Abstract

Presently, the creation of metal nanoparticles (NPs) using plant extracts has rapidly gained an appealing aspect in the realm of modern nanobiotechnology, with substantial merits over traditional techniques. In this context, cadmium oxide (CdO) NPs have been created utilizing a bio-inspired green synthetic approach using Citrus limetta peel extract. The active organic biomolecules within the peel extract functioned as reductants and stabilizers for NPs, resulting in pure CdO NPs. The structural, chemical, optical, and topological traits were evaluated utilizing XRD, FTIR, FESEM, EDX, HRTEM, UVDRS, and PL analyses. The synthesized CdO NPs are about 54 nm in size with a quasi-spherical morphology. The computed band gap of NPs was 2.59 eV, which validated the cubic phase formation of CdO NPs. The photocatalytic studies of the as-fabricated CdO NPs were investigated through Rhodamine B (RhB) dye degradation via H2O2-assisted AOP under sunlight. The effect of H2O2, photocatalyst loading, RhB dye concentration, contact time, scavengers, and recyclability study was also investigated in detail to demonstrate the functionality of the photocatalyst. Approximately 85% of the dye was decomposed within 60 min, revealing its excellent photocatalytic performance of CdO NPs. Therefore, the research outcomes thus offer that the CdO NPs may have a substantial potential for ecological remediation through a photocatalytic approach.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Water is an indispensable component of ecological and human life, and access to clean drinking water is a universal challenge [1, 2]. Rapid industrialization, population growth, and agricultural expansion have increased the imperative need for a fresh and drinkable water supply [3]. The challenge of water pollution has worsened nowadays due to the uncontrolled and careless release of wastewater comprising diverse pollutants, including heavy metals, organic dyes, inorganic salts, personal care products, and pesticides [4,5,6,7]. The manufacturing of textiles and dyes has expanded substantially since the discovery of synthetic dyes [8]. However, discharging synthetic dyes from these industries into local water reservoirs poses several risks to aquatic and human life [9]. Among the diverse organic dyes, Rhodamine B (RhB) (Fig. 1) is a prominent common dye extensively utilized in different industries, including textiles, food, and leather [10, 11]. However, this dye is extremely poisonous and possesses mutagenic and carcinogenic properties for all living things [12]. Additionally, RhB poses a serious and persistent threat to aquatic life, particularly plants, as it reduces light penetration, which lowers photosynthesis and tampers with the natural cleansing systems [13]. Because of this, RhB must be entirely eradicated from industrial effluent to prevent the harmful impacts its presence in the ecosystem causes. Therefore, diverse nanomaterial-based photocatalysts have been applied to purify water polluted with RhB dye [14, 15].

Nowadays, research on advanced nanotechnology is becoming more and more admired because of its innovative and exciting breakthroughs in multiple domains [16, 17]. This swiftly emerging field significantly impacts applied biology, chemistry, electronics, physics, and material science disciplines [17,18,19,20]. Generally, nanotechnology addresses the study of materials and technology with dimensions ranging from 1 to 100 nm. This advanced technology explores integrating these nanoscale materials into larger frameworks and controlling their chemical and physical traits [21,22,23]. Presently, diverse nanoparticle (NP) morphologies are being synthesized, including nanocubes, nanoflowers, nanoneedles, nanorods, nanoplates, nanoshells, and nanospheres [24,25,26]. Because of their extensive surface area and unusual chemical and physical traits contrasted to their bulk counterparts, nanoparticles (NPs) have attracted tremendous curiosity [27,28,29]. As a result, multifunctional nanomaterials are being developed at the cutting edge of nanotechnology for miscellaneous uses, including biomedical, cosmetics, catalysis, drug delivery therapies, energy storage, foods, paints, solar cells, textiles, and optical, medical, and electronic devices [30,31,32,33].

Among different metal oxides, CdO is recognized as one of the intriguing metal oxides with a band gap of ~ 2.5 eV and an n-type semiconductor [34, 35]. Its unusual physicochemical features reveal prospective uses in organic light-emitting diodes, IR reflectors, gas sensors, transparent electrodes, solar cells, photovoltaic cells, biological activities, and photocatalysis [35,36,37]. To date, several approaches for the creation of CdO NPs have been documented in the literature, namely thermal decomposition [38], sol-gel [39], solid state [40], spray pyrolysis [41], solvothermal [42], microwave-assisted [43], mechanochemical [44], laser ablation [45], hydrothermal synthesis [46], co-precipitation [47], chemical bath deposition [48], with attractive shapes namely belts, particles, rods, sheets, and wires [34, 49]. However, these strategies are time-consuming, demand high energy, generate harmful byproducts, and use noxious chemicals and capping agents that adversely affect the ecosystem. Therefore, it is essential to design straightforward and environmentally safe technologies for creating nanoparticles without deleterious compounds. As a result, green synthesis is crucial for advancing sustainability and spurring innovation in chemical synthesis. It provides solutions to global environmental issues while simultaneously satisfying the demands of the scientific community and the industrial sector [50,51,52].

Furthermore, it has long been known that CdO is poisonous and poses major risks to both the human health and environment [53,54,55]. Researchers are searching for safer alternatives for the production of CdO due to the inherent hazards connected with it, even if it is useful in many industrial applications [34, 56]. A paradigm change toward safer and more sustainable synthesis techniques is required due to the toxicity of CdO. Using the green chemistry approaches is a viable substitute that shows promise for reducing the adverse impacts of CdO and satisfying the needs of contemporary technology [57, 58].

Citrus sinensis is a member of the Rutaceae family and is most likely native to Southeast Asia [59]. Citrus fruits are becoming more popular because of their many health advantages, flavor, and refreshing aroma [60]. Due to the presence of significant organic biomolecules, including alkaloids, carbohydrates, coumarins, flavonoids, peptides, vitamins, steroids, and volatile compounds, which prove that medicine and food originated from the identical source, hence Citrus sinensis portions are processed to make food products [60,61,62,63]. Furthermore, Citrus sinensis’s non-edible peels contain bioactive compounds (Fig. 2) that have numerous medicinal benefits, including antibacterial, antifungal, anti-obesity, antiosteoporotic, antiparasitic, antiproliferative, and insecticidal actions [61, 62]. Therefore, the proposed work focuses on creating NPs through an eco-benevolent approach for possible application in environmental remediation. Since bio-waste is being applied as an initial biological precursor, this technique successfully handles waste without harming the environment.

A few investigations have been attempted to manufacture CdO NPs from botanical extracts. Diverse botanical extracts employed in the green manufacturing of CdO NPs are listed in Table 1. Therefore, this work describes the solely green creation of CdO NPs implementing aqueous extracts of Citrus sinensis peels as efficient natural reductants and stabilizers. The structural, chemical, optical, and topological traits of the biologically manufactured CdO NPs were evaluated using diverse instrumental techniques. Furthermore, the photocatalytic efficacy of the as-manufactured CdO NPs was explored utilizing RhB dye degradation through H2O2-assisted AOP under sunlight. Therefore, the produced CdO NPs can be applied as a photocatalyst to decompose organic dyes in water bodies.

2 Experimental

2.1 Materials

The healthy fruits of Citrus sinensis were collected from the local markets. All the required chemicals (AR grade) were acquired from SRL Chem, India, and were employed without additional purification. Double-distilled water (ddH2O) was utilized for the experiments. All equipment was sterilized before use.

2.2 Preparation of Peel Extract

Healthy peels of Citrus sinensis fruits are incised into small pieces and washed thoroughly with ddH2O. After precisely 5 g of the finely chopped Citrus sinensis peels were weighed, they were added to a 250 mL beaker with 100 mL of ddH2O, thoroughly mixed, and allowed to boil for 15 min. The pale yellow extract was acquired after filtering using Whatman No. 1 filter paper. The resultant filtrate was stored in a conical flask at 4 °C.

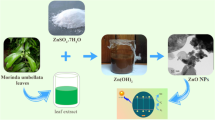

2.3 Green Fabrication of CdO NPs

For the biogenic fabrication of CdO NPs, the cadmium salt Cd(NO3)2·4H2O was applied to manufacture CdO NPs via an eco-friendly strategy. Initially, 3.08 g of cadmium nitrate and 50 mL of pale yellow peel extract were taken in a beaker. Then, the resultant solution was agitated uniformly through a magnetic stirrer at RT for 60 min at 1500 rpm. Thereafter, the beaker was placed in a hot oven at 100 °C. The obtained material was calcined in a muffle furnace at 500 °C for 2 h and employed for further investigations. Figure 3 describes the pictorial illustration for green manufacturing of CdO NPs through Citrus sinensis peel extract.

2.4 Assessment of the Photocatalytic Activity

The photocatalytic efficacy of the manufactured photocatalyst was investigated by monitoring the decomposition of RhB dye under sunlight. An optimum amount of the photocatalyst was mixed with the 50 mL of the optimized dye solution in a 100 mL beaker and stirred in the dark for 30 min to attain adsorption/desorption equilibrium, followed by the addition of an optimized amount of hydrogen peroxide and irradiating the reaction mixture under natural sunlight. All the photodegradation tests were performed in July between 10 am to 2 pm at the NIT, Silchar, Assam, India. The mean temperature during the experiment was 33 ± 2°C. The light intensity was measured using a luxmeter placing it near the base of the beaker. The average light intensity was 723.18 W/m2. The degradation of RhB was noticed by measuring a reduction in the absorption intensity at λmax = 664 nm through a UV-Vis spectrophotometer.

No notable adsorption of RhB was noticed after 30 min of stirring in the dark, nor was any significant photolysis observed after irradiating the dye solution under sunlight for 60 min. Irradiation of dye solution with hydrogen peroxide alone caused a degradation of 10.23%, which is almost negligible compared to the CdO + H2O2 system.

The performance of the photodegradation experiment was computed through the accompanying formula:

Here, Co and C are the initial and final concentrations of RhB after time t, respectively.

The below equation was applied to determine the pseudo-first-order (PFO) reaction kinetics of RhB photodegradation:

Here, k is the PFO rate constant, and t is time in min.

2.5 Characterizations

Several instrumentation techniques were applied to acquire comprehensive insight into the crystal structure, chemical bonding, elemental composition, microstructure, and optical features of calcined nanoparticles. The crystallographic formation of CdO NPs was explored by X-ray powder diffraction (XRD, Panalytical X’PERT PRO diffractometer). Infrared spectra of Citrus sinensis peel powder and CdO NPs were acquired on a 4600 typeA FTIR spectrophotometer using a KBr pellet. Microstructural properties and the chemical composition of the fabricated material were explored with VEGA3 TESCAN equipped with a field-emission scanning electron microscope (FESEM) and energy-dispersive X-ray (EDX) spectroscopy detector. Furthermore, a high-resolution transmission electron microscope (HRTEM, JEM-2100) was applied to explore the topologies of CdO NPs properly. The optical traits of the manufactured material were identified by UV-Vis (Jasco Spectrophotometer V-770) with a range of 200 to 800 nm. An FP-8200 Spectrofluorometer is applied to study the photoluminescence (PL) feature of CdO NPs.

3 Results and Discussion

3.1 XRD Study

To account for the presence of the CdO phase in the as-manufactured material, the XRD characterization technique was implemented, and the pattern so obtained has been depicted in Fig. 4. The strong and narrow diffraction peaks observed in the pattern are indicative of the highly crystalline nature of the sample. The diffraction peaks observed at 2θ (diffraction angles) values of 33.03o, 38.4o, 55.4o, 66.03o, and 69.4o correspond to the diffraction peaks belonging to the (hkl) values of (110), (200), (220), (311), and (222) as highlighted in Fig. 4, respectively, according to the JCPDS card no. 05-0640 [70]. The assignments of all the observed diffraction peaks for CdO NPs indicate the high purity of this sample. Further, the indexed diffraction peaks confirm the formation of a simple cubic phase of CdO NPs. The mean crystallite size, as calculated utilizing Scherrer’s equation [71], was 54.18 nm.

3.2 FTIR Study

An FTIR study was used to confirm that the phytochemicals of the Citrus sinensis peel extract function as reductants and stabilizers during the biosynthesis of CdO NPs. In this regard, Fig. 5 depicts the FTIR spectral data of the Citrus sinensis peel powder and as-synthesized CdO NPs, wherein all the prominent bands have been marked. From the two spectra, a shift in the band positions about CdO NPs may be identified respectively to that of the bio-extract, indicating the interaction of the phytochemicals with the NPs.

The bands at 3408.9 cm− 1 and 3453.2 cm− 1 may be attributed to the presence of the -OH band of the carbohydrates and phenolic compounds [72]. The band appearing at 2934.4 cm− 1 is due to the C-H band of the stretching vibration of the aliphatic hydrocarbon chains, either from the methyl or methylene group from the lipids present in the bio-extract [72]. The bands at 2356.4 cm− 1 and 2335.1 cm− 1 are due to the C ≡ C stretching vibration [73]. The band indicates the presence of phenolic molecules in the bio-extract as aromatic alkenes at 1747.2 cm− 1. The band around 1627.3 cm− 1 may be ascribed to the unsaturated aromatic compounds [74]. The bands at 1432.8 cm− 1 and 1437.7 cm− 1 are characteristic of the aliphatic chains such as the -CH2 and -CH3 groups. The band at 1313.75 cm− 1 is due to the 3°carbon atoms, while the band at 1133.9 cm− 1 in the case of CdO NPs is due to the carboxylate group, respectively [75]. The bands at 1039.5 cm− 1 and 935.3 cm− 1 correspond to the C-O-H or C-O-R alcohol or ester linkages.

Shifts in the band positions may be observed in the case of unsaturated bonds of the carboxylate group of enzymes and alkynes arising from the bio-extract used during synthesis. Thus, it may be concluded that these groups were mainly accountable for the stabilization of the as-manufactured CdO NPs. A similar observation has been reported elsewhere [75].

3.3 Optical Study

The UV-Vis DRS spectral data of the bio-produced CdO NPs is displayed in Fig. 6(a), while Fig. 6(b) represents the Tauc plot. From Fig. 6(a), a large absorbance band ranging from 350 to 500 nm was obtained, which may be attributed to the existence of various defect states in the sample. Moreover, data indicated that the band transitions in the sample are both direct as well as indirect [66], and the sample absorbs in the UV-Vis region. The mean absorbance was observed at 430.2 nm, as marked in Fig. 6(b). Additionally, the band gap of this sample, CdO NPs, was computed utilizing the Tauc plot, as shown in the inset figure, and was found to be 2.59 eV. The reported value of CdO NPs lies in the range of 1.1 eV to 3.3 eV [66].

3.4 PL Analysis

It was observed from the optical that the as-prepared CdO NPs may possess various defect states. In order to verify this analysis, RT PL analysis was conducted as well as the estimation of the nature and the density of the ion deficiencies and defects in the biosynthesized CdO NPs was performed.

Figure 7 shows the PL spectral data of the as-manufactured CdO NPs. In the wavelength plot against intensity, only a visible emission peak located at 576.2 nm was observed. A similar observation has been reported elsewhere [76], wherein the Authors obtained a distinct absorption peak at 534 nm. As compared to their results, in the present study, a shift towards the longer wavelength side was observed that may be evinced by the difference in the nature of the material, wherein the current study is based on CdO NPs while in the reported literature [76], the material was CdO nanorods developed on silicon substrate. The existence of this sharp band could be assigned to the near-band-edge emission of CdO NPs [66, 76].

3.5 Morphological Analysis

Figure 8(a) presents the SEM image of the as-synthesized CdO NPs. It may be noticed from this image that most of the particles have agglomerated. While a clear distinction between the individual grains can be made, the morphology of the individual particles is irregular. Additionally, few particles have acquired quasi-hexagonal morphology. The mean particle size was computed to be 235 nm. Figure 8(b) reveals the EDX spectrum of the particles, and the inset table provides information on the weight and atomic percentages of the elements found in the sample. From this table, it is clear that only the elements Cd and O were present in the material with no impurity elements. As a result, the findings obtained from the XRD data were further supported by this investigation.

3.6 HRTEM Analysis

For the microstructural analysis, the HRTEM technique was employed, and the so-obtained image has been depicted in Fig. 9. From Fig. 9(a), the particles appear to have an irregular structure similar to the observation given by SEM analysis. Since a quasi-spherical morphology and microstructure were obtained, it may be assumed here that the amount of the peel extract used was insufficient to control a regular-known structure of the particles. Figure 9(b) represents the HRTEM picture with the lattice fringes. Through this image, the value of the inter-planar spacing was computed to be 2.27 Å, indicating the (111) diffraction plane of CdO NPs [77].

3.7 Effect of Diverse Parameters for the Photocatalytic Decomposition of Rhodamine B Dye

3.7.1 Effect of H2O2

Hydrogen peroxide (H2O2) is a renowned oxidizing agent in Photo Fenton-like photocatalytic reactions. Therefore, the effect of H2O2 was investigated using 20 mg of the manufactured photocatalyst dispersed in 10 ppm of RhB dye, as highlighted in Table 2. The reaction solution was stirred in the dark without adding H2O2 to attain adsorption-desorption equilibrium. No significant reduction (< 5%) in the absorption maxima of the dye was observed, ruling out the possibility of the absorption of the dye by the prepared photocatalyst. Under visible light, the same solution was exposed to radiation. After 60 min, only 29.49% photodegradation was observed without H2O2. The H2O2 concentration of the reaction mixture varied from 0 mL/50 mL to 0.5 mL/50 mL. The photodegradation of the RhB dye increases upon increasing the amount of H2O2. A maximum decomposition of 79.43% could be attained at an H2O2 dosage of 0.3 mL within 60 min with a PFO rate constant of 0.02816 min− 1, which started declining after that (Fig. 10a and b). An initial increase in photodecomposition performance was ascribed to the self-degradation of H2O2 according to the following reaction [78]:

The photogenerated hydroxyl radicals increased the photodecomposition of the RhB dye. However, a fall in the decomposition efficacy upon increasing the dosage of H2O2 was due to the self-scavenging properties of hydroxyl radicals generating less reactive HO2● radicals at higher concentrations according to the reaction below [79]:

Therefore, according to the findings, 0.3 mL H2O2 was determined to be an optimum dosage for additional photocatalytic studies. It is also crucial to note that only H2O2, in the absence of a photocatalyst, does not show any significant photodegradation of RhB dye within 60 min of irradiation.

3.7.2 Effect of Photocatalyst Dosage

The optimization of the photocatalyst dosage is crucial to minimize the waste of the photocatalyst while achieving maximum decomposition of the dye. The impact of the photocatalyst dosage was explored by altering the amount of CdO from 10 mg to 30 mg in a 50 mL 10 ppm solution of RhB and 0.3 mL of H2O2 dosage (Table 3). As seen in Fig. 11(a) and (b), the photodecomposition of the dye elevates with increasing the photocatalyst dosage. This boost in the decomposition rate was due to the increased formation of hydroxyl radicals due to more exposed active sites as the amount of the photocatalyst rises [80]. The maximum photodecomposition performance of 83.62% with a PFO rate constant of 0.03167 min− 1 could be attained using 25 mg of the photocatalyst and then started to decline further. Upon further increasing the amount of the photocatalyst, the opacity of the solution increases, which prevents the light from reaching the solution and causes a decrease in the photodegradation efficiency [81]. Therefore, 25 mg/50 mL–0.5 g/L photocatalyst dosage was chosen for further optimization experiments.

3.7.3 Effect of Initial Dye Concentration

The impact of RhB dye concentration was investigated by keeping the photocatalyst dosage constant at 25 mg using 0.3 mL H2O2, and the concentration of RhB varied from 10 to 30 ppm (Table 4). As indicated in Fig. 12(a) and (b), initially, the photodecomposition performance increased up to 15 ppm. Then, a further increase in the dye concentration caused a fall in the decomposition performance due to the inability of the light to penetrate the solution [82]. Moreover, higher photocatalyst loading was required for the degradation of higher dye concentrations, which, in turn, will enhance the opacity of the solution, thereby decreasing the photodegradation of the dye [83]. Furthermore, other reports claimed that a higher dye concentration would block the active sites of the photocatalyst, diminishing the creation of reactive oxygen species (ROS), which would also cause a decrease in the photodecomposition efficacy [84]. The highest degradation of 85.44% with a PFO rate constant of 0.03338 min− 1 was attained within 60 min of solar irradiation.

3.7.4 Effect of Contact time

Under ideal circumstances of 0.3 mL of H2O2, 25 mg of catalyst, and 15 ppm of initial organic component concentration, the impact of contact duration on the photocatalytic decomposition of RhB was examined (Fig. 13). It should be emphasized that after 60 min of irradiation, no further rise in the decomposition performance was seen. The depletion of the photocatalyst surface’s active surface sites may cause this conclusion. 85.44% is attained, which is the maximum photodegradation efficiency.

3.7.5 Effect of Scavenging Agents

The literature claims that the photodegradation of dyes is controlled by the ROS concentration produced during the reaction. Therefore, to explore the impact of these ROS and charge carriers (e− and h+) on the photodegradation of RhB, a few trapping agents were added before irradiating the reaction solution to trap these species and to affirm which among these performed a key function in the photodecomposition of RhB [85]. Benzoic acid (BA), ascorbic acid (AC), potassium persulfate (PS), and disodium EDTA (EDTA) were employed as the scavengers of hydroxyl radicals, superoxide radicals, electrons, and holes, respectively. As seen in Fig. 14, the BA, AC, and EDTA notably hindered the photodecomposition of RhB. With the addition of 1 mmol of these agents, the photodegradation of RhB slumped to 28.68%, 39.15%, and 54.37% in the presence of BA, AC, and EDTA, respectively. However, PS does not significantly hinder the degradation of the dye, suggesting OH●, O2●−, and h+ served a key function in the photodegradation process.

3.8 Degradation Mechanism

The photodegradation process of hazardous pollutants, such as RhB, in the presence of the manufactured CdO photocatalyst and visible light is presented in Fig. 15. When visible light was applied to the photocatalyst, the electron was driven from the VB to the CB, generating holes (h+). A significant boost in photocatalytic activity was seen upon slowing down the recombination of electron-hole pairs. Meanwhile, the above equations can be used to ascertain the CB and VB potentials. The VB potential of CdO was found to be -0.04 eV, according to previously reported work by Munawar et al. [86]. Thus, the CB position was found to be -2.63 eV using the following Eq.

Based on the band gap (2.59 eV) analysis from UV-DRS and the ROSs obtained from the previously reported scavengers experiment, a charge transfer mechanism for the photodegradation of RhB was conjectured. Because CdO has a greater capacity to absorb visible light, visible light causes it to produce photogenerated holes (h+) on VB and photogenerated electrons (e−) on CB. Because the VB potentials of CdO cannot exceed the potential required to create OH●, (OH●/H2O = + 1.99 eV/NHE, OH●/OH− = +2.40 eV/NHE), the h+ photogenerated in the VB of CdO cannot react with the H2O or OH− in the solution [87]. As a result, they do not form OH● radical and eventually accrue on the VB. However, because the CB potential of CdO is greater than that of O2/O2●− (-0.33 eV/NHE), the e- on the CB of CdO can mix with O2 and react to form O2●−, which can then directly react with the pollutants [88]. The following equations demonstrate the mechanism for RhB degradation.

3.9 Reusability Studies

The investigation of the recyclability of the manufactured photocatalyst is vital to assisting the recyclability and stability of the material. The photocatalyst was centrifuged, cleaned with ddH2O, and dried in an oven at 80 °C before reusing it for the subsequent cycle. Figure 16 shows that the photocatalyst could be reused for up to five subsequent cycles with no significantly declining photocatalytic activity. A further fall in the photocatalytic activity could be due to the blockage of the active sites of the photocatalyst by the accumulation of the dye molecules and intermediate degradation products, which slowed down the production of ROS.

Furthermore, XRD analysis was applied to explore the retrieved CdO NPs to look into their stability and crystalline structure. When comparing the XRD patterns of the retrieved CdO NPs to those of fresh catalyst, no noticeable changes were seen in the crystallographic planes or peak positions (Fig. 17). This result corroborates the claim that the catalyst does not leach following the photocatalytic process and confirms that the considerable stability of the manufactured CdO NPs.

The literature describes diverse biologically fabricated metal oxide catalysts for the decomposition of RhB dye from aqueous media. Table 5 highlights a comparison study with other reported photocatalysts applied for RhB dye degradation.

4 Conclusion

The present study effectively demonstrated the green fabrication of CdO NPs with Citrus sinensis peel extract. Various analytical techniques were applied to characterize the manufactured NPs, and the results revealed the presence of pure cubic phase CdO NPs. The photocatalytic performance of the manufactured CdO NPs was disclosed for the degradation of RhB dye. The influence of various reaction factors, including H2O2 dose, photocatalyst loading, dye concentration, and contact time, were optimized, and the outcomes revealed that the fabricated CdO NPs demonstrated outstanding dye degradation capability, with an 85% degradation of 15 ppm RhB after 60 min of exposure to natural sunlight. This highlights their potential for industrial contamination cleanup, especially in RhB dye degradation. Furthermore, the scavengers and recyclability tests demonstrated the functionality of the synthesized CdO NPs as a sustainable photocatalyst. Overall, the biogenic synthesis of CdO NPs has great potential for RhB dye degradation, paving the door for creating low-cost, robust materials for analytical and environmental remediation applications.

References

Jury WA, Vaux HJ Jr (2007) The emerging global water crisis: managing scarcity and conflict between water users. Adv Agron 95:1–76

Abbott BW et al (2019) Human domination of the global water cycle absent from depictions and perceptions. Nat Geosci 12(7):533–540

He C et al (2021) Future global urban water scarcity and potential solutions. Nat Commun 12(1):4667

Schwarzenbach RP et al (2010) Global water pollution and human health. Annu Rev Environ Resour 35:109–136

Rad SM, Ray AK, Barghi S (2022) Water pollution and agriculture pesticide. Clean Technol 4(4):1088–1102

Ellis JB (2006) Pharmaceutical and personal care products (PPCPs) in urban receiving waters. Environ Pollut 144(1):184–189

Maheshwari K, Agrawal M, Gupta A (2021) Dye pollution in water and wastewater. In: Novel materials for dye-containing wastewater treatment, pp. 1–25

Slama HB et al (2021) Diversity of synthetic dyes from textile industries, discharge impacts and treatment methods. Appl Sci 11(14):6255

Forgacs E, Cserháti T, Oros G (2004) Removal of synthetic dyes from wastewaters: a review. Environ Int 30(7):953–971

Bar N, Chowdhury P (2022) A brief review on advances in rhodamine B based chromic materials and their prospects. ACS Appl Electron Mater 4(8):3749–3771

Beija M, Afonso CA, Martinho JM (2009) Synthesis and applications of rhodamine derivatives as fluorescent probes. Chem Soc Rev 38(8):2410–2433

Jain R et al (2007) Removal of the hazardous dye rhodamine B through photocatalytic and adsorption treatments. J Environ Manage 85(4):956–964

Baldev E et al (2013) Degradation of synthetic dye, rhodamine B to environmentally non-toxic products using microalgae. Colloids Surf B 105:207–214

Al-Buriahi AK et al (2022) Elimination of rhodamine B from textile wastewater using nanoparticle photocatalysts: a review for sustainable approaches. Chemosphere 287:132162

Aarthi T, Madras G (2007) Photocatalytic degradation of rhodamine dyes with nano-TiO2. Ind Eng Chem Res 46(1):7–14

Liu Y et al (2019) Nanotechnology-based antimicrobials and delivery systems for biofilm-infection control. Chem Soc Rev 48(2):428–446

Malik S, Muhammad K, Waheed Y (2023) Nanotechnology: a revolution in modern industry. Molecules 28(2):661

Lowry GV, Avellan A, Gilbertson LM (2019) Opportunities and challenges for nanotechnology in the agri-tech revolution. Nat Nanotechnol 14(6):517–522

Smith DM, Simon JK, Baker JR Jr (2013) Applications of nanotechnology for immunology. Nat Rev Immunol 13(8):592–605

Sapsford KE et al (2013) Functionalizing nanoparticles with biological molecules: developing chemistries that facilitate nanotechnology. Chem Rev 113(3):1904–2074

Baig N, Kammakakam I, Falath W (2021) Nanomaterials: a review of synthesis methods, properties, recent progress, and challenges. Mater Adv 2(6):1821–1871

Cuong HN et al (2022) New frontiers in the plant extract mediated biosynthesis of copper oxide (CuO) nanoparticles and their potential applications: a review. Environ Res 203:111858

Narwal N et al (2023) Emerging micropollutants in aquatic ecosystems and nanotechnology-based removal alternatives: a review. Chemosphere, p. 139945

Mayeen A et al (2018) Morphological characterization of nanomaterials. In: Characterization of nanomaterials. Elsevier, pp 335–364

Kumar S, Nann T (2006) Shape control of II–VI semiconductor nanomaterials. Small 2(3):316–329

Yang L et al (2019) Anisotropic nanomaterials for shape-dependent physicochemical and biomedical applications. Chem Soc Rev 48(19):5140–5176

Li Y, Shen W (2014) Morphology-dependent nanocatalysts: rod-shaped oxides. Chem Soc Rev 43(5):1543–1574

Harish V et al (2023) Cutting-edge advances in tailoring size, shape, and functionality of nanoparticles and nanostructures: a review. J Taiwan Inst Chem Eng 149:105010

Chauhan A et al (2023) Recent trends in phyto-mediated iron-based nanomaterials for environmental remediation and biomedical applications. Inorg Chem Commun, 111976

Mauter MS et al (2018) The role of nanotechnology in tackling global water challenges. Nat Sustain 1(4):166–175

Biswas P et al (2023) Advanced implications of nanotechnology in disease control and environmental perspectives. Biomed Pharmacother 158:114172

Pansambal S et al (2023) Bioengineered cerium oxide (CeO2) nanoparticles and their diverse applications: a review. Appl Nanosci 13(9):6067–6092

Dabhane H et al (2021) A review on environmentally benevolent synthesis of CdS nanoparticle and their applications. Environ Chem Ecotoxicol 3:209–219

Rather AH et al (2022) Recent progress in the green fabrication of cadmium sulfide and cadmium oxide nanoparticles: synthesis, antimicrobial and cytotoxic studies. Mater Sci Engineering: B 286:116022

Ghotekar S (2019) A review on plant extract mediated biogenic synthesis of CdO nanoparticles and their recent applications. Asian J Green Chem 3(2):187–200

Aldeen TS, Mohamed HEA, Maaza M (2020) Bio-inspired single phase Monteponite Cdo nanoparticles via natural extract of phoenix roebelenii palm leaves. J Inorg Organomet Polym Mater 30:4691–4701

Thema F et al (2015) Green synthesis of Monteponite CdO nanoparticles by Agathosma betulina natural extract. J Alloys Compd 646:1043–1048

Yufanyi DM et al (2014) CdO nanoparticles by thermal decomposition of a cadmium-hexamethylenetetramine complex. J Mater Sci Res 3(3):1

Khan SA et al (2022) Photocatalytic degradation of methyl orange by cadmium oxide nanoparticles synthesized by the sol-gel method. Optik 251:168401

Tadjarodi A, Imani M, Kerdari H (2013) Application of a facile solid-state process to synthesize the CdO spherical nanoparticles. Int Nano Lett 3:1–6

Nakate UT et al (2019) Room temperature LPG sensing properties using spray pyrolysis deposited nano-crystalline CdO thin films. Surf Interfaces 17:100339

Kaviyarasu K et al (2014) One dimensional well-aligned CdO nanocrystal by solvothermal method. J Alloys Compd 593:67–70

Rajesh N et al (2014) Investigation of CdO nanostructures synthesized by microwave assisted irradiation technique for NO2 gas detection. J Alloys Compd 607:54–60

Yang H et al (2004) Preparation of CdO nanoparticles by mechanochemical reaction. J Nanopart Res 6:539–542

Mostafa AM et al (2017) Synthesis of cadmium oxide nanoparticles by pulsed laser ablation in liquid environment. Optik 144:679–684

Karthik K et al (2017) Photocatalytic and antibacterial activities of hydrothermally prepared CdO nanoparticles. J Mater Sci: Mater Electron 28:11420–11429

Abbas S et al (2021) Characterization of CdO nanoparticles prepared by co-precipitation method under different pH and calcination temperatures. Appl Phys A 127(7):505

Thambidurai M, Dang C (2018) Structural, morphological and optical properties of CdO nanostructures synthesized by chemical bath deposition method. Mater Lett 221:244–247

Spencer JA et al (2022) A review of band structure and material properties of transparent conducting and semiconducting oxides: Ga2O3, Al2O3, In2O3, ZnO, SnO2, CdO, NiO, CuO, and Sc2O3. Appl Phys Rev 9(1)

Hussain I et al (2016) Green synthesis of nanoparticles and its potential application. Biotechnol Lett 38:545–560

Gour A, Jain NK (2019) Advances in green synthesis of nanoparticles. Artif Cells Nanomed Biotechnol 47(1):844–851

Shreyash N et al (2021) Green synthesis of nanoparticles and their biomedical applications: a review. ACS Appl Nano Mater 4(11):11428–11457

Suhani I et al (2021) Impact of cadmium pollution on food safety and human health. Curr Opin Toxicol 27:1–7

El Kholy S, Giesy JP, Al Y, Naggar (2021) Consequences of a short-term exposure to a sub lethal concentration of CdO nanoparticles on key life history traits in the fruit fly (Drosophila melanogaster). J Hazard Mater 410:124671

Bernard A (2008) Cadmium & its adverse effects on human health. Indian J Med Res 128(4):557–564

Nivetha A, Mangala Devi S, Prabha I (2019) Fascinating physic-chemical properties and resourceful applications of selected cadmium nanomaterials. J Inorg Organomet Polym Mater 29:1423–1438

Balmuri SR et al (2017) Effect of surfactant in mitigating cadmium oxide nanoparticle toxicity: implications for mitigating cadmium toxicity in environment. Environ Res 152:141–149

Pagar K et al (2023) Bio-inspired synthesis of CdO nanoparticles using Citrus Limetta peel extract and their diverse biomedical applications. J Drug Deliv Sci Technol 82:104373

Dongre P et al (2023) Botanical description, Chemical Composition, Traditional uses and Pharmacology of Citrus sinensis: an updated review. Pharmacological Research-Modern Chinese Medicine, p 100272

Alam F et al (2022) Citrus flavonoids as potential therapeutic agents: a review. Phytother Res 36(4):1417–1441

Favela-Hernández JMJ et al (2016) Chemistry and Pharmacology of Citrus sinensis. Molecules 21(2):247

Zahr S et al (2023) Phytochemistry and biological activities of Citrus sinensis and Citrus limon: an update. J Herb Med, : p. 100737

Khan MK, Dangles O (2014) A comprehensive review on flavanones, the major citrus polyphenols. J Food Compos Anal 33(1):85–104

Permana Y, Yulizar Y (2017) Potency of Parkia speciosa Hassk seed extract for green synthesis of CdO nanoparticles and its characterization. in IOP conference series: Materials science and engineering. IOP Publishing

Al Jubory SYO (2020) Banana fruit peels as capping and reducing agents to creating cadmium oxide nanoparticles and evaluation its activity against E. Coli and C. Albicans. Plant Archives 20(2):2046–2050

Thovhogi N et al (2016) Physical properties of CdO nanoparticles synthesized by green chemistry via Hibiscus Sabdariffa flower extract. J Alloys Compd 655:314–320

Nasrullah M et al (2020) Green and chemical syntheses of CdO NPs: a comparative study for yield attributes, biological characteristics, and toxicity concerns. ACS Omega 5(11):5739–5747

Savale A et al (2017) Green synthesis of fluorescent CdO nanoparticles using Leucaena leucocephala L. extract and their biological activities. J Bacteriol Mycol Open Access 5(5):00148

Ghotekar S et al (2024) Eco-friendly fabrication of CdO nanoparticles using Polyalthia longifolia leaves extract for antibacterial and electrochemical sensing studies. J Sol Gel Sci Technol, 1–12

Somasundaram G et al (2019) Hydrothermal synthesis of CdO nanoparticles for photocatalytic and antimicrobial activities. Results Mater 4:100044

Holzwarth U, Gibson N (2011) The Scherrer equation versus the’debye-scherrer equation’. Nat Nanotechnol 6(9):534–534

Mogole L et al (2021) Green synthesis of silver nanoparticles using aqueous extract of Citrus sinensis peels and evaluation of their antibacterial efficacy. Green Process Synthesis 10(1):851–859

Khaskheli MI et al (2011) Use of orange peel waste for arsenic remediation of drinking water. Waste Biomass Valoriz 2:423–433

Zapata B et al (2009) Thermo-kinetics study of orange peel in air. J Therm Anal Calorim 98(1):309–315

Vincent J, Lekha NC (2022) Bio-engineered copper oxide nanoparticles using Citrus Aurantifolia enzyme extract and its anticancer activity. J Cluster Sci 33(1):45–53

Zaien M, Ahmed N, Hassan Z (2012) Growth of cadmium oxide nanorods by vapor transport. Chalcogenide Lett 9(3):115–119

Kim K-Y et al (2017) Characteristics of NaNO3-promoted CdO as a midtemperature CO2 absorbent. ACS Appl Mater Interfaces 9(25):21563–21572

Gadore V, Mishra SR, Ahmaruzzaman M (2023) Green and environmentally sustainable fabrication of SnS2 quantum dots/chitosan nanocomposite for enhanced photocatalytic performance: Effect of process variables, and water matrices. J Hazard Mater 444:130301

Mishra SR, Gadore V, Ahmaruzzaman M (2023) Development of high-performance bi-functional novel CdSnS 2 atom clusters for adsorption of rose Bengal and AOP-assisted degradation of methylene blue, vol 9. Water Research & Technology, Environmental Science, pp 586–602. 2

Ashiq H et al (2022) G-C3N4/Ag@ CoWO4: a novel sunlight active ternary nanocomposite for potential photocatalytic degradation of rhodamine B dye. J Phys Chem Solids 161:110437

Raha S, Mohanta D, Ahmaruzzaman M (2021) Novel CuO/Mn3O4/ZnO nanocomposite with superior photocatalytic activity for removal of Rabeprazole from water. Sci Rep 11(1):15187

Raha S, Ahmaruzzaman M (2020) Facile fabrication of g-C3N4 supported Fe3O4 nanoparticles/ZnO nanorods: a superlative visible light responsive architecture for express degradation of pantoprazole. Chem Eng J 387:123766

Begum S, Mishra SR, Ahmaruzzaman M (2022) Fabrication of ZnO–SnO2 nanocomposite and its photocatalytic activity for enhanced degradation of Biebrich scarlet. Env Sci Pollution Res 29:87347–87360. 58

Chen X et al (2017) Preparation of ZnO photocatalyst for the efficient and rapid photocatalytic degradation of azo dyes. Nanoscale Res Lett 12:1–10

Sankeetha S et al (2023) A novel Ni doped BaTiO3/h-BN nanocomposite for visible light assisted enhanced photocatalytic degradation of textile effluent and phytotoxicity evaluation. Ceram Int 49(4):6125–6138

Munawar T et al (2020) Synthesis of novel heterostructured ZnO-CdO-CuO nanocomposite: characterization and enhanced sunlight driven photocatalytic activity. Mater Chem Phys 249:122983

Mishra SR, Gadore V, Ahmaruzzaman M (2023) Inorganic–organic hybrid quantum dots for AOP-mediated photodegradation of ofloxacin and para-nitrophenol in diverse water matrices. NPJ Clean Water 6(1):78

Saravanan R et al (2011) ZnO/CdO composite nanorods for photocatalytic degradation of methylene blue under visible light. Mater Chem Phys 125(1–2):277–280

Rajendrachari S et al (2021) Photocatalytic degradation of rhodamine B (RhB) dye in waste water and enzymatic inhibition study using cauliflower shaped ZnO nanoparticles synthesized by a novel one-pot green synthesis method. Arab J Chem 14(6):103180

Sundara Selvam PS et al (2020) Green synthesis of SnO 2 nanoparticles for catalytic degradation of rhodamine B. Iran J Sci Technol Trans A: Sci 44:661–676

Haseena S et al (2022) Bio-synthesize of photocatalytic Fe2O3 nanoparticles using Leucas aspera and Jatropha podagrica leaf extract for an effective removal of textile dye pollutants. Optik 249:168275

Adinaveen T, Karnan T, Selvakumar SAS (2019) Photocatalytic and optical properties of NiO added Nephelium lappaceum L. peel extract: an attempt to convert waste to a valuable product. Heliyon 5(5)

Javid-Naderi MJ et al (2023) Green synthesis of copper oxide nanoparticles using okra (Abelmoschus esculentus) fruit extract and assessment of their cytotoxicity and photocatalytic applications. Environ Technol Innov 32:103300

Ansari A et al (2022) Green synthesis of TiO2 nanoparticles using Acorus calamus leaf extract and evaluating its photocatalytic and in vitro antimicrobial activity. Catalysts 12(2):181

Acknowledgements

The authors KP and SG are warmly grateful to the Material Analysis & Research Centre, Bengaluru, and the SAIF, NEHU, Shillong, India, for providing the characterization support. Also, author KP is grateful to Dhananjay Shinde for collecting fresh fruits from the market for the study.

Author information

Authors and Affiliations

Contributions

Conceptualization (KP, SRM), investigation (VG, MA), formal analysis (PB, DS, MCV), validation (KP, SRM), visualization (KP, DS), writing of original draft (PB, VG, SG), supervision (SG), reviewing and editing (K-YAL, SG).

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no conflicting interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pagar, K., Gadore, V., Mishra, S.R. et al. Bio-inspired Sustainable Fabrication of CdO Nanoparticles Using Citrus sinensis Peel Extract for Photocatalytic Degradation of Rhodamine B Dye. Top Catal 67, 1169–1182 (2024). https://doi.org/10.1007/s11244-024-01983-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-024-01983-z