Abstract

Determination of dig-limits is one of the most critical steps in grade control and short-term mine planning. Dig-limits optimization aims to maximize profit by identifying the optimal destinations of blasted materials while honoring equipment selectivity. Dig-limits determined in the pre-blast stage are not operational in the post-blast stage due to blast movement. Based on blast design configuration and rock characteristics, blasted materials will move in certain directions. The magnitude of blast movement in those directions varies across bench levels called flitches. Determining dig-limits without considering blast movement can cause significant ore losses and dilution, leading to severe financial losses. In this paper, a new methodology is proposed for quantifying uncertainty in blast movement and assessing the impact of this uncertainty on dig-limits optimization. Blast movements were modeled by using field measurement data obtained from blast movement monitoring balls that were installed in blast holes. The multivariate distributions for measured blast movements across flitches were fitted using drawable vine copula, and blast movement realizations were generated using Monte Carlo simulation. A mixed-integer linear programming model was used to determine the optimal dig-limits for all economic block models corrected and adjusted with blast movements realizations. An ore probability map was generated showing locations of ore and waste blocks in a probabilistic fashion. A case study for demonstrating the proposed methodology is presented. In this case study, two scenarios were investigated; the first scenario incorporated blast movement in determining dig-limits, while the second scenario discarded blast movement effect on dig-limits. The result of this comparison showed that discarding blast movement when determining dig-limits can lead to over-estimation of the expected profit by 65.3% when compared with the other scenario that incorporated blast movement. Post-blasting ore and waste areas with high risk of being misallocated by the dig-limits were identified.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

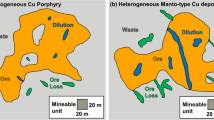

Ore–waste classification is an essential part of grade control and short-term mine planning. It aims to maximize profit from short-term mining operations by sending the blasted materials to their optimal destinations and reducing ore losses and dilution while honoring the selectivity of mining equipment. A block model is generated to understand the spatial distribution of ore and waste zones within a bench. This model is a simplified representation of the bench, and it consists of a number of small computer-generated blocks called selective mining units (SMUs). SMUs are the smallest volumes of materials on which ore–waste classification decisions are made (Sinclair & Blackwell, 2006). These SMUs are too small to be mined by themselves. Therefore, SMUs are grouped together into spatially coherent clusters called dig-limits, which can be mined by large mining equipment. The misclassification of SMUs can cause significant ore losses and dilution issues, which lead to severe financial losses. This misclassification problem becomes even more evident when ore cannot be distinguished visually from waste during mining operations, such as in most (if not all) gold deposits. During bench blasting, ore and waste blasted rocks are moved by the blast in various directions and distances throughout the blasted section of the bench. It becomes difficult to quantify the distance of this blast movement accurately as a consequence of the variations of geologic and rock properties. These variations may add uncertainty in ore and waste boundaries, resulting in financial losses. Therefore, assessing blast movement uncertainty is considered a crucial predecessor step before determining optimal dig-limits. If dig-limits are determined pre-blast, they will have a limited or no operational use post-blast due to blast movements.

Most of the current methods applied to determine dig-limits are based on the experience of the grade control geologists, who manually digitize ore and waste polygons on a bench-by-bench basis. Their judgment on the shape of dig-limits is guided by rock types and cutoff grade, which varies according to deposit type, ore recoveries, and other economic factors such as commodity price and operational costs. However, this manual determination of dig-limits suffers from several limitations: (1) It is subjective; (2) it takes a relatively long time to manually digitize dig-limits; (3) it does not produce optimal dig-limits that maximizes profit; (4) it does not correctly account for the differential blast movements within a bench among flitches; and (5) it does not account for the unavoidable uncertainty in modeling blast movement. These limitations may result in profit losses caused by dilution and ore loss.

To overcome those limitations in solving the dig-limits problem, various methods have been proposed in the literature. Most of these proposed methods rely on heuristics and metaheuristics algorithms such as simulated annealing (Isaaks et al., 2014a, 2014b; Deutsch, 2017; Norrena & Deutsch, 2000), genetic algorithms (Ruiseco, 2016; Ruiseco et al., 2016; Ruiseco & Kumral, 2017; Williams et al., 2021), heuristics (Richmond & Beasley, 2004; Vasylchuk & Deutsch, 2018, 2019a), greedy searches (Wilde & Deutsch, 2015), or they adopted a hybrid approach such as combining branch and bound with simulated annealing to determine the dig-limits (Deutsch, 2017). In this hybrid approach, when the branch and bound need many iterations, simulated annealing takes part resulting in sub-optimal solutions. The mentioned techniques can solve big computational problems in a relatively short time. However, they do not guarantee optimality and they require careful selection for input parameters to obtain near-optimal results.

Another way of solving a dig-limits problem is spatial clustering. Tabesh and Askari-Nasab (2011) proposed a hierarchical clustering algorithm for generating dig-limits based on a similarity index, which includes distance between blocks, rock types, destinations, metal grade, and the shape of mining cuts to produce spatially coherent clusters or dig-limits. The generated clusters are refined in a later stage using a Tabu search. However, this post-processing step reduces cluster homogeneity and increases ore loss and dilution. Tabesh and Askari-Nasab (2013) proposed another spatial hierarchical clustering algorithm to define spatially coherent groups of blocks used at different stages of mine planning. Their algorithm accounts for mining shapes and the direction of mining when creating these clusters. Tabesh and Askari-Nasab (2019) extended their proposed spatial clustering algorithm to account for geological uncertainty and proved that it could be implemented on real-size block models and generate clusters within a reasonable processing time. Salman et al. (2021) explored a block clustering algorithm based on the K-means clustering algorithm to define dig-limits. This algorithm aggregates blocks with a similar grade, rock types, and spatial proximity and generates clusters with controllable sizes that are used as dig-limits.

The clustering approaches summarized above are used to produce mine schedules quickly by dividing open-pit benches into a number of clusters and grouping SMUs with the same characteristics together to form dig-limits. However, these approaches do not find optimal dig-limits when forming their clusters to separate ore from waste. They also require careful selection for input clustering parameters, such as the desired number of clusters, making the solution very subjective. Moreover, the dig-limits optimization problem is formulated as a mixed-integer linear programming (MILP) problem (Kumral, 2015; Sari & Kumral, 2018; Nelis & Morales, 2021). These models guarantee optimality but they usually require a longer time to find the optimal solutions.

Many dig-limits optimization techniques do not account for blast movement when determining optimal dig-limits. Therefore, determination of dig-limits that ignore blast movements is impractical (Thornton et al., 2005; Engmann et al., 2013). The possible dilution associated with blast movement can be minimized if blast movement is considered appropriately (Zhang, 1994; Yennamani, 2010). As a result of incorporating blast movement in determining dig-limits, ore recovery can increase because mined materials are sent to their optimal destinations (Gilbride, 1995; Harris, 1997; Taylor & Firth, 2003).

Modeling blast movements throughout a bench section is an essential step for determining optimal dig-limits. There are three approaches for modeling blast movements in the literature: (1) by conducting a multi-physical simulation of blast movements (Zou & Jun, 2021); (2) by modeling blast movements using physical field measurements (Isaaks et al., 2014a, 2014b; Vasylchuk & Deutsch, 2019b; Yu et al., 2021); and (3) by training machine learning algorithms on previous blast movement information to predict future blast movement in a mine (Yu et al., 2020, 2021). Physical field measurements are also required for validating multi-physics simulation models of blast movement. Moreover, these measurements may be used as input data in machine learning algorithms for training purposes. If the mechanism behind the blast movement distance is not well quantified, there will be high ore losses and dilution levels. Given that blasting is a relatively cheap process in mining, the operations tend to overbreak rock, leading to turbulent movements. In other words, the financial benefits acquired from reaching small particle sizes through blasting can be lost due to ore loss and dilution caused by blast movement.

Regardless of which approach is used for modeling blast movements, there will be inevitable uncertainty associated with the direction and distance of blast movement. Rosa and Thornton (2011) remarked that blast movements are uncertain because of inconsistencies of blast design and rock mass characteristics. They emphasized the fact that accurate calculation of blast movement is not possible if there are no detailed physical field measurements. Moreover, there would be inevitable human factor issues and geologic uncertainty. As a matter of fact, no method precisely guarantees predictions for blast movements. When physical field measurements are not available, evaluating the risk associated with rock movement uncertainty will be essential to quantify dilution and ore loss.

Based on previous research conducted on modeling blast movement, the uncertainty in blast movement remains unstudied. For this reason, this research is proposed to assess the effect of blast movement uncertainty on dig-limit optimization while honoring the selectivity of mining equipment. The originality of this paper is twofold: (i) a combined approach of blast movements and the dig-limit optimization; and (ii) the quantification of risk attributed to blast movement in bench sections such that the effects of blast movement uncertainty on profit, dilution, and ore losses are measured.

The paper was organized as follows. The proposed methodology is elaborated in the next section, followed by a case study demonstrating the importance of incorporating blast movement in dig-limits optimization. Finally, the conclusions and future work are provided.

Methodology

The methods in this paper are based on combined approaches: MILP, the simulation of blast movements through Monte Carlo simulations (MCS) using drawable vine copula (D-vine) and statistical analysis. Figure 1 summarizes the methodology used in this research.

A grade control block model is formed using exploration drill holes and blast holes resource database. The estimation methods such as ordinary kriging (OK) can be used to estimate ore grades and produce a grade control block model. OK is one of the most widely used interpolation techniques. In the context of resource estimation, OK estimates the grade at an SMU location by using a variogram model and grade data in the neighborhood of the estimation location. The variogram model provides OK with covariance values used to assign weights for the neighboring grade data to estimate the unknown grade value at an SMU location. This process is repeated until all SMUs in a grade control block model are estimated. The most significant advantage of using OK is that it is the best linear unbiased estimation technique compared to other techniques such as inverse distance weighting. This grade control block model should cover the investigated section of the bench that needs to be blasted. When creating the grade control block model, the number of SMUs in the vertical direction should equal the number of bench levels called flitches.

The grade control block model is transformed into an economic block model by applying various parameters, including cost, price, recovery, and metal quantity, to all SMUs. The principal input parameters used in generating an economic block model are operational costs, metal price, and ore recovery. These parameters are used to calculate a break-even cutoff grade (COGB.E.) and compute the profit. COGB.E. is calculated as

where \({C}_{p}\) is the processing cost per tonne, \({C}_{m}\) is the mining cost per tonne, \(p\) is the metal price, and \(r\) is the ore recovery. \(CO{G}_{B.E.}\) is used to distinguish ore SMUs from waste SMUs because the former includes the cost of mining, which is vital for calculating the profit of all SMUs in an economic block model. The profit obtained from an ore SMU is

where \({P}_{i,j}\) is the profit of SMU located in i and j on a bench if it is assessed as ore, \({m}_{i,j}\) is the contained metal of SMU i, j, and \(t\) is SMU tonnage. If the mined material is considered waste based on \(CO{G}_{B.E.}\), then the profit generated from mining this waste SMU is calculated as

where \({W}_{i,j}\) is the extraction cost of SMU located in i and j on a bench if it is assessed as waste. After generating an economic block model, two initial input parameters must be specified: (1) blast movement direction and distance; and (2) minimum mining width. The direction and magnitude of blast movement are estimated from physical field measurements using blast movement monitor (BMM) balls. Minimum mining width must be specified based on the selectivity of the equipment used for mining the bench.

The extent of horizontal blast movement is different in each flitch because of the blast design and rock characteristics. In general, most explosives are placed in mid-holes. This placement results in blasted rocks in the middle flitches of a bench moving further than the upper and lower flitches. These differential movements generate a D-like shape structure prior to settling a new location. Figure 2 illustrates a typical D-like shape of blast movements. The number of flitches depends on the blasting design and SMU sizes used in the estimation stage. Typically, the direction of blast movement is parallel to the initiation direction of the blast (Gilbride, 1995).

Even though the use of BMM balls in determining the magnitude of blast movement is considered one of the best and the most reliable sources of blast movement information, the measurements of blast movement obtained from these balls remain uncertain. That is because (1) BMM balls do not cover the entire blasted section of the bench, (2) it is difficult to determine the locations of the BMM balls post-blasting accurately, and (3) the blast movement distances associated with the balls vary even within the same flitch. For these reasons, the uncertainty in modeling blast movement needs to be quantified before determining any dig-limits because it significantly impacts ore loss, dilution, and, subsequently, mine profit.

After bench blasting, the new locations of the BMM balls are determined, and they are used to calculate the magnitude and the overall direction of blast movement. To help modeling blast movement across bench flitches, blast movement data collected from BMM balls are grouped together based on the bench flitch within which they are located. Then, a multivariate statistical distribution is fitted to the blast movement measurements across these flitches. This multivariate distribution honors the existing correlations between flitch movements. By applying MCS to the fitted multivariate distribution of blast movement measurements, several blast movement realizations are generated. These realizations yield the expected D-like shape from blast movements. There is always a possibility of producing unexpected shapes because of issues emerging from the implementation of blasting operation, and unforeseen rock and geologic features that affect the magnitude of blast movement. This method can successfully produce realizations of these unexpected shapes.

In this paper, the multivariate relationships between blast movements of bench flitches were modeled using D-vine copula, a subclass of regular vine copula (R-vine), which was proposed by Aas et al. (2009). This method preserves the multivariate correlations between the blast movements of bench flitches using bivariate copulas and a nested set of trees. Figure 3 shows an example of D-vine copula trees for the blast movement measurements of three flitches where F1 is blast movement for Flitch1, F2 is blast movement for Flitch2, and F3 is blast movement for Flitch3. F1F2 and F2F3 are the bivariate blast movement copula distributions between Flitch1-Flicth2 and Flitch2-Flitch3. F1F3|F2 is the Flitch1 and Flitch3 bivariate copula distribution given Flitch2 blast movement. Bivariate copulas are functions that describe the dependency among two one-dimensional distributions. If both marginal distributions and copula are known, then the entire bivariate distribution of those two one-dimensional distributions is also known. Following Sklar’s theorem (Sklar, 1959), if H(x,y) is a two-dimensional distribution function with marginal distribution functions F(x) and G(y), then there exists a copula C such that

When applying copulas to blast movement scenarios F(x) and G(y), which are two continuous marginal distributions, they will represent blast movement magnitudes in two bench flitches. Based on Sklar’s theorem, if both marginal distributions are continuous, then a unique copula must exist.

Copulas are used for modeling complex multivariate relationships. Nevertheless, they have been applied to solve a limited number of mining-related problems (Ardian & Kumral, 2021; Singh et al., 2021). In this paper, the D-vine copula was selected for modeling blast movement across flitches. This decision of selecting the D-vine copula instead of the C-vine copula was made due to the nature of the problem, in which all flitch movements are equally important. There is no single flitch movement that controls all other flitch movements when rocks are blasted. The C-vine copula is only used in fitting multivariate distributions when one variable controls several other variables. This situation does not exist in the blast movement problem.

A number of well-known bivariate copula distributions can be used to fit bivariate relationships of blast movements between flitches such as Gaussian and Archimedean copulas. The Gaussian copula is used to model linear bivariate relationships, whereas Archimedean copulas are used to model nonlinear or heteroscedastic bivariate relationships. Clayton, Frank, and Gumbel are good examples of Archimedean copulas. These bivariate Archimedean distributions have a single parameter that controls the degree of dependence (θ). The θ of the Archimedean copula is the leading and only parameter used in constructing a bivariate Archimedean distribution, and it indicates the association between random variables. The θ can be derived from Kendall’s tau correlation coefficient due to its ability to disentangle the marginal distribution effect, which is suitable for nonparametric methods (Frees & Valdez, 1998; Chemen & Teilly, 1999). Kendall’s tau correlation coefficient is computed as

where ncondordant is the number of concordant pairs, ndiscordant is the number of discordant pairs, and n is the sample size. For Clayton, Frank, and Gumbel copulas, the value of θ can be calculated using Eqs. 6, 7, and 8, respectively (Genest & Favre, 2007):

where \({Y}_{1}\left(\theta \right)\) is the Debye’s model, which can be estimated as (Genest & Favre, 2007)

For modeling Archimedean-type copulas (e.g., Clayton, Gumbel, and Frank), Nelsen (2007) provided the models given in Eqs. 10, 11, and 12, respectively:

where C is the bivariate copula function. In order to estimate copula, the original values of the two one-dimensional distributions are converted to u and v. Then, u and v follow a uniform distribution with [0,1]. Examples of Gaussian and Archimedean copulas are presented in Figure 4.

Most phenomena in nature exhibit a nonlinear or heteroscedastic behavior. The linearity assumption is typically considered to simplify most real-life problems. Therefore, the Clayton model is highly recommended for modeling blast movement data across flitches where blast movement correlations between the movements of these flitches are stronger near blast holes. They get weaker and weaker when the distance becomes larger from the nearby blast holes.

The proposed methodology can deal with blast movements in any direction. First, the azimuth angle of the overall blast movement direction is initiated as an input parameter. Then, the SMUs within a block model are further divided into smaller SMUs. Thus, small SMU movements can be captured, and the accuracy of dig-limit optimization is increased. Later, all pre-blast small SMUs are moved to the direction specified. N number of blast movement simulations generated from D-vine copula multivariate distribution using MCS is applied to the centroids of the pre-blast small SMUs. This step results in generating N number of post-blast economic block models that include block economic values, the geological properties of the deposit, grade, metal quantities, and block profits. In the end, post-blast economic block models are submitted to dig-limit optimization model.

Before running dig-limits optimization, the 3D post-blast economic block models are transformed into 2D economic block models. In doing so, the x and y coordinates of their centroids are kept the same, and the contained metal values of all SMUs with the same x and y coordinates are added together such that a 2D model is obtained. This step reduces the size of the dig-limits optimization problem significantly. Also, this step does not have an impact on the final dig-limits because dig-limits are drawn on 2D maps, and they are not determined on a flitch-by-flitch basis. Another important step for reducing further the size of dig-limits optimization processing time is that of re-gridding the small SMUs. In this step, SMUs are re-gridded back to their original SMU size, and the total amount of contained metal and profit are calculated for these re-gridded SMUs. This re-gridding step may slightly increase ore loss and dilution applied to the SMU model. This step generates 2D post-blast economic block models that contain the amount of contained metal at original SMU support. Finally, the re-gridded 2D economic block models are used as an input to the dig-limits optimization model to generate a number of dig-limits realizations corresponding to the number of post-blast 2D economic block models.

The formulation of dig-limit optimization used in this research was based on the MILP model developed by Sari and Kumral (2018). This model was re-coded using Python 3.8 and ran on the CPLEX solver (IBM, 2021). The objective function was to maximize the profit of the blasted section of the bench while satisfying equipment selectivity constraints. To describe this approach in simple words, equipment dimensions were defined as an n x n frame where n represents the number of SMUs in x- and y-directions. Every SMU should be assigned to a frame in which all SMUs in it are either ore SMUs or waste SMUs. A frame is called a valid frame if all SMUs inside it are either ore or waste. If an SMU belongs to more than one frame, it should be assigned at least one valid frame. The dig-limits optimization model is formulated as

where \({x}_{i}{,}_{j}\) is a binary decision variable at i,j SMU, \({P}_{i,j}\) is the economic value of SMU i,j when mined as ore, and \({W}_{i,j}\) is the economic value of SMU i,j when mined as waste. The i and j are SMU indices in x- and y-directions, respectively.

Subject to

where \(\gamma \) and \(\delta \) are the frame index in x- and y-directions, respectively, and \({b}_{i,j, {f}_{a}, {f}_{b}}\) is a decision variable that represents the total number of SMUs (xij) at (i, j) locations that belong to a frame where

where Dx and Dy are the numbers of SMUs in the x- and y-directions, respectively, n is the minimum mining width in SMU terms, and fa and fb are frame indices in x- and y-directions, respectively. The decision variable \({b}_{i}{,}_{j}{,}_{fx}{,}_{fy}\) is transformed to a new binary decision variable, \({v}_{i}{,}_{j}{,}_{fa}{,}_{fb}\), controlling if a frame is valid; thus,

where \({v}_{i}{,}_{j}{,}_{fa}{,}_{fb}\) is a valid frame. This constraint ensures that a SMU is assigned at least to one valid frame; thus,

To remove incomplete frames at the corners, the following constraints were added:

where

where

After running dig-limits optimization using all 2D economic block models generated from the N blast movement realizations, N numbers of dig-limits realizations are generated. These N realizations of dig-limits are used to calculate the probability of having ore and waste for all SMUs. Furthermore, uncertainty in ore loss and dilution amounts can be quantified, and profit distribution can be generated for the blasted section of the bench.

Case Study

In this section, a case study demonstrating the impact of blast movement uncertainty on dig-limits optimization is presented. First, a 3D grade control block model was generated from blast hole resource database at a porphyry gold mine. The block model definition is summarized in Table 1. Next, this block model was used to generate an economic block model applying a cutoff grade based on economic and metallurgical input parameters listed in Table 2.

The section of the bench under consideration was partitioned into three flitches. Each flitch had a thickness of 5 m. Blast movement data were simulated from 51 BMM ball field measurements, which cover the three flitches at 17 locations. In other words, each blast hole had three BMM balls. The movement direction was northeast (45° azimuth) toward the two free faces of the bench on the north and east sides. The direction of movement was ascertained by comparing the pre-blast locations of BMM balls against their post-blast locations. The blast movement data were best fitted to triangular distributions, which are widely used in engineering simulations. It is a helpful distribution because it has fixed minimum and maximum values, unlike the normal distribution and other distributions where their minimum and maximum values go to positive and negative infinity. The selection of a distribution extending to both infinities (e.g., normal distribution) might generate unrepresentative results. These distributions were used to fit Clayton bivariate copulas and D-vine multivariate copulas between flitches blast movements. MCS was then used to generate 1000 realizations of blast movements from the fitted D-vine copula distribution to check the reproduction of multivariate relationships between flitch movements.

Figure 5 shows the results of simulating blast movement realizations through MCS using a D-vine copula where the lines represent the fitted triangular distributions for the three flitches. In Figure 5, \(n\) is the number of realizations, \({\mu }_{x}\) is the mean of the simulated realizations, \({X}_{50}\) is the median of the simulated realizations, \(\sigma \) is the standard deviation, \(CV\) is the coefficient of variation, \({X}_{\mathrm{min}}\) is the minimum value, and \({X}_{\mathrm{max}}\) is the maximum value. Figure 6 shows if the multivariate relationships between blast movements are agreed upon after simulating blast movement realizations from the D-vine copula. A comparison of the observed movements from BMM balls and the simulated blast movement realizations using MCS is presented in Figure 7. As can be seen in this figure, the movement of Flitch2 can extend as long as 50 m. This extreme value can be observed in rare cases and related to the distribution parameter fitted. These movements were applied to the centroids of the blocks in flitches at depths of 2.5 m, 7.5 m, and 12.5 m. The sound reproduction of the multivariate input relationships between BMM measurements and simulated realizations is observed in Figures. 6 and 7.

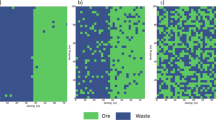

One hundred blast movement realizations were submitted to the dig-limits optimization model to determine the optimal destinations for the SMUs while honoring equipment selectivity. A minimum mining width of 10 m by 10 m was selected to represent the selectivity of the shovel’s bucket used to mine the section of the bench. The optimal dig-limits for the 100 blast movement realizations were produced and then used to generate the ore probability map. Figure 8 summarizes the results of the proposed methodology, starting from identifying pre-blast destinations, simulating blast movement realizations, identifying post-blast destinations, applying dig-limits optimization on post-blast 2D economic block models, generating post-blast dig-limits realizations, and finally producing the ore probability map.

As shown in Figure 8, the ore probability map was generated. In the map, the areas shown in yellow and navy blues were certain ore and waste areas, respectively. The greenish areas might be either ore or waste, and they are referred to as risk areas in this paper. These risk areas need special attention when determining the best destination for their materials. The ore probability map can be used to determine areas where careful grade control sampling program should be implemented. This map helps optimize the number of grade control samples so that grade control geologists can design a sampling program that focuses on a more detailed sampling of high-risk areas. As a result of producing an ore probability map, risk areas were identified (Fig. 9). This ore risk map can be used to reduce the number of check samples taken during grade control, and this will result in reducing the cost and the time needed in assaying certain ore and waste areas, thus increasing the profit from mining this section of the bench. It is apparent that the spatial distribution of risky areas relies on three factors: (1) the degree of heterogeneity of the mineralization; (2) the difference in the magnitude of blast movement across flitches; and (3) the cutoff grade. A low degree of heterogeneity will reduce the number of risky areas in the blasted section of the bench. A high cutoff grade generates more isolated ore areas than a low cutoff grade, increasing the risk areas. Having a significant difference in blast movement magnitude across flitches increases the dilution and ore losses, which also increases the risk areas.

Additionally, the best locations for installing BMM balls can be determined using ore risk maps. In fact, BMM balls are known for their high costs and their intermediate recovery rate after blasting. Therefore, identifying high-risk areas before blasting brings more valuable information on the magnitude and direction of blast movement at those uncertain locations and can reduce the extra cost attributed to installing BMM balls at low-risk areas. To generate blast movement realizations and produce ore risk maps, grade control geologists can utilize their knowledge and experience from previous blasting operations conducted on benches with similar geological features and blast designs. This pre-blast study will enable grade control geologists to generate ore risk maps and determine high-risk areas within the bench that are considered ideal locations for installing BMM balls.

To show the effect of ignoring blast movement impact on dig-limits optimization, another scenario was investigated where the same proposed dig-limits optimization model was applied on the same grade control block model using the same input parameters but without considering blast movement. Figure 10 shows the results of this scenario, where original ore and waste SMUs were compared to their optimal pre-blast destinations after applying dig-limits optimization.

The results of running dig-limit optimization on a pre-blast economic block model show that equipment selectivity increased the amount of ore loss by 3.2% and dilution by 35.4%. Neglecting this amount of ore loss and dilution would lead to an over-estimation of the profit from approximately $2.36 Million to $2.80 Million (15.7% profit over-estimation).

In this case study, equipment selectivity was considered relatively low when compared to the size of SMUs. The low equipment selectivity (1) increased dilution by adding extra waste to the mined ore and (2) increased ore losses by mining small portions of the ore as waste while mining the surrounding waste and then sending it to the waste dump. Consequently, the low equipment selectivity decreased the profit obtained from mining. The problem of profit decrease is further accelerated when the effect of blast movements is ignored in the dig-limit optimization. To understand the effect of neglecting blast movements when determining optimum dig-limits, the profit values calculated for each optimized dig-limits realization were compared with the single profit value obtained when no blast movements were considered. The comparison shows that the profit obtained from single optimum dig-limits that ignored blast movements was over-estimated by 65.3% when compared with the expected profit value where blast movements were incorporated into the process. Figure 11a denotes the distribution of profit realizations when blast movements were considered in determining dig-limits. Figure 11b presents the distribution of profit over-estimation caused by neglecting the effect of blast movements.

Modeling blast movement prior to running dig-limits optimization has a significant impact on the resulting dig-limits. The results obtained from this study should not be generalized for all mineral deposits because mineral deposits vary in the spatial distribution of their mineralization, cutoff grade, and blast designs. However, this study shows the importance of incorporating blast movement when determining optimal dig-limits to generate a more realistic assessment of the expected profit. In addition, the reconciliation programs at the mine should include blast movements when tracking ore and waste at stockpiles and process plants.

Conclusions and Future Work

Quantifying risk in dig-limits optimization to account for the unavoidable uncertainty in blast movement prediction is important for grade control and short-term mine planning. This paper’s contribution lies in quantifying the uncertainty attributed to blast movements on the optimal dig-limits through a copula-based simulation approach. Physical field measurements for blast movement obtained from BMM balls were used to furnish the multivariate blast movement distributions for a number of flitches within benches using a D-vine copula. The realizations of blast movements were generated through MCS after fitting a D-vine copula distribution to the blast movements of flitches. The MILP algorithm was utilized to find the optimal dig-limits for all realizations of blast movements. The generated ore probability map shows locations of ore and waste in a probabilistic fashion. The expected profit from a modeled bench was over-estimated by 65.3% on average when blast movement was disregarded in comparison with the expected profit modeled from the same bench when the blast movement realizations were incorporated in the proposed workflow. High-risk ore and waste areas post-blasting were identified from the ore probability map. Due care should be taken when mining these uncertain (high-risk) areas.

Future work will focus on adding geological uncertainty in conjunction with the blast movement uncertainty to produce optimal dig-limits. Further, the proposed methodology will be extended to cover more than two destinations. At the same time, local variations in the direction of blast movement will be modeled and added to the proposed workflow. With the advanced development in parallel computing, aggregation/disaggregation, and decomposition methods such as nested Bender decompositions, the solutions that can be generated in an acceptable time will be explored.

References

Aas, K., Czado, C., Frigessi, A., & Bakken, H. (2009). Pair-copula constructions of multiple dependence. Insurance: Mathematics and Economics, 44(2), 182–198.

Ardian, A., & Kumral, M. (2021). Enhancing mine risk assessment through more accurate reproduction of correlations and interactions between uncertain variables. Mineral Economics, 34, 411–425.

Chemen, R. T., & Teilly, T. (1999). Correlations of Copulas for Decision and Risk. Analysis Management Science, 45(2), 208–224.

Deutsch, M. (2017). A branch and bound algorithm for open pit grade control polygon optimization. In Proceedings of the 38th APCOM Golden, Colorado USA, Ed. Dagdelen, K., pp. 14–18.

Engmann, E., Ako, S., Bisiaux, B., Rogers, W., & Kanchibotla, S. (2013). Measurement and modelling of blast movement to reduce ore losses and dilution at Ahafo Gold Mine in Ghana. Ghana Mining Journal, 14, 27–36.

Frees, E. W., & Valdez, E. A. (1998). Understanding relationships using copulas. North American Actuarial Journal, 2(1), 1–25.

Genest, C., & Favre, A. C. (2007). Everything you always wanted to know about copula modeling but were afraid to ask. Journal of Hydrologic Engineering, 12(4), 347–368.

Gilbride, L. J. (1995). Blast-induced rock movement modelling for bench blasting in Nevada open-pit mines. (Doctoral dissertation, University of Nevada, Reno).

Harris, G. W. (1997). Measurement of blast-induced rock movement in surface mines using magnetic geophysics. (Master thesis, University of Nevada, Reno).

IBM. (2021). IBM ILOG CPLEX Optimization Studio 20.1.0 documentation. https://www.ibm.com/analytics/cplex-optimizer

Isaaks, E., Barr, R., & Handayani, O. (2014a). Modeling blast movement for grade control. In Proceedings of 9th International Mining Geology Conference; Australasian Institute of Mining and Metallurgy. p. 433–440. Adelaide, Australia.

Isaaks, E., Treloar, I., & Elenbaas, T. (2014b). Optimum dig lines for open pit grade control. In Proceedings of 9th International Mining Geology Conference. Australasian Institute of Mining and Metallurgy, pp. 425–432. Adelaide, Australia.

Kumral, M. (2015). Grade control in multi-variable ore deposits as a quality management problem under uncertainty. International Journal of Quality & Reliability Management., 32(4), 334–345.

La Rosa, D., & Thornton, D. (2011). Blast movement modelling and measurement. In Proceedings of the 35th APCOM Symposium, pp. 297–310. Wollongong, NSW, Australasian Institute of Mining and Metallurgy.

Nelis, G., & Morales, N. (2021). A mathematical model for the scheduling and definition of mining cuts in short-term mine planning. Optimization and Engineering. https://doi.org/10.1007/s11081-020-09580-1

Nelsen, R. B. (2007). An introduction to copulas. Springer.

Norrena, K., & Deutsch, C. V. (2000). Automatic determination of dig limits subject to geostatistical, economical and equipment constraints. Edmonton, Alberta, Canada: University of Alberta.

Richmond, A., & Beasley, J. (2004). Financially efficient dig-line delineation incorporating equipment constraints and grade uncertainty. International Journal of Surface Mining, Reclamation and Environment, 18(2), 99–121.

Ruiseco, J. R. (2016). Dig-limit optimization in open pit mines through genetic algorithms. (Master thesis, McGill University, Canada).

Ruiseco, J. R., & Kumral, M. (2017). A practical approach to mine equipment sizing in relation to dig-limit optimization in complex orebodies: Multi-rock type, multi-process, and multi-metal case. Natural Resources Research, 26(1), 23–35.

Ruiseco, J. R., Williams, J., & Kumral, M. (2016). Optimizing ore–waste dig-limits as part of operational mine planning through genetic algorithms. Natural Resources Research, 25(4), 473–485.

Salman, S., Muhammad, K., Khan, A., & Glass, H. J. (2021). A block aggregation method for short-term planning of open pit mining with multiple processing destinations. Minerals, 11(3), 288.

Sari, Y. A., & Kumral, M. (2018). Dig-limits optimization through mixed-integer linear programming in open-pit mines. Journal of the Operational Research Society, 69(2), 171–182.

Sinclair, A. J., & Blackwell, G. H. (2006). Applied mineral inventory estimation. Cambridge University Press.

Singh, J., Ardian, A., & Kumral, M. (2021). Gold-copper mining investment evaluation through multivariate copula-innovated simulations. Mining, Metallurgy & Exploration, 38(3), 1421–1433.

Sklar, M. (1959). Fonctions de repartition an dimensions et leurs marges. L’institut Statistique De L’université De Paris, 8, 229–231.

Tabesh, M., & Askari-Nasab, H. (2011). Two-stage clustering algorithm for block aggregation in open pit mines. Mining Technology, 120(3), 158–169.

Tabesh, M., & Askari-Nasab, H. (2013). Automatic creation of mining polygons using hierarchical clustering techniques. Journal of Mining Science, 49(3), 426–440.

Tabesh, M., & Askari-Nasab, H. (2019). Clustering mining blocks in presence of geological uncertainty. Mining Technology, 49, 426–440.

Taylor, D., & Firth, I. (2003). Utilization of blast movement measurements in grade control. In Proceedings of the 31st APCOM Symposium, Ed. Camisani-Calzolari, 243–247. South Africa.

Thornton, D., Sprott, D., & Brunton, I. (2005). Measuring blast movement to reduce loss and dilution. In International Society of Explosives Engineers Annual Conference, Ed. Jerry Wallace. Orlando, Florida, Feb 6–9, 2005. Cleveland, Ohio USA.

Vasylchuk, Y. V., & Deutsch, C. V. (2018). Optimization of surface mining dig limits with realistic selectivity. Report of Center for Computational Geostatistics, University of Alberta, Edmonton, Alberta, Canada.

Vasylchuk, Y. V., & Deutsch, C. V. (2019a). Optimization of surface mining dig limits with a practical heuristic algorithm. Mining, Metallurgy & Exploration, 36(4), 773–784.

Vasylchuk, Y. V., & Deutsch, C. V. (2019b). Approximate blast movement modelling for improved grade control. Mining Technology, 128(3), 152–161.

Wilde, B., & Deutsch, C. V. (2015). A short note comparing feasibility grade control with dig limit grade control. Report of Center for Computational Geostatistics, University of Alberta, Edmonton, Alberta, Canada.

Williams, J., Singh, J., Kumral, M., & Ruiseco, J. R. (2021). Exploring deep learning for dig-limit optimization in open-pit mines. Natural Resources Research, 30(3), 2085–2101.

Yennamani, A. L. (2010). Blast induced rock movement measurement for grade control at the Phoenix mine. (Master thesis, University of Nevada, Reno). 233 p.

Yu, Z., Shi, X., Zhou, J., Chen, X., Miao, X., Teng, B., & Ipangelwa, T. (2020). Prediction of blast-induced rock movement during bench blasting: Use of gray wolf optimizer and support vector regression. Natural Resources Research, 29(2), 843–865.

Yu, Z., Shi, X., Zhou, J., Rao, D., Chen, X., Dong, W., Miao, X., & Ipangelwa, T. (2021). Feasibility of the indirect determination of blast-induced rock movement based on three new hybrid intelligent models. Engineering with Computers, 37(2), 991–1006.

Zhang, S. (1994). Rock movement due to blasting and its impact on ore grade control in Nevada open pit gold mines (Doctoral dissertation, University of Nevada, Reno).

Zou, Z., & Jun, Y. (2021). Modelling blast movement and muckpile formation with the position-based dynamics method. International Journal of Mining, Reclamation and Environment, 35(4), 306–317.

Acknowledgments

This work was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) (Fund number: 236482). The authors thank the NSERC for this support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hmoud, S., Kumral, M. Effect of Blast Movement Uncertainty on Dig-Limits Optimization in Open-Pit Mines. Nat Resour Res 31, 163–178 (2022). https://doi.org/10.1007/s11053-021-09998-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-021-09998-z