Abstract

The zero-order reaction rates (specific rate constants) for isothermal decomposition at 120 °C of plastic bonded explosives (PBXs) were measured by means of the Czech vacuum stability test, STABIL. The PBXs are based on 1,3,5-trinitro-1,3,5-triazinane (RDX), β-1,3,5,7-tetranitro-1,3,5,7-tetrazocane (HMX), cis-1,3,4,6-tetranitro-octahydroimidazo-[4,5-d] imidazole (BCHMX), and ε-2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane (ε-HNIW, ε-CL-20) with 9 wt.% of the C4 type matrix, i.e., a matrix containing 25 wt.% of polyisobutylene, 59 wt.% of dioctyl sebacate and 16 wt.% of the oil HM46. Dependencies were found between the specific rate constants mentioned and the detonation velocities of the PBXs, and consequently between these constants and the impact of pure explosive fillers, i.e., RDX, β-HMX, ε-HNIW, RS-ε-HNIW, and BCHMX and, at the same time, the corresponding PBXs. The results obtained are compared with those from a recent analogous study of PBXs using an SBR (Formex P1) binder which could increase the PBXs’ reactivity in comparison with C4 matrix. These results also help to dispel a widely held view about HNIW being a relatively sensitive explosive.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Following on from the work described in papers [1–3] we continue here the study of plastic bonded explosives (PBXs) by means of the modified Czechoslovak manometric method (vacuum stability test) which was developed mainly for studying the thermal stability of propellants [2–4] and which is generally known under the name of STABIL [1–3]. This study is compatible with a recently published analogous paper about PBXs with a Formex P1 matrix as the binder [1] and is to be considered as a continuation of paper [2].

This study is focused on PBXs with a polyisobutylene binder (PIB), softened by dioctyl sebacate (DOS), i.e., with the C4 matrix, whose active fillers are attractive cyclic nitramines BCHMX (cis-1,3,4,6-tetranitro-octahydroimidazo-[4,5-d]imidazole), RDX (1,3,5-trinitro-1,3,5-triazinane), HMX (1,3,5,7-tetranitro-1,3,5,7-tetrazocane), and ε-HNIW (2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane, ε-CL-20) [5–8]. These explosives are treated in this paper from the point of view of their behavior under the STABIL measurement conditions. Outputs are compared with detonation velocities of the PBXs studied, with their impact sensitivities, and with the results of an analogous study of the Formex P1 type explosives [1].

Experimental

Preparation of plastic bonded explosives

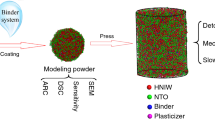

The C4 matrix refers to a non-energetic binder containing 25 wt.% of polyisobutylene, 59 wt.% of dioctyl sebacate (DOS), and 16 wt.% of the oil HM46. Preparation of the binder was carried out by mixing small pieces of two types of polyisobutylene (disintegrated by rolling) with the sebacate and the HM46 oil. The plastic explosives themselves were prepared [5–7] by mixing 91 wt.% of the particular nitramine with 9 wt.% of the binder. The formulations were mixed in a computer controlled Brabender Plastograph at 70 °C under vacuum for 70 min. The samples prepared were then extruded using a 40 mm single screw extrusion machine to obtain long charges of plastic explosive with a diameter of 16 mm [5–7]. The RDX used was a product of Dyno Nobel (a mixture of Classes 2 and 5 according to the MIL-DTL-398B standard), β-HMX was imported from Russia and its particle size distribution was close to Class 3 as described in the MIL-DTL-4544C standard, and ε-HNIW was a product of the Explosia Pardubice pilot plant production unit. For the PBX preparation in this research we used purified and recrystallized ε-HNIW (from an ethyl acetate––n-heptane system) containing 1 % of impurities. HNIW with reduced sensitivity (RS-HNIW), prepared in our laboratory [9], was also included in this study. BCHMX was prepared by a two step laboratory synthesis at the Institute of Energetic Materials [10]. Samples of the PBXs used are shown in Table 1 and in the Figures as follows: RDX-C4, HMX-C4, BCHMX-C4, HNIW-C4, and RS-HNIW-C4.

STABIL vacuum stability test

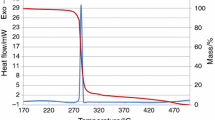

We used a modernized STABIL 16-Ex apparatus [11] (manufactured by OZM Research; the original apparatus is described in Ref. [2]). The amount of the samples used for measurements was 1 g. Tests were performed over 360 min. The temperature for the isothermal measurements was chosen to be 120 °C. The samples in evacuated glass test tubes were placed into the heating block and heated to the desired temperature. Pressure transducers continuously estimated the pressure increase in the glass tubes. The results were in the form of time dependence of the gas pressure evolved per 1 g sample––the corresponding curves up to 360 min measurement are shown in Fig. 1; here the large increase in pressure in the first period of decomposition is caused mainly by the moisture content in the PBXs studied (these samples are the “technical grade” quality). Straight lines were obtained by linearization of the data for each curve for isothermal exposure over 50–320 min and presented in Table 1; the slopes of these lines, k, correspond to the reaction velocity of evolution of gaseous products in a zero-order reaction [1, 2, 4] and, therefore, k represents the specific rate constant (here the k values are in kPa g−1 min−1).

Other characteristics of the PBXs studied or their nitramine fillers

Experimental detonation velocities of the PBXs studied were taken from Elbeih et al. [5–7]. Impact sensitivity data of the crystalline fillers of PBXs were taken from paper [12] for RDX, β-HMX, and BCHMX; and from paper [13] for ε-HNIW and RS-ε-HNIW; the data for the C4 PBXs prepared from these nitramines are published in paper [14] excluding sensitivity of RS-HNIW-C4 which was determined by means of a method from Elbeih et al. [14] i.e., using a standard impact tester (Julius Peters) with exchangeable anvil, with the amount of tested substance being 50 mm3, and with a 2 kg drop hammer weight (the probit analysis [15] was used to determine the probability levels of the initiation).

Results and discussion

As already mentioned, Fig. 1 implies that the formation of gaseous products is a zero-order reaction in the observed initiation phase of the PBXs’ decomposition. Thus the rate of thermal decomposition is equal to the specific rate constant, k, of the reaction. Figure 1 also shows the high thermal reactivity of the BCHMX-C4 explosive; this nitramine is more sensitive than RDX, β-HMX, and ε-HNIW, as well as other kinds of PBXs based on BCHMX and the nitramines mentioned [1, 7, 8]. This fact is explained partially by the molecular structure of BCHMX [16] and partially by its solubility in plasticizers of solvents [17, 18] which can eliminate the stabilizing influence of the crystal lattice [18] (about this effect see also in [19, 20]); the effect of the crystal lattice, of course, is increased in energetic materials with crowded molecules [21].

In a previous paper [1] it has already been mentioned that autocatalysis is missing during detonation [22, 23], which means that the kinetic data of such low-temperature processes can only be extrapolated to detonation conditions in which the influence of autocatalysis is excluded [2, 4, 22]. On this basis, it can be supposed that a relationship exists between the kinetic characteristics of the curves in Fig. 1 and the detonation velocities of the explosives studied (as has already been shown in zeman et al. [2]). Figure 2 is a confirmation of this assumption; here specific rate constants from thermal decomposition show a linear relationship to the detonation velocities of PBXs containing RDX, β-HMX, and RS-ε-HNIW. The data for BCHMX-C4 and HNIW-C4 do not correlate, however, due to the higher thermal reactivity of these PBXs (see in Fig. 1); this difference in the case ε-HNIW versus RS-ε-HNIW rests in the crystal disorders in the first kind mentioned, compared with the more orderly crystals with rounded edges in the case of RS-ε-HNIW [13, 24].

On the basis of the well-known relationships between detonation parameters and sensitivities to mechanical impulses [3, 4, 14, 25], the characteristics of the low-temperature zero-order decomposition of energetic materials should also correlate with their sensitivities [1, 2, 4]. In this paper we used the impact sensitivities of the PBXs’ nitramine’s fillers (NA), i.e., pure RDX, β-HMX, ε-HNIW, RS-ε-HNIW, and BCHMX, and also those of the corresponding PBXs studied. As Figs. 3 and 4 show, in both cases mentioned, logarithmic relationships have resulted.

Logarithmic relationship between impact sensitivities of the pure explosive fillers and specific rate constants of the zero-order thermal decomposition of the PBXs studied in the sense of Fig. 1

Logarithmic relationship between impact sensitivities of the PBXs studied and specific rate constants of the zero-order thermal decomposition of these PBXs in the sense of Fig. 1

According to the comparison with the impact sensitivity of pure nitramines (NA) in Fig. 3, data for HNIW-C4, i.e., with the disturbed crystals of HNIW, good correlation has been found between the data of RDX-C4 and HMX-C4. It looks as if HNIW, with impact sensitivity 4–4.5 J, is a variant of its ε-modification. On the other hand, data for RS-HNIW-C4 and BCHMX-C4 create a pair of explosives with sterically crowded molecules of nitramine fillers. This division distinguishes the C4 PBXs from analogous explosives with Formex P1 binder where the relationship mentioned has only one shape [1].

Analogous comparisons on the basis of impact sensitivities of the group of PBXs studied (Fig. 4) show a division of these explosives into a subgroup with nitramine fillers with crowded molecules and a subgroup with a pair of HMX-C4 and RDX-C4. Besides the initiation reactivity of the pure nitramine fillers, the bulk moduli of the final PBXs might play some role here (for this see, for example, information in Haycraft et al. [26]; Qiu et al. [27]), mainly in the slope of the relation cited for the HMX and RDX based PBXs (in comparison with Fig. 3). This assumption might be supported by the relationships in Fig. 5 (i.e., relationships between impact sensitivities of PBXs and their pure nitramine fillers): here a relation with a positive slope should equate to the dominating initiation reactivity of nitramine fillers, while in a relation with negative slope the elastic properties of the corresponding PBXs should be the prevailing influence.

Comparison of the specific rate constant, k, of the thermal decomposition from the study of PBXs with the Formex P1 binders (see Zeman et al. [1]) with those of C4 PBXs from this study gives Fig. 6. The binder cited contains 25 % of styrene-butadiene rubber (SBR) and 75 % of an oily material. This comparison shows that the k values of Formex explosives are higher than those of the C4 PBXs. However, the rate constants of both the PBXs with the HNIW and BCHMX fillers are relatively close; to this fact an intercept value near zero corresponds with the appropriate line in Fig. 5. On the other hand, the thermal reactivity of the Formex explosives with RDX and HMX fillers is of a higher order compared with their C4 analogs. This higher reactivity might be caused by the SBR binder in the Formex PBXs (especially influence of the aromatic part of the binder).

Comparison of the specific rate constants (in kPa g−1 min−1) of thermal decomposition of the C4 (this paper) and Formex P1 Zeman et al. [1] PBXs

Conclusions

Using a modification of the vacuum isothermal stability test, the Czech system STABIL [1–4], in the study of the thermal reactivity of plastic bonded explosives with the C4 matrix, pressure–time curves in the first 5 h of measurement are obtained which correspond closely to the zero-order reaction of gaseous products formation. Due to this fact, a dependency exists between the corresponding zero-order reaction velocities (the specific rate constants) and detonation velocities of the explosives studied. As was to be expected, relationships exist between the impact sensitivities not only of the pure nitramine’s fillers but also of the PBXs on their base, on the one hand, and the specific rate constants of the zero-order thermal decomposition of the PBXs studied, on the other. However, these relationships are not consistent for all the PBXs studied because the PIB (C4) matrix does not fully eliminate the specific influence of the nitramine filler’s molecular structure (crowding in their molecules) on the initiation reactivity of the corresponding PBXs. This represents a difference from the recently studied PBXs with Formex P1 binder (SBR matrix) [1] where their matrices increase the reactivity of the nitramine fillers to such an extent that the above-mentioned specific influence of molecular structure is practically eliminated there. The results of this paper dispel again a widely held view about HNIW being a relatively sensitive explosive (about this sensitivity see already Elbeih et al. [13]; Chen et al. [28]).

References

Zeman S, Elbeih A, Yan QL. Note on the use of the vacuum stability test in the study of initiation reactivity of attractive cyclic nitramines in the Formex P1 matrix. J Therm Anal Calorim. 2012; doi:10.1007/s10973-012-2487-z.

Zeman S, Gazda Š, Štolcová A, Dimun A. Dependence on temperature of the results of the vacuum stability test for explosives. Thermochim Acta. 1994;247:447–54.

Chovancová M, Zeman S. Study of initiation reactivity of some plastic explosives by vacuum stability test and non-isothermal differential thermal analysis. Thermochim Acta. 2007;460:67–76.

Zeman S. Sensitivities of high energy compounds. In: Klapoetke T, editor. High energy density materials, Series: structure & bonding, vol. 125. New York: Springer; 2007. p. 195–271.

Elbeih A, Pachmáň J, Zeman S, Vávra P, Trzciński WA, Akštein Z, Šelešovský J. Study of plastic explosives based on attractive cyclic nitramines. Part I. Detonation characteristics of explosives with PIB binder. Propellants Explos Pyrotech. 2011;36:433–8.

Elbeih A, Pachmáň J, Trzciński WA, Zeman S, Akštein Z, Šelešovský J. Detonation characteristics of plastic explosives based on attractive nitramines with polyisobutylene and poly(methylmethacrylate) binders. J Energ Mater. 2012;30:358–71.

Elbeih A, Pachmáň J, Zeman S. Thermal stability and detonation characteristics of pressed and elastic explosives on the basis of selected cyclic nitramines. Cent Eur J Energ Mater. 2010;7(3):217–32.

Zeman S, Elbeih A, Akštein Z. Preliminary study of several plastic bonded explosives based on cyclic nitramines. Chin J Energ Mater (HanNeng CaiLiao). 2011;16(1):8–12.

Elbieh A, Husarová A, Zeman S. Method of preparation of ε-2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane with reduced shock sensitivity. Czech Patent Application PV 2011–608 (Sept 29, 2011), University of Pardubice.

Klasovitý D, Zeman S. Method of preparing of cis-1,3,4,6-tetranitrooctahydroimidazo-[4,5-d]imidazole (BCHMX). Czech Patent # 302068 (July 27, 2009), University of Pardubice.

Krupka M. Devices and equipment for testing of energetic materials. In: Vagenknecht J (ed) Proceedings of the 4th Seminar “New trends in research of energetic materials”. Pardubice: University of Pardubice, April 2001 p. 222.

Atalar T, Jungová M, Zeman S. A new view of relationships of the N–N bond dissociation energies of cyclic nitramines. Part II. Relationships with impact sensitivity. J Energet Mater. 2009;27(3):200–16.

Elbeih A, Husarova A, Zeman S. Path to ε-HNIW with reduced impact sensitivity. Cent Eur J Energ Mater. 2011;8(3):173–83.

Elbeih A, Jungová M, Zeman S, Vávra P, Akštein A. Explosive strength and impact sensitivity of several PBXs based on attractive cyclic nitramines. Propellants Explos Pyrotech. 2012;37(3):329–34.

Šelešovský J, Pachmáň J. Probit analysis––a promising tool for evaluation of explosives’ sensitivity. Cent Eur J Energ Mater. 2010;7(3):269–78.

Klasovitý D, Zeman S, Růžicka A, Jungová M, Roháč M. cis-1, 3, 4, 6-Tetranitrooctahydroimidazo-[4, 5-d]imidazole (BCHMX), its properties and initiation reactivity. J Hazard Mater. 2009;164:954–61.

Korobko AP, Drozd SN, Milekhin YuM, Shishov NI, Lyubimenko TN, Beztuzheva TA, Krasheninikov SV, Levakova IV, Afanasyev ES. Rastvorimost nitraminov v plastifikatorakh energeticheskokh kondesirovannykh system (Solubility of nitramines in plasticizers of the energetic condensed systems). In: Sinditskii VP, Serushkin VV, Shepelov YuG, editors. Uspekhi v spetsialnoy khimii i khimikheskoy tekhnologii (Successes in special chemistry and chemical technology). Moscow: Ross Khem-Tekhnol Univ Mendeleeva; 2010. p. 250–4.

Goncharov TK, Dubikhin VV, Nazin GM, Prokudin VG, Aliev ZG. Thermal decomposition of cis-2,4,6,8-tetranitro-1H,5H-2,4,6,8-tetraazabicyclo[3.3.0]octane. Russ Chem Bull Int Ed. 2011;60(6):1138–43.

Manelis GB, Nazin GM, YuI Rubtsov, Strunin VA. Thermal decomposition and combustion of explosives and powders. Boca Raton: Taylor & Francis Group, CRC Press; 2003.

Manelis GB, Nazin GM, Prokudin VG. Zavisimost termikheskoy stabilnosti energeticheskikh soedinenii ot physico-khimikheskikh svoystv krystallov (Dependence of thermal stability of energetic compounds on physicochemical properties of crystals). In: Sinditskii VP, Serushkin VV, Shepelov YuG, editors. Uspekhi v spetsialnoy khimii i khimikheskoy tekhnologii (Successes in special chemistry and chemical technology). Moscow: Ross Khem-Tekhnol Univ Mendeleeva; 2010. p. 191–5.

Zeman S, Friedl Z. Relationship between electronic charges at nitrogen atoms of nitro groups and onsets of thermal decomposition of polynitro arenes. Cent Eur J Energ Mater. 2004;1(1):3–21.

Dremin AN. Toward detonation theory. Heidelberg: Springer; 1999.

Zeman S. Study of the initiation reactivity of energetic materials. In: Armstrong RW, Short JM, Kavetsky RA, Anand DK, editors. Energetics science and technology in Central Europe. CECD Series. College Park: University of Maryland; 2012. p. 132–67.

Yan QL, Zeman S, Svoboda R, Elbeih A, Málek J. The effect of crystal structure on the thermal initiation of CL-20 and its C4 bonded explosives (II): models for overlapped reactions and thermal stability. J Therm Anal Calorim. 2012;. doi:10.1007/s10973-012-2629-3.

Zeman S, Jungová M, Husarová A. Friction sensitivity of nitramines. Part III. Comparison with detonation characteristics. Chin J Energ Mater (HanNeng CaiLiao). 2011;19(6):610–2.

Haycraft JJ. The elastic constants and related properties of the epsilon polymorph of the energetic material CL-20 determined by Brillouin scattering. J Chem Phys. 2009;131:214501/1–8.

Qiu L, Xiao H. Molecular dynamic study of binding energies, mechanical properties, and detonation performance of bicyclo-HMX-based PBXs. J Hazard Mater. 2009;164:329–36.

Chen H, Li L, Jin S, Chen S, Jiao Q. Effects of additives on ε-HNIW crystal morphology and impact sensitivity. Propellants Explos Pyrotech. 2012;37(1):77–82.

Acknowledgements

The authors express their gratitude to Mrs. Monika Šubrtová from the Institute of Energetic Materials, University of Pardubice, for her precise measurements in the STABIL apparatus and basic evaluation of the corresponding recordings.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zeman, S., Elbeih, A. & Yan, QL. Notes on the use of the vacuum stability test in the study of initiation reactivity of attractive cyclic nitramines in the C4 matrix. J Therm Anal Calorim 112, 1433–1437 (2013). https://doi.org/10.1007/s10973-012-2710-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2710-y