Abstract

Various strategies are investigated for the synthesis of jasminaldehyde over heterogeneous catalysts. The jasminaldehyde synthesis via conventional cross-aldol condensation of heptanal with benzaldehyde using heterogeneous catalyst with a heptanal:benzaldehyde ratio of 1:4 was performed. Even with 100% conversion of heptanal with 100% selectivity, only 25% benzaldehyde reacts and 75% of benzaldehyde has to remain unreacted as the heptanal:benzaldehyde ratio is 1:4. So here, a strategy was applied in which, addition of heptanal in regular intervals to the reaction mixture was performed by keeping the ratio of heptanal:benzaldehyde as ~ 1:4. This could afford to convert 62% of benzaldehyde to jasminaldehyde with 69% selectivity in 20 h. Heptanal can be obtained by hydroformylation of 1-hexene. Hence in the next strategy, the investigations had been performed for the synthesis of jasminaldehyde via a tandem reaction by individually carrying out hydroformylation and aldol condensation. Hydroformylation of 1-hexene to heptanal and further condensation of this product mixture with benzaldehyde to jasminaldehyde, using heterogeneous catalysts HRh(CO)(PPh3)3 encapsulated HMS (HF-1) and amino functionalized chitosan (CH-1) respectively were studied. The study was also extended to perform a single-pot hydroformylation and aldol condensation using heterogeneous catalysts (HF-1) and (CH-1) together. All the strategies were found to be effective for selective synthesis for jasminaldehyde, however the performance for addition of heptanal in regular intervals to the reaction mixture was remarkable due to being capable to consume 62% benzaldehyde.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The perfumery fine chemical jasminaldehyde used as an aroma compound in perfumes possesses the characteristic scent of jasmine. Jasminaldehyde or α-amyl cinnamaldehyde is synthesized by condensation of heptanal with benzaldehyde using acid or base catalyst (Scheme 1) [1, 2]. Generally, this condensation is done in the presence of liquid alkali as a catalyst taken in more than stoichiometric amounts and adding heptanal slowly into benzaldehyde at moderate reaction temperature [3, 4]. This homogenous catalytic route using liquid alkalis has drawbacks of recyclability and disposal of alkali used. This process is associated with the problems like handling of strong liquid NaOH or KOH, separation and disposal of spent KOH or NaOH which require post-synthesis work-up and corrosion of reaction vessel. The process is not environment friendly also. A huge amount of spent liquid base gets generated during the formation of the product from aldol condensation in homogeneous conditions. It is estimated that approximately, 10–15 percent of spent base solutions are generated during the product formation in homogeneous aldol condensation [5]. Heterogeneous catalysts offer the potential advantage of easy separation, recycling of the catalysts and easy purification of the products. Hence heterogeneous catalysis is one of the emerging research areas to overcome the drawbacks of recyclability associated with homogeneous catalysis for many industrially required organic transformations for the production of bulk and fine chemicals. We are actively engaged since last 15 years in our wide research programme to develop heterogeneous catalytic systems, for the production of bulk chemicals like aldehydes [6,7,8,9,10,11,12,13,14,15,16,17,18], acids [19,20,21,22] and fine perfumery chemical jasminaldehyde [2, 23,24,25].

Many solid base as well as acid heterogeneous catalysts are developed to overcome the drawbacks of homogeneous catalysts for the synthesis of jasminaldehyde. Solid acid catalysts like Al-MCM-41, alumino silicates, ALPOs, acidic zeolites and PTSA-MCM-41 were used for this condensation reaction [1, 3, 26, 27]

Modified chitosan [23], reconstructed hydrotalcites [28] mesoporous cubic Ia3d materials (Al-KIT-6) [29] Mg–Al mixed oxide supported on hexagonal mesoporous silica [30], reusable NaOH-CTAB micellar system [31], Mg–Al mixed oxides [32, 33], potassium modified alumina [34], amino modified MOF [35], modified zirconia [36], silica immobilized piperazine [37], various solid supported cesium and potassium catalysts [38] are some of the recent results on heterogeneous/reusable base catalytic systems for jasminaldehyde synthesis. Acid–base bifunctional catalysts were also found to be active for jasminaldehyde synthesis [39]. The reaction kinetics of the jasminaldehyde synthesis over heterogenous catalysts are also studied which gave insight into the mechanism of reaction [2, 40].

Most of the reported condensation process for jasminaldehyde discusses the conventional reaction setup and conditions. In view of above and our focus to develop heterogeneous catalysts, and since jasminaldehyde is a fine chemical and produced industrially, a pressing need is realised to perform strategic investigations aiming solid base chitosan catalysed heterogeneous aldol condensation for the synthesis of jasminaldehyde. Apart from that, various synthetic strategies are discussed and compared here in the present study for jasminaldehyde synthesis. In present work, amino functionalized chitosan catalyst (CH-1) [24] is used as a base catalyst for aldol condensation and HRh(CO)(PPh3)3 encapsulated hexagonal mesoporous silica (HF-1) [9, 11, 13, 16, 17] as hydroformylation catalyst.

The first strategy involves to perform the conventional reaction on a fixed ratio of heptanal and benzaldehyde. In the second strategy the experiment was designed to carry out aldol condensation by stepwise addition of heptanal into the reaction mixture containing benzaldehyde and catalyst under the identical reaction conditions of first strategy, aiming for the maximum consumption of benzaldehyde during the condensation. Stepwise addition of heptanal afforded an appreciable consumption of benzaldehyde of 62% under the present employed experimental designing and reaction conditions. In the third strategy, the hydroformylation of 1-hexene was carryout using HF-1 as heterogeneous catalyst for the formation of heptanal, and thus formed heptanal was separated and used as heptanal source for aldol condensation with benzaldehyde catalysed by CH-1 for the synthesis of jasminaldehyde. This third strategy parallels with the synthesis of jasminaldehyde practiced in industry, where jasminaldehyde is ultimately produced from the castor bean plant and not usually derived from jasmine essential oil. Ricinoleic acid, the principal constituent of castor oil, undergoes cracking to undecylenic acid and heptanal. Thus produced heptanal is separated by distilling and is then reacted with benzaldehyde in the presence of a basic catalyst (trans-aldol condensation) to give jasminaldehyde and water. In the fourth strategy the hydroformylation of 1-hexene and aldol condensation were carried out in a single-pot using an autoclave for the jasminaldehyde synthesis. There are many tandem single pot reactions starting from hydroformylation to other valuable products through aldols [6,7,8, 10, 18, 41,42,43] hydrogenation [10, 44, 45] and aminomethylations [14, 15, 46]. To the best of our knowledge, this is the first report, if any, for the stepwise addition of heptanal into benzaldehyde over heterogeneous catalyst for the synthesis of jasminaldehyde and also the single pot synthesis of jasminaldehyde via hydroformylation—aldol condensation route. The present work accounts and discusses the effect and significance of the investigated strategies on the selective synthesis of jasminaldehyde.

Materials and methods

Materials

Aminopropyltrimethoxysilane (APTMS), heptanal, tetraethylorthosilicate, chitosan and 1-hexene were procured from Sigma-Aldrich USA. Hexadecyl amine was procured from Sisco Laboratories, India. Syn gas (1:1) was purchased from Alchemie gases and Chemicals Pvt. Ltd., India. Toluene was procured from Spectrochem, India. All chemicals were used without further purification.

Synthesis of catalysts

The catalyst for aldol condensation [24] and hydroformylation [9] were synthesized and characterized according to previous reports.

Aldol catalyst was synthesized by treating chitosan with APTMS. Chitosan (1.5 g) and APTMS (1 g) were dissolved in toluene (25 ml) in a 50 ml RB flask connected with a water condenser. Inert atmosphere was created by nitrogen filled in a balloon. It was refluxed in an oil bath at 110 °C for 24 h. The catalyst was filtered, dried at 100 °C and denoted as CH-1.

Hydroformylation catalyst was synthesized by in situ encapsulation method. Hexadecyl amine (2.7 mmol) was dissolved in an ethanol–water mixture. To this stirring solution HRh(CO)(PPh3)3 (0.07 mmol) was added. To the suspension obtained, TEOS (10.0 mmol) was added drop wise. The precipitate formed was stirred for 1 h and then aged for 18 h. The precipitate was washed with 1:1 ethanol–water mixture and dried in vacuum at room temperature. The catalyst was denoted as HF-1.

Catalyst characterization

CH-1 catalyst was characterized by C, H, N elemental analysis and for accessible amino groups. HF-1 catalyst was characterized by P-XRD, FT-IR, 31P-CPMAS NMR and surface area analysis. FT-IR was recorded using Perkin-Elmer, GX-FTIR by KBr pellet method. Elemental analysis (C, H, N) was carried out with Perkin-Elmer CHNS/O analyzer (Series II, 2400). Powder X-ray diffraction of the catalyst was recorded with Phillips X’Pert MPD system using Ni-filtered Cu Kα radiation (= 1.54050 Å) over a 2θ range of 1–8° at a step time of 0.05° s−1. 31P-CPMAS NMR was recorded in a Bruker 500 Ultrashield system. The surface area analysis and pore size distribution of the catalyst was determined by N2 adsorption at 77.4 K using a Sorptometer (ASAP-2010, Micromeritics). Catalyst was degassed at 80 °C for 4 h prior to the measurement.

Methods of reaction: hydroformylation and aldol condensation

For the conventional heterogeneous aldol condensation, heptanal (2.6 g), benzaldehye (10 g) and CH-1 catalyst (400 mg) were taken in a 100 ml two-necked round bottom flask. One neck was connected to a water condenser and another neck was fixed with a silicon rubber septum. N2 gas was purged into the reaction mixture for 5 min and then the top of the water condenser was fitted with a balloon filled with N2 gas to create inert atmosphere. The RB flask was kept in an oil bath at 140 °C kept over a magnetic stirrer. Aliquots of sample were taken at suitable intervals and analyzed using GC (Shimadzu GC-17A).

For the synthesis of jasminaldehyde by slow addition of heptanal to benzaldehyde was conducted as follows. Benzaldehyde (10 g) was taken in round bottom flask and heptanal (2.6 g) was added to keep heptanal to benzaldehyde ratio of 1:4. Chitosan catalyst CH-1 (400 mg) was added and reaction mixture was heated to 140 °C under stirring. After 2 h of reaction, a small quantity of sample was withdrawn and analyzed. Further, 0.35 ml (~ 280 mg) heptanal was added to the reaction mixture using a syringe at 2 h. The addition of 0.35 ml was continued at every 30 min up to 8 h. After that, the addition of 0.35 ml was done at every 1 h up to 12 h. The reaction was continued by adding 0.35 ml at every 1 h interval for 15 h. Aliquots of samples were taken out and analyzed at selected intervals. The product was analyzed by GC.

Hydroformylation was conducted in a 100 ml autoclave reactor (Autoclave Engineers, USA). In an experiment, 15 g of 1-hexene is dissolved in 50 ml of toluene and 200 mg of catalyst (HF-1) was added. The reactor was fitted and flushed twice with N2 gas and the reactor was heated to 80 °C. The reactor was charged with syn gas (CO:H2 = 1:1) up to 40 bar. Reaction was initiated with stirring at 950 rpm. Aliquots of samples were collected and analyzed in GC.

For the tandem hydroformylation-aldol condensation to jasminaldehyde, the hydroformylation reaction was first conducted for 12 h. The product mixture was separated from the HF-1 catalyst and analyzed with GC. The product mixture was distilled to remove toluene and iso-hexene in a rotavapor, and the final product mixture was weighed. Required amount of the product mixture was weighed out and was mixed with required amount of benzaldehyde (heptanal:benzaldehyde ratio of 1:4) in a RB flask. Catalyst CH-1 (400 mg) was added and the condensation reaction was conducted at 140 °C. The product was analyzed by GC. Conversions were taken with respect to heptanal only and iso-heptanal remained unreacted.

Single pot synthesis of jasminaldehyde was conducted as per the following procedure. 1-Hexene (7.5 g) and benzaldehyde (10 g) were taken in a 100 ml autoclave with 25 mL toluene. 200 mg of HF-1 catalyst and 400 mg of CH-1 catalyst were also added and pressurized with 1:1 syn gas up to 40 bar. Autoclave was heated to 140 °C and stirred for 16 h. Small quantity of sample were withdrawn at specific interval and analyzed. The product mixture was separated by filtration and analyzed by GC. n-Tridecane was used as the internal standard in all of the above reactions.

Results and discussion

Characterization of catalysts

CH-1 catalyst

C, H, N analysis was conducted for chitosan and also APTMS functionalized chitosan (CH-1). The results are: Chitosan (C: 40.02, H: 6.72, N: 8.63) and CH-1 (C: 41.26, H: 6.94, N: 11.02). This confirms the functionalization of chitosan with APTMS. The percentage of accessible amino group was determined by the Schiff base formation of the CH-1 catalyst with salicylaldehyde [24]. The percentage of accessible amino group was found to be 32.6%.

HF-1 catalyst

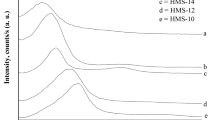

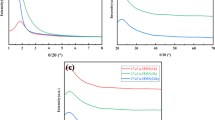

Catalyst characterization results are given in supplementary material. P-XRD pattern of the catalyst showed a peak at 2θ of 2.08 corresponding to (100) plane of HMS. 31P CPMAS NMR spectrum of the catalyst showed two peaks at 50.0 and 38.60 ppm. N2 sorption isotherm showed type-IV isotherm. BET surface area and BJH pore diameter of the catalyst were found to be 16.08 m2 g−1 and 6.6 nm respectively. These observations match with those reported in our previous studies and confirmed the encapsulation of rhodium complex inside the pores of HMS [9].

Condensation of heptanal with benzaldehyde

The condensation of heptanal with benzaldehyde was carried out using the CH-1 catalyst and the result is given in Table 1 (Entry 1–3). Conversion was 55% at 2 h with 75% selectivity for jasminaldehyde. The reaction gave 99% conversion with respect to heptanal at 6 h. The selectivity to jasminaldehyde was increased to 79% and self-condensed 2-pentyl nonenal was 18%. Benzaldehyde was oxidized to benzoic acid with 3% selectivity in products.

The product distribution [6] for jasminaldehyde formed in mmol was calculated in terms of the conversion of heptanal and the selectivity of aldol products, jasminaldehyde and 2-pentyl 2-nonenal only and the percent of jasminaldehyde was determined (Eq. 1) as follows.

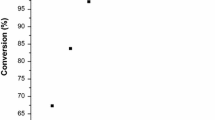

The conversion increased almost linearly on increasing the time from 2 to 6 h and the formation of jasminaldehyde increased from 9.4 to 18.4 mmol Table 1 (Entries 1–3). Selectivity remained almost constant but had a slight increase from 75 to 79% with time. This reaction was the conventional aldol reaction. Here benzaldehyde is taken in excess to prevent the self-condensation of heptanal. Hence the atom economy with respect to benzaldehyde was very low. Maximum formation of 18.4 mmol of jasminaldehyde observed here (Entries 3) from 94.2 mmol of benzaldehyde is indicative of the consumption of ~ 20% of the benzaldehyde i.e. 80% of benzaldehyde is left unreacted. More insight into the reaction was given by the pictorial representation of conversion and selectivity with respect to time (Fig. 1).

Another reaction more promising in terms of the making more consumption of benzaldehyde, was conducted by slow addition of heptanal by keeping the ratio of heptanal: benzaldehyde ratio near 1:4 in the beginning of the reaction. The rate of addition of heptanal was determined with the help of time dependent analysis of the products. The formation of jasminaldehyde was found to be appreciably increased (Table 1, Entries 4–8) on increasing the addition of heptanal and time. At 2 h, jasminaldehyde formed (Table 1, Entry 4) from 22.7 mmol of heptanal was 9.3 mmol. With slow addition of heptanal and time the formation of jasminaldehyde was continuously increased to 58.1 mmol with 81.6 mmol (Table 1, Entry 8) of the slowly added heptanal. This strategy afforded the formation of 58.1 mmol of jasminaldehyde from 94.2 mmol of benzaldehyde pinpointing that 62% benzaldehyde could be consumed here, which is three times more than conventional process. The rest of 38% percent benzaldehyde is left unreacted. A time dependent study revealed that the conversion increased with increase in time and addition of heptanal. The selectivity of jasminaldehyde was slightly higher at lower time (Table 1, Entry 4, 5). But as the reaction time increased, the addition of heptanal at every half an hour made an increase in heptanal concentration. This made an increase in self-condensation with a slight decrease in selectivity of jasminaldehyde. The former reaction (Entry 3) had 79% selectivity to jasminaldehyde (18.4 mmol), and this reaction (Entry 8) had a lower selectivity of 69% for jasminaldehyde but with a higher yield (58.1 mmol) with respect to benzaldehyde. A clear picture can be obtained with the pictorial representation of the time dependent conversion and selectivity (Fig. 2). Here the conversion increased largely in the first 2 h, and the slope of increase of conversion got decreased after. This was due to the addition of heptanal to the reaction, which increases the heptanal concentration and requires more time for its conversion. Selectivity was higher at the beginning and started to decrease slightly after the addition of heptanal which is already discussed above. The conversion vs time plot (Fig. 2) indicated that the conversion was increasing and had not attained saturation even after 20 h with addition of 82.5 mmol of heptanal. This strategy showed promising forthcoming to further enhance the consumption of benzaldehyde for which much more specific reactor design and some special automated slow addition of heptanal equipment can have potential to extent this reaction procedure to give a still better activity and selectivity.

Time dependent jasminaldehyde synthesis by slow addition of heptanal, Reaction conditions: benzaldehye = 10 g (94.2 mmol), catalyst (CH-1) = 400 mg, temperature = 140 °C, heptanal added to the reaction in parts according to Table 1 (entries 4 to 8)

Hydroformylation-aldol condensation to jasminaldehyde: a two pot tandem reaction

Another thought was, “from where we can get heptanal?” In the industrial synthesis of jasminaldehyde, distilled heptanal obtained from castor bean plant is used for its cross aldol condensation with benzaldehyde in the presence of a basic catalyst. In view of this hydroformylation is a good tool to obtain heptanal from 1-hexene and accordingly, hydroformylation was conducted with 1-hexene and syngas using a heterogeneous catalyst for that we were expertise by doing a series of experiments [9, 11, 13] The results of hydroformylation are given in Table 2. A 12 h reaction gave 99% conversion of 1-hexene with 39% selectivity to n-heptanal. The n/iso ratio was low (1.03) as it is in heterogeneous constrained conditions. It can be seen that the n/iso ratio was better at lower reaction time with low conversion. As the reaction proceeds, more and more 1-hexene converts to iso-hexene over the catalyst leading to formation of iso-heptanal. This makes the decrease in n/iso ratio [9].

The product mixture after 12 h from the reaction given in Table 2 was filtered to remove the catalyst and then the solvent and iso-hexene were distilled off. Now the product mixture contains only heptanal, iso-heptanal and 2-ethyl 3-methyl butanal. 10 g of the product mixture was used as heptanal source for jasminaldehyde synthesis. The jasminaldehyde synthesis was conducted as like a conventional aldol reaction and the results obtained are shown in Table 3. Conversion was calculated with respect to the heptanal and for the selectivity determination; only jasminaldehyde, 2-pentyl nonenal and side product benzoic acid were considered. Other two aldehydes present were not active for aldol condensation in the given conditions and hence is not included in calculating the conversion and selectivity. At lower time of 2 h, the conversion was very low (18%) with jasminaldehyde selectivity 58%. As the reaction time increased, conversion also increased steadily and reached upto 90% at 24 h of reaction. The selectivity to jasminaldehyde was increased to 80%. The decrease in conversion may be due to the blockage of basic site by the adsorption of iso-heptanal present in the reactant mixture.

Hydroformylation-aldol condensation to jasminaldehyde: a single-pot reaction

A combined reaction of hydroformylation followed by aldol condensation may be a promising reaction sequence for the synthesis of jasminaldehyde. A single pot synthesis of jasminaldehyde via a hydroformylation—aldol condensation tandem reaction in single pot was conducted. This removed the intermediate work up steps between hydroformylation and condensation. The scheme of single pot jasminaldehyde synthesis is shown in Scheme 2.

The synthesis of jasminaldehyde was conducted with calculated amount of 1-hexene and syngas, and benzaldehyde was taken in approximate excess of four times by calculation of the earlier hydroformylation reaction given in Tables 2 and 3. Hydroformylation catalyst and aldol catalysts were added to the reaction mixture to perform single pot synthesis. The result obtained by single pot synthesis is given in Table 4.

The conversion was calculated with respect to 1-hexene and all the products from hydroformylation to aldol condensation together were considered for calculation of selectivity. It is observed that, the condensation reaction was slow at lower reaction time. For 4 h, the conversion of 1-hexene was only 36% with selectivity for heptanal (24%), iso-heptanal (35%) and jasminaldehyde (17%). Lower n/iso ratio was due to the condensation of heptanal formed with benzaldehyde to yield jasminaldehyde over CH-1 catalyst. This observation was almost in line with Table 2 (entry 1) showing higher n/iso ratio at lower time. On increasing the reaction time, both conversion and selectivity for jasminaldehyde was increased. Conversion of 70% for 1-hexene was obtained for hydroformylation step and overall selectivity to jasminaldehyde was increased to 35% at 16 h of reaction time. When we calculated for heptanal to jasminaldehyde, 74% of the heptanal formed was converted to jasminaldehyde and self-condensed products with 80% selectivity to jasminaldehyde. A small amount of benzoic acid was formed < 1% as the reaction was done in a closed reactor. Also there had some amount of 2-hydroxyphenylmethyl heptanal, which is the aldol product initially formed. The hydroformylation reaction was slowed down by the presence of base catalyst and benzaldehyde as it is evident from low 1-hexene conversion to aldehydes. Also the possible coordination of carboxylic group of benzoic acid formed with rhodium could be another reason for catalytic poisoning leading to lowering the conversion. Similar carboxylate rhodium complexes and deactivation of catalysts are reported in literature [47]. A promising potential lies in this strategy to increase the conversion of heptanal and selectivity of jasminaldehyde by allowing the reaction for more time.

Mass balance for the best performed strategy

In order to account the mass balance [21] the best performed strategy affording the formation of 58.1 mmol of jasminaldehyde from 94.2 mmol of benzaldehyde with 62% consumption of benzaldehyde, was subjected for quantification of the reactants and products for having an insight in to the reaction system under the employed reaction conditions of entry 8 of Table 1, and corresponding data are listed in Table 5.

The product distribution [6] for jasminaldehyde was determined by Eqs. 1 given above, and for 2-pentyl 2-nonenal and benzoic acid by Eqs. 2 and 3 respectively.

The charged amounts of benzaldhyde and heptanal were 94.2 mmol and 81.6 mmol respectively. The reacted heptanal was 79.2 mmol yielding 58.1 mmol of jasminaldehyde and 21.1 mmol of 2-pentyl 2-nonenal. The reacted benzaldehyde (61.7 mmol) was accounted for the major formation of jasminaldehyde (58.1 mmol) and some benzoic acid (3.6 mmol). Neat 32.5 mmol of benzaldehyde remained unconsumed; however it can be further reacted by adding more heptanal and further increasing the time more than 20 h, since Fig. 2 suggested that the conversion was continuing to increase and not attained saturation under the employed reaction conditions.

Comparison of the performance with other heterogeneous catalytic systems

It is of significance to have an insight into the performance of the CH-1 catalyst with other closely related heterogeneous catalyst systems for the synthesis of jasminaldehyde. The CH-1 catalyst compared with other catalysts reported in literature is shown in Table 6.

CH-1 catalyst has comparable conversion and selectivity with some of the reported catalysts, and was better than many of the reported catalysts. ALPO (Entry 6), chitosan (Entry 8), MOS3 (Entry 10), Mg–Al hydrotalcite (Entry 12), Ni–Mg–Al (Entry 13) and chitosan metal oxide hybrid catalysts (Entry 14, 15) were comparable or better performed in terms of conversion and selectivity with that of CH-1 catalyst (Entry 1). Other catalysts like PTSA-MCM-41 (Entry 7) and Fe-AlP (Entry 9) had comparable selectivity for jasminaldehyde but with lesser conversion. The reaction with CH-1 catalyst was performed at higher temperature of 140 °C than other catalysts. The reaction by slow addition of heptanal was also comparable in terms of conversion. Stepwise addition of heptanal could convert 79.1 mmol of heptanal in 20 h (Entry 2). From 94.2 mmol of the benzaldehyde, the reacted benzaldehyde (61.7 mmol) yielded 58.1 mmol of jasminaldehyde. The merit of the present work was on designing the experiments with higher amount of heptanal and benzaldehyde. Also the stepwise slow addition of heptanal could convert much more amount of benzaldehyde.

Conclusions

Jasminaldehyde synthesis over heterogeneous catalysts was performed through different approaches. The studied methods were (1) conventional heterogeneous aldol condensation, (2) an improved aldol condensation by slow addition of heptanal, (3) a tandem reaction of hydroformylation of 1-hexene and aldol condensation with benzaldehyde and (4) a single pot hydroformylation-aldol condensation reaction. Highest selectivity (79%) was observed for the conventional heterogeneous aldol condensation, but about 75% of benzaldehyde was left unreacted. Reaction with slow addition of heptanal to the reaction mixture showed 69% jasminaldehyde selectivity in 20 h with 62% consumption of benzaldehyde, which is further improvable by increasing the time more than 20 h. In the approach of a tandem hydroformylation of 1-hexene to heptanal and aldol condensation with benzaldehyde, a conversion of 90% with respect to heptanal with 80% jasminaldehyde selectivity was obtained. The work was extended to single pot hydroformylation-aldol condensation and gave good conversions and selectivity.

References

Climent MJ, Corma A, Forne V, Guil-Lopez R, Iborra S (2002) Aldol condensations on solid catalysts: a cooperative effect between weak acid and base sites. Adv Synth Catal 344:1090–1096

Sudheesh N, Sharma SK, Khokhar MD, Shukla RS (2011) Kinetic investigation on the modified chitosan catalyzed solvent-free synthesis of jasminaldehyde. J Mol Catal A Chem 339:86–91

Climent MJ, Corma A, Guil-Lopez R, Iborra S, Primo J (1998) Use of mesoporous MCM-41 aluminosilicates as catalysts in the preparation of fine chemicals: a new route for the preparation of jasminaldehyde with high selectivity. J Catal 175:70–79

Payne LS (1990) Improvements in and relating to aldol condensation. EP 0392579A2

Spivey JJ, Gogate MR (1996) Research Triangle Institute, USEPA Grant, Pollution Prevention in Industrial Condensation Reactions

Srivastava VK, Sharma SK, Shukla RS, Jasra RV (2006) The ‘single-pot’ synthesis of C2n+2 aldol derivatives from Cn-alkenes using multi-functional catalyst. Catal Commun 7:879–884

Sharma SK, Srivastava VK, Shukla RS, Parikh PA, Jasra RV (2007) One-pot synthesis of C8 aldehydes/alcohols from propylene using eco-friendly hydrotalcite supported HRhCO(PPh3)3 catalyst. New J Chem 31:277–286

Srivastava VK, Sharma SK, Shukla RS, Jasra RV (2008) Rhodium metal complex and hydrotalcite based environmentally friendly catalyst system for the selective synthesis of C8-aldehydes from propylene. Ind Eng Chem Res 47:3795–3803

Sudheesh N, Sharma SK, Shukla RS, Jasra RV (2008) HRh(CO)(PPh3)3 encapsulated mesopores of hexagonal mesoporous silica (HMS) aacting as nanophase reactors for effective catalytic hydroformylation of olefins. J Mol Catal A Chem 296:61–70

Sharma SK, Shukla RS, Parikh PA, Jasra RV (2009) The multi-step reactions for the synthesis of C8 aldehydes and alcohol from propene in a single pot using an eco-friendly multi-functional catalyst system: Kinetic performance for parametric optimization. J Mol Catal A Chem 304:33–39

Sudheesh N, Sharma SK, Shukla RS, Jasra RV (2010) Investigations on the kinetics of hydroformylation of 1-hexene using HRh(CO)(PPh3)3 encapsulated hexagonal mesoporous silica as a heterogeneous catalyst. J Mol Catal A Chem 316:23–29

Sudheesh N, Chaturvedi AK, Shukla RS (2011) RhCl(TPPTS)3 encapsulated into the hexagonal mesoporous silica as an efficient heterogeneous catalyst for hydroformylation of vinyl esters. Appl Catal A Gen 409–410:99–105

Sudheesh N, Parmar JN, Shukla RS (2012) Hydroformylation of propene heterogeneously catalyzed by HRh(CO)(PPh3)3 encapsulated into hexagonal mesoporous silica: parametric variation and mass transfer study. Appl Catal A Gen 415–416:124–131

Sudheesh N, Shukla RS (2013) Rhodium complex encapsulated functionalized hexagonal mesoporous silica for heterogeneous hydroaminomethylation. Appl Catal A Gen 453:159–166

Sudheesh N, Shukla RS (2014) Rhodium exchanged ETS-10 and ETS-4: efficient heterogeneous catalyst for hydroaminomethylation. Appl Catal A Gen 473:116–124

Khokhar MD, Shukla RS, Jasra RV (2015) Rh complex encapsulated hexagonal mesoporous silica as an efficient heterogeneous catalyst system for selective hydroformylation of styrene. Reac Kinet Mech Cat 114:265–277

Khokhar MD, Shukla RS, Jasra RV (2015) Hydroformylation of dihydrofurans catalyzed by rhodium complex encapsulated hexagonal mesoporous silica. J Mol Catal A Chem 400:1–6

Jasra RV, Srivastava VK, Shukla RS, Bajaj HC, Bhatt SD (2007) Process for preparing aldol derivatives from alkenes using catalyst. US patent 7294745 B2

Maru MS, Ram S, Adwani JH, Shukla RS (2017) Selective and direct hydrogenation of CO2 for the synthesis of formic acid over a Rhodium hydrotalcite (Rh-HT) catalyst. ChemistrySelect 2:3823–3830

Maru MS, Ram S, Shukla RS, Khan NH (2018) Ruthenium-hydrotalcite (Ru-HT) as an effective heterogeneous catalyst for the selective hydrogenation of CO2 to formic acid. Mol Catal 446:23–30

Ansari MB, Shukla RS, Mo YH, Park SE (2021) Carbamate intermediates over mesoporous carbon nitrides in CO2 mediated oxidation reaction. Chem Eng J Adv 6:100102

Maru MS, Patel P, Khan NH, Shukla RS (2021) Cu-hydrotalcite (Cu-HT) as an efficient catalyst for the hydrogenation of CO2 to formic acid. Curr Catal 9:59–71

Sudheesh N, Sharma SK, Shukla RS (2010) Chitosan as an eco-friendly solid base catalyst for the solvent free synthesis of jasminaldehyde. J Mol Catal A Chem 321:77–82

Jose T, Sudheesh N, Shukla RS (2010) Amino functionalized chitosan as an eco-friendly solid base catalyst for selective solvent-free self condensation of linear aldehydes. J Mol Catal A Chem 333:158–166

Adwani JH, Khan NH, Shukla RS (2015) An elegant synthesis of chitosan grafted hydrotalcite nano-bio composite material and its effective catalysis for solvent-free synthesis of jasminaldehyde. RSC Adv 5:94562–94570

Climent MJ, Corma A, Garcia H, Guil-Lopez R, Iborra S, Fornes V (2001) Acid-base bifunctional catalysts for the preparation of fine chemicals: synthesis of jasminaldehyde. J Catal 197:385–393

Ganga VSR, Abdi SHR, Kureshy RI, Khan NH, Bajaj HC (2016) p-Toluene sulfonic acid (PTSA)-MCM-41 as a green, efficient and reusable heterogeneous catalyst for the synthesis of jasminaldehyde under solvent-free condition. J Mol Catal A Chem 420:264–271

Sharma SK, Parikh PA, Jasra RV (2010) Reconstructed Mg/Al hydrotalcite as a solid base catalyst for synthesis of jasminaldehyde. Appl Catal A Gen 386:34–42

Prabhu A, Palanichamy M (2013) Mesoporous cubic Ia3d materials for the preparation of fine chemicals: synthesis of jasminaldehyde. Microporous Mesoporous Mater 168:126–131

Yadav GD, Aduri P (2012) Aldol condensation of benzaldehyde with heptanal to jasminaldehyde over novel Mg-Al mixed oxide on hexagonal mesoporous silica. J Mol Catal A Chem 355:142–154

Vashishtha M, Mishra M, Shah DO (2013) A novel approach for selective cross aldol condensation using reusable NaOH-cationic micellar systems. Appl Catal A Gen 466:38–44

Gholami Z, Tisler Z, Pavla V, Velvarska R, Stepanek K (2020) Solvent free synthesis of jasminaldehyde in a fixed-bed flow reactor over Mg-Al mixed oxide. Catalysis 10:1033

Vrbkova E, Tisler Z, Vyskocilova E, Kadlec D, Cerveny L (2018) Aldol condensation of benzaldehyde and heptanal: a comparative study of laboratory and industrially prepared Mg-Al mixed oxides. J Chem Technol Biotechnol 93:166–173

Vrbkova E, Vyskocilova E, Cerveny L (2017) Potassium modified alumina as a catalyst for the aldol condensation of benzaldehyde with linear C3–C8 aldehydes. Reac Kinet Mech Cat 121:307–316

Vermoortele F, Ameloot R, Vimont A, Serre C, Vos DD (2011) An amino-modified Zr-terephthalate metal-organic framework as an acid-base catalyst for cross-aldol condensation. Chem Commun 47:1521–1523

Kumar TEM, Shamshuddin SZM, Mubarak NM (2017) Simple and efficient synthesis of jasminaldehyde over modified forms of zirconia: acid-base bifunctional catalysts. Indian J Chem Technol 24:548–554

Perez-Sanchez M, de Maria PD (2013) Synthesis of natural fragrance jasminaldehyde using silica-immobilized piperazine as organocatalyst. Catal Sci Technol 3:2732–2736

Vrbkova E, Vyskocilova E, Krupka J, Cerveny L (2016) Aldol condensation of benzaldehyde with heptanal using solid-supported cesium and potassium catalysts. Progress Rect Kinet Mech 41:289–300

Hamza A, Nagaraju N (2015) Amorphous metal-aluminophosphate catalysts for aldol condensation of n-heptanal and benzaldehyde to jasminaldehyde. Chin J Catal 36:209–215

Heynderickx PM (2019) Activity coefficients for liquid organic reactions: towards a better understanding of true kinetics with the synthesis of jasmin aldehyde as show case. Int J Mol Sci 20:3819

Fang X, Jackstell R, Franke R, Beller M (2014) Domino-hydroformylation/aldol condensation catalysts: highly selective synthesis of α, β–unsaturated aldehydes from olefins. Chem Eur J 20:13210–13216

Strochmann M, Vossen JT, Vorholt AJ, Leitner W (2020) Recycling of two molecular catalysts in the hydroformylation/aldol condensation tandem reaction using one multiphase system. Green Chem 22:8444–8451

Kollar L, Pongracz P (2018) Tandem hydroformylation/aldol condensation reactions: synthesis of unsaturated ketones from olefins. J Organomet Chem 866:184–188

Sharma SK, Parikh PA, Jasra RV (2009) Synthesis of 2-methylpentanol from ethylene in a single pot using eco-friendly HRh(CO)(PPh3)3 supported on activated hydrotalcite as a multi-functional catalyst. J Mol Catal A Chem 301:31–38

Li Y, Zhou Q, Wang D, Wang P, Lu Y, Liu Y (2017) Co-catalysts for one-pot tandem hydroformylation-aldol condensation-hydrogenation with involvement of phosphino-phosphonium based bi-functional ligand and aniline. Mol Catal 439:25–30

October J, Mapolie SF (2021) Sequential hydroaminomethylation/Pd-catalyzed hydrogenolysis as an atom efficient route to valuable primary and secondary amines. Tetrahedron Lett 70:153018

Abatjoglou AG, Bryant DR, D’Esposito LC (1983) Rhodium-catalyzed low pressure hydroformylation of vinyl esters: solvent and phosphine effects on catalyst activity, selectivity and stability. J Mol Catal 18:381–390

Sharma SK, Patel HA, Jasra RV (2008) Synthesis of jasminaldehyde using magnesium organo silicate as a solid base catalyst. J Mol Catal A Chem 280:61–67

Sharma SK, Parikh PA, Jasra RV (2008) Eco-friendly synthesis of jasminaldehyde by condensation of 1-heptanal with benzaldehyde using hydrotalcite as a solid base catalyst. J Mol Catal A Chem 286:55–62

Kadib AE, Molvinger K, Bousmina M, Brunel D (2010) Improving catalytic activity by synergic effect between base and acid pairs in hierarchically porous chitosan@ titania nanoreactors. Org Lett 12:948–951

Kadib AE, Molvinger K, Bousmina M, Brunel D (2010) Decoration of chitosan microspheres with inorganic oxide clusters: rational design of hierarchically porous, stable and cooperative acid-base nanoreactors. J Catal 273:147–155

Acknowledgements

CSMCRI communication No. IMC 03, CSIR-CSMCRI—128/2021. Authors thank Council of Scientific and Industrial Research (CSIR), New Delhi, India for the financial support through Network Project on the Development of Specialty Inorganic Materials for Diverse Applications. The authors also acknowledge Analytical Division and Central Instrumentation Facility for providing instrumental analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sudheesh, N., Shukla, R.S. Investigations on different efficient strategies for the selective synthesis of jasminaldehyde over HRhCO(PPh3)3–hexagonal mesoporous silica and chitosan catalysts. Reac Kinet Mech Cat 135, 1485–1502 (2022). https://doi.org/10.1007/s11144-022-02196-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02196-9