Abstract

To investigate the effect of different permeable pavement surface materials on the removal of pollutants from urban storm-runoff, six commonly surface materials (porous asphalt, porous concrete, cement brick, ceramic brick, sand base brick, and shale brick) were selected in this study and the research was carried out by column experiments. Except the concentrations of total suspended solids (TSS), chemical oxygen demand (COD), ammonia nitrogen (NH4-N), nitrate nitrogen (NO3-N), total nitrogen (TN), and total phosphorus (TP) in the influent and effluent that were measured, the removal mechanism of pollutants was discussed further. The results indicate that the surface materials influence the removal efficiency of pollutants greatly and have different effects on certain pollutant. Furthermore, the physical interception and adsorption would be the main mechanism for the removal of pollutants from runoff. For example, for all surface materials, the average removal efficiency of TSS is nearly about 90.0% because of physical interception. Due to the amount of iron oxide, the removal efficiency of COD, NO3-N, and TN of shale brick was 88.2, 35.1, and 17.5%, respectively. NH4-N and TN can be easily removed by porous asphalt due to the high content of organic matter. By lacking of useful adsorption sites, all the surface materials had little effect on the removal of TP from runoff. This research could offer useful guidelines for the better design of permeable pavement system and promote the insight into the removal mechanism of pollutants in permeable pavement system.

Different types of materials for the different types of pollutants in the runoff purification capacity were significantly different, overall, shale brick and porous asphalt Shale bricks and porous asphalt have a better purification effect according to the six kinds of materials

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

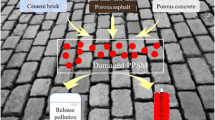

Green stormwater infrastructure, such as permeable pavement system (PPS), has been widely used in urban stormwater management (Liu et al. 2016; Wang et al. 2016; Wootton-Beard et al. 2016). Compared with conventional pavement systems, PPS shows widespread effectiveness in reducing runoff quantity, delaying peak flow and reduced peak runoff rates due to their high surface infiltration rates (Bean et al. 2007; Brattebo and Booth 2003; Collins et al. 2008; Legret and Colandini 1999; Roseen et al. 2009). Furthermore, PPS can reduce the concentrations of several stormwater pollutants (Brown and Borst 2015; Drake et al. 2014a, b; Eck et al. 2012).

Except for the preserving the natural hydrologic functions, many studies identified that PPS offers the possibility of a useful method that can reduce the pollutant loads in stormwater, especially for total suspended solids (TSS) and heavy metals (Dietz 2007; Fassman and Blackbourn 2011; Sansalone et al. 2008). Rushton compared the permeable paving and impervious paving of parking at the Florida Aquarium in Tampa, USA (Rushton 2001). Results indicated that permeable paving with a swale could reduce the pollutant loads by at least 75% for heavy metals and TSS. Brown et al. investigated the TSS removal abilities in two kinds of permeable pavement: porous asphalts and open-jointed paving blocks (Brown et al. 2009). Results illustrated that both pavements could reduce the concentration of TSS with the range from 90 to 96%. Pagotto et al. reported that the concentrations of lead and copper in the effluent of porous asphalt were lower than the conventional asphalt (Pagotto et al. 2000). Barrett found that PPS near highway could decrease the concentration of TSS, lead, copper, and zinc greatly (Barrett 2008). Although the remove efficiency of TSS and heavy metals in the runoff was investigated in PPS, relatively little research was conducted on the removal of conventional pollutants. Furthermore, recent researchers showed that PPS has higher concentration of conventional pollutants, such as nitrite and nitrate which probable due to the nitrification (Collins et al. 2010; Drake et al. 2014a).

To investigate the removal efficiency of pollutants in PPS further, some researchers have built PPS in the laboratory and studied their purification effects on conventional pollutants in runoff. For permeable asphalt pavement, except for the high removal efficiency for heavy metals, it also can remove oil, biochemical oxygen demand, chemical oxygen demand, ammonia, and total phosphorus effectively (Jiang et al. 2015). However, permeable asphalt pavement is incompetent in the removal of chloride and total nitrogen. The ceramic permeable brick can effectively purify TSS and TP in the runoff with 79.8 and 74.2%, but is little effective on the removal of chemical oxygen demand, ammonia, and total nitrogen (Niu et al. 2016). However, until to now, the investigation of the removal efficiency of conventional pollutants in PPS is rare and simple.

As the integral part of PPS, the surface material is the top layer which contact with the runoff firstly. The characteristics of the surface material will directly affect water quality in PPS. However, fewer reports focus on the effect of the surface material for the pollutants removal. Furthermore, many studies pay attention to the investigation of the permeable performance of PPS, while ignoring the runoff quality caused by the surface material. With the increasing types of surface materials, more and more attentions should be focused on this region for the better design of PPS.

In this research, six typical kinds of permeable pavement surface materials (porous asphalt, porous concrete, cement brick, ceramic brick, sand base brick, and shale brick) were chosen to build a set of column experiment device to investigate the removal of conventional pollutants from runoff. Parameters of pH, TSS, chemical oxygen demand (COD), ammonia nitrogen (NH4-N), nitrate nitrogen (NO3-N), total nitrogen (TN), and total phosphorus (TP) in influent and effluent were measured. Furthermore, the removal mechanism of these pollutants was discussed. This research could give aid to the design of PPS for better removal of pollution from runoff and potentially promote the understanding of water infiltration and pollution reduction in PPS.

Materials and methods

Materials

Six typical kinds of surface materials (porous asphalt, porous concrete, cement brick, ceramic brick, sand base brick, and shale brick) were selected in this research to investigate the influences of surface materials on the removal of pollutants in PPS. The porous asphalt and porous concrete were prepared at the laboratory of the School of Civil and Transportation Engineering, Beijing University of Civil Engineering and Architecture. The cement brick and shale brick were bought from Ai Dao Ai He (Beijing) Technology Co., Ltd. The ceramic brick and sand base brick were supplied by Beijing million Bangpu Ruike building materials limited company. Other chemicals such as KI, HgI2, KNaC4H4O6·4H2O, K2S2O8, H32Mo7N6O28, ascorbic acid, H2SO4, and NaOH were all purchased from Sinopharm Chemical Reagent Co., Ltd.

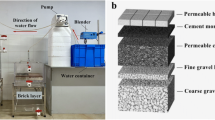

Experimental setup

The developed laboratory apparatus is shown in Fig. 1. A 12-L water bucket is used as the raw water bucket, and six experimental columns (4 cm inner diameter and 20 cm inner height) are used in the whole experiment. For avoiding the side wall effect and making the operation more stable, the inlet tube is under the column and outlet tube is on the top of column.

All six permeable pavement materials were smashed by hammer and sieved the size class from 2 to 5 mm. The six types of permeable pavement were loaded into the same experimental columns. Each column’s filler consists of 1 cm glass bead on the top, 18 cm permeable paving materials, 1 cm glass bead on the bottom, and four pieces of gauze (place between different layers). The pore volume between fillers of each column is 125.42 ml. In order to remove the organic matters of the surface materials, the columns were first washed with pure water for 3 days. During all the experiment, the influent flow rate is maintained at 29.86 ml/min, which is consistent with the requirements of the infiltration rate in PPS obtained by sponge city construction guide in China.

Test methods

In this study, TSS, COD, NH4-N, NO3-N, TN, and TP were chosen as the target pollutant because they are the main pollutants in runoff of the urban area (Brezonik and Stadelmann 2002; Gnecco et al. 2005). Raw water (influent water) was prepared based on the traditional surface runoff from other researchers (Table 1) (Hou et al. 2012), and stored in a 12-L water bucket. The road dust was swept from roads and parking lots and added into solutions to simulate TSS. The chemical analysis of surface materials was carried out with a X-ray fluorescence (XRF, Shimadzu XRF-1800, Japan).

The pore volume number (PV) is the multiple of the pore volume between the fillers in the experimental column which could unify the results in different column experiments with different packing sizes. In this study, water samples were taken at 1.00, 2.19, 3.38, 5.76, 8.08, 10.52, 12.90, 15.16, 20.05, 24.81, and 29.57 times of PV. Experimental process to maintain the objective environment is constant (25 °C). All the water samples were stored in sampling bottles in a refrigerator at 4 °C and analyzed within 48 h after sampling. The measurement methods are shown in Table 2.

Results and discussion

Characteristics of surface layer materials

To investigate the characteristics of six different surface materials, the X-ray fluorescence (XRF) was used to evaluate the main chemical composition in the materials. As shown in Table 3, the main compositions of surface materials are different greatly. For porous asphalt, porous concrete, cement brick, and sand base brick, CaO, SiO2, and MgO were major constituents, with the contents of 54, 20, and 12% in porous asphalt; 54, 20, and 10% in porous concrete; 51, 24, and 11% in cement brick; and 47, 28, and 15% in sand base brick, respectively. Different from the above four materials, the major components of ceramic brick and shale brick are SiO2 and Al2O3 with content of 69 and 18% in ceramic brick and 61 and 18% in shale brick. Furthermore, the surface materials also contained other components such as Fe2O3, K2O, SO3, and Na2O with lower amount.

The changes of pH value in the effluent

The value of pH is directly related to the quality of effluent, the higher or lower pH values will cause great damage to the surface water environment. The changes of pH values in the effluent are illustrated in Fig. 2. With the PV values increased, the pH values in the effluent shows great differences. Compared with initial pH values (7.4), the six kinds of surface materials can be roughly divided into four categories: the pH values in the effluent could be increased (sand base brick and cement brick), decreased (porous asphalt and porous concrete), increased first then decreased (shale brick), and nearly unchanged (ceramic brick). For cement brick and sand base brick, the pH values increased with the PV values increased until 8.60 and 8.85, which may be caused by more lime in the process of production. During the experiments, some of the lime may dissolve into the aqueous solutions, which induced the increasing of pH values. For porous asphalt, the pH values decreased nearly all experiment section which may be caused by the dissolution of organic matter in the surface materials. For porous concrete, although the pH values changed during the experiment time, compared with the initial pH values, there is no obvious change in the final effluent. For shale brick, the pH values increased first, followed by the decreased and finally stabilized at about 7.75. However, the pH value of ceramic brick is increased firstly and nearly unchanged with the PV values increased. Although the pH values in the effluent were great differences due to the different compositions in surface materials, all the pH values are still in the range of 6~9, which still meets the requirements of the standard in surface water environment quality (China 2002).

The changes of TSS in the effluent

TSS is one of the important indexes which measure the degree of pollution in runoff. High concentration of TSS will not only lead to high turbidity in water but also lead to the problem of pipeline clogging. The concentration of TSS in the effluent samples is shown in Fig. 3. Five types of materials, including porous concrete, cement brick, ceramic brick, sand base brick, and shale brick, have good removal efficiency with the PV increased from 1.00 to 29.57. Compared to the initial concentration of TSS (700.0 mg/L), TSS in final effluent were 27.0, 23.1, 34.0, 48.3, and 20.0 mg/L, respectively. Generally speaking, the removal of TSS in runoff mainly depends on the physical interception. The high removal of TSS may be due to the relatively small pore between the particle size (2–5 mm). Compared with other materials, the removal efficiency of TSS on porous asphalt is relatively poor (average about 105.2 mg/L when the pore volume below 12.90), which may be caused by the poor stability of porous asphalt. With the increase of pore volume, the concentration of TSS decreased and finally reduced to 52.0 mg/L when the pore volume is 29.57.

The changes of COD in the effluent

The concentration of COD is also an important index for detecting the environmental quality of runoff. The high concentration of COD will cause the degradation of the dissolved oxygen content of the water, resulting black and odorous water. As shown in Fig. 4, with the PV values increased, the concentration of COD in the effluent showed great differences for six kinds of materials. The changes can be roughly divided into three categories, compared with initial concentration of COD (419.0 mg/L): the COD in the effluent could be increased, decreased, and decreasing-rising. For cement and sand base brick, the COD concentration increased with the PV values increased until 683.9 and 542.9 mg/L, which may be caused by more organic binder in the process of production. During the experiments, some of organic binder in cement brick and sand base brick may dissolve into the aqueous solutions, which induced the increasing concentration of COD. For shale brick and ceramic brick, with the PV value increased, the concentration COD declined finally to 49.2 and 170.4 mg/L. The high removal efficiency may be attributed to the abundant microporous structure in the materials which could offer useful adsorption site for the COD removal. In addition, the effect treatment of shale brick is better than ceramic brick, which may be caused by iron oxide in the materials (Table 3) (Koupai et al. 2016). For porous asphalt and porous concrete, with the PV value increased, the COD concentration showed a decreasing-rising trend. For the porous asphalt, the COD concentration is 139.6 mg/L when the PV is 1.00. With PV value increasing further, the concentration of COD increased gradually, and finally reached 269.6 mg/L, which is similar with the result of Jiang et al. (2015). The porous concrete exhibits similar characteristics to porous asphalt, only difference is that the treatment effect is relatively poor than porous asphalt; the COD concentration is 253.6 mg/L when the PV is 1.00 and final effluent (PV = 29.57) is 377.6 mg/L. The decreases of COD can be attributed to the interception and adsorption of porous asphalt and porous concrete. The surface of porous asphalt and porous concrete has a certain number of adsorption sites for COD. In this study, with the amount of water increases gradually, the adsorption point of the surface of the material is gradually absorbed and saturated, which leads to the decrease of the removal rate of COD. The reason why porous asphalt is superior to porous concrete is probably due to the periphery of the porous asphalt is wrapped by organic matter, which may provide more useful adsorption sites for COD pollution.

The changes of NH4-N in the effluent

In urban water environment, too much NH4-N will cause a large number of algae in water, causing eutrophication. The change of NH4-N values for six different surface materials is shown in Fig. 5. With the PV values increased, all the materials showed the similar trend that the concentration of NH4-N decreased greatly first then followed by a relatively increased. Compared with the initial concentration (5.0 mg/L), the concentration of NH4-N decreased to 1.6, 1.7, 2.1, 3.2, and 3.9 mg/L for shale brick, ceramic brick, cement brick, porous concrete, and sand base brick, respectively, when the value of PV is 1.00. With the values of PV increased further, the removal efficiency of NH4-N gradually decreased. When the value of PV reached 29.57, the NH4-N concentrations were in the range of 4.31~4.88 mg/L. Due to the short running time of the experiment, the microbial degradation and nutrient transformation such as nitrification and denitrification could not be observed. The high removal efficiency of NH4-N is mainly attributed to the ion exchange caused by the monovalent and divalent cations in the surface materials. According to previous study, the monovalent could enhance the ion exchange capacity between materials and NH4-N and the process can be illustrated as follows (Soetardji et al. 2015)

As shown in Table 3, due to the high content of Na and K, ceramic brick and shale brick had higher removal efficiency for NH4 + than other materials. On the contrary, cement brick, sand base brick, and porous concrete that showed less removal efficiency may be attributed to the less content of monovalent cations. Different from other materials, with the PV increased from 3.38 to 29.57, the removal efficiency NH4-N of porous asphalt was relatively stable which is similar to the results reported by Lucas Antunes et al. and Jiang et al. (Antunes et al. 2016; Jiang et al. 2015). This result may be attributed to the organic matter on the surface of asphalt material which provides more adsorption sites for NH4-N.

The changes of NO3-N in the effluent

NO3-N is not toxic, but it will be converted into nitrite, thereby endangering human health. As shown in Fig. 6, six surface materials will purify part of NO3-N but the effect is different. Shale brick showed that the best removal efficiency with the concentration of NO3-N is 3.9 mg/L when PV is 29.57. The mechanism of NO3-N removal was mainly caused by interception and redox adsorption. In this study, due to the high concentration of iron in shale brick, the higher removal efficiency of NO3-N was observed which is consistent with the previous research (Zhang et al. 2010). The other four types of material including porous concrete, porous asphalt, sand base brick, and cement brick have a less effect on the removal of NO3-N. Furthermore, there is no statistical difference of NO3-N between ceramic brick’s inlet and effluent. These results were consistent with the data shown in Table 3, the mass percent of Fe2O3 in shale brick is the highest (9.15%), which induces its excellent effect on the treatment of NO3-N.

The changes of TN in the effluent

TN is an important indicator of water quality monitoring; too high or too low concentration will lead to changes in the water environment of the community, resulting in water pollution. Figure 7 shows the influence of different surface material on the removal of TN in runoff. Overall, the six materials share the same changes (decreasing-rising) with the degree difference. The composition of TN was mainly composed of high concentration of NH4-N and NO3-N and a small amount of organic nitrogen in road dust. The removal of TN mainly depends on the physical and chemical characteristics of surface materials. The porous asphalt and shale brick have the lower average concentration of TN in the final effluent, mainly due to it has a better removal effect of NH4-N and NO3-N (Figs. 5 and 6). These results were consistent with the other four materials which had little effect on the removal of NH4-N and NO3-N in Figs. 5 and 6.

The changes of TP in the effluent

TP is one of the most important indexes of surface water; too much phosphorus discharged into the water will lead to the abnormal growth and reproduction of aquatic organisms and plants. Figure 8 shows the changes of TP in different materials. For all materials, with the PV values increase, the concentration of TP decrease firstly followed by the increase. The removal mechanism of TP is normally due to the adsorption process and chemical precipitation reaction. When the pore volume is 1.00, cement brick has the best effect of phosphorus removal with the concentration of 0.2 mg/L, followed by sand base brick and porous concrete (0.4 mg/L), which may be due to the mass calcium ions in the surface materials. Research have shown that phosphate and calcium ions are easy to precipitate after contact to produce low solubility calcium phosphate, thus reducing the phosphate content of water (Jiang et al. 2015). The process can be written as follows

Although the mass of calcium is relative high, the asphalt’s surface is coated with organic matter, which wrapped on the surface of the gravel and blocking the adsorption site of TP, resulting in the poor adsorption. With the increase of the PV, all the material treatment results were continuously reduced; the concentration of TP in the effluent is between 1.0 and 1.1 mg/L when the PV up to 29.57. This may be due to the result of less adsorption sites and less Ca2+ content.

Influence of material comparison

With the rapid development of urbanization, PPS is widely used to manage hydrologic and water quality impacts of stormwater runoff. In this research, the purification effect of different kinds of surface layer materials on pollutants in runoff was studied. Compared with other materials, shale brick and porous asphalt show great advantages in the removal of pollutants from runoff. Therefore, from the aspect of water treatment, shale brick and porous asphalt may be the most suitable materials for PPS. However, other materials can also be used for the removal of a certain pollutants from runoff. For example, cement brick and sand base brick could be used as the surface materials of PPS for the regions where the concentration of TP in runoff is higher and could not be used in the area where the concentration of COD in high due to the release of COD. In addition, the removal efficiency of materials could be enhanced by adding appropriate iron oxide into the surface or the inside of materials due to higher adsorption capacity.

Conclusions

In this study, six commonly used surface materials in PPS were selected to investigate insight into the removal efficiency and mechanism of pollutants from runoff. Results showed that the characteristics of surface materials influenced the removal efficiency greatly. Compared with other materials, the shale brick has a relative good removal effect on nearly all runoff pollutants, followed by porous asphalt. However, other surface materials have good removal efficiency for a certain pollutants. The removal mechanism is mainly due to the interception and adsorption caused by the different compositions of surface materials. This work could offer useful guideline for the better design and installation of PPS in the removal of pollutants from stormwater.

References

Antunes L, Thives L, Ghisi E (2016) Potential for potable water savings in buildings by using stormwater harvested from porous pavements. Water 8:110–128

Barrett ME (2008) Effects of a permeable friction course on highway runoff. J Irrig Drain Eng 134:646–651

Bean EZ, Hunt WF, Bidelspach DA (2007) Evaluation of four permeable pavement sites in eastern North Carolina for runoff reduction and water quality impacts. J Irrig Drain Eng-ASCE 133:583–592

Brattebo BO, Booth DB (2003) Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res 37:4369–4376

Brezonik PL, Stadelmann TH (2002) Analysis and predictive models of stormwater runoff volumes, loads, and pollutant concentrations from watersheds in the Twin Cities metropolitan area, Minnesota, USA. Water Res 36:1743–1757

Brown RA, Borst M (2015) Nutrient infiltrate concentrations from three permeable pavement types. J Environ Manag 164:74–85

Brown C, Chu A, Duin BV, Valeo C, Marsalek J, Schreier H (2009) Characteristics of sediment removal in two types of permeable pavement. Water Qual Res J Can 44:59–70

China (2002) Environmental quality standards for surface water. Chinese Environmental Protection Industry, pp 1–9

Collins KA, Hunt WF, Hathaway JM (2008) Hydrologic comparison of four types of permeable pavement and standard asphalt in Eastern North Carolina. J Hydrol Eng 13:1146–1157

Collins KA, Hunt WF, Hathaway JM (2010) Side-by-side comparison of nitrogen species removal for four types of permeable pavement and standard asphalt in Eastern North Carolina. J Hydrol Eng 15:512–521

Dietz ME (2007) Low impact development practices: a review of current research and recommendations for future directions. Water Air Soil Pollut 22:351–363

Drake J, Bradford A, van Seters T (2014a) Stormwater quality of spring-summer-fall effluent from three partial-infiltration permeable pavement systems and conventional asphalt pavement. J Environ Manag 139:69–79

Drake J, Bradford A, Van Seters T (2014b) Winter effluent quality from partial-infiltration permeable pavement systems. J Environ Eng 140

Eck BJ, Winston RJ, Hunt WF, Barrett ME (2012) Water quality of drainage from permeable friction course. J Environ Eng 138:174–181

Fassman EA, Blackbourn SD (2011) Road runoff water-quality mitigation by permeable modular concrete pavers. J Irrig Drain Eng 137:720–729

Gnecco I, Berretta C, Lanza LG, Barbera PL (2005) Storm water pollution in the urban environment of Genoa, Italy. Atmos Res 77:60–73

Hou PQ, Ren YF, Wang XK, Ouyang ZY, Zhou XP (2012) Research on evaluation of water quality of Beijing urban stormwater runoff. Environ Sci (in Chinese) 33:71

Jiang W, Sha A, Xiao J, Li Y, Huang Y (2015) Experimental study on filtration effect and mechanism of pavement runoff in permeable asphalt pavement. Constr Build Mater 100:102–110

Koupai JA, Nejad SS, Mostafazadeh-Fard S, Behfarnia K (2016) Reduction of urban storm-runoff pollution using porous concrete containing iron slag adsorbent. J Environ Eng 142(04015072):1–7

Legret M, Colandini V (1999) Effects of a porous pavement with reservoir structure on runoff water: water quality and fate of heavy metals. Water Sci Technol 39:111–117

Liu W, Chen W, Feng Q, Peng C, Kang P (2016) Cost-benefit analysis of green infrastructures on community stormwater reduction and utilization: a case of Beijing, China. Environ Manag 58:1–12

Niu ZG, Lv ZW, Zhang Y, Cui ZZ (2016) Stormwater infiltration and surface runoff pollution reduction performance of permeable pavement layers. Environ Sci Pollut Res Int 23:2576–2587

Pagotto C, Legret M, Cloirec PL (2000) Comparison of the hydraulic behaviour and the quality of highway runoff water according to the type of pavement. Water Res 34:4446–4454

Roseen RM, Ballestero TP, Houle JJ, Avellaneda P, Briggs J, Fowler G, Wildey R (2009) Seasonal performance variations for storm-water management systems in cold climate conditions. J Environ Eng 135:128–137

Rushton BT (2001) Low-impact parking lot design reduces runoff and pollutant loads. J Water Resour Plan Manag 127:1–7

Sansalone J, Kuang X, Ranieri V (2008) Permeable pavement as a hydraulic and filtration interface for urban drainage. J Irrig Drain Eng 134:666–674

Soetardji JP, Claudia JC, Ju YH, Hriljac JA, Chen TY, Soetaredjo FE, Santoso SP, Kurniawan A, Ismadji S (2015) Ammonia removal from water using sodium hydroxide modified zeolite mordenite. RSC Adv 5:83689–83699

Wang M, Zhang D, Adhityan A, Ng WJ, Dong J, Tan SK (2016) Assessing cost-effectiveness of bioretention on stormwater in response to climate change and urbanization for future scenarios. J Hydrol:1–30

Wootton-Beard P, Xing Y, Prabhakaran RD, Robson P, Bosch M, Thornton J, Ormondroyd G, Jones P, Donnison I (2016) Review: improving the impact of plant science on urban planning and design. Buildings 6:48

Zhang J, Hao Z, Zhang Z, Yang Y, Xu X (2010) Kinetics of nitrate reductive denitrification by nanoscale zero-valent iron. Process Saf Environ Prot 88:439–445

Acknowledgements

This work was supported by Beijing outstanding talent project for excellent youth team (2015000026833T0000), Beijing Advanced Innovation Center of Urban Design for Future Cities: Sponge City Development and Water Quantity & Quality Risk Control (UDC2016040100), and Natural Science Foundation of China (No. 51678025).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

About this article

Cite this article

Li, H., Li, Z., Zhang, X. et al. The effect of different surface materials on runoff quality in permeable pavement systems. Environ Sci Pollut Res 24, 21103–21110 (2017). https://doi.org/10.1007/s11356-017-9750-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-9750-6