Abstract

Determination of the characteristics of native starches is crucial in order to select their best application in various industrial fields. Thus, two different types of non-traditional native starches from the Dioscoreaceas species (Dioscorea sp. and Dioscorea piperifolia Humb. var. Wild) were studied regarding their thermal, structural and rheological properties. The results were contrasted with traditional commercial starch sources (potato, cassava and corn). From the thermogravimetric results (TG/DTG), D. piperifolia starch obtained the highest thermal stability of the samples, except for potato starch. Furthermore, using differential scanning calorimetry and viscoamylograph profiles (RVA), it was found that the Dioscoreaceas starches presented a higher onset (T o) temperature and susceptibility to retrogradation. They also showed lower values in relation to relative crystallinity, which was calculated from their X-ray patterns and tendency to white (L*) colour. The shapes of the Discoreaceas starch granules were determined using electron microscopy; it was found that as the potato starch the Dioscoreaceas starches showed a wide range of particle size.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In general, the food industry is the largest consumer of starch. However, starch is also used to process various products in the paper, chemicals, pharmaceutical and textile industries [1, 2]. Due to restrictions that have been mainly imposed by the food industry, and also because of the concerns about environmental issues, industries are increasingly interested in novel and underutilised sources of starch [3].

Starch is the most abundant carbohydrate reserve in plants and is also the main source of calories in the human diet. It is a non-toxic and renewable material. Products derived from starch have established applications in many fields. Starch granules are composed of two glucose polymers: amylose and amylopectin, which represent approximately 98–99 % of the dry total mass. Amylose is predominantly a linear polymer of a 1–4 linked glucose, whereas amylopectin is a highly branched polysaccharide consisting of a 1–4 linked glucose with a 1–6 linkages at the branch points [1].

The starch derived from cereal crops is the main form that is extracted and commercialised nowadays. Even though plants widely used by humans (root tubers, rhizomes, bulbs) are rich in starch, they are still underused. Brazil and others tropical countries have a large variety of tubers cultivars due to their mild climate [4]. Tubers from the Dioscoreaceae family are estimated to number approximately 600 species [5]. Dioscorea tuber crops are cultivated in many parts of Africa and South East Asia. In Brazil, the cultivation is mainly performed by traditional farmers for their own consumption and commercialised in the north-east of the country [5, 6]. In these tubers, the starch is the most abundant constituent, making up to 20–60 % of total content; it serves as a sustainable source of starch for food and other industrial uses [7–9].

Thermal analysis can be used to show the behaviour of starch granules when they are heated. For example, the differential scanning calorimetry (DSC) technique can be used to investigate the phase transitions of starch/water systems (gelatinisation process) and to estimate transition enthalpies [10]. Furthermore, the structural configuration, paste and colour properties of starch play an important role in the development of food processing and new products [11].

In this context, there is a need to investigate non-traditional starch sources which may be suitable for industrial use as additives to fulfil other specific purposes. Thus, the objective of this research was to study the thermal, rheological and structural properties of starch from Dioscoreaceae family tubers (Dioscorea sp. and Dioscorea piperifolia Humb. var. Wild) and compare them with commercialised starches.

Materials and methods

The starches (500 g), from cassava (Manihot esculenta), corn (Zea mays) and potato (Solanum tuberosum) were purchased commercially in the city of Curitiba, Paraná, Brazil. The tubers of white yam (Dioscorea sp.) and aerial yam (D. piperifolia Humb. var. Wild.), which are presented in Fig. 1, were harvested from a crop area located in Aripuanã, Mato Grosso, Brazil. The tuber starches were obtained using the method described in a previous study [12]. The codification of the samples was as follows: samples of the native starches [white yam D. sp.—(a); aerial yam D. piperifolia—(b)]; commercial starches [potato—(c); cassava—(d) and corn—(e)].

To obtain the thermal profile of the samples, in terms of mass loss under a controlled programmed temperature, the analysis was performed using TGA-50 thermal analysis system equipment (Shimadzu, Japan). All the mass loss percentages and the derivative thermogravimetric results were determined using TA-60 WS data analysis software [1, 2, 13].

The DSC analysis was performed using a thermal analysis system (TA-Instruments, DSC-Q200 model, USA). The system was previously calibrated with 99.99 % purity indium, with a melting point of T p = 156.6 °C, ΔH = 28.56 J g−1. The thermal profiles were recorded under an air flow of 50 mL min−1 with a heating rate of 10 °C min−1 and the samples, which weighed about 2.5 mg, were placed in sealed aluminium crucibles. A water:starch w/w (4:1) mixture was prepared and maintained for 60 min in order to equilibrate the moisture content [1, 2, 13].

In order to study the pasting properties of the samples, the viscoamylograph profiles were obtained using a rapid viscometer (Newport Sci., RVA-4 model, Australia). A suspension of 2.24 g of starch in 25.76 g of distilled water underwent a controlled heating and cooling cycle following the methodology described in the literature [14, 15].

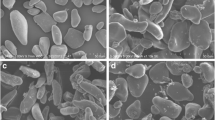

The morphology of the starch granules and their surface area were examined using a scanning electron microscope (Tescan, VEGA 3, Kohoutovice, Czech Republic) under an acceleration voltage of 15 kV and magnification of 1000× after the samples had been coated with plasma of gold and palladium [1, 2, 16]. The average size of the starch granules was calculated using ImageJ free software (version 1.49v).

The X-ray diffraction powder patterns (XRD) of the samples were investigated using an X-ray diffractometer (Rigaku, Ultima 4 model, Japan), and the degree of relative crystallinity was quantitatively estimated using Eq. 1. The method followed was as described in the literature [14, 17–19]

where X c relative crystallinity, A p peak area, A b base area.

A MiniScan EZ 4500L spectrophotometer (Hunter Inc., USA) was used to determine the colour parameters of the starch samples (L*, brightness, which ranges from 0 (black) to 100 (white); a*, positive values (red) and negative (green) and b*, positive (yellow) to negative (blue)) [1, 2, 14, 20].

All the results were analysed for variance (ANOVA). Duncan’s test was used to compare the means of the samples at 95 % confidence level (p < 0.05) utilising STATISTICA 7.0 software (StatSoft Inc., Tulsa, OK, USA).

Results and discussion

The thermal decomposition of the starch samples occurred in three main steps, as can be observed in the curves shown in Fig. 2. The first step of mass loss, which was associated with the first peak followed by a stability step, was attributed to dehydration due to the water loss of the starch granules. The decomposition and oxidation of the organic matter and consecutive reactions were associated with the second and third steps, respectively [1, 13, 20, 21]. Similar results were observed in previous studies [1, 16, 20–25].

Differences were observed regarding the derivative thermogravimetric profiles (DTG curves) of the studied samples. In relation to the first step (dehydration), it could be seen that the samples of white yam starch (a) and potato starch (c) presented a well-defined peak compared to the other samples; this can be attributed to the higher values for moisture content (a—17.95 %; c—15.89 %), Table 1. The moisture content of the samples, b, d and e, was from 9 to 12 %. Low moisture content can increase the stability of starches, and it also facilitates transport and storage [26]. Furthermore, the third peak (oxidation) in the DTG curve (Fig. 2) of sample b (aerial yam) was different from the others. This could have been related to the slightly high depolymerisation (which occurs above 300 °C under an oxidative atmosphere) of the starch molecules [21, 22, 27] compared with the other samples. Table 1 shows the third event for sample b, which presented the highest mass loss (21.47 %) of all samples that were analysed.

The aerial yam starch (sample b), as listed in Table 1, presented a slightly higher range of stability step (108–235 °C) when compared to the other samples, except for the potato starch. Thus, sample b could be considered a starch more stable to thermal degradation when compared to cassava and corn starches.

The results calculated from the TG/DTG curves are listed in Table 1. The residue corresponding to the mineral content of the samples was 0.64, 0.89, 0.83, 0.98 and 1.09 % for samples a, b, c, d and e, respectively.

The DSC technique was used to study the gelatinisation process of the different starch samples. The profiles of the curves are depicted in Fig. 3, and Table 2 shows all the calculated results, which were carried out in triplicate.

Figure 3 shows the very different endothermic events (calorimetric curves) that occurred for the analysed samples. The initial temperatures, which were attributed to the change of the baseline, were quite similar for samples a and b (Dioscoreaceas starches) and also for samples c and d (potato and cassava).

The gelatinisation process leads to irreversible changes in the structure of starch molecules, such as granules swelling and crystallite melting. As can be seen from the results in Table 2, the native starches from the Dioscorea species presented the highest values for the evolved temperatures of the gelatinisation process (T o, T p, T c). These values were expected, due to the botanical sources of the yam starches which contain approximately 15–30 % of amylose of its total starch (60–85 %) in dry basis [23]. When starch contains a high amylose content, it requires higher temperatures and a greater amount of energy for gelatinisation to occur. In solution, the linear structure of amylose assists in rapidly aligning with itself, resulting in more extensive hydrogen bonding and high gel strength. Thus, a high amount of energy is required to break these bonds and gelatinise [28]. Similar results were obtained in previous studies of different species of yam starches (Dioscoreaceas) [25, 29–31].

In the present study, the Discorea starch from the white yam cultivar (sample a) showed the highest ΔH value (15.56). A previous study obtained even higher ΔH values (17.32–18.98 J g−1) for seven types of Discorea starches from Sri Lanka. Campbell et al. [32] studied the influence of the variation of the size of starch granules on its functional properties. They found that starches with larger sized diameter particles can result in higher temperatures for DSC values. The Dioscoreaceas starches (samples a and b) had shown an average granule size of 29.57, 31.14 µm, respectively (Table 2), as well as higher ΔH values, as related above. Regarding the ΔH values obtained for sample b (D. piperifolia), this native starch consumed less energy to form the starch gel in comparison with the potato sample (35.55 µm).

One of the most important characteristics when recommending the technological application of amylaceous materials is viscosity. Viscosity curves can show the behaviour of the starch paste during heating and cooling [33]. The pasting properties for the starch samples obtained by the RVA profiles are presented in Fig. 4, and the main results are listed in Table 3.

The pasting temperatures obtained by RVA corroborated the onset temperatures of gelatinisation that were registered by the DSC analysis. The higher values recorded by RVA are due to the fact that this technique is less sensitive in detecting when starch granules begin to disrupt their configuration [33]. Compared to the commercial samples, the higher pasting temperatures presented by the yam starches (samples a and b) may have been related to a high resistance to the swelling and rupture of the starch granules. All the results for peak viscosity, peak time, setback, breakdown and final viscosity were significantly different between the samples. In spite of the fact that sample c (potato) showed a high value for peak viscosity (8982.30 ± 0.42 mPa s), the highest value in terms of final viscosity was achieved for the white yam starch (sample a—5324.50 ± 4.95 mPa s). This result obtained for the white starch suggests that the native starch would be a better alternative than potato starch to be used in the food industry as a basis for soups, gravies, sauces, baby foods, etc. [34]. Highly viscous starch presents a heavy body, shorter texture and a lower level of breakdown in cooking, thereby functioning as a better food system stabiliser [34]. The setback parameter can provide an idea of the proportion of the partial association with the amylose and amylopectin macromolecules after the gelatinisation process [35]. This association expels the water molecules from the gel, forming hard pastes in a process known as retrogradation [35]. Starches that have a higher tendency to retrogradation (setback values), such as those presented by the Dioscoreaceas starches (samples a and b), are considered to be resistant starches [36]. Starches that present such results can be applied as a basis for bioplastic material due to their ability to form cohesive films [37]. Different results for setback are found in the literature regarding Dioscorea starch sources [7, 23, 38]. These differences can be attributed to the botanical origin, chemical composition, the method used and the conditions of analysis [33].

Figure 5 shows the morphological images of the studied samples acquired by SEM. The micrographs showed that the shapes and sizes of the starches granules for the analysed samples differed significantly between themselves. The starch granules from samples a, b and c range from large to medium size, and samples a and b were predominantly triangular in shape. The results obtained for all the samples were similar to those in previous studies [3, 7–9, 21, 23, 25]. Based on the micrograph images of the starch granules, the average size was calculated and the results are listed in Table 2. In terms of these results, all samples analysed presented significant differences. Sample a showed a range between 24 and 40 µm with an average size of 29.57 µm. Sample b ranged between 24 and 41 µm with an average size of 31.14. Determining the shape and size of starch particles is important in order to understand their technological behaviour [39]. For example, in the pharmaceutical industry the shape of starch granules influences their density during packing in a tableting machine or in filling gelatine capsule shells [39]. The pharmaceutical industry is interested in starch granules that show a wide range of particle size, such as the ones obtained for samples a, b and c (Dioscoreaceas and potato starches), which implies better technological performance [39]. The range of particles size for potato, cassava and corn starch were 11–49, 10–13 and 9–17 µm, respectively.

Observing the diffraction patterns (Fig. 6), regarding the main peaks the samples of the Dioscoreaceas species, were different from the commercial starch samples. The diffraction patterns of samples a and b were very similar to the ones obtained in previous studies of Dioscorea permsimilis and Dioscorea opposita [8, 40]. However, sample b showed a different pattern from a sample of the same species presented in the literature [7]. These differences can be attributed to the origin of the cultivars (climate, region, period of collection), the methodology used and the data analysis. The patterns can be better analysed by the results as presented in Table 2. Depending on the strongest diffraction peaks that are registered, starch can be categorised as follows: type A (main peaks at 15°, 17°, 18° and 20° into 2θ); type B (5°, 6°, 15°, 17°, 18° and 23°) or type C (a mixture of types A and B = 5.5°, 15°, 17°, 22° and 23°), the last one is normally attributed to rhizome starches [1, 3]. Therefore, in this study the main peaks into 2θ presented for samples a (5°, 16°, 22° and 23°) and b (15°, 17° and 22°) can be classified as type C starches as well as the ones obtained for the commercial samples (Fig. 6).

The results for the degree of relative crystallinity showed that samples a and b were significantly different from the commercial starch samples. Furthermore, these Dioscorea starch samples showed the lowest values for relative crystallinity, which were 16.78 and 11.87 %, respectively. These results are different from the data obtained in the literature [7, 41] for D. sp. (35 %) and for D. piperifolia (32.06 %). These differences were mainly due to the composition of the starch, the moisture content and the botanical source [8]. These low values can be attributed to high amylose content [23]. Starches composed of large amounts of amylose molecules have great potential for the development of resistant edible films [31], and high amylose starches are considered to be healthier for human consumption because of their resistance to digestion [36, 42]. Considering the results for low relative crystallinity and high setback for samples a and b, the amount of amylose could contribute for the differences between those starches and the commercial samples. It is also relevant to mention that a low degree of relative crystallinity of a starch can increase the enthalpy (ΔH) of the gelatinisation process [43], as shown by sample a (D. sp.—white yam) (Table 2).

The results of the colour properties are presented in Table 4. Visually, all the starch samples were white, with the exception of the starch from sample b (D. piperifolia), which was yellow. The visual colour observation of sample b was confirmed by the results for the b* parameter, which registered a positive value of +35.65 (yellow) and the lowest value for brightness (L*) of +72.36. Sample a (D. sp.) also presented a lower value for the L* parameter when compared to the commercial starch samples although it showed the least tendency to yellow (b* = 1.57) of all the samples. Similar results were found for these cultivars in previous studies [7–9, 23]. Regarding sample (b) from the D. piperifolia starch, the presence of pigments like carotene in its tuber [44] carried over to the starch, which may have been responsible for its colour properties. Starches that bring pigmentation from their source can be applied in product formulations without a negative impact on their colour characteristics because the crucial factor is the amount that is applied [45].

Conclusions

The TG/DTG curves showed that the yam starches obtained a higher stability step compared to the commercial starch samples of cassava and corn. The DSC and RVA results verified the initial temperature of the gelatinisation process. It was possible to observe that the Dioscoreaceas samples showed a strong tendency to retrogradation (RVA—setback) and that the starch sample from D. sp. had the higher value for gelatinisation enthalpy. The XRD crystallinity patterns of type C starches were observed for the Dioscoreaceas samples, which also presented the lowest values for relative crystallinity. All the colour results for the samples were significantly different, and the aerial yam was the most coloured sample, tending to yellow. From the characteristics displayed in this study, Dioscoreaceas starches could be useful as a raw material for different commercial applications.

References

Hornung PS, Oliveira CS, Lazzaroto M, Lazzarotto SRS, Schnitzler E. Investigation of the proto-oxidation of cassava starch granules. J Therm Anal Calorim. 2015;123:2129–37.

Oliveira CS, Andrade MMP, Colman TAD, Costa FJOG, Schnitzler E. Thermal, structural and rheological behavior of native and modified waxy corn starch with hydrochloric acid at different tempertures. J Therm Anal Calorim. 2014;115:13–8.

Huang J, Zhao L, Man J, Wang J, Zhou W, Huai H, Wei C. Comparison of physicochemical properties of B-type nontraditional starches from different sources. Int J Biol Macromol. 2015;78:165–72.

Leonel M, Cereda MP. Caracterização físico-química de algumas tuberosas amiláceas. Ciênc Tecnol Aliment. 2002;22:65–9.

Nascimento WF, Siqueira MVBM, Ferreira AB, Ming LC, Peroni N, Veasey EA. Distribution, management and diversity of the endangered Ameridian yam (Dioscorea trifida L.). Braz J Biol. 2015;75:104–13.

Okunlola A, Odeku OA. Evaluation of starches obtained from four Dioscorea species as biding agent in chloroquine phosphate tablet formulations. Saudi Pharm J. 2011;19:95–105.

Jiang Q, Gao W, Xia L, Xia Y, Wang H, Wu S, Huang L, Liu C, Xiao P. Characterizations of starches isolated from five different Dioscorea L. species. Food Hydrocoll. 2012;29:35–41.

Jiang Q, Gao W, Shi Y, Xia L, Wang W, Huang L, Xiao P. Physicochemical properties and in vitro digestion of starches from different Dioscorea plants. Food Hydrocoll. 2013;32:432–9.

Falade KO, Ayetigbo OE. Effects of annealing, acid hydrolysis and citric acid modifications on physical and functional properties of starches from four yam (Dioscorea spp.) cultivars. Food Hydrocoll. 2015;43:529–39.

Bicudo SCW, Demiate IM, Bannach G, Lacerda LG, Carvalho-Filho MAS, Ionashiro M, Schnitzler E. Thermoanalytical study and characterization of native starches of Paraná pine seeds (Araucaria angustifolia, Bert O. Ktze) and European chestnut seeds (Castanea sativa Mill). Eclet Quim. 2009;34:7–12.

Sangseethong K, Termvejsayanon N, Sriroth K. Characterization of physicochemical properties of hypochlorite and peroxide-oxidized cassava starches. Carbohydr Polym. 2010;82:446–53.

Lacerda LG, Colman TAD, Baub T, Carvalho MAS, Demiate IM, Vasconcelos EC, Schnitzler E. Thermal, structural and rheological properties of starch from avocado seeds (Persea americana, Miller) modified with standard hypochlorite sodium. J Therm Anal Calorim. 2014;115:1893–9.

Cordoba LP, Ribeiro LS, Colman TAD, Oliveira CS, Andrade MMP, Costa FJOG, Schnitzler E. Effect of hydrochloric acid in different concentrations and temperatures up to some properties of organic cassava starch. Braz J Therm Anal. 2013;2:6–11.

Colman TAD, Demiate IM, Schnitzler E. The effect of microwave radiation on some thermal, rheological and structural properties of cassava starch. J Therm Anal Calorim. 2014;115:2245–52.

Andrade MMP, Oliveira CS, Colman TAD, Costa FJOG, Schnitzler E. Effects of heat-moisture treatment on organic cassava starch. J Therm Anal Calorim. 2014;115:2115–22.

Granza AG, Travalini AP, Farias FO, Colman TAD, Schnitzler S, Demiate IM. Effects of acetylation and acetylation–hydropropylation (dual-modification) on the properties of starch from Carioca bean (Phaseolus vulgaris L.). J Therm Anal Calorim. 2014;119:769–77.

Beninca C, Colman TAD, Lacerda LG, Carvalho-Filho MAS, Demiate IM, Schnitzler E. Thermal, rheological, and structural behaviors of natural and modified cassava starch granules, with hypochlorite solutions. J Therm Anal Calorim. 2013;111:2217–22.

Zhang L, Xie W, Zhao X, Liu Y, Gao W. Study on the morphology, crystalline structure and thermal properties of yellow ginger starch acetates with different degrees of substitution. Thermochim Acta. 2009;495:57–62.

Alberton C, Colman TAD, Souza JA, Oliveira CS, Andrade PMM, Schnitzler E. Thermal analysis, rheology, X-ray diffractometry and Atomic Force microscopy in the evaluation of binary mixtures of “starches hydrocolloids”. J Microbiol Biotechnol Food Sci. 2014;3:305–9.

Hornung PS, Granza AG, Oliveira CS, Lazzaroto M, Schnitzler E. Study of the effects of ultraviolet light and sodium hypochlorite solutions on properties of cassava starch granules. Food Biophys. 2015;10:368–74.

Adamovicz JAL, Cordoba LP, Ribeiro LS, Schnitzler E, Oliveira CS. Evaluation on thermal, rheological and structural properties on the mixture of potato starch and pectin. Carpath J Food Sci Technol. 2015;7:45–52.

Lacerda LG, Filho MASC, Demiate IM, Bannach G, Ionashiro M, Schnitzler E. Thermal behaviour of corn starch granules under action of fungal a-amylase. J Therm Anal Calorim. 2008;93:445–9.

Jayakody L, Hoover R, Liu Q, Donner E. Studies on tuber starches. II. Molecular structure, composition and physicochemical properties of yam (Dioscorea sp.) starches grown in Sri Lanka. Carbohydr Polym. 2007;69:148–63.

Cooke D, Gidley MJ. Loss of crystalline and molecular order during starch gelatinization: origin of the enthalpic transition. Carbohydr Res. 1992;227:103–12.

N’da Kouamé V, Handschin S, Derungs M, Amani G, Conde-Petit B. Thermal properties of new varieties of yam starches. Starch Stärke. 2011;63:747–53.

Costa FJOG, Leivas CL, Waszczynsky N, Godoi RCB, Helm CV, Colman TAD, Schnitzler E. Characterization of native starches of seeds of Araucaria angustifolia from four germplasm collection. Thermochim Acta. 2013;565:172–7.

Aggarwal P, Dollimore DA. Thermal analysis investigation of partially hydrolyzed starch. Thermochim Acta. 1998;319:17–25.

Kenshun L, Rosentrater KA. Distillers grains: production, properties and utilization. 1st ed. Dublin: AOCS Press; 2016.

Pérez E, Gibert O, Rolland-Sabaté A, Segovia X, Sánchez T, Reynes M, Dufour D. Evaluation of the functional properties of promising Dioscorea trifida L. waxy starches for food innovation. Int. J Carbohydr Chem. 2011;2011:1–7.

Xia L, Wenyuan G, Qianqian J, Yanli W, Xinhua G, Luqi H. Physicochemical, crystalline, and thermal properties of native, oxidized, acid, and enzyme hydrolyzed Chinese yam (Dioscorea opposite Thunb) starch. Starch Stärke. 2011;63:616–24.

Pérez E, Rolland-Sabaté A, Dufour D, Guzman R, Tapia M, Raymundez M, Ricci J, Guilois S, Pontoire B, Reynes M, Gibert O. Isolated starches from yams (Dioscorea sp.) grown at the Venezuelan Amazons: structure and functional properties. Carbohydr Polym. 2013;98:650–8.

Campbell MR, Li J, Berke TG, Glover DV. Variation of starch granule size in tropical maize germ plasm. Cereal Chem. 1996;75:536–8.

Zhou Q, Shi W, Meng X, Liu Y. Studies on the morphological, crystalline, thermal properties of an underutilized starch from yam Dioscoreae zingiberensis CH Wright. Starch Stärke. 2013;65:123–33.

Wongsagonsup R, Pujchakarn T, Jitrakbumrung S, Chaiwat W, Fuongfuchat A, Varavinit S, Dangtip S, Suphantharika M. Effect of cross-linking on physicochemical properties of tapioca starch and its application in soup product. Carbohydr Polym. 2014;101:656–65.

Tovar J, Melito C, Herrera E, Rascón A, Pérez E. Resistant starch formation does not parallel syneresis tendency in different starch gels. Food Chem. 2002;76:455–9.

Aalcázar-Alay SC, Meireles MAA. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci Technol. 2015;35:215–36.

Simková D, Lachman J, Hamouz K, Vokál B. Effect of cultivar, location and year on total starch, amylose, phosphorus content and starch grain size of high starch potato cultivars for food and industrial processing. Food Chem. 2013;141:3872–80.

Koksel H, Masatcioglu T, Kahraman K, Ozturk S, Basman A. Improving effect of lyophilization on functional properties of resistant starch preparations formed by acid hydrolysis and heat treatment. J Cereal Sci. 2008;47:275–82.

Riley CK, Adebayo SA, Wheatley AO, Asemota HN. Surface properties of yam (Dioscorea sp.) starch powders and potential for use as binders and disintegrants in drug formulations. Powder Technol. 2008;3:280–5.

Mali S, Grossmann MVE, Yamachita F. Filmes de amido: Produção, propriedades e potencial de utilização. Semin Ciênc Agrár. 2010;31:137–56.

Lin L, Cai C, Gilbert RG, Li E, Wang J, Wei C. Relationships between amylopectin molecular structures and functional properties of different-sized fractions of normal and high-amylose maize starches. Food Hydrocoll. 2016;52:359–68.

Oli P, Ward R, Adhikari B, Torley P. Colour change in rice during hydration: effect of hull and bran layers. J Food Eng. 2016;173:49–58.

Chung H-J, Chang H-I, Lim S-T. Physical aging of glassy normal and waxy rice starches: effect of crystallinity on glass transition and enthalpy relaxation. Carbohydr Polym. 2004;58:101–7.

Rodrigues LL, Sousa MMD, Silva JN, Marques MJ, Brito P, Lima A. Caracterização físico-química e detecção de metabólitos secundários do cará molea (Dioscorea bulbífera). VII Connepi. 2012;7:1–6.

Falade KO, Christopher AS. Physical, functional, pasting and thermal properties of flours and starches of six Nigerian rice cultivars. Food Hydrocoll. 2015;44:479–90.

Acknowledgements

The authors gratefully acknowledge CAPES,Brazil, for the financial resources provided and to C-LABMU—UEPG for the performed instrumental analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hornung, P.S., do Prado Cordoba, L., da Silveira Lazzarotto, S.R. et al. Brazilian Dioscoreaceas starches. J Therm Anal Calorim 127, 1869–1877 (2017). https://doi.org/10.1007/s10973-016-5747-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5747-5