Abstract

Arsenic is a toxic element and is found in natural waters throughout the globe. The purpose of present study is to demonstrate the As (V) uptake by orange peel from real ground water samples through adsorption. Different parameters such as pH, shaking speed, contact time, adsorbent dosage, concentration, volume and temperature etc, were optimized. The maximum uptake capacity was observed at pH-7. The sorption was found to be time dependent and the kinetics followed well by the Morris-weber, Pseudo second order and Elovich equations. The Freundlich, Langmuir, Dubinin Redushkevich and Flory–Huggins isotherm were used to model the adsorption behavior of arsenic retention. Thermodynamic parameters calculated from these isotherms show that the adsorption was spontaneous and endothermic in nature. Orange peel was found to be effective (~85%) for arsenic removal from real water systems containing concomitant ions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The shortage of drinking water is increasing continuously in the world. It is estimated that approximately one-third of the world’s population use ground water for drinking purposes [1]. Heavy metal especially arsenic contaminated drinking water has been emerging as a problematic issue around the globe. Arsenic, one of the world’s most hazardous chemical, is found to exist within the shallow zones of ground water of many countries like Argentina (3,810 μg l−1), Bangladesh (1,000 μg l−1), India (3,700 μg l−1), Pakistan (Muzaffargarh 906 μg l−1), Mexico, Mongolia, Germany, Thailand, China, Chile, USA, Canada, Hungry (5,800 μg l−1), Romania, Vietnam, Nepal, Myanmar, Cambodia, etc in various concentrations [2].

The arsenic contamination has been acknowledged as a “major public health issue” (WHO 1999). Arsenic classified as a group A and category 1 human carcinogen by the US Environmental Protection Agency (US EPA 1997) and the International Association For Research on Cancer (IARC 2004), respectively [3]. Arsenic exists in numerous oxidation states from −3, 0, +3 and +5 [2, 4]. Two forms are common in natural waters: arsenite (AsO −33 ) and arsenate (AsO −34 ), referred to as arsenic (III) and arsenic (V). Pentavalent inorganic arsenic compounds predominate and are stable in oxygen rich aerobic environments. Trivalent arsenates predominate in moderately reducing anaerobic environments such as deep ground water [5]. Long term drinking water exposure causes skin, lungs, bladder, kidney cancer as well as pigmentation changes, skin thickening (hyperkeratosis), neurological disorders, muscular weakness, loss of appetite, and nausea [6, 7]. This differs from acute poisoning, which typically causes vomiting, esophageal and abdominal pain, and bloody “rice water” diarrhea[8, 9] First case of drinking water arsenic poisoning was reported in Taiwan in 1968 [2]. The maximum contaminant level (MCL) of arsenic has been reduced to 10 and 7 μg l−1 by European Commission and National Health & Medical Research committee (NHMRC) of Australia respectively [2].

Viewing the grim situation of arsenic contaminated drinking water, many techniques such as physio-chemical techniques (adsorption, ion exchange, precipitation, coagulation, membrane filtration, permeable reactive methods), and biological techniques (phytoremediation biological treatment with living microbes/bio-filtration) have been used [2]. Among all these techniques adsorption has become known as a cost effective and environmental friendly alternative. Various low cost adsorbents have been used for the removal of arsenic such as, methylated yeast biomass [10], iron oxide coated fungal biomass [11], residue rice polish [12], modified fungal biomass [13], acid-washed crab shells [14], modified cotton cellulose [15], modified coconut coir pith [16], bone char [17], chemically modified saw dust of spruce (Picea abies) [18], shrimp shells [19], HDTMA-modified zeolite [20], surfactant-modified zeolite [21] and iron-coated zeolite [22]. Many of these materials need some type of physical or chemical treatment and do not state effectiveness of adsorbent at very low concentrations. Therefore, in present study we aim to develop a cost effective and locally available biosorbent orange peel (family Rutaceae, genus Citrus, specie aurantium, and botanical name citrus sinesis) commonly known as bitter orange without any modification to reduce the concentration of arsenic to below the acceptable value for drinking water. Orange peel has been used to remove arsenic from real samples in order to check its practical applicability.

Experimental

Reagents and Equipments

Stock solution (1,000 mg l−1, of As (V) was prepared by dissolving arsenic Na3AsO4. 12 H2O, (Merck, Germany) in de-ionized water. Working solutions for experiment were freshly prepared from the stock solution. For adjusting the pH buffers of acetic acid, sodium acetate, potassium chloride, hydrochloric acid and sodium hydroxide were used. Reducing agent for arsenic was prepared by mixing the NaBH4 (0.2% w/v) in NaOH (0.05% w/v). All reagents used were of analytical grade or equivalent.

All pH measurements were carried out at Thermo Scientific Orion 5 Star (pH. ISE. Cond. DO Benchtop, 8102BNUWP; made in USA) PH-meter. Shaking Incubator Model 1-40000 Irmeco GmbH (Geesthacht/Germany) were used for batch adsorption experiments. Atomic Absorption Spectrometer (Analyst 800, Perkin Elmer, USA) connected with Flow Injection System for hydride generation (FIAS 100 Perkin Elmer, USA) were used to measure concentration of arsenic. AAS was equipped with a hallow cathode lamp having current mA 18, wavelength nm 193.7, energy 40, band width 0.7 nm (made in Singapore) and Quartz Tube Atomizer (Universal QAT, part number B300-0350, USA) were used.

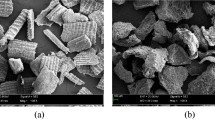

Adsorbent: Collection and Preparation

Orange peels were collected from fresh fruit juice sellers of local market, Hyderabad Sindh, Pakistan. Peels were washed several times with de-ionized water in order to remove adherent dirt particle and air dried peels were kept in incubator at 60°C for 6 h. Dried and grinded peels were passed through electrical sieve shaker (100 mesh). COD (chemical oxygen demand) and pH of effluent was monitored. Initially it was observed that COD was greater than the WHO recommended level therefore the adsorbent were washed many times till the effluent became colorless and its COD became within the range of WHO recommended safe limit. Washed adorbent was air dried and kept in an incubator at 60°C for 24 h.

Characterization of Adsorbent (EDX and FTIR)

Orange peel was characterized by FTIR as well EDX. For EDX analysis BRUKER X-FLASH 4010 133 eV Germany was used. Orange peel was analyzed for detection of surface elements, before and after arsenic adsorption. EDX showed the presence of carbon, oxygen, sodium, aluminum and calcium on the surface of orange peel. A small peak of arsenic appears on peel after its adsorption onto the surface confirming the presence of arsenic on the surface.

FT-IR- Interpretation

The FTIR analysis of dried orange peel before and after As (V) adsorption is given in Fig. 1. Assignment of spectra in Fig. 1 is listed in Table 1. Analysis of FTIR spectrum after As (V) adsorption showed there was a major shift on 28.94 and −42.37 cm−1 in absorption wave number of peaks at 3,295.26 and 1,605.27 cm−1 respectively indicative of a fact that these groups play a role in biosorption process. As (V) loaded orange peel show a small peak at 877.32 cm −1 may attributed to the metal oxygen bond [23].

Batch Equilibrium Studies of Adsorption of As (V)

The metal adsorption behavior of orange peel adsorbent was investigated using batch equilibrium experiments. The volume (20 ml) of arsenic (0.01–50 mg l−1), pH (7), adsorbent (200 mg) was agitated (100 rpm) at temperature (25°C) for 2 h. The adsorbent was filtered and concentration of metal ion in filtrate was examined by Atomic Absorption Spectrometer connected with Flow Injection System.

Following equation was used to calculate percentage uptake (sorption (%)).

where C i and C f , is the initial and final concentration (mol l−1) of metal ions in solution respectively.

Effect of Concomitant Ions on Arsenic Removal

Effect of some common electrolytes in the ratios of 1:10 and 1:100 were examined on the removal efficiency of As (V) by orange peel. In 1:10 ratio 7.5 ml of arsenic (10 mg l−1) and 0.075 ml of an electrolyte (10,000 mg l −1) were taken in 15 ml volumetric flask. In case of 1:100 ratio 7.5 ml of arsenic (10 mg l−1) and 0.75 ml of an electrolyte (10,000 mg l −1) were taken in 15 ml volumetric flask. After maintaining optimum pH 7, volumes of both flasks were made up to 20 ml.

Treatment of Arsenic Contaminated Water Samples

Arsenic contaminated drinking water samples were collected in plastic bottles from different areas of Pakistan. First sample (S1) Hand pump water collected from Sachal colony District Larkana. Second sample (S2) Hand pump water collected from Chak No. 159 Taluka Sadiqabad, District Rahimyar Khan. Third sample (S3) Well water collected from village Bakhtiarpur, Taluka Sehwan, District Jamshoro. Samples were filtered and initial arsenic concentration was determined using AAS-FIAS system. An aliquot of contaminated water was spiked with 50 μg l−1 of arsenic. Adsorption experiments were carried out as stated at optimum conditions. Removal efficiency for both spiked and un-spiked water samples were calculated and are presented in Table 5.

Results and Discussions

Effect of pH and Adsorption Mechanism

Effect of pH on adsorption was monitored by taking 10 ml of metal ion solution (1 mgl−1) and 200 mg of adsorbent material. Solutions were agitated for 2 h at 150 rpm. Temperature was kept constant at 25°C. The uptake capacity of the adsorbent was found to be pH dependent as shown in Fig. 2. As pH increases from 1 to 7, adsorption also increases. A decrease in % adsorption can be observed at pH values > 7. Similar trend has been observed by A. Ohki et al. [24] for the removal of As (V) on aluminum loaded Zeolite.

As (V) have different species in aqueous medium depending on pH of the solution. H3 AsO4, H2 AsO4 −, HAsO4 2−, and AsO4 3− are the dominant As (V) species in pH ranges of <2.26, 2.26–6.76, 6.76–11.29, and >11.29, respectively [25].

It is suggested that the As (V) adsorption mostly occurs at active sites on aluminum species present on the surface. The adsorption of As (V) ion onto the orange peel may proceeds from the formation of aluminum hydroxide on the surface of Al containing orange peel, followed by the replacement of the hydroxide anion by the As (V) ion in aqueous media, which can be described as follows:

and/or

Similar mechanisms have been reported in the adsorption of As (V) by a lanthanum-loaded silica gel [26] pH of the solution also increases after adsorption (Fig. 2), suggesting the exchange of basic group in the As (V) solution after adsorption.

It should be pointed out, that the Al(OH)3 given here is just an example of aluminum species present on the surface of orange peel, while some other aluminum species, including several polynuclear hydrolysis products, such as AlOH2+, Al(OH)2+, Al13O4(OH)24 7+, and Al(OH)4−, etc may also emerge in the adsorption system [24].

Effect of Shaking Speed

Adsorption capacity of orange peel at different shaking speed was investigated keeping pH constant at 7; agitation speed was varied from 50 to 250 rpm. There was initial increase in uptake capacity up to 150 rpm after 150 rpm the uptake capacity decreased and up to 40% decrease was observed at around 250 rpm (Fig. 3). Therefore, 150 rpm has been selected for further experiments.

Effect of Volume of Adsorbate

In order to find out effect of volume on retention of arsenic, 0.1 g of adsorbent was taken in five flasks containing arsenic solution ranges from 10 to 70 ml. Solution pH was maintained at 7 and samples were agitated for 2 h at 150 rpm. The constant adsorption was observed up to 20 ml and decreased uptake capacity by increasing volume of arsenic solution up to 70 ml. This behavior may be explained as total number of moles of arsenic increases with increasing volume of solution as compared to the available adsorbent sites.

Effect of Amount of Adsorbent

Amount of adsorbent has basic importance in adsorption experiments. It is generally believed that those adsorbents are considered to be efficient whose small amount show maximum uptake capacity. Therefore, its effect on removal efficiency have been investigated by varying amount of adsorbent from 100 to 700 mg, keeping pH 7, temperature 25°C, agitation speed 150 rpm and time 2 h. From the results it was observed that adsorption capacity increases slightly with increasing amount of adsorbent. This trend may be explained on basis of increasing binding sites with increasing amount of adsorbent. Capacity difference of around 13% was observed while changing amount from 100 to 200 mg but up to 700 mg the change was only 8%, therefore for further experiments 200 mg of adsorbent were selected.

Effect of Contact Time and the Kinetics of Adsorption

Adsorption equilibria studies are important to determine the efficacy of adsorption. Keeping all other parameters e.g. pH, agitation speed, amount of adsorbent, volume of adsorbate and shaking speed at constant (pH 7, volume 20 ml, amount 200 mg, concentration 10 mgl−1 and temperature 25°C) values, the agitation time was varied from 0 min (addition of adsorbent to arsenic contaminated water and its immediate filtration without any agitation has been designated as adsorption at 0 time) to 24 h. At different stipulated intervals of time flasks were taken out from shaker and were analyzed for residual arsenic concentration. The adsorption of As (V) was found to be time dependent. The sorption was rapid in the first 60 min, before becoming more gradual until equilibrium was reached at around 2 h. Metal uptake remains constant up to 24 h (Fig. 4). As the orange surface is bare in the initial stage, the sorption kinetics is fast and normally governed by the diffusion process from the bulk solution to the surface [27]. In the later stage the sorption is likely an attachment-controlled process. The rate constant of intra particle diffusion is calculated from the slope of Moriss-Weber equation by plotting q t (mg g−1) against (t)1/2, \( q_{t} = R_{d} \sqrt t \). Equation holds very well (correlation coefficient = 0.9985) up to 60 min with R d value of 0.435 mg g−1 but deviates with increasing agitation time (Fig. 5). Based on Morris-Weber plot (Fig. 4), the adsorption of As (V) is comprised by two phases (i.e. up to 60 min and second is up to 24 h), suggesting that intra-particle diffusion is not the rate limiting step for the whole reaction [28]. It can also be seen that the linear portion of the curve did not pass through the origin (Intercept value; 1.113). This indicates that mechanism of As (V) adsorption on orange peel was complex and both the surface adsorption as well as intra-particle diffusion. Similar phenomenon has been observed for the adsorption of arsenic on bone char by Chen et al. [17].

In order to further understand the kinetics of As (V) removal through orange peel, pseudo-first order, pseudo-second order models Eq. 2 and Elovich Eq. 3 were used to testify the observed data. It was found that data did not follow first order rate equation. Therefore, pseudo second order rate equation was tested in the following linear form.

where k is the pseudo second order rate constant (g mg−1min−1), qe is the amount of arsenic ion adsorbed at equilibrium (mg g−1), and qt is amount of arsenic ion on the orange peel at specified time (mg g−1). The pseudo second order rate constants were determined by plotting t/qt versus t. A straight line with correlation coefficient of 1.00 was obtained which shows very good agreement of experimental data with the pseudo second-order kinetic model which is based on the assumption that the rate limiting step is chemisorption [29]. According to work of Goldberg and Johnston [30] the mechanism of As (V) adsorption onto metal oxides seems to be formation of inner and outer sphere surface complexes. Thus, the formation of chemical bond is involved. This supports the involvement of surface Aluminum at the surface of orange peel for As (V) binding. Similar phenomena have been observed by Chen et al. and Urik et al. [17, 18] for the biosorption of As (V) on bone char and sawdust respectively.

Elovich equation was plotted as following simplified form

where qt is the sorption capacity at time t (mg.g−1), α is the initial adsorption rate (mg.g−1 min−1) and, β is desorption constant (mg.g−1 min−1) during any one experiment.

Plot of qt versus ln t is linearly correlated with coefficient of correlation 0.985, this supports that the adsorption system belongs to pseudo-second order kinetic and the rate determining step may be the chemisorptions involving valance forces through exchange of electron [12]. The constants α and β computed from the slope and intercept of the graph are 4.14 mg g−1 min−1 and 0.338 g mg−1 respectively.

The effectiveness of the diffusion of exchanging ions within the adsorbent particles of radius r and control of film diffusion in sorption may be deduced from the linear fit of the data to the Reichenberg Eq. 4:

where Q = qt/qm, Bt = π2Di/γ2, qt is adsorbed concentration at time t, qm is maximum sorption capacity of the adsorbent, Di is an effective diffusion coefficient of ions exchanging inside the adsorbent particle. The value of Bt (a mathematical function of Q) can be evaluated for each value of Q using the following the following equation.

The plot of Bt versus t is linear from 0 to 90 min with a regression coefficient of 0.9923. As regression line does not pass through origin (Fig. 6) this indicates that intra particle diffusion is not the sole rate controlling step [12].

Equilibrium Adsorption Models

Many sorption isotherm models have been successfully applied to experimental data [31]. Four two parameter models including Freundlich, Langmuir, D-R and Flory–Huggins are examined in present study over the concentration range of 6.6 × 10−7mol l−1–6.6 × 10−4mol l−1.

Langmuir Isotherm assumes monolayer coverage of adsorbate over adsorbent. Langmuir isotherm contains two important parameters q m and K L [32].

The Langmuir equation can be presented as

This equation is often written in different linear forms but in present studies it is tested in following form

where C e is the equilibrium concentration of As (V) in solution (mol l−1), q e is the amount of arsenic on surface (mol g−1), q m is the maximum amount of arsenic adsorbed corresponding to monolayer coverage and K L is the constant related to the binding energy of solute. Constants calculated from Eq. 5 are presented in Table 2. Values of co-relation coefficient strongly supports that the data follow Eq. 6. The increase of K L values with temperature rise signifies the endothermic nature of adsorption process [32]. The essential characteristic of Langmuir isotherm can be expressed in terms of dimensionless constant separation factor R L [33] which is defined as:

According to the value of R L , the isotherm shape can be interpreted as R L > 1, unfavorable; R L = 1, linear; R L = 0 Irreversible and 0 < R L < 1 favorable [33]. The R L values calculated for the adsorption of arsenic on orange peel was in the range of 0.00015–0.99 at all temperatures investigated (Table 2) showing the favorable nature of adsorption.

Freundlich Adsorption Isotherm is an empirical equation and is most widely used. Freundlich Equation can be plotted in following linear form:

where K F and \( \frac{1}{n} \) are Freundlich constants representing adsorption capacity and adsorption intensity respectively; q e and C e are as previously described. The values of \( \frac{1}{n} \) obtained from Freundlich isotherm (Table 3) are greater than unity (n, less than unity) suggest the presence of a concave isotherm [34], similar values of n for biosorption studies have been reported in literature [34–36]. Igwe et al. [37] have reported n value of 0.38 for the adsorption of Cd (II) on maize husk. It is suggested that this type of curve is likely to be caused by complex nature of adsorbent material and its varied multiple active sites [32].

D-R Adsorption Isotherm D-R isotherm was also used to fit the experimental data. This isotherm assumes no homogeneous surface of the adsorbent and takes the form

ε is Polanyi potential and is equal to RT ln (1 + 1/C e ), T is temperature and R is general gas constant; β is related to the mean free energy of adsorption per mole of the adsorbent when it is transferred from infinite distance in the solution to the surface of the solid. q e and C e are as previously described; A linear relationship would be obtained in a plot of lnq e versus ε2. Evaluated data provides good correlation at all temperatures investigated (Table 3). Magnitude of energy of adsorption up to 308 K is 7.62–7.96 kJ mol−1 suggesting the sorption process may be physical where as at temperatures higher than 308 value of E is > 8 (Table 2) attributed to the chemical nature of adsorption [12].

Flory–Huggins Isotherm is chosen to account for the surface coverage [32]. The FH isotherm has the linear form:

where θ = 1−C e /C i ., Table 3 shows Flory–Huggins (FH) constants calculated at different temperatures. In general it may be argued that the fit between experimental adsorption data and the isotherm model is only mathematically meaningful and does not provide any evidence of the actual adsorption mechanism nevertheless, some parameters (e.g. Langmuir adsorption capacity) are important for designing an adsorption system. Additionally, the thermodynamic parameters such as the Gibbs free energy (∆G) can also be deduced from the Langmuir and Flory–Huggins isotherm [38]. Following equation can be used to calculate ∆G

where K corresponds to; b and K FH in Langmuir and Flory-Huggin equation respectively. Gibbs free energy values calculated are listed in Table 4. Negative values of ∆G indicate that the adsorption of arsenic on orange peel was spontaneous, under experimental conditions. ΔG values obtained from both isotherms (Langmuir and FH) are comparable at lower temperatures (up to 303 K) where as values obtained by Flory–Huggins isotherm are more negative than values obtained from Langmuir isotherm. In addition standard enthalpy change (∆H) and standard entropy change (∆S) in the process can be obtained using equation [39].

The plots of ∆G versus T were found to be linear for all three isotherms (Table 4) and the values of ∆S and ∆H were determined from the slop and intercept of the plots. As shown in Table 4, the positive values of enthalpy indicate that the adsorption process is endothermic. Ting et.al. [38] have reported the similar phenomenon for the biosorption of Cd(II) and Cu(II) grafted biomass. Negative value of ∆S shows association, fixation or immobilization of solute molecules on the surface of the sorbent.

Surface Coverage The Langmuir type equation related to surface coverage was used to study the surface coverage behavior of adsorbent

where K is the adsorption co-efficient, C i the initial concentrations and θ, the surface coverage.

The fraction of orange peel surface covered by As (V) was studied by plotting the surface coverage values (θ) against As (V) concentration. The data presented in Fig. 7 shows increase in initial metal concentration, increases the surface coverage until the surface is nearly fully covered with a monomolecular layer. Surface coverage ceases significantly with concentration of As (V) at higher levels and the reaction rate become independent of As (V) concentration. Similar trends have been reported for the biosorption of Ni(II) golden shower biomass [40].

Effect of Matrix Electrolytes

As orange peel adsorbent has been developed for the remediation of arsenic from real water systems. It is important to study the effect of other common electrolytes present in real water system on removal efficiency. During experiment optimum conditions (pH 7, rpm 150, time 2 h, amount of adsorbent 0.1 g, volume 15 ml and temp. 45°C) were maintained. Effect of some common electrolytes was examined in the ratios 1:10 and 1:100 on the removal efficiency of As (V) by orange peel. The results are given in a histogram shown in Fig. 8. As clear from the Fig. 8 addition of common ions to the solution containing As (V) does not have very adverse effect on the percent recovery of As (V) by orange peel showing the practical applicability of orange peel for As (V) removal. Increase in the removal efficiency (up to 5%) has been observed by addition of Fe(II) and carbonate salts.

Applications of the Method

The proposed adsorbent was applied for the removal of As (V) from arsenic contaminated drinking water. Table 5 shows the removal of arsenic from contaminated water. In most of the cases orange peel is effective for the treatment of contaminated water with the residual concentration up to WHO safe limit.

Conclusions

It can be concluded that orange peel can be effectively used for the treatment of arsenic contaminated water. Adsorbent is effective even at very low arsenic concentrations and in the presence of concomitant ions. Kinetic and adsorption isotherm models suggest the multiple types of adsorption sites and complex mechanism of adsorption. In order to realize its potential as a commercial adsorbent for industrial as well as household filters, uptake of arsenic under continuous conditions must be evaluated. Currently such an investigation is being undertaken.

References

Nickson, R.T., Mc Arthur, J.M., Shrestha, B., Kyaw-Myint, T.O., Lowry, D.: Arsenic and other drinking water quality issues, Muzaffargarh District. Pak. Appl. Geochem. 20, 55–68 (2005)

Mondal, P., Majumuder, C.B., Mohanty, B.: Laboratory based approaches for arsenic remediation from contaminated water: recent developments. J. Hazard. Mater. 137, 464–479 (2006)

Pandy, P.K., Choubey, S., Verma, Y., Pandy, M., Chandrashekhar, K.: Biosorptive removal of arsenic from drinking water. Bioresour. Technol. 100, 634–637 (2009)

Smedley, P.L., Nicolli, H.B., Macdonald, D.M.J., Barros, A.J., Tullio, J.O.: Hydro geochemistry of arsenic and other inorganic constituents in ground waters from La Pampa, Argentina. Appl. Geochem. 17(3), 259–284 (2002)

Mandal, B.K., Suzuki, K.T.: Arsenic round the world: a review. Talanta 58, 201–235 (2002)

Jain, C.K., Ali, I.: Arsenic: occurrence, toxicity and speciation techniques. Water Res. 34, 4304–4312 (2000)

WHO (World Health Organization): Environmental Health Criteria, 18: Arsenic. World Health Organization, Geneva (1981)

Kiping, M.D.: Environment and man. In: Lenhan, J., Fletcher, W.W. (eds.) Arsenic, The Chemical Environment, vol. 6. Glasgow (1997)

Ng, J.C., Wang, J., Shraim, A.: A global health problem caused by arsenic from natural sources. Chemosphere 52(9), 1353–1359 (2003)

Seki, H., Suzuki, A., Maruyama, H.: Biosorption of chromium (VI) and arsenic (V) onto methylated yeast biomass. J. Colloid Interf. Sci. 281, 261–266 (2005)

Pokhrel, D., Viraraghavan, T.: Organic arsenic removal from aqueous solutions by iron-oxie coated fungal biomass: an analysis of factors influencing adsorption. Chem. Eng. J. 140, 165–172 (2008)

Ranjan, D., Talat, M., Hasan, S.H.: Biosorption of arsenic from aqueous solution using agricultural residue rice polish. J. Hazard. Materi. 166, 1050–1059 (2009)

Loukidou, M.X., Kostas, A.M., Anastasios, I.Z., Maria, L.K.: Removal of As (V) from waste waters by chemically modified fungal biomass. Water Res. 37, 4544–4552 (2003)

Niu, C.H., Volesky, B., Cleiman, D.: Biosorption of arsenic (V) with acid washed crab shells. Water Res. 41, 2473–2478 (2007)

Zhao, Y., Huang, M., Wei, W., Wei, J.: Synthesis of the cotton cellulose based Fe(III)-loaded adsorbent for arsenic (V) removal from drinking water. Desalination 249, 1006–1011 (2009)

Anirudhan, T.S., Unnithan, M.R.: Arsenic (V) removal from aqueous solutions using an anion exchanger derived from coconut coir pith and its recovery. Chemosphere 66, 60–66 (2007)

Chen, Y.N., Chai, L.Y., Shu, Y.D.: Study of arsenic (V) adsorption on bone char from aqueous solution. J. Hazard. Mater. 160, 168–172 (2008)

Urik, M., Littera, P., Sevc, J., Kolencik, M., Cernasky, S.: Removal of arsenic (V) from aqueous solutions using chemically modified sawdust of spruce (Picea abies): kinetics and isotherm studies. Int. J. Environ. Sci. Tech. 6, 451–456 (2009)

Chio, C.P., Lin, M.C., Liao, C.M.: Low-cost farmed shrimp shells could remove arsenic from solutions kineticslly. J. Hazard. Mater. 171, 859–864 (2009)

Yusof, A.M., Nik Malek, N.A.N.: Removal of Cr(VI) and As (V) from aqueous solutions by HDTMA-modified zeolite Y. J. Hazard. Mater. 162, 1019–1024 (2009)

Chutia, P., Kato, S., Kojima, T., Satokawa, S.: Adsorption of As (V) on surfactant-modified natural zeolite. J. Hazard. Mater. 162, 204–211 (2009)

Jeon, C.S., Baek, K., Park, J.K., Oh, Y.K., Lee, S.D.: Adsorption Characteristics of As (V) on iron-coated zeolite. J. Hazard. Mater. 163, 804–808 (2009)

Socrates G.: Infrared Characteristic Group Frequencies. Wiley-Interscience Publication, NY (1980)

Xu, Y., Nakajima, T., Ohki, A.: Adsorption and removal of arsenic(V) from drinking water by aluminum-loaded Shirasu-zeolite. J. Hazard. Mater. B92, 275–287 (2002)

Su, T., Guan, X., Tang, Y., Gu, G., Wang, J.: Predicting competitive adsorption behavior of major toxic anionic elements onto activated alumina: a speciation-based approach. J. Hazard. Mater. 176, 466–472 (2010)

Wasay, S.A., Haron, M.D.J., Tokunaga, S.: Adsorption of fluoride, phosphate, and arsenate ions on lanthanum-impregnated silica gel. Water Environ. Res. 68, 295–300 (1996)

Morris, W.J., Weber, C.: Kinetics of adsorption on carbon from solution. J. Sanita Eng. Division ASCE 89, 31–59 (1963)

Basha S., Murthy Z.V.P.: Kinetic and equilibrium models for biosorption of Cr(VI) on chemically modified seaweed, Cystoseira indica. Process Biochem. 42, 1521–1529 (2007)

Ho, Y.S.: Second order kinetic model for the sorption of cadmium onto tree fern: a comparison of linear and non-linear models. Water Res. 40(1), 119–125 (2006)

Goldberg, S., Johnston, C.T.: Mechanism of arsenic adsorption on amorphous oxides evaluated using microscopic measurements, vibrational spectroscopy, and surface complexation modeling. J. Colloid Interf. Sci. 234, 204–216 (2001)

Foo, K.Y., Hameed, B.H.: Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 156, 2–10 (2010)

Febrianto, J., Kosasih, A.N., Sunarso, J., Ju, Y.H., Indraswati, N., Ismadji, S.: Equilibrium and kinetic studies in adsorption of heavy metals using biosorbent: a summary of recent studies. J. Hazard. Mater. 162, 616–645 (2009)

Memon, S.Q., Memon, N., Solangi, A.R., Memon, J.R.: Sawdust: a green and economical sorbent for thallium removal. Chem. Eng. J. 140, 235–240 (2008)

Delle Site, A.: Factors affecting sorption of organic compounds in natural sorbent/water systems and sorption coefficients for selected pollutants. A review. J. Phys. Chem. Ref. Data 30, 187–439 (2001)

Popuri, S.R., Jammala, A., Reddy, K.V.N.S., Abburi, K.: Biosorption of hexavalent chromium using tamarind (Tamarindus indica) fruit shell—a comparative study. Electron. J. Biotechnol. 10, 358–367 (2007)

Gokhale, S.V., Jyoti, K.K., Lele, S.S.: Kinetic and equilibrium modeling of chromium (VI) biosorption on fresh and spent Spirulina platensis/Chlorella vulgaris biomass. Bioresour. Technol. 99, 3600–3608 (2008)

Igwe, J.C., Abia, A.A.: Equilibrium sorption isotherm studies of Cd(II), Pb(II)and Zn(II) ions detoxification from waste water using unmodified and EDTA modified maize husk. Electron. J. Biotechnol. 10, 536–548 (2007)

Deng, S., Ting, Y.P.: Fungal biomass with grafted poly(acrylic acid) for enhancement of Cu(II) and Cd (II) biosorption. Langmuir 21, 5940–5948 (2005)

Genc-Fuhrman, H., Tjell, J.C., Mc Conchie, D.: Adsorption of arsenic from water using activated neutralized red mud. Environ. Sci. Technol. 38, 2428–2434 (2004)

Hanif, M.A., Nadeem, R., Bhatti, H.N., Ahmed, N.R., Ansari, T.M.: Ni(II) biosorption by Cassia fistula (golden shower) biomass. J. Hazard. Mater. B139, 345–355 (2007)

Acknowledgments

Authors are very thankful to International Foundation for Science (IFS) for providing funds to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khaskheli, M.I., Memon, S.Q., Siyal, A.N. et al. Use of Orange Peel Waste for Arsenic Remediation of Drinking Water. Waste Biomass Valor 2, 423–433 (2011). https://doi.org/10.1007/s12649-011-9081-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-011-9081-7