Abstract

Bentonite was modified with cationic surfactant hexadecyl trimethyl ammonium bromide (HTAB) as landfill liner to retard the transportation of bisphenol A (BPA) for the first time. The modification was confirmed to form a lateral bi-layer in the interlayer space of bentonite by scanning electron microscope, X-ray diffraction, and Fourier transform infrared spectroscopy. The introduction of HTAB into the internal position of bentonite led to an increased interlayer space of bentonite from 15.0 to 20.9 Å and a higher sorption affinity for BPA (10.449 mg/g of HTAB-bentonite and 3.413 mg/g of raw bentonite). According to the Freundlich model, the maximum adsorption capacity of the HTAB-bentonite was found to be 0.410 mg/g. The sorption capacity of raw bentonite and HTAB-bentonite both decreased at alkaline conditions. Although the hydraulic conductivity of HTAB-bentonite was higher than that of raw bentonite, results of laboratory permeability and column tests indicated that HTAB-bentonite obviously extended the BPA breakthrough time by 43.4 %. The properties of the HTAB-bentonite revealed its notable advantages as components of landfill liners material to retain BPA in leachate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

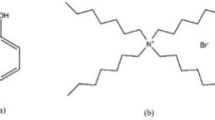

Bisphenol A [2, 2-bis(4-hydroxyphenyl) propane, BPA] has caused great concern for its potential risk to the environment. BPA has a weak acute toxicity to aquatic biota. Examples of LC50 values are 1.1 mg/L for shrimp and 4.7 mg/L for minnow (Alexander et al. 1998) and those of EC50 values are 10 mg/L for water flea and 1.0–3.1 mg/L for green algae (Yamamoto et al. 2001). According to Krishnan et al. (1993), BPA also has estrogenicity that will increase the rate of proliferation of human breast cancer cells.

Several studies have demonstrated that the BPA concentrations in landfill leachate were extremely high. According to the Environmental Agency of Japan (1997), the levels of BPA in freshwater and sea water samples ranged from 0.010 to 0.268 μg/L. However, the BPA concentration in raw leachate from solid waste landfills in Japan ranged from 6.32 to 2980 μg/L (Yasuhara et al. 1999), and the maximum BPA concentration reported from a landfill site was 17,200 μg/L (Yamamoto et al. 2001). These levels were much higher than the environmental levels of BPA reported by the Environmental Agency of Japan (Yamamoto et al. 2001).

Modern engineered landfills involve some categories of barriers that will separate the buried wastes from the underground water system (Rowe et al. 2004). Due to the characteristics of the wastes and the percolation through the liner layers by excess rainwater (Christensen et al. 2001), leachates are generated with characteristic physicochemical properties, which can permeate the liner barrier and contaminate the surroundings and groundwater (Sánchez-Jiménez et al. 2012). Consequently, chemical leaching is considered to be an important source of BPA found in the aquatic environment (Vandenberg et al. 2007). Therefore, enhancing the sorption capacity of earthen liner materials should be considered to improve liner performance since normal landfill liners may fail to retard BPA and other pollutants at high concentrations (Bartelt-Hunt et al. 2005).

In practice, compacted clay soils are widely used in landfill liners for their large capacity of attenuation and relatively low cost. However, they are less efficient in blocking the transport of hydrophobic organic pollutants. Cationic surfactants or quaternary ammonium salts with a long hydrocarbon chain are of special interest due to their adsorption by clays, highly reactive for retaining hydrophobic compounds which are not retained by natural clays (Carrizosa et al. 2004; Sánchez-Marítn et al. 2006). Bentonites are the most preferred clay minerals for modification owing to their high surface area and cation exchange capacity (CEC). Surfactant-modified bentonites are widely used as adsorbents to adsorb some organic pollutants in wastewater treatment (Alkaram et al. 2009; Zhou et al. 2010). However, few studies have been carried out on employing surfactant-modified bentonites as landfill liners to retain BPA in leachate.

Therefore, the objective of this study was to modify bentonite with hexadecyl trimethyl ammonium bromide (HTAB) and evaluate its performances to retain BPA, including adsorptive capacity, hydraulic conductivity, and diffusion property.

Materials and methods

Materials

The bentonite used in this study was obtained from Weifang Huawei Bentonite Co., Ltd. (Shandong, China), which contained the prevailing component smectite (86–89 % by mass) and traces of calcite, feldspar, and quartz. The analysis of its chemical composition by X-ray fluorescence spectrometry showed the existence of 60.08 % of SiO2, 13.42 % of Al2O3, 2.46 % of CaO, 2.45 % of Fe2O3, 2.20 % of K2O, 1.93 % of MgO, 0.41 % of Na2O, and the loss on ignition (L.O.I.) was 17.05 %. The CEC of the bentonite was 82 meq/100 g of mineral as determined by the sodium saturation method proposed by Hesse (1971). The bentonite samples were dried at 90 °C and grinded to pass through a 60-mesh sieve, of which only the portion passing through the sieve was collected for use.

Methanol was of high-performance liquid chromatography (HPLC) grade, and all other chemicals and reagents were of analytical grade. HTAB was purchased from Ling Feng Chemical Co. (Shanghai, China) and used as a modifier. BPA used to produce a stock solution of 100 mg/L, was received from Tokyo Chemical Industry Company (Tokyo, Japan) and all working solutions were prepared by diluting the stock solution with deionized water.

Preparation of HTAB-modified bentonite

The raw bentonite was organically modified by adsorption of HTAB, which produced HTAB-modified bentonite (abbreviated as HTAB-bentonite) for further investigation. The HTAB-bentonite was synthesized by cation exchange with HTAB solution (20 mmol/L) through thorough stirring. The amount of organic cation was equivalent to the CEC of bentonite minerals because even higher proportions of HTAB would not enhance the cation exchange (Klapyta et al. 2001). The mixture was agitated at 200 revolutions per minute (rpm) in a water bath oscillator (HHS-4 Boxun, Shanghai, China) at 30 °C for 6 h. The HTAB-bentonite was separated from the mixture by filtration and washed with deionized water several times until there was no foam observed in the eluate. The residue was then dried at 90 °C for 6 h, activated under 105 °C for 1 h, and grinded to pass through a 60-mesh sieve.

Characterization of bentonite and HTAB-bentonite

The d-spacing in the bentonite and HTAB-bentonite were identified by an X-ray diffractometer (XRD) (D8 ADVANCE, Bruker-AXS, Germany) using a Cu Kα radiation (40 kv, 40 mA), at a scanning speed of 0.48° 2θ/min from 3° to 80°. The particle morphology was observed by scanning electron microscope (SEM) (JSM-7401F, JEOL, Japan). The Fourier transform infrared spectroscopy (FTIR) spectra were recorded by a FTIR spectrophotometer (IRPrestige-21, Shimazu, Japan) using the KBr method (Dong et al. 2010).

Batch adsorption tests

Batch tests were conducted by allowing an accurately weighted amount of raw bentonite or HTAB-bentonite to reach the equilibrium with BPA solutions of different concentrations. The procedure of preparing the synthetic BPA solution includes two steps: firstly, BPA was dissolved in ethanol; secondly, the BPA-ethanol solution was diluted with distilled water (Cao et al. 2009). The concentration of the stock solution was 50 mg/L, and the BPA solutions at desired concentrations were obtained by diluting the stock solution with distilled water. All adsorption tests were carried out at various time intervals and pH levels, aiming to investigate the adsorption behavior of BPA at different contact time and pH values.

The raw bentonite or HTAB-bentonite (1 g) and aqueous BPA solution (150 mL) of different concentrations were mixed in each flask, and then put into a temperature-controlled orbital shaker which was rotated at a constant speed of 180 rpm. Samples were taken out from the controlled-temperature environment at intervals, and centrifuged for 6 min at 5,500 rpm using a centrifuge (LG10-2.4A, Jinli, China) to obtain the supernatant.

In order to determine the effect of pH on the adsorption of BPA on the raw bentonite and HTAB-bentonite, the pH values of the solutions from 4 to 10 were then adjusted by adding 0.001–0.1 M HNO3 or NaOH solution. A pH meter (Starter 2C, Ohaus, USA) was used to adjust to a desired pH value. The same amount of bentonite (1 g) and BPA solution were put into several pretreated conical flasks and then rotated at a constant speed of 180 rpm with a temperature-controlled orbital shaker at 25 °C. The solutions were then centrifuged to obtain the supernatants for determining the BPA concentration.

After different adsorption time, the supernatants of suspensions were collected and filtered through a 0.45-μm membrane filter. The BPA concentrations were determined using an Agilent HPLC system with a C18 column at 30 °C (Suciu et al. 2012). The mobile-phase reservoirs contained a 30/70 v/v mixture of water and methanol with a flow rate of 1 mL/min. The wavelength used for detection was 278 nm. Blank tests were conducted to evaluate the BPA adsorption on the inner surface of the flasks. Two duplicate adsorption tests were performed under each condition to obtain an average value.

The amount of BPA adsorbed per unit mass of adsorbent at time t (q t , mg/g) and at equilibrium (q e, mg/g) was calculated using the following mass balance equations:

where C 0 and C e (mg/L) are the initial and equilibrium BPA concentrations in the solution; C t (mg/L) is the residual BPA concentration at time t; V (L) represents the volume of the solution, and m (g) is the mass of the adsorbent used.

Permeability tests

The hydraulic conductivity, as a key parameter for clay landfill liners, is required to be less than 1 × 10−7 cm/s (Benson et al. 1994). Permeability tests were performed on the raw bentonite and HTAB-bentonite, which were compacted in the permeameter molds with the back pressure saturated by the permeant fluid at 193 kPa for 48 h. The confining cell pressure in all experiments was 206.8 kPa. The permeant fluid used in all experiments was a 0.002 N CaSO4 solution.

The optimum water content was determined using the standard Proctor Compaction Method (ASTM D698) (Daniel 1994). The bentonite samples were prepared by adding deionized water to the air-dried soils to achieve water content 2 % wetter than the optimum water content in order to obtain the lowest hydraulic conductivity of bentonite samples (Daniel and Benson 1990). A changing-head permeability test using flexible-wall permeameters (Nanjing Soil Instrument Factory, Nanjing, China) was conducted to measure the hydraulic conductivity following the procedure in SL237-1999 (Yang et al. 2012).

Hydraulic conductivity experiments were completed when three criteria were met: (1) results of three consecutive permeability determinations were within ±25 % of their mean, (2) the ratio of the inflow rate to the outflow rate for the specimen was between 0.75 and 1.25, and (3) a plot of permeability versus time showed no distinct rising or falling trend (Bartelt-Hunt et al. 2005). When these criteria were met, the final three permeability measurements were averaged and recorded as the mean value.

Column breakthrough tests

Two column experiments were conducted to determine the breakthrough BPA concentrations of the raw bentonite and HTAB-bentonite when permeated with the BPA solution. The scheme of the column test is shown in Fig. 1. Included within the experimental device, the glass column has an inside diameter of 85 mm and a total length of 350 mm. To simulate the density in the field (i.e., 90 % relative compaction), the tested bentonite was set in the main part of the column and compacted in layers (Ghosh et al. 2012). Below and above the compacted soil layers, two consecutive layers of filter paper and glass wool were placed. The compacted bentonite column was permeated initially with distilled water to achieve the first exposure effect (Gleason et al. 1997). Then, synthetic BPA solution was used to simulate the BPA in landfill leachate with an initial concentration of 10 mg/L. The solution was allowed to vertically pass through the bentonite at a steady rate of 0.15 mL/min, which is controlled by a peristaltic pump (BT100LC, Chuang Rui, China). Effluent was periodically collected to measure the concentration of BPA in the effluent solution by HPLC (Suciu et al. 2012).

Results and discussion

Characterization of raw bentonite and HTAB-bentonite

Results of the XRD analysis for raw bentonite and HTAB-bentonite (Fig. 2a) clearly indicated that the d-spacing of HTAB-bentonite increased from 15.0 to 20.9 Å, which could be attributed to the cation exchange and intercalation of HTAB. Depending on the packing density and chain length, the organic ions will lie flat on the bentonite surface in a monolayer, a bi-layer, a pseudo tri-molecular layer, or a paraffin-type structure (Sreedharan and Sivapullaiah 2012). Lagaly (1984) has found that the basal spacing of alkyl ammonium bentonite increased with the organic chain length and organic loading on the organobentonite that is organically modified bentonite. A basal spacing up to 14 Å for the unit cell is designated as a monolayer arrangement of the alkyl ammonium chain in the interlayer, as the anhydrous basal spacing of raw bentonite mineral is 15 Å. A lateral bi-layer arrangement forms when the spacing is larger than 14 Å less than 17.7 Å. Spacing larger than 21 Å is representative of a tri-layer arrangement, while any spacing varying from 17.7 to 21 Å is considered as a pseudo tri-layer arrangement (Sreedharan and Sivapullaiah 2012). It can be inferred from the XRD results that alkyl ammonium chains are intercalated in the clay lattice of the bentonite and arranged in a lateral bi-layer. Thus, the HTAB-bentonite displayed a very large hydrophobic external surface, which strongly favored the sorption of BPA in anionic or molecular forms, and could even enhance the introduction of some molecules inside the interlayer.

Figure 2b shows the FTIR spectra of the raw bentonite and HTAB-bentonite. In the raw bentonite, except the broad band at 1430 cm−1 assigned to the calcite impurity and the peak at 797 cm−1 assigned to the quartz, all the other observed bands should be assigned to smectite (Vuković et al. 2006). The strong adsorption bands at 2918, 2850, and 1460 cm−1 were observed in the HTAB-bentonite. The 2918 and 2850 cm−1 can be assigned to the symmetric and asymmetric stretching vibrations of methyl and methylene groups, while the 1460 cm−1 band can be attributed to their bending vibrations (Özcan et al. 2004). These results prove the presence of HTAB on the bentonite.

Figure 3 displays the different micrographs of the raw bentonite, HTAB-bentonite alone, and with loaded BPA. A stratified structure is observed for the raw bentonite (Fig. 3a). The surface morphology of the HTAB-bentonite changed slightly due to the modification with HTAB (Fig. 3b), which was reported by Senturk et al. (2009). From the comparison of Fig. 3b, c, it is found that the BPA solution made the HTAB-bentonite swell, and numerous heterogeneous pores are observed on the HTAB-bentonite surface where BPA can be trapped and adsorbed greatly. Therefore, the structure of HTAB-bentonite can enhance the BPA adsorption capacity and exhibited a tendency to form agglomerates.

Batch adsorption tests

Sorption kinetics

Different kinds of mechanisms may have an effect on the adsorption process of BPA, such as mass transfer, diffusion control, chemical reactions, and particle diffusion (Yang et al. 2012). The sorption process of the porous adsorbents usually includes (1) namely diffusion in liquid phase, (2) external mass transfer to particle surface, (3) internal diffusion inside of adsorbents, and (4) attachment onto the sorption sites (Zhou et al. 2010). It can be seen that the sorption equilibrium of BPA on the raw bentonite can reach after 180 min (Fig. 4), while that on the HTAB-bentonite can reach only after 120 min. The HTAB-bentonite took much less time to reach the sorption equilibrium, which might be ascribed to the different microstructures that are the numerous heterogeneous pores observed on the HTAB-bentonite surface (Fig. 3) and further the diffusion of BPA within the porous adsorbent.

To further understand the sorption kinetics and find the more suitable model, the pseudo-second-order and Elovich models were selected to fit the kinetic data. These two models assume that the sorption is a chemical interaction during the sorption process, and they can be expressed as follows, respectively:pseudo-second-order kinetic model (Ho 2006):

Elovich model (Chabani et al. 2007):

where k (h−1) is the rate constant of pseudo-second-order adsorption, q e and q t (mg/g) are the amount of BPA adsorbed per unit mass of adsorbent at equilibrium and at time t, v 0 (mg/g h) represents the initial sorption rate, a (mg/g h) is the initial rate of sorption, and b (g/mg) is related to the extent of surface coverage.

The pseudo-second-order kinetic model fitted the data better than the Elovich model did, and the corresponding parameters were also calculated in Table 1. It can be observed that the HTAB-bentonite almost has triple sorption capacity (q e = 10.449 mg/g) as high as the raw bentonite (q e = 3.413 mg/g). The initial sorption rate of BPA on the HTAB-bentonite (v 0 = 2.839 mg/g h) was much faster than that on the raw bentonite (v 0 = 0.140 mg/g h), suggesting the favorable sorption of BPA on the HTAB-bentonite. There is a significant increase in the rate constant k from 0.012 for the raw bentonite to 0.026 for the HTAB-bentonite, which implies that the equilibrium time is shorter for the HTAB-bentonite. This result can be expected because the exchange processes of the HTAB-bentonite with BPA are more rapid and controlled mainly by diffusion, whereas those processes of the raw bentonite with BPA are slower and controlled either by the particle diffusion or by a second-order chemical reaction.

Sorption isotherm

Adsorption isotherms are of great use for better understanding of the adsorption mechanism. From the results of pH effects on the adsorption of BPA on the raw bentonite and HTAB-bentonite, pH 7.0 was chosen as the optimum pH value for sorption isotherms. The experiments were conducted with the initial BPA concentration in the range of 1–10 mg/L at pH 7.0 and contact time (3 h for the HTAB-bentonite and 2 h for the raw bentonite).

Figure 5 shows the adsorption isotherms of BPA on the raw bentonite and HTAB-bentonite. The adsorption capacity of the raw bentonite was negligible, but it was augmented greatly by loading HTAB. The Langmuir and Freundlich equations (Genc-Fuhrman et al. 2004) were adopted to describe the experimental data. The Langmuir isotherm model (Do 1998) makes the assumption that homogeneous monolayer surface adsorption occurs and can be written as follows:

where q e (mg/g) is the mass ratio of the adsorbed BPA and the adsorbent, C e (mg/L) is the equilibrium BPA concentration, Q m (mg/g) is the maximum adsorption capacity of the bentonite, and B is a constant related to the binding strength with BPA.

The Freundlich isotherm model (Do 1998) assumes a heterogeneous and patch-wise surface that is independent on each other. The exponential equation can be expressed as the following:

where K F (mg/g) is the Freundlich constant, which indicates the adsorption capacity and strength of the adsorptive bond, and n is the heterogeneity factor.

The sorption isotherms of BPA on the raw bentonite and HTAB-bentonite can be fitted better by the Freundlich model than the Langmuir model (Table 2). Furthermore, it can be deduced from the values of Freundlich constant (1.252 and 2.632 for the raw bentonite and HTAB-bentonite, respectively) that although the adsorption bonds of both bentonites are weak, those of the raw bentonite are weaker. Therefore, the predominant adsorption mechanism of BPA on the bentonite is anticipated to be physical rather than chemical (Belarbi and Al-Malack 2010). As shown in Fig. 5, the HTAB-bentonite adsorption isotherm is linear or slightly concave up, which is in accordant with the theory that sorption to clays modified by cations with long alkyl chains (such as HTAB) occurs primarily by a partition process between the aqueous solution and the organic medium created by the alkyl chains (Smith et al. 1990). The slight upward concavity of HTAB-bentonite isotherm observed (Fig. 5) can be attributed to the formation of a discrete solute phase on the surface of the clay, which is similar with previous studies (Jaynes and Boyd 1991).

Effect of pH on the adsorption of BPA on raw bentonite and HTAB-bentonite

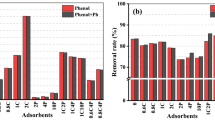

The study on the effect of pH on the adsorption capacity of raw bentonite and HTAB-bentonite was conducted at pH values varing from 4 to 10 because the pH of landfill leachates ranged from 4.5 to 9 (Christensen et al. 2001). The BPA adsorption capacity of the raw bentonite and HTAB-bentonite slightly increased when the pH values varied from 4 to 7 (Fig. 6), indicating that the binding affinity between BPA and the binding sites did not change significantly under acidic conditions. When the pH was higher than 7, the BPA adsorption capacity of the HTAB-bentonite obviously decreased while the raw bentonite did not change significantly.

A similar behavior was observed in other adsorbents mainly because BPA has a pKa of 9.59~10.2 and the concentration of negative BPA anions increased with the high pH values in the range of 7–10 (Yoon et al. 2003; Dong et al. 2010). As the pH value increased in the range of 7–10, the overall surface charge of BPA became more negative, and the electrostatic repulsion between BPA and the sorbent became stronger enough to overcome the binding affinity, which resulted in the reduction in the amount of BPA adsorbed onto the bentonite at alkaline conditions.

In this study, the data of adsorption isotherms are fitted well to the Freundlich model and the HTAB-bentonite has a higher sorption affinity for BPA (10.449 mg/g) comparing with the raw bentonite (3.413 mg/g). Although the adsorption capacity of HTAB-bentonite is not among the highest compared with other adsorbents (Dong et al. 2010), it still has a higher selectivity for BPA under the experiment conditions in this study (e.g., initial BPA concentrations, pH values, and temperature of the solution), which are more relevant to the actual situation of the landfill leachate. All these important controlling parameters have a certain degree of influence on the adsorption capacity of the adsorbents. Furthermore, more attention was paid to its potential practical application as components of landfill liner materials to retain BPA in the leachate, rather than only to pursue the high adsorption capacity of the material itself.

Permeability tests

Unlike the conventional bentonite, which swells in the presence of water, organobentonites exhibit the reverse behavior. They swell in the presence of nonpolar organic liquids (Li et al. 1996), reducing its permeability of the nonpolar organic contaminant, like BPA. According to these properties, HTAB-bentonite can serve as effective bottom liners for landfills to retain BPA.

Figure 7 shows the hydraulic conductivity of the raw bentonite and HTAB-bentonite alone and with water or BPA solution. As shown in Fig. 7a, the permeability values (K) of the HTAB-bentonite increased as the permeant liquid was changed from BPA solution to distilled water. This result indicates that the physical structure of the porous medium varies with different permeant liquids, which further affect the physicochemical reactions between bentonite particles and the organic matters or other impurities including those within the permeant liquid. These physicochemical reactions mainly include filtration and adsorption. While the bentonites were compacted in the permeameter molds, void spaces were still observed which the distilled water could percolate through easily. However, the organobentonites acted as the membrane to some extent, and the impurities in the leachate could be trapped and adsorbed, and therefore reduced the size of the porosity, and lowered permeability coefficient. So, it was difficult for organic compounds like BPA in the leachate to get through the soil void. These results prove that the HTAB-bentonite effectively intercalate BPA into the interlamellar space.

Figure 7b displays that hydraulic conductivities of the raw bentonite and HTAB-bentonite decrease with time and reach a steady value. Finally, the hydraulic conductivity of HTAB-bentonite was slightly larger than that of raw bentonite, but it still met the impermeable criterion of clay liner (K ≤ 1 × 10−7 cm/s) (Benson et al. 1994). The difference observed in the hydraulic conductivity is caused by the inability of the HTAB-bentonite to intercalate significant amounts of water. Because the substitution of the organic cations into the interlamellar space of the bentonite particles creates a hydrophobic surface, the intercalation of water by the organobentonites was strongly blocked consequently (Smitth and Jaffé 1994).

BPA breakthrough curves

Since batch adsorption tests and permeability tests were conducted to evaluate the adsorption affinity and permeability ability of the HTAB-bentonite, to further investigate its diffusion capacity, two column experiments were conducted to determine whether the HTAB-bentonite could increase the BPA breakthrough time and reduce the concentration of BPA in the effluent.

Figure 8 shows the BPA breakthrough curves by the column tests for both bentonites. For the raw bentonite, the initial breakthrough was observed after 113 h. The equilibrium concentration was reached after 220 h, when approximately 94 % of the initial concentration had been traced in the effluent solution, indicating the exhaustion of the soil column. The HTAB-bentonite extended the BPA breakthrough from 113 to 162 h (Fig. 8). The equilibrium concentration was reached after 290 h, when approximately 96 % of the initial concentration was traced in the effluent solution. All the results indicated that the HTAB-bentonite owned a significant ability of decreasing the mobility of BPA in a soil column.

Conclusions

In this work, we modified bentonite with HTAB and evaluated its performances as clay liner material to retain BPA generated in landfills through series of experiments. The introduction of HTAB into the internal position of the bentonite led to a high sorption affinity and selectivity for BPA. The kinetics of adsorption followed the second-order-kinetic model well. The Freundlich model agreed better with the experimental data, and the maximum adsorption capacity was found to be 0.410 mg/g. The HTAB-bentonite is a good adsorbent for BPA considering the experiment conditions in this study, which are more relevant to the actual situation of the landfill leachate. The adsorption of BPA by HTAB-bentonite exhibited high dependence on pH, which decreased with pH values at alkaline conditions. The significant increase in the BPA solution breakthrough time manifested the liner performance improvement of the HTAB-bentonite according to the column experiments. All these results justify the notable advantages as components of landfill liner material to retain BPA in the leachate.

References

Alexander HC, Dill DC, Smith LA, Guiney PA, Dorn PB (1998) Bisphenol A: acute aquatic toxicity. Environ Toxicol Chem 7:19–26

Alkaram UF, Mukhlis AA, Al-Dujaili AH (2009) The removal of phenol from aqueous solutions by adsorption using surfactant-modified bentonite and kaolinite. J Hazard Mater 169:324–332

Bartelt-Hunt SL, Smith JA, Burms SE, Rabideau AJ (2005) Evaluation of granular activated carbon, shale, and two organocalys for use as sorptive amendments in clay landfill liners. J Geotech Geoenviron 131:848–856

Belarbi H, Al-Malack MH (2010) Adsorption and stabilization of phenol by modified local clay. Int J Environ Res 4:855–860

Benson C, Zhai H, Wang X (1994) Estimating hydraulic conductivity of compacted clay liners. J Geotech Eng 120:366–387

Cao FM, Bai PL, Li HC, Ma YL, Deng XP, Zhao CS (2009) Preparation of polyethersulfone-organophilic montmorillonite hybrid particles for the removal of bisphenol A. J Hazard Mater 162:791–798

Carrizosa MJ, Rice PJ, Koskinen WC, Carrizosa I, Hermosín MC (2004) Sorption of isoxaflutole and DKN on organoclays. Clay Clay Miner 52:341–349

Chabani M, Amrane A, Bensmaili A (2007) Kinetics of nitrates adsorption on Amberlite IRA 400 resin. Desalination 206:560–567

Christensen TH, Kjeldsen P, Bjerg PL, Jensen DL, Christensen JB, Baun A, Albrechtsen H, Heron G (2001) Biogeochemistry of landfill leachate plumes. Appl Geochem 16:659–718

Daniel DE (1994) State of the art: laboratory hydraulic conductivity tests for saturated soils, hydraulic conductivity and waste containment transport in soil. ASTM STP 1142, ASTM, 30–78

Daniel DE, Benson CH (1990) Water content-density criteria of compacted soil liners. J Geotech Eng 116:1811–1830

Do DD (1998) Adsorption analysis: equilibrium and kinetics. Imperial College Press, London

Dong Y, Wu D, Chen X, Lin Y (2010) Adsorption of bisphenol A from water by surfactant-modified zeolite. J Colloid Interface Sci 348:585–590

Environment Agency of Japan (1997) Chemicals in the environment (in Japanese)

Genc-Fuhrman H, Tjell JC, McConchie D (2004) Adsorption of arsenic from water using activated neutralized red mud. Environ Sci Technol 38:2428–2434

Ghosh S, Mukherjee S, Sarkar K, Al-hamdan AZ, Asce AM, Reddy KR, Asce F (2012) Experimental study on chromium containment by admixed soil liner. J Environ Eng 138:1048–1057

Gleason M, Daniel D, Eykholt G (1997) Calcium and sodium bentonite for hydraulic containment applications. J Geotech Geoenviron 123:438–445

Hesse PR (1971) A text book of soil chemical analysis. John Murry, London

Ho YS (2006) Review of second-order models for adsorption systems. J Hazard Mater 136:681–689

Jaynes WF, Boyd SA (1991) Clay mineral type and organic compound sorption by hexadecyltrimethyl ammonium-exchanged clays. Soil Sci Soc Am J 55:43–48

Klapyta Z, Fujita T, Iyi N (2001) Adsorption of dodecyl- and octadecyltrimethyl ammonium ions on a smectite and synthetic micas. Appl Clay Sci 19:5–10

Krishnan AV, Starhis PS, Permuth F, Tokes L, Feldman D (1993) Bisphenol-A: an estrogenic substance is released from polycarbonate flasks during autoclaving. Endocrinology 132:2279–2286

Lagaly G (1984) Characterization of clays by organic compounds. Clay Miner 16:1–21

Li J, Smith JA, Winquist AS (1996) Permeability of earthen liners containing organobentonite to water and two organic liquids. Environ Sci Technol 30:3089–3093

Özcan AS, Erdem B, Özcan A (2004) Adsorption of Acid Blue 193 from queous solutions onto Na-bentonite and DTMA-bentonite. J Colloid Interf Sci 280:44–54

Rowe KR, Quigley RM, Brachman RWI, Brook JR (2004) Barrier systems for waste disposal facilities, 2nd edn. Spon Press, London

Sánchez-Jiménez N, Sevilla MT, Cuevas J, Rodríguez M, Procopio JR (2012) Interaction of organic contaminants with natural clay type geosorbents: potential use as geologic barrier in urban landfill. J Environ Manag 95:182–187

Sánchez-Marítn MJ, Rodríguez-Cruz MS, Andrades MS, Sánchez-Camazano M (2006) Efficiency of different clay minerals modified with a cationic surfactant in the adsorption of pesticides: influence of clay type and pesticide hydrophobicity. Appl Clay Sci 31:216–228

Senturk HB, Ozdes D, Gundogdu A, Duran C, Soylak M (2009) Removal of phenol from aqueous solutions by adsorption onto organomodified Tirebolu bentonite: equilibrium, kinetic and thermodynamic study. J Hazard Mater 172:353–362

Smith JA, Jaffé PR (1994) Benzene transport through landfill liners containing organophilic bentonite. J Environ Eng 120:1559–1577

Smith JA, Jaffé PR, Chiou CT (1990) Effect of ten quaternary ammonium cations on tetrachloromethane sorption to clay from water. Environ Sci Technol 24:1167–1172

Sreedharan V, Sivapullaiah PV (2012) Effect of organic modification on adsorption behaviour of bentonite. Indian Geotech J 42:161–168

Suciu NA, Ferrari T, Ferrari F, Trevisan M, Capri E (2012) Pesticide removal from waste spray-tank water by organoclay adsorption after field application: an approach for a formulation of cyprodinil containing antifoaming/defoaming agents. Environ Sci Pollut Res 19:1229–1236

Vandenberg LN, Hauser R, Marcus M, Olea N, Welshons WV (2007) Human exposure to bisphenol A (BPA). Reprod Toxicol 24:139–177

Vuković Z, Milutonović A, Rožić L, Nedić Z, Jovanović D (2006) The influence of acid treatment on the composition of bentonite. Clay Clay Miner 54:697–702

Yamamoto T, Yasuhara A, Shiraishi H, Nakasugi O (2001) Bisphenol A in hazardous waste landfill leachates. Chemosphere 42:415–418

Yang Q, Zhang J, Yang Q, Yu Y, Yang G (2012) Desalination and water treatment behavior and mechanism of Cd (II) adsorption on loess-modified clay liner. Desalin Water Treat 39:10–20

Yasuhara A, Shiraishi H, Nishikawa M, Yamamoto T, Nakasugi O, Okumura T, Kenmotsu K, Fukui H, Nagase M, Kawagoshi Y (1999) Organic components in leachates from hazardous waste disposal sites. Waste Manage Res 17:186–197

Yoon Y, Westerhoff P, Snyder SA, Esparza M (2003) HPLC-fluorescence detection and adsorption of bisphenol A, 17[beta]-estradiol, and 17[alphal]-ethynyl estradiol on powdered activated carbon. Water Res 37:3530–3537

Zhou Q, Deng S, Yu Q, Zhang Q, Yu C, Huang J, He H (2010) Sorption of perfluorooctane sulfonate on organo-montmorillonites. Chemosphere 78:688–694

Acknowledgments

The authors would like to express their sincere gratitude to the National Natural Science Foundation of China (No. 51322901 and No. 51479066), the Major State Basic Research Development Program of China (“973” program, No. 2012CB719804), the Major Science and Technology Program for Water Pollution Control and Treatment (2012ZX07506-002-2) and the Innovation Team of Ministry of Education (IRT13061) for the financial support of this study.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Zhihong Xu

Rights and permissions

About this article

Cite this article

Li, Y., Jin, F., Wang, C. et al. Modification of bentonite with cationic surfactant for the enhanced retention of bisphenol A from landfill leachate. Environ Sci Pollut Res 22, 8618–8628 (2015). https://doi.org/10.1007/s11356-014-4068-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-014-4068-0