in contact with rainwater which increase the pH of the effluent (Chandrappa and Biligiri 2016; Zhang et al. 2018). Researches showed that the pH values rapidly increased at first, followed by a gradual decrease and eventually stabilized at about 10.77 compared with 7.40 pH values of raw water for the cement brick (Zhang et al. 2018). The pollution status and cleaning characteristics of bricks had the greatest relationship to the overall removal rate of pollutants. Moreover, permeable bricks did not have the ability to self-purify, pollutants accumulated in the bricks as time increased. During a complete rainfall event, the pollutants trapped in the initial rainwater might be washed away in the middle and late stages of rainfall, causing secondary pollution of the environment. Hence, it is necessary to strengthen the research on surface permeable brick, especially in decontamination.

Nowadays, there are three common used permeable bricks in Jiangsu province, China, namely, steel slag permeable brick, ceramic permeable brick, and cement permeable brick. The processes and raw materials of the three permeable bricks were different. For instance, ceramic permeable brick was manufactured by sintering process, cement permeable brick and steel slag permeable brick were manufactured by pressure forming, and the raw materials for the latter two were cement and steel slag, which were very different in characteristic. Obviously, the performance of the brick was affected by the nature of the brick. Considering the different manufactured processes and raw materials, it is inevitable to investigate decontamination ability of three kinds of permeable bricks.

In this study, ceramic brick, cement brick, and steel slag brick were chosen to investigate the influencing factors on their decontamination ability such as rainfall intensity and contaminant concentration. The pollution status referred to the cumulative pollution inside the permeable brick, and cleaning characteristics referred to the pollutant discharge of the brick scoured by rainwater were further discussed. The objectives and novelties of this research were to explore the properties of brick and external rainfall factors on the decontamination ability of permeable bricks, which could offer a new perspective for the decontamination research of pervious bricks.

Materials and methods

Experimental setup

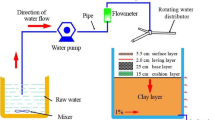

The test device for the permeable brick paving system was shown in Fig. 1. The dimensions of the device were 0.8 m × 0.8 m × 0.5 m. A total of 16 permeable bricks measuring 20 cm × 20 cm × 5.0 cm were placed in close proximity. A 10-mm-diameter outlet pipe was set at the bottom of the permeable brick system. An overflow pipe with a diameter of 10 mm was set at the top of the device.

The prepared rainwater was lifted by a water pump and evenly distributed by a rotating water distributor. The rainwater was sampled after passing through the ceramic permeable brick and the paving system. Samples were taken every 10 min for a total of 2 h, while the outlet pipe of the pavement had a stable outflow. The water sample was collected using a 500-mL polyethylene sampling bottle, and all samples were measured within 48 h.

Pervious brick

The three previous bricks measured 20 cm × 20 cm × 5.5 cm were purchased from Nanjing local building materials market. All the three bricks can be divided into two layers in a common configuration with small constituent materials located on the top and large materials located on the bottom, and the upper layer has a thickness of about 1.0 cm with relatively smaller diameter of the particle, and the lower layer is about 4.5 cm thick (Fig. 2a).

The related properties of three permeable bricks including permeability coefficient and porosity all meet the requirements of the Chinese national standard, permeable paving bricks, and permeable paving flags (GB/T 25993-2010). The main properties of three bricks are shown in Table 1.

Simulated rainfall

The simulated rainfall was carried out according to the situation in Suzhou, the test was based on the 2-h rainfall duration, and the rainfall intensity was altered by adjusting repetition period of rainfall of 5a, 20a, and 50a.

According to the existing monitoring data (Gong et al. 2019; Wang et al. 2019), the concentrations of various pollutants in the artificially prepared rainwater were shown in Table 2.

Characterization of the cleaning

In the cleaning process, The sample was taken every 5 min, and then the average concentration was calculated. The effluent removal rate was defined and calculated to characterize the flushing difficulty of pollutants, and the pollution status and cleaning characteristics of permeable brick.

where η is the effluent removal rate, percent; Ci is the concentration of influent of rainwater, milligram per liter; and Ce is the mean concentration of effluent of washing water, milligram per liter.

Test methods

According to the Chinese National Standard Methods (SEPA of China 2002), SS was determined by the gravimetric method (GB 11901-89); COD was determined by the fast digestion-spectrophotometric method (HJ/T 399-2007); concentrations of NH3-N, TN, and TP were determined by the spectrophotometric method; and concentrations of Zn, Cu, Pb, and Cd were determined by atomic absorption spectrophotometry. According to linear transverse winding test of Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete (ASTM C457), the chord size distribution was measured by using air void analyzer(Rapid air 457, Germany).

The main experimental equipment was as follows: air void analyzer (Rapid air 457, Germany), UV spectrophotometer (L5S, China), high-pressure steam sterilization pot (YX280A, China), peristaltic pump (MP-15RN, China), magnetic stirrer (Chijiu84-1, China), and atomic absorption spectrophotometer (TAS-990, China). All the water used in the experiment was ultra-pure water made by an ultra-pure water machine (Buisafer-20TAB, China)

In order to ensure the accuracy of the results, all the data in this test have been repeated more than 3 times, and the average value was taken.

Results and discussion

Characterization of the brick

There are many irregular voids and pores inside the permeable bricks to improve the permeable effect. Naturally, porosity and chord size distribution are two important indicators characterizing the filtration of bricks. Smaller porosity and reasonable chord size distribution was beneficial to improve the brick filtration effect (Yong et al. 2013).

The permeability coefficient of upper layer of ceramic brick, cement brick, and slag brick was 3.1 × 10−2, 3.6 × 10−2, and 2.6 × 10−2 cm/s, which was highly consistent with the porosity of 24.82%, 26.72%, and 24.29% with goodness of fit being 90.42%. The reason for the correlation might be that the rainwater mainly flowed through the pores inside the brick, and the porosity was positively correlated to the seepage velocity.

The chord size distribution of the ceramic brick was shown in Fig. 3. The upper layer of ceramic permeable brick on the cross-section had a smaller proportion of pores in the 0.5–4.0-mm specification than lower layer, while the two layers had a porosity of 24.82% and 58.66%, respectively (Fig. 3). Obviously, the presence of larger pore size increased the porosity of the lower layer, and the distribution of the pores, small pores lying on the top and big pores being on the bottom, objectively made the upper layer function as a sieve, and upper layer may play a more critical role in purification process (Winston et al. 2016).

The chord size distribution of the upper layer of three permeable bricks was shown in Fig. 4, in which chord size was used to represent the size of the pore, and the chord length frequency was used to represent the number of pores. As shown in Fig. 4, the upper layer of ceramic permeable brick did not contain large particles of 1.5–3.0 mm, and the pore ratio of 0.5–1.5 mm is smaller than cement and slag bricks, which meant the ceramic brick had more small pores. The more uniform and dense pore distribution may be caused by sintering and melting of ceramic raw materials.

Although the permeability coefficient was closely related to the porosity of upper layer, however, the purification effect was more likely to relate with chord size distribution; therefore, the rationality of the chord size distribution needs to be further analyzed combining with the comparison of filtering effect

The influence of concentrations

Pollutant removal rates of three permeable bricks under different contaminant concentrations are shown in Fig. 5. As can be seen form Fig. 5, with the increase of contaminant concentrations, the removal rate was basically stable except for the significant decrease in NH4+-N, TN. The removal rates of NH4+-N, TN decreased significantly with the increase of contaminant concentrations. When the contaminant concentrations increased from low concentration to high concentration, the average removal rate of the pollutants decreased by 16.57% and 13.45%, respectively. NH4-N and TN were mainly removed by the adsorption of the brick materials, and the permeable brick had a poor adsorption effect on these pollutants (Zhang et al. 2018; Li et al. 2017; Niu et al. 2016; Bean et al. 2007). For example, the removal rate of NH4+-N by three kinds of permeable bricks was only 5–15%, which meant the bricks had weak resistance to impact load of NH4+-N. The removal rate of NH4+-N rapidly decreased because the adsorption capacity of the brick was limited in the case of an increase of concentrations. The contaminant concentrations had little effect on the removal rates of SS, TP, Cu, Zn, Pb, and Cd. When the contaminant concentrations increased from low concentration to high concentration, the average removal rate merely decreased by 2.80%, 4.54%, 2.86%, 2.17%, 2.44%, and 2.51%, respectively. This might result from the large removal capacity of these pollutants by permeable bricks. High concentration would only shorten the filtration lifespan without affecting the removal efficiency. Combining the removal rates of different pollutants, we could conclude that contaminant concentrations had a great influence on pollutants with lower removal rate and had little effect on pollutants with higher removal rate. The physical interception inside the permeable brick played a major role in the removal of SS, TP, and heavy metals in the permeable brick (Liu et al. 2019; Jiang et al. 2015; Niu et al. 2016); these pollutants were mainly filtered by the voids and pores inside permeable bricks. At the low concentration of the pollutants, the internal voids in the permeable bricks were gradually occupied during the rainfall process, which was helpful in retaining more pollutants, which meant a process of improving efficiency and a certain buffer capacity for the removal of these kinds of pollutants. Thereby increasing the concentrations would not have a significant effect relying on the buffer capacity (Liu et al. 2019; Sansalone et al. 2012).

Ceramic permeable brick had a higher removal rate for SS and TP, indicating that the uniform and dense pore distribution was instrumental in the retention of particulates (Yong et al. 2013). The chord size distribution of ceramic permeable brick was good at filtering the particulate matter, so the pore size distribution is reasonable for the filtration of SS.

The pH changes before and after filtration of three permeable bricks are shown in Fig. 6. As shown in Fig. 6, the pH of the cement and steel slag permeable bricks had a certain increase because that both of them belonged to the non-sintered bricks, which contained a certain amount of cement. During the brick forming process, the hydration reaction of the cement produced alkaline substances such as calcium hydroxide, and the contact between rainwater and alkaline substances or washing out of alkaline materials lead to an increase of the pH after filtration (Zhang et al. 2018; Li et al. 2017). Contrary to the non-sintered permeable bricks, the pH increase of ceramic permeable brick was not obvious because the high temperature in sintering allowed raw material to be fully melted without the generation of alkaline materials.

The influence of rainfall intensity

Change of effluent concentrations of three permeable bricks under different rainfall intensities is shown in Fig. 7. As shown in Fig. 7, with the increase of rainfall intensity, the effluent concentration increased, and the removal efficiency of various permeable bricks on various pollutants showed a downward trend. This was mainly because the increase of rainfall intensity improved the seepage velocity of rainwater in the brick, which would reduce hydraulic retention time and contact opportunity between rainwater and brick materials (Liu et al. 2019; Niu et al. 2016).

In terms of specific pollutants, the removal rates of NH4-N, TN and COD decreased significantly with the increase of rainfall intensity; when the repetition period of rainfall increased from 5 to 50 years, the average removal rate of the three pollutants in three bricks decreased by 9.71%, 11.34%, and 9.64%, respectively. These three pollutants are mainly removed by the adsorption of the brick materials (Liu et al. 2019; Drake et al. 2013; Jiang et al. 2015; Niu et al. 2016; Razzaghmanesh and Borst 2019), and the seepage velocity of the rainwater in the permeable brick reduced the adsorption effect. The rainfall intensity had little effect on the removal rates of SS, TP, Cu, Zn, Pb, and Cd; when the rainfall return period increased from 5 to 50 years, the removal rate merely decreased by 4.55%, 5.72%, 5.50%, 4.17%, 4.70%, and 4.48%, respectively. The SS was mainly removed by the physical interception (Jiang et al. 2015; Niu et al. 2016), and other pollutants were easily adsorbed on the SS or removed along with the filtering of the SS (Jiang et al. 2015; Drake et al. 2014; Sansalone et al. 2012; Liu et al. 2016), The removal rate of these pollutants was less affected by rainfall intensity. It might result from the large removal capacity of these pollutants by permeable bricks. The seepage velocity of rainwater inside the brick was no longer the main factor restricting its removal efficiency.

In terms of specific bricks, ceramic permeable brick had the advantage of better removal in SS, TP, Cu, Zn, Pb, and Cd, especial for the SS and TP, in the background of higher removal rate; the change of removal rate caused by rainfall intensity had less influence on these targets. That is, ceramic permeable brick had better adaptability to these targets in the change of rainfall intensity. However, the removal efficiency of NH4+-N, TN and COD by ceramic permeable brick was not high, and TN and COD efficiency were the lowest in three bricks, which indicated the poor adaptability to these pollutants. Therefore, brick selection under different rainfall intensities should be considered by the classification of pollutants

Combining the removal rates of different pollutants, we could conclude that rainfall intensity had a great influence on pollutants with lower removal rate and had little effect on pollutants with higher removal rate.

Quality of cleaning water

Changes in pH of three brick washing effluents was shown in Fig. 8. As could be seen from Fig. 8, the effluent pH increased at first and then tended to be stable, especially for the cement permeable brick and steel slag brick, which was also due to the contact of water with alkaline substances (Chandrappa and Biligiri 2016; Zhang et al. 2018).

The effluent removal rate of pollutants in cleaning effluent of three permeable bricks is shown in Fig. 9. As can be seen from Fig. 9, different trends in the removal rate of pollutants were presented in cleaning effluent.

Except for the COD, TN and NH4+-N, the concentration of the conventional contaminants in the cleaning effluent was stable in the later stage with the removal rate being in the range of 95–99%, while the relatively high concentration made it easy to be washed out in the early stage. It can be seen that these pollutants were not easily washed out. In particular, it was pointed out that the effluent removal rate of SS was maintained at a high level in the whole cleaning process, indicating that SS was difficult to be cleaned out. Thus, it is easy to block the internal voids and pores inside the permeable brick, which may be one of the main reasons for the clogging of brick after long term use (Liu et al. 2019; Niu et al. 2016; Sansalone et al. 2008; Beecham et al. 2009). The concentration of COD, TN and NH4+-N in the cleaning effluent decreased with the cleaning time continued; the effluent removal rate of pollutants increases gradually, indicating that the three pollutants trapped in the permeable brick were easy to be washed out in the cleaning process. In comparison, COD was less likely to be washed out among the three pollutants.

Combining with the effect of decontamination, this falls into a paradox that the pollutants easily removed in the filtration process are not easy to be washed out, and the pollutants difficultly removed are easily flushed out. The soluble pollutants such as COD, TN and NH4+-N was difficult to be removed but easy to be washed out. Therefore, the treatment of these kinds of pollutants would be the difficulty and hot spot in the research of permeable brick.

Conclusions

In this study, ceramic permeable brick, cement permeable brick, and steel slag permeable brick were selected to study their decontamination performance, the influencing factors such as rainfall intensity and contaminant concentration were investigated, and the cleaning characteristics of the permeable brick was discussed further. Based on the results from this study, the following conclusions could be drawn.

-

(1)

From the perspective of cross-section structure, three bricks all can be divided into the upper layer and the lower layer. Small pores lying on the top and big pores being on the bottom objectively makes the upper layer a sieve, which might play a more critical role in purification process. The uniform and dense pore distribution of ceramic permeable brick was instrumental in the retention of particulate matters.

-

(2)

Contaminant concentration and rainfall intensity had little effect on pollutants with higher removal rate but had a great influence on pollutants with lower removal rate. SS, TP, Cu, Zn, Pb, and Cd were less influenced by the change of the contaminant concentration and rainfall intensity.

-

(3)

The dissolved pollutants such as NH4+-N and TN were mainly removed by the chemical adsorption, while the permeable brick had a poor adsorption effect and weak resistance to impact load, the removal rate of these pollutants rapidly decreased because the adsorption capacity was limited in the case of an increase of concentrations or repetition period of rainfall.

-

(4)

Non-sintered bricks containing a certain amount of cement increased the pH after filtration, because alkaline substances such as calcium hydroxide was produced owing to the hydration reaction of the cement during the brick forming process. Ceramic permeable brick had not obvious effect on pH since the high temperature in sintering allowed raw material to be fully melted without the generation of alkaline materials.

-

(5)

The trapped SS was not easily washed out; this might be responsible for the clogging of bricks after long term use. The soluble pollutants such as COD, TN, and NH4-N were difficult to be removed but easy to be washed out. Therefore, the treatment of this kind of pollutants was the difficulty for permeable brick.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Bean EZ, Hunt WF, Bidelspach DA (2007) Evaluation of four permeable pavement sites in eastern north Carolina for runoff reduction and water quality impacts. J Irrig Drain Eng 133:583–592

Beecham S, Kandasamy J, Pezzaniti D (2009) Influence of clogging on the effective life of permeable pavements. P I Civil Eng-Wat M 162:211–220

Boogaard F, Lucke T (2019) Long-term infiltration performance evaluation of Dutch permeable pavements using the full-scale infiltration method. Water 11:320

Brown RA, Borst M (2014) Evaluation of surface infiltration testing procedures in permeable pavement systems. J Environ Eng 140:82–82

Chandrappa AK, Biligiri KP (2016) Pervious concrete as a sustainable pavement material research findings and future prospects: a state-of-the-art review. Constr Build Mater 111:262–274

Chu L, Fwa TF (2019) Evaluation of surface infiltration performance of permeable pavements. J Environ Eng 238:136–143

Collins KA, Hunt WF, Hathaway JM (2010) Side-by-side comparison of nitrogen species removal for four types of permeable pavement and standard asphalt in eastern North Carolina. J Hydrol Eng 15:512–521

Drake JA, Bradford A, Marsalek J (2013) Review of environmental performance of permeable pavement systems: state of the knowledge. Water Qual Res J Can 48:203–222

Drake J, Bradford A, Van Seters T (2014) Winter effluent quality from partial-infiltration permeable pavement systems. J Environ Manag 140:1–13

Fassman EA, Blackbourn S (2015) Urban runoff mitigation by a permeable pavement system over impermeable soils. J Hydrol Eng 15:475–485

Gong MM, Cai CH, Miao HQ, Hong JX, Zhu FL, Xu ZB, Fang XB (2019) Pollution characteristic and source apportionment of road rainfall runoff in different functional zones of Lin’an. Admin Technique Environ Monitor 31:18–22

Hernandez-Crespo C, Fernandez-Gonzalvo M, Martin M (2019) Influence of rainfall intensity and pollution build-up levels on water quality and quantity response of permeable pavements. Sci Total Environ 684:303–313

Imran HM, Akib S, Karim MR (2013) Permeable pavement and stormwater management systems: a review. Environ Technol 34:2649–2656

Jiang W, Sha AM, Xiao JJ, Li YL, Huang Y (2015) Experimental study on filtration effect and mechanism of pavement runoff in permeable asphalt pavement. Constr Build Mater 100:102–110

Kia A, Wong HS, Cheeseman CR (2019) High-strength clogging resistant permeable pavement. Int J Pavement Eng:1–12. https://doi.org/10.1080/10298436.2019.1600693

Kuruppu U, Rahman A, Rahman MA (2019) Permeable pavement as a stormwater best management practice: a review and discussion. Environ Earth Sci 78:327

Legret M, Colandini V, Marc CL (1996) Effects of a porous pavement with reservoir structure on the quality of runoff water and soil. Sci Total Environ 189-190:335–340

Li H, Li Z, Zhang X, Li Z, Liu D, Li T, Zhang Z (2017) The effect of different surface materials on runoff quality in permeable pavement systems. Environ Sci Pollut Res 24:21103–21110

Lin ZZ, Yang H, Chen HM (2019) Influence of fillers on the removal of rainwater runoff pollutants by a permeable brick system with a frame structure base. Water Sci Technol 80:2131–2140

Lin ZZ, Yang H, Chen HM, Ouyang XY, Liu ZQ (2020) Comparison of the decontamination performance of three permeable bricks: adsorption and filtration experiments. Pol J Environ Stud 29:3225–3233

Liu XF, Hicher P, Muresan B, Saiyouri N, Hicher PY (2016) Heavy metal retention properties of kaolin and bentonite in a wide range of concentration and different pH conditions. Appl Clay Sci 119:365–374

Liu J, Yan HX, Liao ZY, Zhang K, Arthur RS, Tao T (2019) Laboratory analysis on the surface runoff pollution reduction performance of permeable pavements. Sci Total Environ 691:1–8

Newman AP, Puehmeier T, Shuttleworth A, Pratt CJ (2014) Performance of an enhanced pervious pavement system loaded with large volumes of hydrocarbons. Water Sci Technol 70:835–842

Niu ZG, Lv ZW, Zhang Y, Cui ZZ (2016) Stormwater infiltration and surface runoff pollution reduction performance of permeable pavement layers. Environ Sci Pollut Res 23:2576–2587

Rahman MA, Imteaz MA, Arulrajah A, Piratheepan J, Disfani MM (2015) Recycled construction and demolition materials in permeable pavement systems: geotechnical and hydraulic characteristics. J Clean Prod 90:183–194

Razzaghmanesh M, Borst M (2019) Long-term effects of three types of permeable pavements on nutrient infiltrate concentrations. Sci Total Environ 670:893–901

Rowe A, Borst M, O'Connor T (2010) Environmental effects of pervious pavement as low impact develop- pment installation in urban regions. Chapter 13. In: Chang NB (ed) The Effects of Urbanization on Ground-water: an Engineering Case-Based Approach for Sustainable Development. ASCE, Reston, pp 344–366

Sansalone J, Kuang X, Ranieri V (2008) Permeable pavement as a hydraulic and filtration interface for urban drainage. J Irrig Drain Eng 134:666–674

Sansalone J, Kuang X, Ying G, Ranieri V (2012) Filtration and clogging of permeable pavement loaded by urban drainage. Water Res 46:6763–6774

Wang HL, Cao XY, Ren YF, He YX, Liu YF, Wang SQ, Wang XK, Li ZX (2019) Analysis on pollution load of rainfall runoff in Beijing urban arterial roads. Acta Sci Circumst 39:1860–1867

Winston RJ, Al-Rubaei AM, Blecken GT, Viklander M, Hunt WF (2016) Maintenance measures for preservation and recovery of permeable pavement surface infiltration rate-the effects of street sweeping, vacuum cleaning, high pressure washing, and milling. J Environ Manag 169:132–144

Yang H, Lin ZZ, Huang X, Jia QS, Li YL, Liu YY, Chen HM (2019) Rainwater runoff pollution removal experiment using a ceramic permeable brick system with a frame structure base. Fresenius Environ Bull 28:9924–9934

Yong CF, Mccarthy DT, Deletic A (2013) Predicting physical clogging of porous and permeable pavements. J Hydrol 481:48–55

Zhang ZY, Li ZF, Zhang XR, Liu DQ, Li ZR, Li HY (2018) Systematically investigated the influences of permeable pavement materials on the water quality of runoff: batch and column experiments. Water Air Soil Pollut 229:155

Funding

This study was financially supported by the Major Science and Technology Program for Water Pollution Control and Treatment (No.2017ZX07205003).

Author information

Authors and Affiliations

Contributions

Suhua Han, Ye Yang, and Shuang Liu analyzed and interpreted the experimental data. Minbo Lu was a major contributor in writing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Disclaimer

The funders had no role in the design of the study and collection, analysis, and interpretation of data and in writing the manuscript.

Competing interests

The authors declare that they have no competing interests

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, S., Yang, Y., Liu, S. et al. Decontamination performance and cleaning characteristics of three common used paved permeable bricks. Environ Sci Pollut Res 28, 15114–15122 (2021). https://doi.org/10.1007/s11356-020-11706-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-11706-y