Abstract

The thermal decomposition kinetics of cashew gum, an exudate polysaccharide from A. occidentale L., has been investigated by thermogravimetric analysis in nitrogen and air atmospheres and non-isothermal conditions. The heating rates were of 5, 10, and 20 K min−1 and gas flow of 20 mL min−1. The NETZSCH Thermokinetics 3 software estimated the activation energy and pre-exponential factor with Friedman and Ozawa–Flynn–Wall methods. Multivariate nonlinear regression analysis was applied to estimate a probable mechanism and lifetime prediction and to describe the thermal decomposition. The results obtained showed that the energy activation is dependent on the conversion degree for both atmospheres. For nitrogen, the most appropriate kinetic model was estimated with two consecutive stage reactions (FnF1 model). For air, the best model was estimated with six stages consecutive and completive reactions (FnFnFnFnFnFn model).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

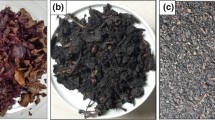

Cashew gum is a bark exudate from Anacardium occidentale L., a tree that can grow up to 10 meters. It is widely grown in many tropical and subtropical countries; the cashew tree is native to northeastern Brazil. However, it can also be found in India, Mozambique, Tanzania, and among other countries. The tree is well known for its nuts that are used as a food ingredient [1]. Exudate gums are among the oldest natural gums, and they were already being used as thickening and stabilizing agents about 5000 years ago [2]. They are generally produced by wounding the tree during pruning or as a direct result of attack by insects or microorganisms [3]. Some of these exudate gums have been used in international trade, such as gum arabic, gum ghatti gum tragacanth, and gum karaya [2].

Cashew gum is a complex polysaccharide that after hydrolysis results in higher galactose content and other constituents such as arabinose, glucose, rhammose, mannose and glucuronic acid [4, 5]. The structural analysis of cashew gum from India revealed a branched polysaccharide consisting of chains of β-(1 → 3)-linked D-galactose residues interspersed with β-(1 → 6) linkages. Arabinose is present as end groups or in short (1 → 2)-linked chains up to five units long. Glucose, rhamnose, mannose, xylose, and uronic acid are all present as end groups [6]. Thermal and rheological characteristics of cashew gum showed similarity to gum arabic [7, 8]. Cashew gum showed health benefits such as antitumor [1] and antihypertensive [9] actives.

Thermal analysis has been widely used for the characterization of polysaccharides such as the determination of glass transition temperature [10], thermal stability [11,12,13], and kinetic studies [14,15,16,17]. Kinetic data are extremely important for performance and for understanding the mechanism of a material, through mathematical models and numerical predictions, especially due to the combination of factors such as heat transfer, mass transfer phenomena, chemical reactions, and thermal stability. Notions of kinetic parameters such as pre-exponential factor and activation energy can help elucidate the mechanism of solid-state reactions, which could be useful to estimate the lifetime of a given material [18]. According to [19], the lifetime of a material is the time after which the material loses its properties to such extent that it cannot fulfill efficiently the function for which it was created. In the literature, there are several studies focused on the lifetime prediction of different materials [20,21,22,23,24,25].

In the previous paper, we studied the thermal behavior of cashew gum by simultaneous TG/DTG/DSC-FTIR analysis under nitrogen and air atmospheres [26]. In this present investigation, we have studied the kinetic parameters of thermal decomposition of cashew gum by Friedman and Ozawa–Flynn–Wall isoconversional methods to propose a probable mechanism and lifetime prediction to explain the thermal decomposition process under nitrogen and air atmospheres.

Kinetic study of thermal degradation

Kinetic analysis of solid state is generally based on the kinetic Eq. (1):

where t is the time, α is the conversion degree, T is the temperature, and \( f(\alpha ) \) is reaction model. The dependence of the process rate on temperature, k(T), is introduced by replacing the Arrhenius equation:

where A is pre-exponential factor, E is the activation energy, and R is the gas constant. Under non-isothermal conditions in which a sample is heated at constant heating rate \( \beta \), rearranging Eq. (2) leads to Eq. (3):

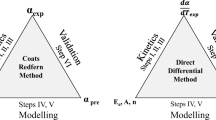

where \( \beta = {{{\text{d}}T} \mathord{\left/ {\vphantom {{{\text{d}}T} {\text{dt}}}} \right. \kern-0pt} {\text{dt}}} \) and \( g(\alpha ) \) is the integral form of the reaction model [19, 27]. Some approximations were proposed using different kinetic models to determine the kinetic parameters on Eq. (3). Using Thermokinetics software through model-free analysis, a kinetic study could be achieved based on the Ozawa–Flynn–Wall and Friedman approximation models [18].

The Friedman and Ozawa–Flynn–Wall methods are isoconversional methods used to estimate values of activation energy, which is a function of the conversion degree. The main advantage related to isoconversional methods is that the activation energy is calculated without any prior knowledge of the analytical form of the conversion function f(α) [28, 29].

The Ozawa–Flynn–Wall method is based on the following Eq. (4):

The Friedman method is based on the following Eq. (5) [18]:

Experimental

Cashew gum: origin and purification

Crude cashew tree exudates were collected from A. occidentale trees in the CNPAT—EMBRAPA, Ceará, Brazil. Cashew gum was purified by alcoholic precipitation as described in the previous work [1].

Methods

The thermal degradation of cashew gum was performed on TG/DSC-FTIR NETZSCH thermal analyzer, model STA 409 PG Luxx under nitrogen and air atmospheres. The experiments were carried out with heating rates of 5, 10 and 20 K min−1 and flow of 20 mL min−1. Themogravimetric (TG) curves were used to investigate the kinetic of thermal degradation in non-isothermal conditions. The determination of kinetic parameters was performed by the NETZSCH Thermokinetics 3 software, using the “model-free” analysis, which uses the Friedman and Ozawa–Flynn–Wall methods. The software also allowed the realization of “model fitting”, where the multivariate nonlinear regression was applied to determine the most suitable reaction model for the decomposition process of cashew gum.

Results and discussion

Figure 1 shows the TG/DTG curves for cashew gum obtained at three heating rates under nitrogen atmosphere. The first mass loss is attributed to moisture evaporation and the main decomposition stage started at around 240 °C, which is related to the decomposition of polysaccharides and there is also a major mass loss. Figure 2 shows the TG/DTG curves for the cashew gum obtained at three heating rates under air. As observed in our previous work [26], the TG/DTG curves under oxidative atmosphere are similar to the curves under nitrogen until the temperature is around 340 °C; however, it is possible to see two peaks in DTG curve under nitrogen and four peaks in DTG curve under air. The peaks observed between 400 and 500 °C in air are related to the oxidation of the carbonaceous material.

In order to better understand the thermal degradation of cashew gum, the kinetic analysis was performed using the temperature between 180 and 360 °C for nitrogen and between 180 and 500 °C for air, which were related to the major degradation of cashew gum.

Figure 3 shows the Friedman and Ozawa–Flynn–Wall analysis for the cashew gum under nitrogen atmosphere. In Fig. 3a, which shows the Friedman analysis, there are two peaks. The first peak started at around 247 °C, and the second peak occurred at around 264 °C and 322 °C. The presence of two peaks indicates that the decomposition happens in at least two stages. In Fig. 3b, which shows the Ozawa–Flynn–Wall analysis, it can observed that the straight lines referring to isoconversions showed higher parallelism in the range of 282 and 308 °C, which correspond to maximum decomposition of cashew gum.

Table 1 shows the values obtained for activation energy (E a) and pre-exponential factor logarithm (log A) in agreement with the conversion degree (α) for Friedman and Ozawa–Flynn–Wall analysis under nitrogen atmosphere. It can be seen that both methods showed that the activation energy is dependent on the conversion degree. The dependence of the activation energy on the degree of conversion is an indication of the presence of a multiple-stage reaction [27].

Figure 4 shows the Friedman and the Ozawa–Flynn–Wall analysis for cashew gum under air atmosphere. In Fig. 4a, four peaks were observed in Friedman analysis. The first two peaks appeared in the same temperature range performed in the analysis under nitrogen. The third peak occurred between 384 and 431 °C, and the fourth peak occurred between 431 and 462 °C. Once more, these peaks correspond to TG analysis. In Fig. 4b, which shows the Ozawa–Flynn–Wall analysis, the straight lines referring to isoconversions showed higher parallelism between 270 and 308 °C, as observed in TG analysis under nitrogen and parallelism in the range of 431 and 462 °C.

Table 2 shows the values obtained for activation energy (E a) and pre-exponential factor logarithm (log A) in agreement with the conversion degree (α) for Friedman and Ozawa–Flynn–Wall analysis under air atmosphere. As observed in nitrogen atmosphere, the E a values founded are dependent on the conversion degree.

When evaluating the data obtained by isoconversional methods, it was possible to propose a probable mechanism to explain the process of thermal decomposition of cashew gum. The simulations were performed on Thermokinetics 3 software, and the kinetic models tested were the following: consecutive, parallel, and competitive stages, with reaction order (F1, F2, and Fn) and autocatalytic reactions (Cn). According to the evaluation of the statistical F-test of the software, the importance of a model is observed when the experimental values of F are lower than the critic value.

Figure 5 shows the result of simulation for the chosen kinetic model under nitrogen. The obtained results showed that the most appropriate model to describe the thermal decomposition process was of two consecutive stages, being the first stage of n order (Fn), \( f(\alpha ) = (1 - \alpha )^{\rm{n}} \), and the second stage of first order (F1), \( f(\alpha ) = (1 - \alpha )^{1} \).

The kinetic parameters found for the first stage were: E a = 195.9 kJ mol−1, log A = 17.1, and reaction order = 2.7. For the second stage, the values obtained were: E a = 197.7 kJ mol−1, log A = 15.7, and reaction order = 1.0.

Figure 6 shows the result of the simulation for the chosen kinetic model under air. The results obtained for the decomposition process were of the consecutive and completive reactions with six stages, and all reaction of n order (Fn), \( f(\alpha ) = (1 - \alpha )^{\rm{n}} \).

The kinetic parameters found for the first stage were: E a = 178 kJ mol−1, log A = 15.1, and reaction order = 3.7. For the second stage, the values obtained were: E a = 174.2 kJ mol−1, log A = 13.7, and reaction order = 0.4; for the third stage: E a = 155.9 kJ mol−1, log A = 8.9, and reaction order = 0.8; for the fourth stage: E a = 81.6 kJ mol−1, log A = − 5.9, and reaction order = 2.4; for the fifth stage: E a = 187.9 kJ mol−1, log A = 22.1, and reaction order = 2.7; and for the sixth stage: E a = 150.2 kJ mol−1, log A = 10.7, and reaction order = 0.4.

Through the selected models, it was possible to predict the lifetime of cashew gum in the studied conditions. Figures 7 and 8 show the isotherms predictions in nitrogen and air atmospheres. It can be seen cashew gum exhibited very high stability with a lifetime of 20 years, from 40 to 80 °C, with a conversion degree of less than 5% in both atmospheres.

Conclusions

Thermal decomposition kinetics of cashew gum was studied in nitrogen and air and in non-isothermal conditions. The kinetic parameters were estimated by Friedman and Ozawa–Flynn–Wall isoconversions models, and multivariate nonlinear regression analysis was applied to estimate a probable mechanism. Two peaks were recognized in Friedman analysis in nitrogen, and four peaks were recognized in Friedman analysis in air. In both atmospheres, the activation energy values were dependent on the conversion degree. In nitrogen condition, the kinetic model was estimated with two consecutive stages (FnF1). In air condition, the kinetic model was estimated with six consecutive and competitive stages (FnFnFnFnFnFn model). Cashew gum showed very high stability with a lifetime of 20 years, from 40 to 80 °C, in nitrogen and air atmospheres, as predicted by the model-free analysis.

References

Mothé CG, Souza IV, Calazans GMT. Antitumor activity of cashew gum from Anacardium occidentale L. Agro Food Ind Hi-Tech. 2008;19:38–40.

Verbeken D, Dierckx S, Dewettinck K. Exudate gums: occurrence, production, and applications. Appl Microbiol Biotechnol. 2003;63(1):10–21.

Marques MR, Xavier-Filho J. Enzymatic and inhibitory activities of cashew tree gum exudate. Phytochemistry. 1991;30:1431–3.

de Paula RCM, Rodrigues JF. Composition and rheological properties of cashew tree gum, the exudate polysaccharide from Anacardium occidentale L. Carbohydr Polym. 1995;26:177–81.

Mothé CG, Freitas JS. Extraction, purification of cashew polysaccharide and characterization by GC-MS, FTIR, NMR, TG/DTG. I J Res Rev Appl Sci. 2013;16(3):401–8.

Anderson DMW, Bell PC. Structural analysis of the gum polysaccharide from Anacardium occidentale. Anal Chim Acta. 1975;79:185–97.

Mothé CG, Rao MA. Thermal behavior of gum arabic in comparison with cashew gum. Thermochim Acta. 2000;357:9–13.

Mothé CG, Rao MA. Rheological behavior of aqueous dispersions of cashew gum and gum arabic: effect of concentration and blending. Food Hydrocollids. 1999;13:501–6.

Carestiato T, Aguila MB, Mothé CG. The effects of cashew gum as anti-hypertensive agent—thermoanalytical investigation and micrographs of heart samples of SHR. J Therm Anal Calorim. 2009;97:717–20.

Ferrero C, Martino MN, Zaritzky NE. Effect of hydrocolloids on starch thermal transitions, as measured by DSC. J Therm Anal Calorim. 1996;47:1247–66.

Villetti MA, Crespo JS, Soldi MS, Pires ATN, Borsali R, Soldi V. Thermal degradation of natural polymers. J Therm Anal Calorim. 2002;67:295–303.

Zohuriaan MJ, Shokrolahi F. Thermal studies on natural and modified gums. Polym Testing. 2004;23:575–9.

Hornung PS, do Prado Cordoba L, da Silveira Lazzarotto SR, Schnitzler E, Lazzarotto M, Ribani RH. Brazilian Dioscoreaceas starches. Thermal, structural and rheological properties compared to commercial starches. J Therm Anal Calorim. 2017;127:1869–77.

Mothé CG, Correia DZ, de Franca FP, Riga AT. Thermal and rheological study of polysaccharides for enhanced oil recovery. J Therm Anal Calorim. 2006;85:31–6.

Varhegyi G, Antal MJ Jr, Szekely T, Szabo P. Kinetics of the thermal decomposition of cellulose, hemicellulose, and sugarcane bagasse. Energy Fuel. 1989;3:329–35.

Mohammad S, Massey S, Akbar J, Ashraf CM, Masih R. Thermal analysis of some natural polysaccharide materials by isoconversional method. Food Chem. 2013;140(1):178–82.

Hao YH, Huang Z, Ye QQ, Wang JW, Yang XY, Fan XY, Li YL, Peng YW. A comparison study on non-isothermal decomposition kinetics of chitosan with different analysis methods. J Therm Anal Calorim. 2017;128(2):1077–91.

Mothé MG, Leni FML, Mothé CG. Kinetic parameters of different asphalt binders by thermal analysis. J Therm Anal Calorim. 2011;106:679–84.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Blanco I. Lifetime prediction of food and beverage packaging wastes. J Therm Anal Calorim. 2016;125(2):809–16.

Hao YH, Huang Z, Ye QQ, Wang JW, Yang XY, Fan XY, Li YL, Peng YW. A comparison study on non-isothermal decomposition kinetics of chitosan with different analysis methods. J Therm Anal Calorim. 2017;128(2):1077–91.

Tsai SY, Hwang BF, Wang YH, Lin CP. Moisture desorption and thermal properties of polysaccharide from pulsed light irradiated Flammulina velutipes. J Therm Anal Calorim. 2017;127(1):469–81.

Sasca VZ, Verdeş O, Popa A. The estimation of thermal endurance for some heteropoly acidic catalysts from thermogravimetric decomposition data. J Therm Anal Calorim. 2017;127:273–82.

Lu YH, Cao Y, Lu YW, Yang T. Thermal stability and lifetime of [AMIM] Cl-PFSA composite membranes. J Therm Anal Calorim. 2017;128(3):1601–15.

Kim Y, Ambekar A, Yoh JJ. Toward understanding the aging effect of energetic materials via advanced isoconversional decomposition kinetics. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6778-2.

Mothé CG, Freitas JS. Thermal behavior of cashew gum by simultaneous TG/DTG/DSC-FT-IR and EDXRF. J Therm Anal Calorim. 2014;116(3):1509–14.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;340:53–68.

Mothé CG, Miranda IC. Study of kinetic parameters of thermal decomposition of bagasse and sugarcane straw using Friedman and Ozawa–Flynn–Wall isoconversional methods. J Therm Anal Calorim. 2013;112:1–9.

Opfermann J, Kaisersberger E. An advantageous variant of the Ozawa–Flynn–Wall analysis. Thermochim Acta. 1992;203:167–75.

Acknowledgements

The authors would like to thank Brazilian Agencies: Brazilian Federal Agency for Support and Evaluation of Graduate Education (CAPES), Carlos Chagas Filho Foundation for Research Support-Rio de Janeiro (FAPERJ), and Brazilian Council for Scientific and Technological (CNPq) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mothé, C.G., de Freitas, J.S. Lifetime prediction and kinetic parameters of thermal decomposition of cashew gum by thermal analysis. J Therm Anal Calorim 131, 397–404 (2018). https://doi.org/10.1007/s10973-017-6844-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6844-9