Abstract

Acid-tolerant yeasts are one of the important keys to producing ethanol from acidic substrates, especially from molasses and agricultural waste. In this study, selected cultivars of yeasts isolated from a variety of locations such as botanical gardens in Thailand urban areas, which are often found highly polluted in the air such as carbon dioxide which is a cause of acid rain. There is limited information about how tolerant yeasts, are or their functional properties related to the environment. Yeast species were determined by using the 18S rDNA sequence guide. The level of acid tolerance was evaluated by adding to the culture medium lactic acid (300–900 mM), acetic acid (100–400 mM), and propionic acid (25–100 mM). 18S rDNA analysis has shown a %similarity of the nucleotide sequence higher than 98.65% compared to the database. Schwanniomyces etchellsii strains found in urban city soil were notable for their tolerance of lactic acid up to 100 mM. There are two main types of yeasts in overall acid tolerance: S. etchellsii, which is recognized as an osmotic pressure-resistant species that is highly resistant to fermentation inhibitors and produces ethanol; and Schizosaccharomyces pombe, which cell wall has been reported to be characterized by accumulation of α-(1,3)-glucan and malic acid can be used in metabolic pathways. The results show that S. pombe, isolated from rice paddy fields, can grow efficiently in acetic and propionic acid up to 400 mM and 100 mM, respectively. This species could be cultured in ethanol at a concentration of 12.5% (v/v). Moreover, it presented high ethanol and acetic acid production of 14.5–15.9 g/L and 7–10 g/L, respectively, with or without acidic conditions. In comparison, S. etchellsii, isolated from the botanical garden soil, which is grown in acetic, propionic, and lactic acid, was also indicated to be an organic acid-tolerant species.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Yeasts are eukaryotic organisms that are widely found in natural resources. They are particularly useful in commercial applications, including the food industry (beer, wine, and bread), biomass production (single cell protein or SCP), and the biofuel industry (ethanol, diesel, and jet fuel precursor) (Walker and Stewart 2016). Concerning the production of organic acids, when extracellular pH is lower than the intracellular pH, it may lead to intracellular acidification and the accumulation of its dissociated form, affecting cellular metabolism at various levels. Yeast performance is always affected by an acid concentration during the production of bioethanol and yeast-derived products. Intracellular pH and extracellular pH determine the achievement and ability of the cell to survive and trig metabolic tract under pressure. By the way, acid-tolerant host cells and acidophilic yeast should be focused extensively to overcome conditions in that criteria to reduce cell viability and production achieve especially when using cellulosic hydrolysate substrate. In parallel, the neutralization process can be minimized during large-scale fermentation of organic acid and chemical commodities. During fermentation, alkaline adjustment is always performed during production to balance ions in extracellular to reduce factors that interfere with cell growth in the broth. Sun et al. 2020 described the effect of neutralization and a subsequent step typically conducted with a strong acid (to recover the organic acid in its undissociated form). This practice implies significant costs for the acid and base. Moreover, all acid reactants are finally released into the environment leading to the cost of waste treatment. The use of acidophilic and acid-tolerant species is a talented way to overcome high-cost processing and pollution issues.

Thus, yeasts become attractive hosts because they are tolerant to multiple environmental stresses. In particular, the acid-tolerant ability of yeasts is usually preferred over bacteria due to their higher tolerance to low extracellular pH (Loureiro and Malfeito-Ferreira 2003; Sauer et al. 2010). Currently, there are many reports of the usage of yeasts as a host for producing carboxylic acids, such as S. cerevisiae, Candida krusei (current name, Pichia kudriavzevii), Zygosaccharomyces bailii, Kluyveromyces lactis, and Schizosaccharomyces pombe (Kildegaard et al. 2016; Halm et al. 2004; Branduardi et al. 2014; Koivistoinen et al. 2013; Takayama et al. 2018). However, the appearance of acid tolerance has limitations and differences in species. The investigation of the effects of organic acid and physiological analysis on yeast species is required to understand their ability. Moreover, acid-tolerant yeasts have benefits in lignocellulosic hydrolysate fermentation, which is contaminated with phenolics and weak acids from the pretreatment process. These inhibitory compounds influence metabolic functions and the fermentation ability of microbial cells (Guo and Olsson 2016) Guo (Warnecke and Gill 2005). Even though gene engineering is a useful tool for improving stress tolerance along with increasing the target products, it might consume time and reduce some abilities of the host cell, such as cell survival and growth. Thus, the advantage of using a wild-type strain, especially the strain that is involved in Biosafety Level 1, benefits laboratory operations and shortens the engineering step for a strong acid strain. Therefore, in this study, screening of strains to achieve new high acid-tolerance isolates was performed. The physiological study on yeast species was performed to demonstrate the effect of organic acid on microorganisms. Selected high-tolerant isolates can be adapted for further application of efficiently acid-resistant strains for commercial organic acid bioprocesses.

Carboxylic acids are organic compounds containing one or more carboxyl functional groups in the molecule. The molecular structure and carbon-chain length of carboxylic acids are significant to their properties. Carboxylic acids with carbon chains of fewer than five carbon atoms are soluble in water. The solubility has decreased since the carbon atoms have increased, which is the hydrocarbon portion. The hydroxyl group (–OH) of the carboxyl group can be substituted by other functional groups such as amides, esters, nitriles, and acid halides, resulting in carboxylic acid derivatives (Chahardoli et al. 2020; Malainey 2011). These compounds are crucial for numerous applications in industries such as food, pharmaceuticals, agriculture, and other industrial fields. Several carboxylic acids, such as acetic acid, lactic, succinic, and 3-hydroxy propionic, have been considered as potential platform chemicals to provide a sustainable alternative for the expanding non-fossil-based industry (Badea et al. 2018). Acetic acid is one of the most important chemical reagents and feedstocks. It acts as a substance for synthesizing polyvinyl acetate, which is utilized to make adhesives, synthetic fibers, and textiles, as well as cellulose acetate for the photographic film (Merli et al. 2021; Yadav et al. 2021). Lactic acid is an essential chemical with high potential applications in the food, textile, and pharmaceutical industries as well as the manufacture of hygiene and esthetic products in the cosmetic industry (Martinez et al. 2013). In the food industry, propionic acid is an important organic that serves as an antimicrobial agent for food preservatives and as an agent for artificial flavors and fragrances. Moreover, this acid acts as an intermediate in the synthesis of herbicides and as a precursor for the synthesis of cellulose acetate propionate (Ahmadi et al. 2017). 3-Hydroxypropionic acid is an attractive carboxylic compound that can be served as a precursor to producing various high-added-value chemicals such as acrylic acid, malonic acid, and 1,3-propanediol. The dehydration reaction of 3-hydroxy propionic acid leads to acrylic acid which has been widely utilized in diapers, paints, adhesives, and specialty coatings (Matsakas et al. 2014; Ji et al. 2018).

Currently, these organic acids are produced by chemical processes from petroleum raw materials and by bioprocesses from carbohydrate fermentation. Due to increasing petroleum demand, the rising cost of fuel, and concerns about environmental pollution, the production of carboxylic acids from bioprocess has been interesting in terms of cheaper and renewable substrate, mild reaction conditions, and ease of operation (Lidén 2017). However, there are many disadvantages to fermentation due to low productivity and product yield. One of the limitations of acid production is end-product inhibiting because most organic acids are toxic to microbial growth. When the acid concentration is high, cell growth is significantly reduced, resulting in decreased cell activity and production (Warnecke and Gill 2005). Therefore, microbial hosts that could adapt and propagate in the presence of high concentrations of weak acids at low pH are a crucial method for achieving high production.

Materials and methods

Sample collection

Selected samples were collected focuses on low-pH habitats in the environment. Soil samples were collected from urban city botanical garden (GPS location 13.735144220125242, 100.53006541052142, Bangkok, Thailand), organic rice paddy fields (GPS location 16.477158141269772, 100.32583098650754, Phichit province, Thailand) and Fruit from plantations such as pineapple, lime, and snake fruit were taken (GPS location 13.307596921621212, 101.25733861424133 Chonburi, Prachuap Khiri Khan, and 12.779960063363838, 101.64008272251995, Rayong provinces). Honey and honeycomb were collected from Big Bee Farm (GPS location 13.736498736857634, 100.73336439121582, Chonburi province). Seven samples were collected using sterile equipment into a sterile tube or a sampling bag and stored at 4 °C until use. pH of samples was detected between 5.0 and 6.5.

Isolation of acid-tolerant yeast

One gram of the sample was suspended in 10 mL of sterile distilled water and shaken for homogeneity. The soil suspension was transferred to a modified YPD medium containing 1% yeast extract, 2% peptone, 2% glucose, and 50 mM acetic acid. The initial pH of the medium was adjusted to four with HCl. The cultured broth was incubated at 30 °C for 3 days in a shaking incubator, then transferred to fresh YPD medium containing 50 mM acetic acid and incubated at 30 °C. After 48 h for the third subculture, the active culture from each sample was serially diluted up to 10–5. The dilution of 100 µl was spread on YPD agar supplemented with 100 µg/mL chloramphenicol and incubated at 30 °C for 48 h. Colonies were subcultured in YPD medium supplemented with chloramphenicol to achieve pure isolation. To select the best isolate for the acid tolerant strain, pure isolates were cultured in YPD medium supplemented with 100 mM acetic acid and incubated at 30 °C for 48 h.

Morphological and physiological characteristics

The morphological characteristics of colonies were determined after growth for 48 h at 30 °C on YPD agar to study the basis of color, margin, and elevation. The arrangement of yeast cells and budding were performed by staining with lactophenol cotton blue. Physicochemical characteristics were investigated in the fermentation of different carbohydrates and the effect of temperature and ethanol tolerances on cell growth. Different carbon sources including glucose, fructose, galactose, mannose, arabinose, xylose, sucrose, maltose, lactose, cellobiose, and starch were performed at 20 g/L sugar in minimal medium. To determine the effect of temperature on the growth, yeast strains were incubated at different temperatures (35°, 37°, 40°, 42°, and 45 °C). The effects of concentrations of 5%, 7.5%, 10%, 12.5%, 15%, and 20% ethanol were investigated on the isolates for 48 h.

Investigation of acid-tolerant yeast

To evaluate the acid tolerance of isolates, a single colony of each isolate was incubated in YPD medium at 30 °C for 24 h. Cultured broth was collected by centrifuge at 4000 g for 5 min and suspended in sterile distilled water. The suspended cells (1 × 107 cells/mL) were tenfold serially diluted from 107 to 104 cells/mL. The diluted solutions of 107, 106, 105, and 104 cells/mL were spotted onto YPD gar containing acetic (100–500 mM), lactic (300–1200 mM), or propionic acid (25–100 mM) at different concentrations and incubated at 30 °C for 48 h. S. cerevisiae TISTR 5344 was used as a control strain.

Molecular identification

Yeast genomic DNA was extracted from pure isolate following the E.Z.N.A. Yeast DNA kit (Omega Biotek, USA). The D1/D2 domain of the 26S rDNA fragment was amplified by PCR with NL1 (5′-GCATATCAAAAGCGGAGGAAAAG-3′) and NL4 primer (5′-GGTCCGTGTTTCAA GACGG-3′). PCR amplification was conducted according to the Phusion Taq DNA polymerase protocol (Biolabs, UK). The PCR products were purified and sequenced by the Pacific Science Co., Ltd. (Thailand). The nucleotide sequences of 26S rDNA were compared with the sequence data in the National Center of Biotechnology Information (NCBI) using the basic local alignment search tool (BLASTn, Genbank).

Solvent production

The ethanol and acetic acid production of the isolated strain in the culture medium containing 50 g/L of glucose was examined. Batch fermentation was performed in a 250 ml Erlenmeyer flask containing 50 ml of YPD medium. The cultured flasks were inoculated with an initial optical density at 600 nm (OD600) of 0.5 and incubated at 30 °C under a shaking condition at 180 rpm for 72 h. Batch fermentation was conducted in triplicates.

Analysis method

Samples were withdrawn from the fermented broth at different time intervals for analysis. The growth was measured by the optical density at 600 nm using a spectrophotometer (Biotek Epoch Microplate Spectrophotometer, USA). The samples were centrifuged at 10,000 g for 10 min and the supernatant was analyzed for ethanol, acetic acid, and sugar concentration. Solvent products were analyzed by gas chromatography (GC-2010A Shimadzu, Japan) using DB-WAX column and flame ionization detector (FID). The temperatures of the column, injector, and detector were 45, 250, and 260 °C, respectively. Helium was used as a carrier gas. Sugar concentration was measured via the dinitro salicylic acid (DNS) colorimetric method. The concentration of the colored complex was determined with the spectrophotometer at 540 nm. The production yield and ethanol percentage were calculated by following equation:

Results and discussions

Isolation of acid-tolerant yeast

To isolate acid-tolerance yeasts, the culture medium was supplemented with an acid at least pH 4. In this study, the YPD medium was supplemented with 50 mM acetic acid for the first screening. Acetic acid was chosen for screening in the current study because it is a by-product of yeast fermentation and a major inhibitor of yeast fermentation. It was found that thirty-three isolates were observed on YPD agar containing 50 mM acetic acid from the soil, lime, and pineapple samples. No colonies were detected from snake fruit, honey, or honeycomb. Five isolates were obtained after incubation in YPD agar containing 100 mM acetic acid, including BG1, BG3, and BG4 from botanical garden soil, PP3 from pineapple, and RF2 from rice paddy field soil (Table 1). There were a few microorganisms that were found in pineapple and lemon samples on YPD containing acetic acid. It might be that yeasts were often discovered in sweet fruits (Tikka et al. 2013) and were found in rotted fruit more often than the overripe fruit, which was used in this study. While the snake fruit that was used in this experiment was barely ripe. Apparently, the harvesting stage of fruit is associated with the microorganism community. Moreover, natural compounds from citrus fruit can be served as antimicrobial agents with low toxicity (Conte et al. 2007). Meanwhile, honey is reported to have antimicrobial, antiseptic, and antioxidant properties due to its extremely viscous nature to prevent infection (Lehmann et al. 2019). In soil, there are many different groups of microorganisms such as bacteria, fungi, and protozoa. Plant and animal residues, both living and dead, that accumulate in the soil become carbon and energy sources for microbes. The physical properties of soil, including pH, moisture, porosity, temperature, and nutrients, play a crucial role in managing the diversity of the soil microbial communities. For example, the structure of the bacterial and fungal communities, along with their metabolism, has been observed to differ as a consequence of various soil moisture conditions (Li et al. 2017).

Morphological and physiological characteristics

The characteristics of effective yeasts that are desired in various industrial biotechnology applications should exhibit multiple stress tolerance. Consequently, five isolates, which could grow on 100 mM acetic acid, were selected to estimate the acid, ethanol, and thermo-tolerance.

The colony morphology of all isolates was white or creamy white, circular with raised edges. Microscopic observation of the isolates showed a variety of several types of cells. Isolate BG1 presented an ovoidal to an elongated structure having single or bipolar budding cells (Fig. 1A). BG3 indicated an ovoidal shape, while BG4 and PP3 were spheroidal in shape and formed budding (Fig. 1B, C, and D). RF2 had a cylindrical rod shape and was divided close to the cell middle (Fig. 1E). Filament and spore were not observed under the cultural condition used in this study.

The selected strains were cultured with different carbon sources. They showed different abilities to utilize carbon sources (Table 2). All the isolates were able to ferment glucose, fructose, and mannose. None of the isolates exhibited the capacity to consume lactose because most yeasts lacked the lactase enzyme which breaks down lactose into glucose and galactose. Interestingly, the PP3 isolate demonstrated the ability to utilize various carbon sources.

Investigation of acid, ethanol, and thermo-tolerance

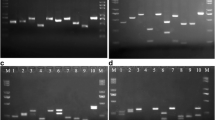

To evaluate the acid-tolerant yeasts, organic acids including acetic, propionic, and lactic acid were chosen to determine their stress. The results show that each isolate demonstrated different growth profiles with the various acid concentrations compared with the reference strain (Fig. 2). There were three isolates of yeasts, BG1, BG3, and PP3, that presented weak growth on 100 mM acetic acid, and no growth was observed on YPD agar when acetic acid was higher than 100 mM. The best acetic acid tolerance yeast was RF2, which was able to grow on 400 mM acetic acid, while the spoilage yeast Zygosaccharomyces bailii, which was infamous for being extremely preservative-tolerant, completely inhibited growth at 28 g/L (465 mM) acetic acid. Moreover, the RF2 strain was able to grow at higher propionic acid concentrations than the other strains. Nevertheless, this strain was low-tolerant to lactic acid. Isolates BG1, BG3, and BG4 indicated lactic acid tolerance at 900 mM. Interestingly, the BG4 strain had the best multi-acid tolerance performance, showing tolerance to acetic (300 mM), propionic (75 mM), and lactic acid (900 mM). On the other hand, the PP3 strain demonstrated the least ability to tolerate acid. Mira et al. (Mira et al. 2010) described that the resistant capability and response to various organic acids are associated with multiple transcription factors to adapt and resist in the presence of weak acids. Some species can consume organic acid as a carbon source. The cell wall also plays a significant role in yeast adaptation to organic weak acids (Ribeiro et al. 2022).

The results of the ethanol tolerance tests revealed that five strains could grow well at 5–7.5% (v/v) ethanol (Fig. 3A). There were BG1 and RF2 strains that indicated growth at 10% (v/v) ethanol, but cell growth was decreased by 50% compared with control without ethanol addition. It was found that RF2 and S. cerevisiae TISTR5344 could grow when the ethanol concentration was raised to 12.5%. No growth of isolates occurred at 15% (v/v) ethanol. Previous studies have reported that many yeast strains can grow well in the presence of 5–8% ethanol. However, when the concentration of ethanol was up to 12–15%, some strains had trouble growing because high ethanol concentration inhibited cell division, decreased cell vitality, and increased cell death (Stanley et al. 2010; Benito et al. 2017).

To be considered thermotolerant yeasts, they should be able to grow at a temperature of 40 °C. Here, it was found that three of five strains (BG3, BG4, and PP3) grew at 42 °C, while BG1 and RF2 strains could not be grown at a temperature higher than 35 °C (Fig. 3B). It was clear that the BG3, BG4, and PP3 isolates that could survive at temperatures higher than 40 °C were thermotolerant strains. The advantage of using thermotolerant strains is that it reduces the cost of the cooling process and protects the process from contaminants (Caspeta and Nielsen 2015). However, the consequences of heat stress have effects on cell development. It leads to structural changes in the membrane and stimulates several transcriptional and metabolomic systems, which cause several stressors (Strassburg et al. 2010; Lu et al. 2009). For this reason, no growth of any isolate was observed at 45 °C in this study.

Identification of acid-tolerant yeast by sequence analysis

The basis on of sequence analysis of the D1/D2 domain of 26S rDNA, the sequences of the acid-tolerant yeast strain BG1, BG3, BG4, PP3, and RF2 were identified as Hanseniaspora thailandica, Candida tropicalis, Schwanniomyces etchellsii, Meyerozyma guilliermondii, and Schizosaccharomyces pombe, respectively with maximum similarity of 99%, which is much higher than that in 98.65% to differentiate between two species by 16S rDNA identification method. The phylogenetic analysis confirmed that these isolates were closely related to different yeast species (Fig. 4).

Jindamorakot et al. (Jindamorakot et al. 2009) isolated H. thailandica from insect frass, which was identified as bipolar budding yeast. This strain was reported to be able to produce β-glucosidase to enhance the aroma of wine during alcohol fermentation (Phongprathet et al. 2018). Although the enzyme feature of this strain has previously been reported, the physiology of acid, ethanol, and thermo-tolerance has yet to be investigated. In this study, H. thailandica BG1, was isolated from soil in a botanical garden, indicating a bipolar budding cell, 10% (v/v) ethanol tolerance, and 35 °C for maximum temperature growth. It was also grown on lactic acid plate at 900 mM. Despite a high lactic acid tolerance, this strain presented low acid tolerance for acetic and propionic acids.

C. tropicalis is one of the most important Candida species, which is used in ethanol manufacture from cellulosic biomass. Please, give references to prove it. It is also known as thermotolerant yeast and could ferment xylose (Kuntiya et al. 2013; Phommachan et al. 2022). According to C. tropicalis BG3 results, they were able to ferment xylose and could grow at elevated temperatures. These findings were consistent with the previous report mentioned above. Furthermore, the BG3 strain exhibited the best resistance to lactic acid, whereas growth was inhibited by 150 mM acetic acid and 50 mM propionic acid.

S. etchellsii is also known as Pichia etchellsii, Debaryomyces etchellsii, and Torulaspora etchellsii. P. etchellsii has been described as a thermotolerant yeast that produces b-glucosidases, an enzyme that determines the aroma of food and wine (Wallecha and Mishra 2003). Furthermore, D. etchellsii is reported as an oleaginous yeast capable of accumulating lipids in nitrogen-limited media (Arous et al. 2016a). Zarnowski et al. (Zarnowski et al. 2021) demonstrated that S. etchellsii, which was a halotolerant strain, could form biofilms in seawater media. This organism was also able to reduce the phenolic compounds in the effluent (Arous et al. 2016b). In this research, the S. etchellsii BG4 revealed arabinose fermentation, which is one of the major compositions of hemicellulose. They could grow at an elevated temperature of 42 °C and survive in the presence of 7.5% (v/v) ethanol. Attractively, the S. etchellsii BG4 strain displayed the greatest achievement in acetic, propionic, and lactic acid tolerance. According to their ability, BG4 might be an attractive host for value-added production from various feedstocks such as food, agriculture, and industry, as well as acid-contaminated waste.

In a recent study, Carneiro et al. (Carneiro et al. 2019) reported that M. guilliermondii was the best xylose-consuming strain and showed the potential to produce xylitol with 0.3 g xylitol/g xylose. This organism was characterized as being able to tolerate conditions with low pH and bile salts as well as a high temperature of 42 °C (Zahoor et al. 2021). Although M. guilliermondii PP3 in this work was presented the extremely sensitive to acid and ethanol, they could use a variety of carbon sources. That is a good trait for substrate alterative in metabolite production or conversion into several applications.

S. pombe is well known as fission yeast, which has a long history of being a model organism for the study of eukaryotic cell systems. S. pombe is served as a host in the fermentation industry, especially for value-added chemicals via metabolic engineering such as lactic acid (Ozaki et al. 2017) and 3-hydroxy propionic acid (Takayama et al. 2018) due to its capability for acid tolerance. For this study, S. pombe RF2 demonstrated a high potential for acid tolerance to acetic acid at 400 mM, propionic acid at 75 mM, and lactic acid at 300 mM. Song et al. (Song et al. 2019) found that S. pombe can resist 166 mM (10 g/L) acetic acid and reduced acetic acid to enhance acid tolerance in the fermentation process by consuming acetic acid to form other metabolites. The RF2 strain also established high resistance to ethanol, which agrees with the previous report by Benito et al. (Benito et al. 2017).

Solvent production

The species H. thailandica BG1, M. guilliermondii PP3, and C. tropicalis BG3 were discarded because the strains BG1 and PP3 were highly sensitive to acid, while C. tropicalis is identified as biosafety level 2 (Biedunkiewicz and Bielecki 2010). Thus, S. etchellsii BG4 and S. pombe RF2, which showed the best performance in acid tolerance, were chosen for solvent production investigation. Moreover, the strain S. pombe is defined as biosafety level 1, which was already used in the bio-chemical and wine industries (Gemmill and Trimble 1998; Loira et al. 2018). Even though S. etchellsii was reported as a pathogen, it probably has low pathogenicity (Relich et al. 2015).

It was found that S. pombe RF2 produced ethanol at 14.5 g/L in YPD media and 15.9 g/L in YPD containing 100 mM acetic acid, as well as ethanol production in S. cerevisiae TISTR5344 (Fig. 5B). According to Table 3, the theoretical yield of ethanol production from glucose by S. pombe RF2 was 56.9–62.4%. The ethanol yield percentage of this strain was lower than the finding in Choi et al. (Choi et al. 2010) which demonstrated a theoretical yield of ethanol of 88.4 ± 0.91% with a dry cell weight of 3.40 ± 0.23 g/L. It might be that the metabolic flux of acetyl-CoA in the RF2 strain was flowing to other metabolites as observed in high acetic acid production and biomass. As a result, S. pombe RF2 also indicated high acetic acid production at 10 g/L, which was higher than S. cerevisiae TISTR5344. Acetic acid addition might have a good effect on cell growth of S. pombe RF2 because cell growth in acetic acid medium was quite higher than growth in medium without acetic acid (Fig. 5A). This result agrees with the finding by Song et al. (Song et al. 2019) that S. pombe can consume acetic acid and convert it into another metabolite in the mevalonate pathway. Suyama et al. (Suyama et al. 2017) found that adding acetate to the medium improved the target product. Acetate is converted to acetyl-CoA in the cell and utilized for cell growth. In contrast, S. etchellsii BG4 showed low ethanol and acetic acid production. The ethanol yield of S. etchellsii BG4 was 0.09 g/g. This result was following the results of Thontowi et al. (Thontowi et al. 2017) who reported that S. etchellsii LBF-3-0034 produced ethanol of 9 g/L in a YNS medium containing 100 g/L sugar with several inhibitor compounds, which showed an ethanol yield of 0.09 g/g. However, the BG4 strain achieved high biomass at 21.2 g/L in YPD containing 50 g/L glucose. These findings were consistent with the findings of Arous et al. (Arous et al. 2016a) who established that S. etchellsii had the potential to produce a single-cell protein with high biomass of 15.11 g/L from olive mill wastewater.

Owing to the need to attain huge amounts of bioproducts for industrial applications, optimizing the growth and production conditions of these strains is still required. The type of medium affects the growth ability; for example, fusion yeast needs a rich medium to support a fast growth rate (Petersen and Russell 2016). The initial concentration and type of carbon source are also critical to the final product titer. Moreover, one of the crucial elements in the initiation of the fermentation process is the inoculum size, which relates to nutrient consumption, yeast growth rate, and expected product yield. According to their acid-tolerant properties, alternative low-cost carbon sources, such as acid waste or lignocellulosic waste containing acid, should be investigated.

Conclusions

This study demonstrated a simple, fast, and easy method for the screening of acid-tolerant yeasts. Physiological investigation revealed variation in acid-tolerant ability among the five strains including H. thailandica BG1, C. tropicalis BG3, S. etchellsii BG4, M. guilliermondii PP3, and S. pombe RF2 from different resources. Interestingly, S. pombe RF2 and S. etchellsii BG4 had the greatest acid tolerance, which was suitable properties to serve as hosts for acid production or culture in acidic conditions. Both acid-tolerant strains had different characters, in which S. pombe RF2 showed the best performance in solvent production, while S. etchellsii BG4 presented a high biomass yield and was also a thermotolerance strain. These strains are a crucial host for potential commercial bio-based production.

References

Ahmadi N, Khosravi-Darani K, Mortazavian AM (2017) An overview of biotechnological production of propionic acid: from upstream to downstream processes. Electron J Biotechnol 28:67–75

Arous F, Azabou S, Jaouani A, Zouari-Mechichi H, Nasri M, Mechichi T (2016a) Biosynthesis of single-cell biomass from olive mill wastewater by newly isolated yeasts. Environ Sci Pollut Res 23:6783–6792

Arous F, Mechichi T, Nasri M, Aggelis G (2016b) Fatty acid biosynthesis during the life cycle of Debaryomyces etchellsii. Microbiology 162:1080–1090

Badea GI, Radu GL (2018) Introductory chapter: carboxylic acids - key role in life sciences. In: Badea GI, Radu GL (eds) Carboxylic acid - key role in life sciences. IntechOpen, London, pp 1–5

Benito Á, Calderón F, Benito S (2017) The combined use of Schizosaccharomyces pombe and Lachancea thermotolerans-effect on the anthocyanin wine composition. Molecules 22:739

Biedunkiewicz A, Bielecki A (2010) Hirudo medicinalis Linnaeus, 1758–a probable vector of transmission of fungi potentially pathogenic for humans; initial studies. Pol J Environ Stud 19:43–47

Branduardi P, Dato L, Porro D (2014) Molecular tools and protocols for engineering the acid-tolerant yeast Zygosaccharomyces bailii as a potential cell factory. Yeast metabolic engineering. Humana Press, New York, pp 63–85

Carneiro CVG, Silva FCDPE, Almeida JR (2019) Xylitol production: identification and comparison of new producing yeasts. Microorganisms 7:484

Caspeta L, Nielsen J (2015) Thermotolerant yeast strains adapted by laboratory evolution show trade-off at ancestral temperatures and preadaptation to other stresses. Mbio 6:e00431

Chahardoli A, Jalilian F, Memariani Z, Farzaei MH, Shokoohinia Y (2020) Analysis of organic acids. In: Sanches SA, Nabavi SF, Saeedi M, Nabavi SM (eds) Recent Advances in Natural Products Analysis. Elsevier, Amsterdam, pp 767–823

Choi GW, Um HJ, Kim MN, Kim Y, Kang HW, Chung BW et al (2010) Isolation and characterization of ethanol-producing Schizosaccharomyces pombe CHFY0201. J Microbiol Biotechnol 20:828–834

Conte A, Speranza B, Sinigaglia M, Del Nobile MA (2007) Effect of lemon extract on foodborne microorganisms. J Food Prot 70:1896–1900

Gemmill TR, Trimble RB (1998) All pyruvylated galactose in Schizosaccharomyces pombe N-glycans is present in the terminal disaccharide, 4, 6-O-[(R)-(1-carboxyethylidine)]-Galβ 1, 3Galα1. Glycobiology 8:1087–1095

Guo ZP, Olsson L (2016) Physiological responses to acid stress by Saccharomyces cerevisiae when applying high initial cell density. FEMS Yeast Res 16:7

Halm M, Hornbaek T, Arneborg N, Sefa-Dedeh S, Jespersen L (2004) Lactic acid tolerance determined by measurement of intracellular pH of single cells of Candida krusei and Saccharomyces cerevisiae isolated from fermented maize dough. Int J Food Microbiol 94:97–103

Ji RY, Ding Y, Shi TQ, Lin L, Huang H, Gao Z et al (2018) Metabolic engineering of yeast for the production of 3-hydroxypropionic acid. Front Microbiol 9:2185

Jindamorakot S, Ninomiya S, Limtong S, Yongmanitchai W, Tuntirungkij M, Potacharoen W et al (2009) Three new species of bipolar budding yeasts of the genus Hanseniaspora and its anamorph Kloeckera isolated in Thailand. FEMS Yeast Res 9:1327–1337

Kildegaard KR, Jensen NB, Schneider K, Czarnotta E, Özdemir E, Klein T et al (2016) Engineering and systems-level analysis of Saccharomyces cerevisiae for production of 3-hydroxypropionic acid via malonyl-CoA reductase-dependent pathway. Microb Cell Factor 15:53

Koivistoinen OM, Kuivanen J, Barth D, Turkia H, Pitkänen JP, Penttilä M et al (2013) Glycolic acid production in the engineered yeasts Saccharomyces cerevisiae and Kluyveromyces lactis. Microb Cell Factories 12:82

Kuntiya A, Takenaka S, Seesuriyachan P (2013) High potential of thermotolerant Candida tropicalis no. 10 for high concentration of phenol biodegradation. Food Appl Biosci J 1:59–68

Lehmann DM, Krishnakumar K, Batres MA, Hakola-Parry A, Cokcetin N, Harry E et al (2019) A cost-effective colourimetric assay for quantifying hydrogen peroxide in honey. Access Microbiol 1:10

Li Y, Adams J, Shi Y, Wang H, He JS, Chu H (2017) Distinct soil microbial communities in habitats of differing soil water balance on the Tibetan Plateau. Sci Rep 7:46407

Lidén G (2017) Carboxylic acid production. Fermentation 3:46

Loira I, Morata A, Palomero F, González C, Suárez-Lepe JA (2018) Schizosaccharomyces pombe: a promising biotechnology for modulating wine composition. Fermentation 4:70

Loureiro V, Malfeito-Ferreira M (2003) Spoilage yeasts in the wine industry. Int J Food Microbiol 86:23–50

Lu C, Brauer MJ, Botstein D (2009) Slow growth induces heat-shock resistance in normal and respiratory-deficient yeast. Mol Biol Cell 20:891–903

Malainey ME (2011) Chapter 5: Organic Compounds. In: Malainey ME (ed) A Consumer’s Guide to Archaeological Science, Manuals in Archaeological Method, Theory and Technique. Springer, New York, pp 45–72

Martinez FAC, Balciunas EM, Salgado JM, González JMD, Converti A, de Souza Oliveira RP (2013) Lactic acid properties, applications and production: a review. Trends Food Sci Technol 30:70–83

Matsakas L, Topakas E, Christakopoulos P (2014) New trends in microbial production of 3-hydroxypropionic acid. Curr Biochem Eng 1:141–154

Merli G, Becci A, Amato A, Beolchini F (2021) Acetic acid bioproduction: the technological innovation change. Sci Total Environ 798:149292

Mira NP, Teixeira MC, Sá-Correia I (2010) Adaptive response and tolerance to weak acids in Saccharomyces cerevisiae: a genome-wide view. OMICS J Integr Biol 14:525–540

Ozaki A, Konishi R, Otomo C, Kishida M, Takayama S, Matsumoto T et al (2017) Metabolic engineering of Schizosaccharomyces pombe via CRISPR-Cas9 genome editing for lactic acid production from glucose and cellobiose. Metab Eng Commun 5:60–67

Petersen J, Russell P (2016) Growth and the environment of Schizosaccharomyces pombe. Cold Spring Harb Protoc. https://doi.org/10.1101/pdb.top079764

Phommachan K, Keo-oudone C, Nurcholis M, Vongvilaisak N, Chanhming M, Savanhnaly V et al (2022) Adaptive laboratory evolution for multistress tolerance, including fermentability at high glucose concentrations in thermotolerant Candida tropicalis. Energies 15:561

Phongprathet S, Vichitphan K, Han J, Vichitphan S, Swangkaew J (2018) Hanseniaspora thailandica BC9 β-glucosidase for the production of β-D-hexyl glucoside. J Microbiol Biotechnol 28:579–587

Relich RF, Schmitt BH, Koehlinger J, Wiederhold NP, May M (2015) Schwanniomyces etchellsii: an unusual cause of fungemia in a patient with cholecystitis. Diagn Microbiol Infect Dis 84:221–222

Ribeiro RA, Bourbon-Melo N, Sá-Correia I (2022) The cell wall and the response and tolerance to stresses of biotechnological relevance in yeasts. Front Microbiol 13:953479

Sauer M, Porro D, Mattanovich D, Branduardi P (2010) 16 Years research on lactic acid production with yeast-ready for the market. Biotechnol Genet Eng Rev 27:229–256

Song Z, Du H, Zhang M, Nie Y, Xu Y (2019) Schizosaccharomyces pombe can reduce acetic acid produced by Baijiu spontaneous fermentation microbiota. Microorganisms 7:606

Stanley D, Bandara A, Fraser S, Chambers PJ, Stanley GA (2010) The ethanol stress response and ethanol tolerance of Saccharomyces cerevisiae. J Appl Microbiol 109:13–24

Strassburg K, Walther D, Takahashi H, Kanaya S, Kopka J (2010) Dynamic transcriptional and metabolic responses in yeast adapting to temperature stress. OMICS J Integr Biol 14:249–259

Sun W, Vila-Santa A, Liu N, Prozorov T, Xie D, Faria NT, Ferreira FC, Mira NP, Shao Z (2020) Metabolic engineering of an acid-tolerant yeast strain Pichia kudriavzevii for itaconic acid production. Metab Eng Commun. https://doi.org/10.1016/j.mec.2020.e00124

Suyama A, Higuchi Y, Urushihara M, Maeda Y, Takegawa K (2017) Production of 3-hydroxypropionic acid via the malonyl-CoA pathway using recombinant fission yeast strains. J Biosci Bioeng 124:392–399

Takayama S, Ozaki A, Konishi R, Otomo C, Kishida M, Hirata Y (2018) Enhancing 3-hydroxypropionic acid production in combination with sugar supply engineering by cell surface-display and metabolic engineering of Schizosaccharomyces pombe. Microb Cell Factories 17:176

Thontowi A, Putra FJN, Yopi Y (2017) Evaluation of Non-Saccharomyces cerevisiae strains isolated from sea water against inhibitory compounds for ethanol production. Squalen Bull Mar Fish Postharvest Biotechnol 12:57–65

Tikka C, Osuru HP, Atluri N, Raghavulu PCV (2013) Isolation and characterization of ethanol tolerant yeast strains. Bioinformation 9:421–425

Walker GM, Stewart GG (2016) Saccharomyces cerevisiae in the production of fermented beverages. Beverages 2:30

Wallecha A, Mishra S (2003) Purification and characterization of two β-glucosidases from a thermo-tolerant yeast Pichia etchellsii. Biochim Biophys Acta - Proteins Proteom 1649:74–84

Warnecke T, Gill RT (2005) Organic acid toxicity, tolerance, and production in Escherichia coli biorefining applications. Microb Cell Factories 94:25

Yadav N, Hakkarainen M (2021) Degradable or not? Cellulose acetate as a model for complicated interplay between structure, environment and degradation. Chemosphere 265:128731

Zahoor F, Sooklim C, Songdech P, Duangpakdee O, Soontorngun N (2021) Selection of potential yeast probiotics and a cell factory for xylitol or acid production from honeybee samples. Metabolites 11:312

Zarnowski R, Sanchez H, Andreu C, Andes D, del Olmo M (2021) Formation and characterization of biofilms formed by salt-tolerant yeast strains in seawater-based growth medium. Appl Microbiol Biotechnol 105:2411–2426

Acknowledgements

This work was financially supported by Research and Researchers for Industries (RRI) by Thailand Research Fund [grant numbers PHD61I0031] and Innovation Institute, PTT Public Co. Ltd. Special Thanks for members of Biofuels by Biocatalysts Research Unit for support.

Funding

Research and Researchers for Industries (RRI) by Thailand Research Fund,PHD61I0031,PHD61I0031,PHD61I0031,Innovation Institute,PTT Public Co. Ltd.

Author information

Authors and Affiliations

Contributions

The authors confirm contribution to the paper as follows: All authors reviewed the results and approved the final version of the manuscript. Study conception and design: NB, CG Acquisition of data: SL, CG Analysis and interpretation of data: SL, NB, CG Drafting of manuscript: SL, CG Critical revision: CG.

Corresponding author

Ethics declarations

Competing interests

The author declare no competing interests. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lertsriwong, S., Boonvitthya, N. & Glinwong, C. Schwanniomyces etchellsii, acid-thermotolerant yeasts from urban city soil. World J Microbiol Biotechnol 39, 159 (2023). https://doi.org/10.1007/s11274-023-03602-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-023-03602-7