Abstract

To improve bacteriocin-like inhibitory substance (BLIS) production by Pediococcus pentosaceus ATCC 43200, the influence of pH as well as the addition of sugars—either prebiotic (inulin) or not (sucrose)—on its metabolism were investigated. This strain was grown at pH 5.0 or 6.0 either in glucose-based MRS medium (control) or after addition of 0.5, 1.0 or 1.5% (w/w) sucrose and inulin (GSI-MRS) in the same percentages. In the control medium at pH 5.0, cell mass concentration after 48 h of fermentation (Xmax = 2.26 g/L), maximum specific growth rate (µmax = 0.180 h−1) and generation time (Tg = 3.84 h) were statistically coincident with those obtained in supplemented media. At pH 6.0 some variations occurred in these parameters between the control medium (Xmax = 2.68 g/L; µmax = 0.32 h−1; Tg = 2.17 h) and the above supplemented media (Xmax = 1.90, 2.52 and 1.86 g/L; µmax = 0.26, 0.33 and 0.32 h−1; Tg = 2.62, 2.06 and 2.11 h, respectively). Lactate production was remarkable at both pH values (13 and 16 g/L) and improved in all supplemented media, being 34 and 54% higher than in their respective control media, regardless of the concentration of these ingredients. Cell-free supernatant of the fermented control medium at pH 5.0 displayed an antimicrobial activity against Enterococcus 101 5.3% higher than that at pH 6.0 and even 20% higher than those of all supplemented media, regardless of the concentration of supplements. BLIS production was favored either at pH 5.0 or in the absence of any additional supplements, which were able, instead, to stimulate growth and lactate production by P. pentosaceus.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pediococcus pentosaceus is a Gram-positive bacterium [1] belonging to the group of lactic acid bacteria (LABs), which is the best-known major member of probiotic bacteria [2, 3]. Research and development with LABs has a great interest for applications in food preservation, agriculture, clinical use and environmental science [4] owing to their ability to produce food additives and flavoring compounds [2, 4].

LAB belong to a diverse group of Gram-positive, anaerobic-aerotolerant homofermentative bacteria and l-(+)-lactic acid producer [5, 6] and have been used for centuries for feed and food fermentation [6,7,8,9]. Food fermentation is an important strategy to increase the shelf life of raw food matrices and to influence quality and functionality of foods by improving the taste and flavor fermented foods [6, 9]. LAB has become an important branch of the food industry since they are able to cause rapid acidification of the raw material through the production of organic acids, mainly lactic acid [10]. For these reasons, P. pentosaceus has been widely used in fermentation of vegetables, meats, silage and in cheese production [11]. The ATCC 43200 strain of this species, previously denominated as P. pentosaceus FBB61, was isolated from fermented cucumber [12], and its inhibitory [13] and bactericidal [14] activity was classified as bacteriocin-like [15].

The main bacterial metabolites with potential for use as biopreservative are the antimicrobial peptides, which are described as bacteriocins and bacteriocin-like inhibitory substances (BLIS) [16]. Bacteriocins are defined as ribosomally-synthesized antimicrobial peptides with broad spectrum of action [17], especially against bacteria genetically closely related to the producer strain [18], while BLIS are defined as antimicrobial peptide that were not fully characterized with regard amino acid sequences and biochemical properties [6, 19]. BLIS act as antagonist substances, with bactericidal or bacteriostatic activity against Gram-positive and Gram-negative bacteria, being innocuous for the producer strain [4, 6, 20, 21].

The addition of nutrients to the culture medium, such as carbon sources (glucose, sucrose) and prebiotics (inulin), may improve bacteriocin [22] or BLIS activity. P. pentosaceus has the ability to ferment sucrose [23, 24] and partially even inulin [25], a Generally Regarded as Safe (GRAS) food additive [26, 27] that exerts a prebiotic stimulatory effect on the growth of probiotics [28] owing to the increased amount of fructose available from the glycolytic pathway [29]. Since such an antimicrobial activity is often related to the growth of the producing bacterium, inulin as an ingredient of synbiotic media (containing both probiotic and prebiotic) [30] is expected to simultaneously stimulate the probiotic growth and antimicrobial production [25] as bacteriocin or BLIS.

Important species of bacteria linked to the global incidence of foodborne infection are Enterococcus spp. and Escherichia coli spp. They are facultative anaerobic cocci, resilient by nature and able to survive a wide array of hostile conditions. They can persist in the environment for long periods [31, 32] and can cause spoilage of certain meats [32,33,34]. E. coli species, one of the major foodborne pathogens affecting people worldwide [35], is a group of Gram-negative bacteria, facultative anaerobic and rod-shaped bacteria, commonly found in the lower part of the intestine of warm-blooded animals [36], which account for approximately 69% of the cases of bacterial food-borne disease [37, 38]. Therefore, these both species of bacteria were selected for this study.

Based on the above considerations, this work deals with the influence of initial pH and the simultaneous additions of sucrose and inulin as supplements on the growth of P. pentosaceus ATCC 43200 in glucose-based De Man, Rogosa and Sharpe broth, sugar consumption, lactate production and bacteriocin activity.

Materials and methods

Bacteriocin-producing strain and growth conditions

Pediococcus pentosaceus ATCC 43200 used as bacteriocin producer was purchased from the American Type Culture Collection (ATCC, Manassas, VA, USA) and cultivated in De Man, Rogosa, and Sharpe (MRS) medium (Difco Laboratories, Detroit, USA), pH 6.5 ± 0.2, for 16 h at 37 °C under 100 rpm agitation in orbital shaker, model TE-424 (Tecnal, Piracicaba, SP, Brazil).

Indicator strains and growth conditions

Enterococcus 101 (EN101), isolated from a sample of food, was provided by the Food Department of the School of Pharmaceutical Sciences of the University of São Paulo (São Paulo, SP, Brazil), while E. coli ATCC 25922 was purchased from ATCC. Both were used as indicator strains. To this purpose, 1.0 mL of each indicator strain suspension, previously cryopreserved at − 70 °C in the presence of 20% (v/v) glycerol, was reactivated in 5.0 mL of Brain Heart Infusion (BHI) medium and in Tryptic Soy Broth (TSB) (Difco), respectively, for 16 h at 37 °C without agitation. To perform assays, optical density at 600 nm (OD600nm) of the indicator strains cultures was adjusted to 0.6 with sterile deionized water, corresponding to 2.6 × 1010 CFU/mL for EN101 and 2 × 1010 CFU/mL for E. coli.

Culture media

The MRS medium, containing 20 g/L glucose (Difco Laboratories, Detroit, USA), was used as the control medium after having its pH adjusted to 5.0 or 6.0 with 1.0 N NaOH. The supplemented medium (GSI-MRS) was prepared adding to the MRS medium 0.5, 1.0 or 1.5% (w/w) sucrose (Inlab, São Paulo, SP, Brazil) and inulin (Orafti®, Oreye, Belgium) in the same proportion. Glucose-free media were prepared as the MRS medium (peptone 10 g/L, beef extract 10 g/L, yeast extract 5 g/L, polysorbate 80 1 g/L, ammonium citrate 2 g/L, sodium acetate 5 g/L, magnesium sulfate 0.1 g/L, manganese sulfate 0.05 g/L, dipotassium phosphate 2 g/L), but replacing glucose with sucrose (S-MRS) or inulin (I-MRS). All media were sterilized in autoclave, model SD-75 (Phoenix Luferco, Araraquara, SP, Brazil), at 121 °C for 15 min.

Inoculum preparation and fermentation

Pediococcus pentosaceus pre-inoculum was prepared with 1.0 mL of cryopreserved culture inoculated in 50 mL of MRS medium, pH 6.5 ± 0.2, at 37 °C and under agitation (100 rpm) for 16 h. After obtaining the pre-inoculum of 107–108 CFU/mL, 10.0 mL of this suspension were transferred to 250-mL Erlenmeyer flasks containing 100 mL of MRS medium at pH 5.0 or 6.0 (control) or of supplemented MRS media (0.5, 1.0 or 1.5%) at the same pH. Flasks were incubated in a rotatory shaker (100 rpm) at 30 °C for 48 h. To follow P. pentosaceus growth, samples were collected every 2 h during the first 12 h and then after 24 and 48 h of fermentation. All cultures were performed in triplicate.

Determination of BLIS activity

To determine the BLIS activity, culture samples collected after 4 h of fermentation were centrifuged at 4470×g at 4 °C for 15 min. After adjustment of pH to 6.0 by addition of 1.0 N NaOH, cell-free supernatants (CFSs) were heated at 70 °C for 25 min to inactivate proteases and sterilized by filtration through membranes with 0.45 µm-pore diameter (Millipore, Bedford, MA, USA). The CFS antimicrobial activity was tested against EN101 and E. coli by the agar diffusion method and quantified according to Sidek et al. [39]. Briefly, one hundred µL of each indicator strain suspension (OD600 = 0.6) were added to 10 mL of 1.0% (w/w) melted agar-medium and poured into Petri dishes. After the agar solidified, 50 µL of CFS were placed onto wells made on the agarized medium using tips, and the plates were incubated at 37 °C for 18 h. The antimicrobial activity (A), taken as a measure of BLIS production, was calculated by the equation [39]:

where dH is the diameter of the clearance zone (mm), dW the diameter of the well (6.5 mm), D the eventual dilution factor, V the sample volume (mL), and expressed in AU/mL.

Analytical procedures

During fermentations, P. pentosaceus cell mass concentration was determined by optical density measurements using a calibration curve (R2 = 0.997) of OD600nm versus dry weight (DW) and expressed in gDW/L, while the progressive acidification of media was followed by means of a pHmeter, model 400M1 (Quimis, Diadema, SP, Brazil). Glucose, sucrose and lactate concentrations were determined by a High-Performance Liquid Chromatograph, model LC-20A Prominence (Shimadzu, Kyoto, Japan), equipped with two LC-20AD pumps, a DGU-20A degasser unit, a SIL-20ACHT self-injector, a CTO-20 AC column oven, a RI-210 refractive index detector (Shodex, Kawasaki, Kanagawa, Japan), and a HPX-87H column (300 × 7.8 mm) (Aminex, Bio-Rad, CA, USA). Analyses were performed in triplicate at room temperature using 75:25% acetonitrile:ultrapure water as mobile phase (0.9 mL/min) and high purity glucose and sucrose (Sigma-Aldrich, St. Louis, MO, USA) standard solutions.

Statistical analysis

One-way analysis of variance (ANOVA) and Tukey’s test from Statistica Software 13.3 (TIBICO Software Inc., Palo Alto, CA, USA) was used, considering variations statistically significant when the confidence level (P) was < 0.05.

Results and discussion

Cell growth, yield of biomass and lactate production

The growth of P. pentosaceus ATCC 43200 was followed during fermentations carried out at initial pH values of 5.0 and 6.0, which were previously selected as the best ones for this microorganism (results not shown). Under both conditions, the microorganism was able to grow either in glucose-based MRS medium without any supplement, selected as control, or in all media supplemented with sucrose and inulin (Fig. 1). However, whereas in the control medium at pH 6.0 it started to grow after 6 h, the lag phase was about 4 h longer at the lower pH.

Growth curves at pH 5.0 (solid line and empty grey symbols) and 6.0 (dotted lines and full black symbols) of P. pentosaceus ATCC 43200 in MRS medium selected as control (open grey diamond, filled diamond), in MRS media supplemented with (open grey triangle, filled traingle) 0.5%, (open grey square, filled square) 1.0%, and (open grey circle, filled circle) 1.5% sucrose and inulin. Average of runs carried out in triplicate (n = 3)

Such an influence of initial medium pH on P. pentosaceus lag phase duration agrees with other findings reported in the literature. For instance, when this microorganism was cultivated in medium at pH 4.3, the lag phase was as long as 25 h [40]. Abbasiliasi et al. [41] also identified impaired survival of Pediococcus acidilactici Kp10 under acidic conditions, in that at pH 3.0 percent survival was > 97% up to 3 h incubation, but later it was completely suppressed.

The addition of sucrose and inulin in the MRS medium (GSI-MRS) at pH 5.0 reduced the lag phase duration by 2 h compared with the control (12 h), regardless of the concentration of these supplements. This result demonstrates not only the ability of these ingredients to speed up P. pentosaceus ATCC 43200 adaptation under such acidic conditions, but also the potential synbiotic effect of this probiotic in the simultaneous presence of a prebiotic (inulin) and more than one carbon source (glucose and sucrose). On the other hand, at pH 6.0 there was no difference in the lag phase duration between fermentations carried out in control medium or in supplemented media, thereby pointing out that this may be the optimum pH for the growth of this strain.

After 48 h of fermentation, cell mass concentration (Xmax = 2.26 g/L dry weight) in the control medium at pH 5.0 was statistically coincident (P > 0.05) with those obtained in supplementing sucrose and inulin up to the three selected levels (0.5, 1.0 and 1.5%) (Xmax = 2.69, 2.46 and 2.83 g/L dry weight, respectively). As a result, maximum specific growth rate (µmax = 0.18 h−1) and generation time (Tg = 3.84 h) in the control were equally statistically coincident (P > 0.05) to those in supplemented media (µmax = 0.18, 0.18 and 0.19 h−1; Tg = 3.86, 3.76 and 3.50 h, respectively), confirming that in the presence of glucose, i.e. the preferred carbon source for this microorganism, in its presence, sucrose and inulin addition, even at different levels, did not exert any effect. However, when the initial pH was 6.0, cell mass concentration after the same time was significantly higher in the control (Xmax = 2.68 g/L dry weight) than in the same supplemented media (Xmax = 1.90, 2.52 and 1.86 g/L dry weight, respectively) (P < 0.05), even though no regular dependence of this parameter could be observed. On the other hand, important insights came from maximum specific growth rate (µmax = 0.32, 0.26, 0.33 and 0.32 h−1 respectively) and generation time (Tg = 2.17, 2.62, 2.06 and 2.11 h, respectively), which were, on average, 68% higher and 40% shorter, respectively, compared with those observed under more acidic conditions, hence confirming pH 6.0 as the optimal value. Perez et al. [42] attributed to pH a similar importance on the growth of P. acidilactici NRRL B-5627 in whey, supplemented or not with glucose and yeast extract.

Disappointingly, glucose replacement by only sucrose (S-MRS) or only inulin (I-MRS) almost completely suppressed growth as well as lactate and BLIS productions by P. pentosaceus, regardless of the initial medium pH (results not shown), as also demonstrated by Azevedo et al. [43], indicating that these ingredients were not effectively uptaken as the only carbon source. Therefore, these media will not be taken into further account in this section.

The behavior of yield of lactate on consumed glucose (YP/S) versus time is illustrated in Fig. 2, either at pH 5.0 (panel A) or pH 6.0 (panel B). Irrespectively of the initial pH, P. pentosaceus was able to start lactate production after 2 h of fermentation. However, whereas at pH 5.0 the addition of only 0.5% sucrose and inulin ensured high lactate production at the beginning of fermentation (2 h), much longer time (10 h) was required at higher levels (1.0 and 1.5%). On the other hand, when the initial pH was 6.0, lactate production decreased significantly after 6 h in the control medium, whereas increased in all supplemented media (GSI-MRS). As expected by the complementarity between cell growth and product formation, such a decrease (Fig. 2, panel B) was accompanied by a simultaneous remarkable increase in the yield of biomass on consumed glucose (YX/S) (Fig. 3, panel B). These results suggest that the P. pentosaceus strain used in the present work may have been capable of directly metabolizing the extra carbon source (sucrose) and some of the prebiotic ingredient (inulin) when present in an unfavorable environment like that existing in the medium at pH 5.0. Under such acidic conditions, the addition of supplements to MRS broth remarkably increased this parameter after 10 h (Fig. 3, panel A), whereas no growth improvement was observed at pH 6.0 (Fig. 3, panel B).

Acidification and lactate production

The acidification profiles in the control medium and in all supplemented (0.5, 1.0 and 1.5%) media (GSI-MRS) were statistically coincident (P > 0.05), showing gradual pH decreases from 5.0 to 3.5 (control) or 3.7 (GSI-MRS) and from 6.0 to 3.8 (control) or 3.9 (GSI-MRS) at the end of fermentations (Fig. 4). Such an acidification profile of P. pentosaceus is an interesting feature because it may contribute to decrease the colonic pH and then to prevent the proliferation of non-acid-tolerant bacteria, food-borne pathogens and spoilage organisms [44,45,46], forcing them to utilize the remaining energy to oust excess proton [45].

Lactate production (solid lines) at pH 5.0 (empty grey symbols) and 6.0 (empty black symbols) by P. pentosaceus ATCC 43200 in MRS medium selected as control (open grey diamond, open diamond), in MRS media supplemented with (open grey triangle, open triangle) 0.5%, (open grey square, open square) 1.0%, and (open grey circle, open circle) 1.5% sucrose and inulin. Corresponding acidification profiles (dotted lines) after 48 h at pH 5.0 (full grey symbols) and 6.0 (full black symbols), in MRS medium selected as control (filled grey diamond, filled diamond), in MRS media supplemented with (filled grey triangle, filled triangle) 0.5%, (filled grey square, filled square) 1.0%, and (filled grey circle, filled circle) 1.5% sucrose and inulin

As shown in the same figure, lactate production was remarkable at both pH values (5.0 and 6.0) either in controls or in all GSI-MRS media. However, in these fortified media, lactate production after 48 h of fermentation was, at pH 5.0 (13.0 g/L) and 6.0 (16.0 g/L), 34 and 45% higher than in their respective control media, which highlights the beneficial effect of sucrose and inulin also from lactate production viewpoint, regardless of the concentration of these ingredients.

Even though lactate production was certainly the main event responsible for acidification, it has been reported that prebiotics such as inulin are capable of reducing pH through an indirect mechanism due to the production of other products such as bacteriocins [46, 47] and/or other organic acids [48].

Glucose and sucrose consumption

After 48 h, the consumption of glucose, whose starting concentration was 20.0 g/L in all the fermentations, was always higher in control media, where it was the only sugar, compared with all GSI-MRS media. In control media, it was in fact as high as 70.3 and 89.9% at pH 5.0 and 6.0 (P < 0.05), respectively, while in GSI-MRS media it was, on average, only 56.6±4.6% (P > 0.05) at pH 5.0 and no less than 82.1±7.9% (P > 0.05) at pH 6.0 (results not shown). Such a 45.0% increase in glucose consumption by P. pentosaceus in supplemented media at pH 6.0 compared with pH 5.0 confirms the importance of using an optimal pH also for this response.

As regards sucrose consumption in fortified media, there was no significant difference among them, being about 1.0% as an average (results not shown).

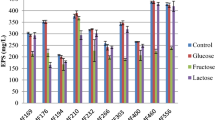

BLIS activity of culture supernatants

The antimicrobial activity of cell free supernatants (CFSs) was assessed against EN101 and E. coli only after 4 h of fermentation, since a kinetic study on P. pentosaceus metabolism [43] revealed that this microorganism was able to release a bacteriocin at the highest concentration just in the late lag phase. Table 1 shows that the antimicrobial activity of EN101 inhibition halo (475.17 AU/mL) induced by the CFS from the control medium at pH 5.0 was 26% higher than that at pH 6.0 (377.15 AU/mL) and even 2.5-fold higher than those induced by CFSs from all supplemented media, regardless of the pH and the concentration of supplements. On the other hand, CFS showed no antimicrobial activity against E. coli (results not shown), as also reported by Azevedo et al. [49].

Consistently with these results, Singh et al. [50] observed that the activity of P. pentosaceus IE-3 bacteriocin was the highest at pH 5.0 and suffered significant loss at pH 8.0, while Mathys et al. [51] observed loss of P. pentosaceus UVAI pediocin activity at pH ≥ 10. In contrast to bacteriocins, Sidek et al. [39] reported stable and active BLIS, produced by Pediococcus acidilactici kp10, at a wide pH range (pH 2.0 to pH 7.0). BLIS production is influenced by initial culture pH, however its production at different pH range seems to be related to the bacteria species used. Abbasiliasi et al. [41] reported that optimum initial culture pH for maximum BLIS production by Lactobacillus paracasei LA107 was pH 8.5, while lower BLIS production was recorded at a pH equal or lower than 4.0, different from that observed most of the time for the Pediococcus species, whose optimum culture pH is ranging from pH 5.0 to 6.5. According to Mortvedt-Abildgaard et al. [52], in parallel with bacteriocins, the observation made by Abbasiliasi et al. [41] is not similar to the production of bacteriocin by other LAB, where the maximum production was detected in media with an initial culture pH ranging from 5.0 to 6.5, which was lower that the optimal pH for growth, depending on the microorganism. These results as a whole demonstrate that bacteriocin or BLIS production was favored either under suboptimal environmental conditions (pH lower than the optimum) or in the absence of any prebiotic able to stimulate growth.

The absence of any antimicrobial activity against E. coli is consistent with the higher resistance of the outer membrane of Gram-negative bacteria against the action of bacteriocins or BLIS in comparison to the Gram-positive ones, which are naturally more susceptible. However, contradictory results can be found in the literature concerning bacteriocin or BLIS activity against Gram-negative bacteria [53, 54].

Pranckuté et al. [55] demonstrated that the ability of Lactobacillus sp. and Lactococcus sp. to metabolize different carbon sources (e.g. sucrose, inulin) and produce bacteriocins was strain specific and, in agreement with the results of this work, glucose was always the preferred carbon source; however, it was consumed more quickly by Lactococcus lactis rather than by Lactobacillus sp.; on the other hand, Lactococcus sp. assimilated poorly inulin, while Lactobacillus sp. were completely ineffective in this respect.

These results suggest that the bacteriocin produced by P. pentosaceus ATCC 43200 could be a promising alternative as a biopreservative in food industry by the production of antimicrobial molecules such as bacteriocin or BLIS.

Conclusion

The metabolism of P. pentosaceus ATCC 43200, a promising BLIS producing strain, was investigated at two different initial values of medium pH as well as in the presence or the absence of sucrose and inulin as supplements of the glucose-based MRS medium. The addition of sucrose and inulin to MRS improved growth and production of lactate by P. pentosaceus, whereas it reduced bacteriocin production/activity. Even though this Pediococcus strain was able to grow either in the culture media with or without supplements, these showed a positive influence on the growth only when the initial pH of the medium was 5.0. Under these suboptimal conditions, P. pentosaceus growth was significantly delayed compared with the same medium at pH 6.0. The initial pH influenced not only the duration of the lag phase, but also the cell growth and the productions of lactate and bacteriocin. Lactate production was remarkable at both pH values either in controls or in all supplemented media. Its production (13–16 g/L) was 34–54% higher than those in their respective control media, which highlights a beneficial effect of sucrose and inulin on lactate production, regardless of the concentration of these ingredients. BLIS activity against Enterococcus 101 exerted by the cell free supernatant from the control medium at pH 5.0 (475.17 AU/mL) was larger than that at pH 6.0 and those of supernatants from all supplemented media. These results as a whole demonstrate that BLIS production by P. pentosaceus was favored either under suboptimal environmental conditions or in the absence of any prebiotic able to stimulate growth.

References

Zhang B, Tong H, Dong X (2005) Pediococcus cellicola sp. nov., a novel lactic acid coccus isolated from a distilled-spirit-fermenting cellar. Int J Syst Evol Microbiol 55(5):2167–2170. https://doi.org/10.1099/ijs.0.63778-0

Gibson GR, Fuller R (2000) Aspects of in vitro and in vivo research approaches directed towards identifying probiotics and prebiotics for human use. J Nutr 130(2):391S–395S

Rolfe RD (2000) The role of probiotic cultures in the control of gastrointestinal health. J Nutr 130(2):396S–402S

Cleveland J, Montiville TJ, Nes IF, Chikinda ML (2001) Bacteriocins: safe, natural antimicrobials for food preservation. Int J Microbiol 71(1):1–20

Liu B, Yang M, Qi B, Chen X, Su Z, Wan Y (2010) Optimizing l-(+)-lactic acid production by thermophile Lactobacillus plantarum AS.1.3 using alternative nitrogen sources with response surface method. Biochem Eng J 59(2):212–219. https://doi.org/10.1016/j.bej.2010.08.013

Behera SS, Ray RC, Zdolec N (2018) Lactobacillus plantarum with functional properties: an approach to increase safety and shelf-life of fermented foods. Biomed Res Int 2018:18. https://doi.org/10.1155/2018/9361614

Axelsson L, Ahrné S, Ahrné S (2000) Lactic acid bacteria. Appl Microb Syst. Springer, Netherlands, pp 367–388

Ray RC, Joshi VK (2014) Fermented foods: past, present and future scenario. In: Ray RC, Montet D (eds) Microorganisms and fermentation of traditional foods. CRC Press, Boca Raton, pp 1–36

Park S, Ji Y, Park H, Lee K, Park H, RamBeck B, Shin H, Holzapfel WH (2016) Evaluation of functional properties of lactobacilli isolated from Korean white Kimchi. Food Control 69:5–12. https://doi.org/10.1016/j.foodcont.2016.04.037

Leroy F, De Vuyst L (2004) Lactic acid bacteria as functional starter cultures for the food fermentation industry. Trends Food Sci Technol 15(2):67–78. https://doi.org/10.1016/j.tifs.2003.09.004

Simpson WJ, Taguchi H (1995) The genus Pediococcus, with notes on the genera Tetragenococcus and Aerociccis. In: Wood BJB, Holzapfel WH (eds) The genera of lactic acid bacteria. Blackie Academic and Professional, London, pp 125–172

Costilow RN, Coughlin FM, Robach DL, Ragheb HS (1956) A study of the acid-forming bacteria from cucumber fermentations in Michigan. Food Res Int 21(1):27–33. https://doi.org/10.1111/j.1365-2621.1956.tb16888.x

Etchells JL, Costilow RN, Anderson TE, Bell TA (1964) Pure culture fermentation of brined cucumbers. Appl Environ Microbiol 12(6):523–535

Piva A, Headon DR (1994) Pediocin A, a bacteriocin produced by Pediococcus pentosaceus FBB61. Microbiol 140(4):697–702. https://doi.org/10.1099/00221287-140-4-697

Rueckert PW (1979) Studies on a bacteriocin-like activity produced by Pediococcus pentosaceus effective against Gram-positive organisms. MS thesis, Michigan State University East Lansing

Leite JA, Tulini FL, Reis-Teixeira FB, Rabinovitch L, Chaves JQ, Rosa NG (2016) Bacteriocin-like inhibitory substances (BLIS) produced by Bacillus cereus: preliminary characterization and application of partially purified extract containing BLIS for inhibiting Listeria monocytogenes in pineapple pulp. LWT Food Sci Technol 72:261–266. https://doi.org/10.1016/j.lwt.2016.04.058

Heng NCK, Wescombe PA, Burton JP, Jack RW, Tagg JR (2007) The diversity of bacteriocins in Gram-positive bacteria. In: Riley MA, Chavan MA (eds) Bacteriocins: ecology and evolution 45-92. Springer, New York, pp 45–92

De Vuyst L, Vandamme EJ (1994) Lactic acid bacteria and bacteriocins: Their practical importance. In: De Vuyst L, Vandamme EJ (eds) Bacteriocins of Lactic Acid Bacteria. Microbiology Genetics and Applications. Blackie Academic and Professional, Glasgow, pp 1–11

Settanni L, Corsetti A (2008) Application of bacteriocins in vegetable food biopreservation. Int J Food Microbiol 121:123–138. https://doi.org/10.1016/j.ijfoodmicro.2007.09.001

Allison GE, Klaenhammer TR (1998) Phage resistance mechanism in lactic acid bacteria. Int Dairy J 8:207–226

Oscáriz JC, Lasa I, Pisabarro AG (1999) Detection and characterization of cerein 7, a new bacteriocin produced by Bacillus cereus with broad spectrum of activity. FEMS Microbiol Lett 178:337–341. https://doi.org/10.1111/j.1574-6968.1999.tb08696.x

Todorov SD, Dicks LMT (2004) Effect of medium components on bacteriocin production by Lactobacillus pentosus ST151BR, a strain isolated from beer produced by the fermentation of maize, barley and soy flour. World J Microbiol Biotechnol 20(6):643–650. https://doi.org/10.1023/B:WIBI.0000043196.09610.de

Soro-Yao AA, Schumann P, Thonart P, Djè KM, Pukall R (2014) The use of MALDI-TOF Mass Spectrometry, ribotyping and phenotypic tests to identify lactic acid bacteria from fermented cereal foods in Abidjan (Côte d’Ivoire). Microbiol J 18(8):78–86. https://doi.org/10.2174/1874285801408010078

Shukla R, Goyal A (2014) Probiotic potential of Pediococcus pentosaceus CRAG3: a new isolate from fermented cucumber. Probiotics Antimicrob Proteins 6(1):11–21. https://doi.org/10.1007/s12602-013-9149-8

Sabo SS, Converti A, Todorov SD, Domínguez JM, Oliveira RPS (2015) Effect of inulin on growth and bacteriocin production by Lactobacillus plantarum in stationary and shaken cultures. Int J Food Sci Technol 50(4):864–870. https://doi.org/10.1111/ijfs.12711

Wagner EM, Jen KLC, Artiss JD, Remaley AT (2008) Dietary alpha-cyclodextrin lowers LDL-C and alters plasma fatty acid profile in LDLr-KO mice on a high-fat diet. Metabolism 57(8):1046–1051. https://doi.org/10.1016/j.metabol.2008.02.020

Holub I, Gostner A, Theis S, Nosek L, Kudlich T, Melcher R, Scheppach W (2010) Novel findings of the metabolic effects of the low glycemic carbohydrate isomaltose (Palatinose™). Br J Nutr 103(12):1730–1737. https://doi.org/10.1017/S0007114509993874

Roberfroid M (2007) Prebiotics: the concept revisited. J Nutr 137(3):830S–837S

Oliveira RPS, Torres BR, Perego P, Oliveira MN, Converti A (2012) Co-metabolic models of Streptococcus thermophilus in co-culture with Lactobacillus bulgaricus or Lactobacillus acidophilus. Biochem Eng J 62:62–69. https://doi.org/10.1016/j.bej.2012.01.004

Gibson GR, Roberfroid MB (1995) Dietary modulation of the human colonic microbiota: introducing the concept of prebiotics. J Nutr 125(6):1401–1412

Van Tyne D, Gilmore MS (2014) Friend turned foe: evolution of enterococcal virulence and antibiotic resistance. Annu Rev Microbiol 68:337–356. https://doi.org/10.1146/annurev-micro-091213-113003

Anderson CA, Jonas D, Huber I, Karygianni L, Wölber J, Hellwig E, Arweiler N, Vach K, Wittmer A, Al-Ahmad A (2016) Enterococcus faecalis from food, clinical specimens and oral sites: prevalence of virulence factors in association with biofilm formation. Front Microbiol 6:1534. https://doi.org/10.3389/fmicb.2015.01534

Franz CM, Huch M, Abriouel H, Holzapfel W, Galvez A (2011) Enterococci as probiotic and their implications in food safety. Int J Food Microbiol 151:125–140. https://doi.org/10.1016/j.ijfoodmicro.2011.08.014

Hammerum AM (2012) Enterococci of animal origin and their significance for public health. Clin Microb Infect 18:619–625. https://doi.org/10.1111/j.1469-0691.2012.03829.x

CDC (2010) Preliminary FoodNet data on the incidence of infection with pathogens transmitted commonly through food – 10 states. Morb Mortal Wkly Rep 59:418–422

Katouli M (2010) Population structure of gut Escherichia coli and its role in development of extra-intestinal infections. Iran J Microb 2:59–72

Greig JD, Ravel A (2009) Analysis of foodborne outbreak data reported internationally for source attribution. Int J Food Microbiol 130(2):77–87. https://doi.org/10.1016/j.ijfoodmicro.2008.12.031

Sofy AR, El-Monem A, Sharaf MA, Al Karim AG, Hmed AA, Moharam KM (2017) Prevalence of the harmful gram-negative bacteria in ready-to-eat-foods in Egypt. Food Public Health 7(3):59–68. https://doi.org/10.5923/j.fph.20170703.02

Sidek NLM, Tan JS, Abbasiliasi S, Wonga FWF, Mustafa S, Ariff AB (2016) Aqueous two-phase flotation for primary recovery of bacteriocin-like inhibitory substance (BLIS) from Pediococcus acidilactici Kp10. J Chromatogr B 1027:81–87. https://doi.org/10.1016/j.jchromb.2016.05.024

Blickstad E, Molin G (1981) Growth and lactic acid production of Pediococcus pentosaceus at different gas environments, temperatures, pH values and nitrite concentrations. Eur J Appl Microbiol Biotechnol 13(3):170–174. https://doi.org/10.1007/BF00703048

Abbasiliasi S, Tan JS, Ibrahim TAT, Ramanan RN, Vakhshiteh F, Mustafa S, Ling TC, Rahim RA, Ariff AB (2012) Isolation of Pediococcus acidilactici Kp10 with ability to secrete bacteriocin-like inhibitory substance from milk products for application in food industry. BMC Microbiol 12:260. https://doi.org/10.1186/1471-2180-12-260

Perez RH, Perez MTM, Elegado FB (2015) Bacteriocins from lactic acid bacteria: a review of biosynthesis, mode of action, fermentative production, uses, and prospects. Int J Phil Sci Technol 8(2):61–67

Azevedo POS, Converti A, Domínguez JM, de Souza Oliveira RP (2017) Stimulating effects of sucrose and inulin on growth, lactate and bacteriocin productions by Pediococcus pentosaceus. Probiotics Antimicrob Proteins 9(4):466–472. https://doi.org/10.1007/s12602-017-9292-8

Adams M, Hall C (1988) Growth inhibition of food-borne pathogens by lactic and acetic acids and their mixtures. Int J Food Sci Technol 23(3):287–292. https://doi.org/10.1111/j.1365-2621.1988.tb00581.x

Holyoak CD, Stratdford M, McMullin Z, Cole MB, Crimmins K, Brown AJ, Coote PJ (1996) Activity of the membrane H1-ATPase and optimal glycolytic flux required for rapid adaptation and growth in the presence of weak acid preservative sorbic acid. Appl Environ Microbiol 62(9):3158–3164

Dunkley KD, Callaway TR, Chalova VI, McReynolds JL, Hume ME, Dunkley CS, Kubena LF, Nisbet DJ, Ricke SC (2009) Foodborne Salmonella ecology in the avian gastrointestinal tract. Anaerobe 15(1–2):26–35. https://doi.org/10.1016/j.anaerobe.2008.05.007

Rehman H, Vahjen W, Kohl-Parisini A, Ijaz A, Zentek J (2009) Influence of fermentable carbohydrates on the intestinal bacteria and enteropathogens in broilers. Worlds Poult Sci J 65(1):75–90. https://doi.org/10.1017/S0043933909000063

Rémésy C, Levrat MA, Gamet L, Demigné C (1993) Cecal fermentations in rats fed oligosaccharides (inulin) are modulated by dietary calcium level. Am J Physiol 264(5 Pt 1):G855–G862. https://doi.org/10.1152/ajpgi.1993.264.5.G855

Azevedo POS, Converti A, Gierus M, Oliveira RPS (2018) Antimicrobial activity of bacteriocin-like inhibitory substance produced by Pediococcus pentosaceus: from shake flasks to bioreactor. Mol Biol Rep 46(1):461–469. https://doi.org/10.1007/s11033-018-4495-y

Singh PK, Sharma S, Kumari Am Korpole S (2014) A non-pediocin low molecular weight antimicrobial peptide produced by Pediococcus pentosaceus strain IE-3 shows increased activity under reducing environment. BMC Microbiol 14:226. https://doi.org/10.1186/s12866-014-0226-2

Mathys S, von Ah Ueli, Lacroix C, Staub E, Mini R, Cereghetti T, Meile L (2007) Detection of the pediocin gene pedA in strains from human faeces by real-time PCR and characterization of Pediococcus acidilactici UVAI. BMC Biotechnol 7:55. https://doi.org/10.1186/1472-6750-7-55

Mortvedt-Abildgaard CI, Nissen-Meyer J, Jelle B, Grenov B, Skaugen M, Nes IF (1995) Production and pH-dependent bactericidal activity of Lactocin S, a lantibiotic from Lactobacillus sake L45. Appl Environ Microbiol 61:175–179

Conventry MJ, Gordon JB, Wilcock A, Harmark K, Davidson BE, Hickey MW, Hillier AJ, Wan J (1997) Detection of bacteriocins of lactic acid bacteria isolated from foods and comparison with pediocin and nisin. J Appl Microbiol 83(2):248–258

Ramírez LAG, Otálvaro EVA (2008) Determinación del potencial bactericida In vitro de un aislado nativo de Lactobacillus casei frente E. coli. Rev Lasallista Invest 5(2):68–73

Pranckuté R, Kaunietis A, Kuisiené N, Citavicius D (2014) Development of synbiotics with inulin, palatinose, α-cyclodextrin and probiotic bacteria. Pol J Microbiol 63(1):33–41

Funding

This study was funded by São Paulo Research Foundation (FAPESP) under Grants [2018/04385-8 and 2018/04563-3] and by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001 and the National Council for Scientific and Technological Development (CNPq). Collaboration of the Promotion of Scientific and Technological Development of CONICYT, FONDECYT / POSTDOCTORAL (N° 3180765) Chile.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Research involving human participants and/or animals

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Souza de Azevedo, P.O., de Azevedo, H.F., Figueroa, E. et al. Effects of pH and sugar supplements on bacteriocin-like inhibitory substance production by Pediococcus pentosaceus. Mol Biol Rep 46, 4883–4891 (2019). https://doi.org/10.1007/s11033-019-04938-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11033-019-04938-w