Abstract

In order to elucidate why the inclusion of a nonpolar desensitizing agent in polymer-bonded explosives (PBXs) affects their sensitivity and safety, the intermolecular interactions between nitroguanidine (NQ: a high-energy-density compound used as a propellant and in explosive charges) and F2C=CF2 were investigated theoretically at the B3LYP/6–311++G(2df,2p) and M06-2X/6–311++G(2df,2p) levels of theory, focusing especially on the influence of intermolecular interactions on the strength of the trigger bond in NQ. The binding energies and mechanical properties of various β-NQ/polytetrafluoroethylene PBXs were also studied via molecular dynamics simulation. The results indicated that the weak intermolecular interactions between NQ and F2C=CF2 have almost no effect on the strength of the trigger bond or the energy barrier to the intramolecular hydrogen-transfer isomerization of NQ, as also confirmed by an AIM (atoms in molecules) analysis. However, the mechanical properties of the β-NQ/polytetrafluoroethylene PBXs were found to be significantly different from those of pure β-NQ: the PBXs showed reduced rigidity and brittleness, greater elasticity and plasticity, and—in particular—better ductility. Thus, β-NQ-based PBXs with polytetrafluoroethylene are predicted to be less sensitive to external mechanical stimuli, leading to reduced explosive sensitivity and increased safety.

Only mechanical properties influence the safety of nitroguanidine-based PBXs

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The search for stable yet insensitive explosives is an important goal in the field of energetic materials chemistry because, compared to sensitive explosives, there is less chance of accidentally triggering the detonation of insensitive explosives during handling, which makes them very attractive to the military [1,2,3,4,5]. Introducing a polar or nonpolar desensitizing agent such as an inorganic salt, stearic acid, Aquadag, or fluoropolymers into an explosive is one way to reduce explosive sensitivity [6].

Unraveling the factors and processes involved in the sensitivity of an explosive requires physical and chemical research at various scales, including the molecular scale, the crystal scale, the particle scale, and the block scale. Some relationships between the sensitivity and properties of the explosive have already been established at particular scales [7,8,9,10,11], and the general mechanism for the change in explosive sensitivity observed upon the addition of a desensitizing agent to an explosive system is known. For example, at the molecular level, a polar desensitizing agent with a strongly polar bond can easily combine with the –NO2 group of the explosive to form a molecule–ion interaction or H-bond, which is regarded as the main stabilizing force in such an explosive [12,13,14]. A theoretical investigation indicated that the strength of the C–NO2 trigger bond—the rupture of which is believed to be a key initial step in detonation [7, 11, 15]—is enhanced in the molecule–cation complex compared with that in the isolated nitrotriazole molecule, leading to the reduced sensitivity of the combined explosive [14]. The generation of intermolecular H-bonds involving the –NO2 groups of explosives, i.e., ON–O···H contacts, is believed to be crucial to reducing the sensitivities of energetic materials, as these H-bonds strengthen trigger bonds [16].

While the presence of a polar desensitizing agent is known to decrease explosive sensitivity by inducing molecule–ion or H-bonding interactions, it is unclear how the addition of a nonpolar desensitizing agent with a polar bond will affect explosive sensitivity. If we consider this at the molecular scale, some of the nonpolar additives, such as fluoropolymers, used in polymer-bonded explosives (PBXs) contain the strongly electronegative F atom, so intermolecular interactions may also occur between the polar C–F bond of the nonpolar additive agent and –NH2, −OH, and –CH3 groups in the explosive.

PBXs are composite materials in which a high-energy explosive material is bound together in a matrix using a small amount of polymeric binder. PBXs have been widely used in many defense due to their safety, high strength, and ease of processing, among other advantages [17,18,19,20]. In a PBX, the polymeric binder is often a nonpolar desensitizing agent such as a plastic. Investigations performed at the molecular and crystal levels have shown that the long molecular chains of a polymer binder that is also a nonpolar desensitizing agent can dampen external stimuli, making the PBX less sensitive [21,22,23]. In particular, such investigations have found that the mechanical properties of the PBX correlate well with its sensitivity. For example, molecular dynamics (MD) simulation was applied to investigate the sensitivity and mechanical properties of β-HMX (β-cyclotetramethylene tetranitramine)-based PBXs with a polymer binder by Xiao et al. The results indicated that the Cauchy pressure (C12 − C44) can be used to accurately gauge the sensitivity of HMX and HMX-based PBXs [24]. The mechanical properties of TATB (1,3,5-triamino-2,4,6-trinitrobenzene) were found to be improved when it was blended with fluoropolymers, and the binding energies between the polymers and TATB or HMX were successfully used to predict the sensitivities of the resulting PBXs [25, 26].

One important question to address at the molecular and crystal levels is whether the interactions between the explosive and the binder influence the strength of the trigger bond and thus the safety of the PBX. When MD simulation was used to compare the average and maximal bond lengths of the trigger bond in the pure explosive with those in the PBXs, no significant differences were observed, and Xu et al. have found that it is impossible by changing the molecular structures of binders to affect the sensitivity of PBXs [27]. This result suggests that the interaction between the explosive and binder does not influence the strength of the trigger bond and the safety of the PBX. Those authors also found that electrostatic and van der Waals interactions were the main interactions between the polymer and the explosive crystal, because the contribution from H-bonds to the nonbonded energy was zero and the distances between the atoms in the fluoropolymers and the atoms on the crystal surface were always more than 3.0 Å [23]. However, according to quantum chemistry calculations and simulation [25, 28, 29], the main interactions in PBXs are intermolecular hydrogen bonds, H···O and H···X (X = F, Cl, etc.), between the explosive molecules and the polymer binder molecules [30]. When calculated at a low level of theory (B3LYP/6-311G*//B3LYP/3-21G* and MO-PM3), the energy associated with intermolecular H-bonds between the explosive and the polymer binder was found to be large—up to 52.98 kJ/mol for the TATB +1,1,3,3,5,5,7,7,9,9-decafluorinedecane system [29].

Thus, according to the recent literature on PBXs [24, 30,31,32,33], there are two points of view about the interactions in PBXs containing nonpolar desensitizing agents: that strong intermolecular H-bonding is present in PBXs, or that such bonding is virtually absent. This confusion prompts a number of questions. How strong is the hydrogen bonding in PBXs containing nonpolar desensitizing agents? If it is present, does the hydrogen bonding contribute to the decreased sensitivity of the PBXs compared to the pure explosive? Are the low sensitivity and the greater safety of PBXs with nonpolar desensitizing agents mainly due to strong intermolecular interactions (such as H-bonding), the binding energies between the polymers and explosives, or particular mechanical properties of the PBXs? The answer to the latter question is very important when choosing the nonpolar desensitizing agent to use as a polymer binder. If strong intermolecular interactions are the main reason for the advantages of PBXs, then it is crucial to choose a binder that will interact strongly with the explosive and thus cause a major change in trigger-bond length. On the contrary, if mechanical properties of the PBXs play a more important role, then it is necessary to choose a long chain binder with relatively good mechanical properties.

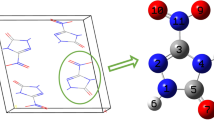

Polytetrafluoroethylene (which has a structural unit of –F2C–CF2–; see Fig. 1) is one of the most important nonpolar desensitizing agents employed with explosives. Research has shown that the mechanical properties of explosives can be considerably improved by blending the explosives with small amounts of fluoropolymers [34, 35]. Nitroguanidine (NQ) is a high-energy-density compound (see Fig. 1) that is often used as a propellant and in explosive charges. A variety of experimental methods have been applied to study the structure of NQ [36,37,38]. Ab initio and density functional methods have been employed to estimate the physical and chemical properties of NQ [39]. NQ is known to exist in two forms: α-NQ and β-NQ, with the latter being more energetically stable (it is 28.16 kJ/mol lower in energy when corrected for the zero point vibrational energy [40]). α-NQ includes –NH2, =NH, and –NH– groups, whereas the β form contains two –NH2 groups. Thus, the complex of NQ with F2C=CF2 may involve a N–H···F intermolecular interaction. Such a noncovalent N–H···F intermolecular interaction may affect the strength of the trigger bond, so the complex of NQ with F2C=CF2 can be used as a molecular model to investigate the possible influence of intermolecular interactions between a nonpolar additive agent and an explosive on the strength of the trigger bond and the safety of the resulting PBX. At the crystal level, PBXs containing NQ and the nonpolar desensitizing agent polytetrafluoroethylene can be employed as model systems to investigate the possible influences of mechanical properties and the binding energy between the polymer and explosive on the sensitivity and safety of PBXs.

In the work reported in the present paper, the intermolecular interactions between NQ and F2C=CF2 and the influence of those interactions on the strength of the trigger bond in NQ were investigated at the molecular level using quantum chemical methods. Also, molecular dynamics simulation was applied to investigate the binding energies and mechanical properties of β-NQ-based PBXs containing the nonpolar desensitizing agent polytetrafluoroethylene at the crystal level. The aim was to clarify whether the decrease in sensitivity and increase in safety that occur upon the formation of PBXs are due to intermolecular interactions (such as H-bonding), the binding energy between the polymer and explosive, or their mechanical properties. The results obtained in this work should prove useful during experiments aimed at the creation of novel PBXs.

Computational details

Quantum chemical calculations

The α and β forms of NQ were considered. NQ:F2C=CF2 (1:1) complexes with an intermolecular N–H···F noncovalent bond were selected and optimized at the B3LYP/6–311++G(2df,2p) level. Structures corresponding to the minimum energy points at the molecular energy hypersurface (NImag = 0) were obtained. The intermolecular interaction energies were calculated using the B3LYP/6–311++G(2df,2p) and M06-2X/6–311++G(2df,2p)//B3LYP/6–311++G(2df,2p) methods, correcting for the basis set superposition error (BSSE) [41]. AIM (atoms in molecules) [42, 43] results were obtained at the B3LYP/6–311++G(2df,2p) level. The above calculations were performed with the Gaussian 09 software package [44].

The bond dissociation energies (BDEs) of the C–NNO2 and N–NO2 bonds were calculated as

where R· and RNNO2/RNO2 refer to the radical and NQ, respectively.

Molecular dynamics calculations

Construction of the polymer model

All molecular dynamics calculations were performed with the Materials Studio (MS) 7.0 program [45]. The chain number (n) of polytetrafluoroethylene was set to either 3, 4, 6, or 8, and the end groups were saturated by the F atom. The resulting four polytetrafluoroethylene polymer models were explored as NVT ensembles in MD simulations using the Discover module and the COMPASS force field. An Anderson thermostat was employed, and the temperature was set to 298 K, the step size was 1.0 fs, and the total simulation time was 3.0 ns. The equilibrium structures of the polymers were obtained from the simulations.

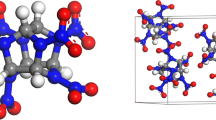

Construction of the β-NQ and PBX models

The crystal parameters of β-NQ were derived from X-ray diffraction. The β-NQ crystal was orthorhombic, with a = 17.58 Å, b = 24.82 Å, c = 3.58 Å [46]. A (3 × 3 × 3) model of crystal cells was constructed. Since the (110) and (010) crystalline surfaces were present [46], we employed the “cutting” model, where the β-NQ crystal was cut along the crystalline surfaces (110) and (010) and placed in periodic boxes with a 20 Å vacuum layer. Each system had 108 β-NQ molecules. Eight primary models were obtained by placing the abovementioned four polytetrafluoroethylene binder chains into the box such that they were parallel to the (110) and (010) surfaces of β-NQ, and then compressing and optimizing via molecular mechanics (MM) until the density was close to 1.75 g cm−3. The corresponding weight percent binder values were 2.80%, 3.60%, 5.17%, and 6.68%, respectively. The initial model of pure β-NQ was compressed to close to its experimental density (1.78 g cm−3 [47]).

The original models of pure β-NQ and the eight PBXs were explored as NVT ensembles and simulated using molecular dynamics (MD) with the COMPASS force field. The Andersen temperature control method was used (298 K). The accuracy of the Ewald method was 1.0 × 10−4 kcal/mol. The cutoff distance and buffer width for the atom-based method were 9.5 Å and 0.5 Å, respectively. A time step of 1.0 fs was set. The total dynamic time was 100,000 fs.

The binding energy E b was calculated using the following formula:

where E tot, E β-NQ, and E polytetrafluoroethylene are the single point energies of PBX, β-NQ, and polytetrafluoroethylene, respectively.

Results and discussion

Investigating the NQ···F2C=CF2 complex

Four complex conformations of α-NQ with F2C=CF2 (denoted α-A to α-D, respectively) and six conformations of β-NQ with F2C=CF2 (denoted β-A to β-F, respectively) were identified (see Figs. S1 and S2 in the “Electronic supplementary material,” ESM). Most of the predicted conformations were difficult-to-find local minima since the potential wells were flat at the B3LYP/6–311++G(2df,2p) level. Only the above ten conformations were considered in the following analysis.

Structure and intermolecular interactions of the complex

All the complex conformations present C 1 symmetry. As can be seen from Fig. S2 of the ESM, the F···H distances in the C–F···H–N contacts are in the range 2.230–2.646 Å at the B3LYP/6–311++G(2df,2p) level, which lies within the commonly accepted range of F···H hydrogen-bond distances. However, the H–N bond lengths in the ten conformations are very similar to or exactly the same as those in the isolated NQ (differences were <0.002 Å; see Table S1 of the ESM), suggesting that the intermolecular F···H–N interactions between NQ and F2C=CF2 are very weak.

Indeed, the intermolecular F···H–N interaction energies calculated at both levels of theory are very weak (see Table 1). The intermolecular interaction energies calculated using the B3LYP method are larger slightly than those obtained using the M06-2X method. Except for β-F (−10.2 kJ/mol), the intermolecular interaction energies calculated at the M06-2X/6–311++G(2df,2p) level are no more than −7.5 kJ/mol. In most cases, the intermolecular H-bonding interaction energies are in the range 20.0–60.0 kJ/mol [12, 13]. This suggests that the main contributors to the intermolecular interactions between NQ and F2C=CF2 may be van der Waals and weak electrostatic interactions. The small values of ρ BCP(H···F) (0.0047–0.0102 a.u.) and the positive ∇2 ρ BCP(H···F) values (see Fig. S2 of the ESM) support the above conclusion. Therefore, intermolecular H-bonding interactions do not appear to influence the stability of the complex, since no hydrogen bond was present among the nonbonded interactions, meaning that there is no hydrogen bonding in the NQ/polytetrafluoroethylene PBXs—only van der Waals and weak electrostatic interactions. Xu et al. also did not find any H-bonding interactions between a fluoropolymer and ε-CL-20 [23].

Influence of intermolecular interactions on the strength of the trigger bond

As mentioned above, the explosive sensitivity is a multiscale property; studying this property requires investigations at the molecular, crystal, particle, and block scales. At the molecular level, the rupture of the trigger bond is a key step in the initiation of detonation. The stronger the trigger bond, the more difficult it is to break, and thus the lower the sensitivity. Therefore, at the molecular level, the sensitivity of nitroguanidine can be assumed to depend upon the strength of the trigger bond.

The first step in the decomposition of the more stable form of NQ, β-NQ, is not immediately apparent: it could be C–NNO2 bond scission, N–NO2 bond cleavage, or dehydrogenation of the NH2 group. Bond strength data computed at the level of the VESCF(BJ)CI semi-empirical MO model by John et al. indicated that the C–NNO2 and N–NO2 bonds are the weakest bonds [48]. Hong et al. proposed that C–NNO2 bond cleavage was not the primary decomposition path, based on data obtained with the MINDO/3 MO theoretical method [49]. Given that β-NQ is more stable than α-NQ, the intramolecular hydrogen-transfer isomerization reaction between the α and β forms also influences the stability (i.e., sensitivity) of NQ. Therefore, Wang et al. carried out an ab initio study of the isomerization reaction between the α and β forms of NQ. The calculated energy barrier for the direct intramolecular hydrogen-transfer isomerization process was only 132.95 kJ/mol [40]. A density functional method (M06-2X) was used to estimate the physical and chemical properties of NQ tautomers in aqueous solution. The results indicated that the difference in Gibbs free energy between the β and α forms was only about 15.00 kJ/mol [39]. The above investigations suggest that the N–H (in the isomerization reaction between the α and β forms), C–NNO2, and N–NO2 bonds are all possible trigger bonds. Therefore, the influence of intermolecular interactions on the bond dissociation energies of the C–NNO2 and N–NO2 bonds as well as the energy barrier to the intramolecular hydrogen-transfer isomerization reaction process from β-NQ to α-NQ were considered at the molecular level.

The C–NNO2 distances (i.e., R C6–N4) in the monomers α-NQ and β-NQ were found to be 1.428 and 1.324 Å at the B3LYP/6–311++G(2df,2p) level, respectively. As can be seen from Fig. S2 of the ESM, in the complexes α-NQ···F2C=CF2 and β-NQ···F2C=CF2, the value of R C6–N4 lies within the ranges 1.426–1.427 Å and 1.325–1.326 Å, respectively, very close to the corresponding values of R C6–N4 in the monomers. The difference between the C–NNO2 bond length in the complex and that in the isolated NQ is very small for both α-NQ and β-NQ: no more than 0.002 Å. At both levels of theory, the BDE of the C–NNO2 bond in each complex is very close to the BDE for the bond in the corresponding monomer (see Table S2 of the ESM). For example, at the M06-2X/6–311++G(2df,2p) level, the BDEs in the monomers α-NQ and β-NQ are −439.7 and −552.6 kJ/mol, respectively, and those in the complexes of α-NQ and β-NQ with F2C=CF2 range from −438.5 to −442.5 kJ/mol and from −552.9 to −554.8 kJ/mol, respectively. AIM analysis indicates that ρ BCP(C6–N4) is 0.2823 and 0.3655 a.u. in the α-NQ and β-NQ monomers, respectively, while the values for their corresponding complexes are 0.2818–0.2832 a.u. and 0.3657–0.3678 a.u., respectively. Therefore, the differences between the monomers and their corresponding complexes in terms of C–NNO2 bond length, BDE of the C–NNO2 bond, and AIM results are very slight, indicating that the strength of the C–NNO2 trigger bond is almost unaffected when F2C=CF2 is added.

Similar to the C–NNO2 trigger bond, the strength of the N–NO2 trigger bond is almost unaffected by the formation of the complex of NQ with F2C=CF2. The N–NO2 distances (i.e., R N1–N4) in the monomers α-NQ and β-NQ are 1.383 and 1.375 Å at the B3LYP/6–311++G(2df,2p) level, respectively. As can be seen from Fig. S2 of the ESM, although the N–NO2 distances in the complexes are shorter than those in the corresponding monomer (except for the complexes α-D and β-F), the differences are very slight—no more than 0.003 Å. For α-D and β-F, the differences are 0.005 and 0.008 Å, respectively. At both levels of theory, the BDE of the N–NO2 bond in each complex is close to the BDE calculated for this bond in the corresponding isolated NQ (see Table S3 of the ESM). For example, at the B3LYP/6–311++G(2df,2p) level, the BDE of the N–NO2 bond in the monomer α-NQ is matched by the BDEs of this bond in the four complexes involving α-NQ; the differences in the BDE of the N–NO2 bond between β-NQ and the complexes of β-NQ with F2C=CF2 are no more than 0.1 kJ/mol. The ρ BCP(N1–N4) results from AIM analysis of the complexes are also close to those obtained for the monomers. The value of ρ BCP(N1–N4) is 0.3485 and 0.3502 a.u. in the α-NQ and β-NQ monomers, respectively. From Fig. S2 of the ESM, the values of ρ BCP(N1–N4) in their corresponding complexes are 0.3483–0.3524 a.u. and 0.3507–0.3535 a.u., respectively. The differences in the bond length, BDE, and AIM results of the N–NO2 trigger bond between the monomers and their complexes are very slight.

The intramolecular hydrogen-transfer isomerization process from β-NQ to α-NQ has been investigated in a number of previous works [40, 48]. In the present work, our main aim was to clarify whether the addition of F2C=CF2 significantly influences this process by considering the reaction pathway, the energy barrier, and the structures of the reactant, product, and transition state. The energetic stability given by the MP2 method is quite close to the actual experimental result [50, 51], so the MP2/6–311++G(d,p) method was used to investigate the intramolecular hydrogen-transfer isomerization process from β-NQ to α-NQ and its complex with F2C=CF2. The results are shown in Fig. 2.

From Fig. 2, regardless of whether the monomers or their complexes are considered, the N7–H5 bond lengthens during the intramolecular hydrogen-transfer isomerization process while the N4–H5 bond becomes shorter. The other bond distances barely change. Thus, the N7–H5 bond is broken and the N4–H5 bond is formed, and the isomerization process or reaction pathway does not change upon the formation of a complex.

If we consider the reactant, product, and transition state, the interatomic distances N7···H5 and N4···H5 are almost unchanged upon the formation of the complex of NQ with F2C=CF2. For example, for the transition state in the intramolecular hydrogen-transfer isomerization process for the monomer (i.e., TS1), the interatomic distances N7···H5 and N4···H5 are 1.336 and 1.320 Å, and they are 1.338 and 1.318 Å in the complex (i.e., TS2), respectively, meaning that the largest change is only 0.002 Å. The bond angle H5–N7–C6 changes from 115.2° to about 66.3° during the process for the monomer, and it changes from 117.9° to about 70.5° during the process for the complex. Furthermore, the energy barrier to the intramolecular hydrogen-transfer isomerization process in the monomer is 172.9 kJ/mol, and it is 169.5 kJ/mol for the isomerization process in the complex—a difference of only 3.4 kJ/mol. Therefore, adding F2C=CF2 has almost no influence on the reaction pathway, energy barrier, and the structures of the reactant, product, and transition state in the intramolecular hydrogen-transfer isomerization process. Note that the distances involved in the intermolecular interactions (i.e., R F14···H) are >3.30 Å, implying that the intermolecular interactions between NQ and F2C=CF2 in the reactant, product, and transition state are very weak.

The electrostatic potential on the 0.001 a.u. molecular surface [52] of F2C=CF2 was computed using the Multiwfn program [53], utilizing the MP2/6–311++G(d,p)-optimized geometry (see Fig. 3). There were found to be strongly positive regions of electrostatic potential above and below the C=C bond region of F2C=CF2, which may be attractive to sites of negative electrostatic potential on the oxygen atom of the –NO2 group of NQ. Therefore, the influence of the intermolecular interaction between the C=C bond of F2C=CF2 and the oxygen atom of the –NO2 group during the intramolecular hydrogen-transfer isomerization process from β-NQ to α-NQ was also investigated. However, although a lot of effort was expended, a new transition state from the new reactant 3 (see Fig. 2) to the complex was not found. The transition state from reactant 3 became the same as that from reactant 2, i.e., TS2. The energy barrier was 4.2 kJ/mol different from that involving the NQ monomer (168.7 kJ/mol for the isomerization process involving reactant 3). Therefore, the intermolecular interaction between the C=C bond and the oxygen atom of the –NO2 group was found to have almost no influence on the isomerization process from β-NQ to α-NQ.

Due to the very weak intermolecular interaction between NQ and F2C=CF2, this interaction may have almost no influence on the strength of the trigger bond and the energy barrier to the intramolecular hydrogen-transfer isomerization process from β-NQ to α-NQ. In other words, the intermolecular interaction barely affects the stability of NQ, and is therefore not the main reason for the changes in the sensitivity and safety of NQ upon complexation. It should be noted that, at the molecular level, the scission of the trigger bond or intramolecular hydrogen-transfer isomerization from β-NQ to α-NQ may not be the only mechanism for initiating detonation. Indeed, there may be many others, such as the solvent effect [39] or H abstraction from the –NH2 group to the O atom of the –NO2 group, resulting in isomerization [48]. Moreover, at the crystal level, the binding energy and mechanical properties of the PBX can influence the stability of the explosive [29, 30, 34, 35], as discussed below.

Investigating β-NQ/polytetrafluoroethylene PBXs at the crystal level

Binding energy

The binding energy can be used to measure the interaction energy between the components in a mixed system. The larger the binding energy, the stronger the interaction between the components is, and the more thermodynamically stable the system becomes, leading to better component compatibility.

The binding energies E b between β-NQ and polytetrafluoroethylene on the (110) and (010) surfaces of β-NQ in PBXs with binder concentrations of 2.80–6.68% are summarized in Table 2. The binding energy at each binder concentration on the (110) surface of β-NQ is close to the corresponding binding energy on the (010) surface of β-NQ; the largest difference is only 58.21 kJ/mol.

From Table 2, the values of the binding energies E b are in the range 456.93–680.58 kJ/mol. These values are not large, so β-NQ and polytetrafluoroethylene are not strongly bound together. At a binder concentration of about 4.2%, the binding energies E b for ε-CL-20-based PBXs with Estane 5703 (polyurethane), GAP (polyazideglyceraether), HTPB (hydroxy-terminated polybutadiene), and PEG (polyethylene glycol) are in the range 618.59–853.09 kJ/mol. The binding energy between ε-CL-20 and F2314 (a copolymer polymerized from vinylidenedifluoride and chlorotrifluoroethylene at a molar ratio of 1:4) is 410.60 kJ/mol [27]. That for ε-CL-20(001)/F2314 at a binder concentration of 9.45% is 748.01 kJ/mol [30]. The weak binding energies between β-NQ and polytetrafluoroethylene indicate poor compatibility. Thus, we can infer that the weak binding energies between NQ and polytetrafluoroethylene binder barely influence the safety of the resulting PBXs, so the binding energy is not the main reason for the change in sensitivity observed upon the formation of PBXs. Note that, as mentioned above, no hydrogen bond was included in the nonbonded interactions between NQ and F2C=CF2; only weak van der Waals and electrostatic interactions. According to Table 2, as the binder concentration increases, the binding energy increases too, and the compatibility of NQ with the binder improves.

Mechanical properties

The mechanical properties of energetic materials are an important consideration from the perspective of the handling and usage of the explosive. In the statistical mechanics of elasticity [54], the material stress and strain tensors are denoted σ and ε, respectively. The generalized Hooke’s law is stated as σ i = C ij ε j , where C ij is the elastic coefficient. Some plastic properties (hardness, tensile strength, and fracture strength) can be related to the elastic modulus [55]. The hardness and the tensile strength, representing the resistance to plastic deformation, are proportional to the shear modulus G. Fracture strength is proportional to the bulk modulus K. The tensile modulus E and Poisson’s ratio γ can be obtained by inserting the values of K and G into the equation E = 2G(1 + γ) = 3K(1 − 2γ). K/G and the Cauchy pressure (C 12 − C 44) can also be employed as criteria for evaluating the ductility or brittleness of a material.

Utilizing MD simulations and the “constant strain” approach [54], the mechanical properties (K, G, C 12 − C 44, γ, E, and K/G) of the above models of β-NQ-based PBXs with different concentrations of a polytetrafluoroethylene binder were obtained at the (110) and (010) surfaces of β-NQ and are collected in Table 3.

From Table 3, at each concentration of binder, the values of all the mechanical properties at the (110) surface of β-NQ are very close to their values at the (010) surface of β-NQ, indicating that the mechanical properties of the β-NQ/polytetrafluoroethylene PBXs do not depend on the β-NQ crystal surface considered. Xiao et al. investigated the mechanical properties of PBXs composed of TATB (1,3,5-triamino-2,4,6-trinitrobenzene) and a fluoropolymer by a MD method. They found that, because the binding energy between fluoropolymer and TATB varied with the TATB crystal surface considered, the mechanical properties of the resulting PBX depended on the TATB crystal surface examined [26]. Note that, as mentioned above, the binding energy between polytetrafluoroethylene and the (110) or (010) surface of β-NQ is very small.

As can be seen in Table 3, there are obvious differences between the mechanical properties of pure β-NQ and those of the β-NQ/polytetrafluoroethylene PBXs. The elastic modulus is the ratio of stress to strain, and it is a measure of material rigidity. The moderate value of the tensile modulus E (4.283 Gpa) of pure β-NQ shows that it possesses moderate rigidity, in accordance with a previous investigation [47]. When β-NQ is coated with polytetrafluoroethylene, regardless of the weight percent of binder, the values of the tensile modulus E, the bulk modulus K, and the shear modulus G all decrease compared to those of β-NQ, showing that the PBXs are more elastic than pure β-NQ, i.e., they are significantly less able to resist deformation than pure β-NQ. According to Zhang et al. [56], the magnitude of a compressive stimulus is closely related to explosive sensitivity. The larger the compressive stimulus, the higher the explosive sensitivity. For the same compressive stimulus, the weaker the ability to resist deformation, the lower the explosive sensitivity. Thus, the explosive sensitivities of the PBXs are low in comparison with that of pure β-NQ. In other words, the nonpolar desensitizing agent polytetrafluoroethylene can effectively buffer against external mechanical stimuli, leading to reduced explosive sensitivity and increased safety, as confirmed by many experimental results. For example, our group found that the initiation capacity of the booster pellet decreased with increasing polytetrafluoroethylene content. When the composition of the main explosive charge was NQ:polytetrafluoroethylene = 51:48 or 43:56, the initiation capacity was 100%. However, when the composition was NQ:polytetrafluoroethylene = 40:59, the initiation capacity decreased to 0% [57,58,59]. Therefore, its mechanical properties are the dominant influence on the stability and explosive sensitivity of β-NQ, and changes in those properties upon the complexation of β-NQ with polytetrafluoroethylene are the main reason for the significant differences in sensitivity and safety between β-NQ and the PBXs. Xiao et al. found that the mechanical properties of an explosive were closely related to its sensitivity [26, 29].

The value of Poisson’s ratio γ increased from 0.327 in pure β-NQ to 0.349–0.357 and 0.340–0.358 at the (110) and (010) surfaces of β-NQ in the PBXs, respectively, indicating that the PBXs are more plastic than pure β-NQ. Although the value of γ rises as the concentration of the binder in the PBX increases from 2.80% to 6.68%, this rise in γ is relatively small, showing that the plasticity of the PBXs barely changes as the binder concentration is increased from 2.80% to 6.68%.

A positive Cauchy pressure (C 12 − C 44) value indicates that the material possesses good ductility, and the larger the Cauchy pressure, the better the ductility. As can be seen from Table 3, the Cauchy pressure for pure β-NQ is moderate (1.002), indicating that the ductility of pure β-NQ is also moderate. When β-NQ is coated with polytetrafluoroethylene, the Cauchy pressure increases (regardless of the amount of binder added), showing that the ductility of PBX improves. As the additive concentration is increased, the Cauchy pressure initially rises but then it decreases. The maximum Cauchy pressure at the (110) and (010) surfaces of β-NQ occurs for the PBX with a binder concentration of 5.17%, showing that this PBX has the best ductility. These results show that although adding the binder can improve the ductility of the explosive, adding excessive concentrations of binder can degrade the ductility of the PBX.

The value of K/G can be used to evaluate the toughness of the PBX, with a large value usually indicating that the material is very tough or ductile [55]. From Table 3, adding the polytetrafluoroethylene binder can increase the K/G value of the β-NQ in comparison with pure β-NQ, meaning that the addition of binder improves the toughness or ductility of the β-NQ-based PBX. As the binder concentration is increased, the K/G value at the (110) surface of β-NQ first increases and then decreases. The maximum K/G value is obtained for the PBX with 3.60% binder, showing that this PBX is the toughest or most ductile. The results show that although adding the binder can improve the toughness or ductility of the explosive, adding excessive concentrations of binder may degrade the ductility, just as seen for the Cauchy pressure. However, we found that the K/G value at the (010) surface of β-NQ always increased with the binder concentration.

To summarize, the mechanical properties of the β-NQ/polytetrafluoroethylene PBXs are markedly different from those of the pure β-NQ crystal: the PBXs are less rigid, less brittle, more elastic and plastic, and—in particular—far more ductile. We can infer that the reason for these excellent mechanical properties of the β-NQ/polytetrafluoroethylene PBXs is that the long molecular chains of the nonpolar desensitizing agent (polytetrafluoroethylene) partially dampen external stimuli, thus protecting the β-NQ from the stimuli to some extent; indeed, the results of other studies support this inference [21,22,23]. Thus, creating β-NQ-based PBXs with polytetrafluoroethylene could buffer the explosive from external mechanical stimuli, leading to reduced explosive sensitivity and increased safety.

Conclusions

In this study, the intermolecular interactions between NQ and F2C=CF2 and the influence of those interactions on the strength of the trigger bond in NQ were investigated at the B3LYP/6–311++G(2df,2p) and M06-2X/6–311++G(2df,2p) levels of theory, and the binding energies and mechanical properties of β-NQ/polytetrafluoroethylene PBXs were studied by molecular dynamics simulation. The results indicate that the intermolecular interactions between NQ and F2C=CF2 are very weak, meaning that they exert almost no influence on the strength of the trigger bond and the energy barrier to the intramolecular hydrogen-transfer isomerization of NQ. In other words, intermolecular interactions do not influence the safety of the PBXs. The binding energy also does not influence the safety of the PBXs. However, the tensile, bulk, and shear moduli of the PBXs are all considerably lower than those of the pure β-NQ crystal, indicating that the PBXs are less rigid, less brittle, and more elastic and plastic. Compared with those for the pure β-NQ crystal, the values of γ, C 12 − C 44, and K/G are all higher for the PBXs, demonstrating their enhanced plasticity and ductility. These β-NQ-based PBXs with polytetrafluoroethylene could therefore buffer the explosive from external mechanical stimuli to some degree, leading to reduced explosive sensitivity and increased safety. This is the main reason for the observed changes in sensitivity and safety upon the complexation of β-NQ with polytetrafluoroethylene. The results obtained in this work should prove useful in attempts to create new and improved PBXs experimentally.

References

Bedrov D, Ayyagari C, Smith GD, Sewell TD, Menikoff R, Zaug JM (2001) Molecular dynamics simulations of HMX crystal polymorphs using a flexible molecule force field. J Comput Aided Mater Des 8:77–85

Duan XH, Wei CX, Liu YG, Pei CH (2010) A molecular dynamics simulation of solvent effects on the crystal morphology of HMX. J Hazard Mater 174:175–180

Thottempudi V, Shreeve JM (2011) Synthesis and promising properties of a new family of high-density energetic salts of 5-nitro-3-trinitromethyl-1H-1,2,4-triazole and 5,5′-bis(trinitromethyl)-3,3′-azo-1H-1,2,4-triazole. J Am Chem Soc 133(49):19982–19992

Bolton O, Simke LR, Pagoria PF, Matzger AJ (2012) High power explosive with good sensitivity: a 2:1 cocrystal of CL-20:HMX. Cryst Growth Des 12(9):4311–4314

Landenberger KB, Bolton O, Matzger AJ (2013) Two isostructural explosive cocrystals with significantly different thermodynamic stabilities. Angew Chem Int Edit 52(25):6468–6471

Ou YX, Liu JQ (2005) High energy density compounds. National Defence and Industry Press, Beijing

Li JS (2010) A quantitative relationship for the shock sensitivities of energetic compounds based on X–NO2 (X = C, N, O) bond dissociation energy. J Hazard Mater 180:768–772

Cao CZ, Gao S (2007) Two dominant factors influencing the impact sensitivities of nitrobenzenes and saturated nitro compounds. J Phys Chem B 111:12399–12402

Zhao J, Cheng XL, He B, Yang XD (2006) Neural networks study on the correlation between impact sensitivity and molecular structures for nitramine explosives. Struct Chem 17:501–507

Song XS, Cheng XL, Yang XD, He B (2006) Relationship between the bond dissociation energies and impact sensitivities of some nitro-explosives. Propell Explos Pyrot 31:306–310

Tan BS, Long XP, Peng RF, Li HB, Jin B, Chu SJ, Dong HS (2010) Two important factors influencing shock sensitivity of nitro compounds: bond dissociation energy of X–NO2 (X = C, N, O) and Mulliken charges of nitro group. J Hazard Mater 183:908–912

Ren F, Cao D, Shi W, Gao H (2016) A theoretical prediction of the relationships between the impact sensitivity and electrostatic potential in strained cyclic explosive and application to H-bonded complex of nitrocyclohydrocarbon. J Mol Model 22:97

Wang BG, Ren FD, Shi WJ (2015) A theoretical investigation into the strength of N-NO2 bonds, ring strain and electrostatic potential upon formation of intermolecular H-bonds between HF and the nitro group in nitrogen heterocyclic rings C(n)H2(n)N-NO2 (n = 2-5), RDX and HMX. J Mol Model 21:302

Zhang L, Ren FD, Cao DL (2013) A comparative theoretical investigation into the strength of the trigger-bond in the Na+, Mg2+ and HF complexes involving the nitro group of R-NO2 (R = −CH3, −NH2 and -OCH3) or the C=C bond of (E)-O2N-CH = CH-NO2. J Mol Model 19:2499–2507

Murray JS, Concha MC, Politzer P (2009) Links between surface electrostatic potentials of energetic molecules, impact sensitivities and C–NO2/N–NO2 bond dissociation energies. Mol Phys 107:89–97

Li BH, Shi WJ, Ren FD (2013) A B3LYP and MP2(full) theoretical investigation into the strength of the C-NO2 bond upon the formation of the intermolecular hydrogen-bonding interaction between HF and the nitro group of nitrotriazole or its methyl derivatives. J Mol Model 19:511–519

Gibbs TR, Popolato A (1980) LASL explosive property data. University of California Press, Berkeley

Dong HS, Zhou FF (1984) High energy explosives and correlative physical properties. Science Press, Beijing

Sun GX (1984) Polymer blended explosives. Defense Industry Press, Beijing

Simpson RL, Urtiew PA, Omellas DL (1997) CL-20 performance exceeds that of HMX and its sensitivity is moderate. Propell Explos Pyrot 22:249–255

Sun GX (1984) Polymer composite explosives. National Defense Industry Press, Beijing

Xiao JJ, Ma XF, Zhu W, Xiao HM (2005) Molecular dynamics simulations of polymer bonded-explosives (PBXs): modelling, elastic properties and their dependence on temperatures and concentrations of binders. In: Proceedings of the Eighth Seminar “New Trends in Research of Energetic Materials,” The University of Pardubice, Pardubice, The Czech Republic, April 19–21. University of Pardubice, Pardubice

Xu XJ, Xiao HM, Xiao JJ, Zhu W, Huang H, Li JS (2006) Molecular dynamics simulations for pure ε-CL-20 and ε-CL-20-based PBXs. J Phys Chem B 110:7203–7207

Xiao JJ, Wang WR, Chen J, Ji GF, Zhu W, Xiao HM (2012) Study on structure, sensitivity and mechanical properties of HMX and HMX-based PBXs with molecular dynamics simulation. Comput Theor Chem 999:21–27

Xiao JJ, Fang GY, Ji GF, Xiao HM (2005) Simulation investigations in the binding energy and mechanical properties of HMX-based polymer-bonded explosives. Chin Sci Bull 50:21–26

Xiao JJ, Huang YC, Hu YJ, Xiao HM (2005) Molecular dynamics simulation of mechanical properties of TATB/fluorine-polymer PBXs along different surfaces. Sci China Ser B-Chem 48:504–510

Xu XJ, Xiao JJ, Huang H, Li JS, Xiao HM (2007) Molecular dynamics simulations on the structures and properties of ε-CL-20-based PBXs—primary theoretical studies on HEDM formulation design. Sci China Ser B Chem 50:737–745

Li JS, Xiao HM, Dong HS (2000) Quantum chemistry study on PBX—molecular interaction of TATB with methane and polyethylene. Explos Shock Waves 20(3):221–227

Xiao HM, Li JS, Dong HS (2001) A quantum-chemical study of PBX: intermolecular interactions of TATB with CH2F2 and with linear fluorine-containing polymers. J Phys Organ Chem 14:644–649

Xu XJ, Xiao JJ, Huang H, Li JS, Xiao HM (2010) Molecular dynamic simulations on the structures and properties of ε-CL-20 (0 0 1)/F2314 PBX. J Hazard Mater 175:423–428

Zhu W, Xiao JJ, Zhu WH, Xiao HM (2009) Molecular dynamics simulations of RDX and RDX-based plastic-bonded explosives. J Hazard Mater 164:1082–1088

Zhu W, Wang XJ, Xiao JJ, Zhu WH, Sun H, Xiao HM (2009) Molecular dynamics simulations of AP/HMX composite with a modified force field. J Hazard Mater 167:810–816

Yu YC, Zhu W, Xiao JJ, Guo X, Tang G, Zheng J, Xiao HM (2010) Molecular dynamics simulation of binding energies and mechanical properties of energetic systems with four components. Acta Chim Sin 68:1181–1187

Xiao JJ, Ma XF, Huang YC, Zhu W, Xiao HM (2004) Molecular dynamics simulation of mechanical properties of TATB/fluorine-polymers PBX. Chin J Energy Mater 12:488–492

Xiao JJ, Huang H, Li JS, Zhang H, Zhu W, Xiao HM (2007) MD simulation study on the mechanical properties of HMX crystals and HMX/F2311 PBXs. Acta Chim Sin 65:1746–1750

Murmann RK, Glaser R, Barnes C (2005) Structures of nitroso and nitroguanidine X-ray crystallography and computational analysis. J Chem Crystallogr 35(4):317–325

Choi C (1981) Refinement of 2-nitroguanidine by neutron powder diffraction. Acta Crystallogr B 37(10):1955–1957

Kumler WD, Sah PPT (1953) The structure of nitroguanidine and nitroaminoguanidine. J Org Chem 18(6):669–675

Anastasiia G, Leonid G, Andrea MS, Frances CH, Deborah F, Steven L, John B, Jerzy L (2015) Computational study of nitroguanidine (NQ) tautomeric properties in aqueous solution. Struct Chem 26:1273–1280

Wang W, Ren F, Bi Y, Wang W (2005) Ab initio study on the isomerization reaction of nitroguanidine. Chin J Chem Phys 18:765–770

Boys SF, Bernardi F (1970) The calculation of small molecular interactions by the differences of separate total energies. Some procedures with reduced errors. Mol Phys 19:553–566

Bader RFW (1990) Atoms in molecules, a quantum theory. Oxford University Press, Oxford

König BFW, Bader RFW, Tang TH (1982) Calculation of the average properties of atoms in molecules. II. J Comput Chem 3:317–328

Frisch MJ, Trucks GW, Schlegel HB, Scuseria GE, Robb MA, Cheeseman JR, Scalmani G, Barone V, Mennucci B, Petersson GA, Nakatsuji H, Caricato M, Li X, Hratchian HP, Izmaylov AF, Bloino J, Zheng G, Sonnenberg JL, Hada M, Ehara M, Toyota K, Fukuda R, Hasegawa J, Ishida M, Nakajima T, Honda Y, Kitao O, Nakai H, Vreven T, Montgomery Jr JA, Peralta JE, Ogliaro F, Bearpark M, Heyd JJ, Brothers E, Kudin KN, Staroverov VN, Kobayashi R, Normand J, Raghavachari K, Rendell A, Burant JC, Iyengar SS, Tomasi J, Cossi M, Rega N, Millam JM, Klene M, Knox JE, Cross JB, Bakken V, Adamo C, Jaramillo J, Gomperts R, Stratmann RE, Yazyev O, Austin AJ, Cammi R, Pomelli C, Ochterski JW, Martin RL, Morokuma K, Zakrzewski VG, Voth GA, Salvador P, Dannenberg JJ, Dapprich S, Daniels AD, Farkas O, Foresman JB, Ortiz JV, Cioslowski J, Fox DJ (2009) Gaussian 09. Gaussian Inc., Wallingford

Accelrys Software Inc. (2013) Materials Studio 7.0. Accelrys Software Inc., San Diego,

Bryden JH, Burkardt LA, Hughes EW, Donohue J (1956) The crystal structure of nitroguanidine. Acta Crystallogr 9:573–578

Keshavarz MH (2007) Theoretical prediction of detonation pressure of CHNO high energy materials. Indian J Eng Mater Sci 14:77–80

John S, Maxwell GP (1975) Electronic ground state structure and chemistry of nitroguanidine. Aust J Chem 28:2629–2640

Hong S, Fu X (1991) A quantum chemical study on the mechanism of thermolysis of nitroguanidine. Acta Phys Chim Sin 7:30–35

Macias AT, Norton JE, Evanseck JD (2003) Impact of multiple cation–π interactions upon calix[4]arene substrate binding and specificity. J Am Chem Soc 125:2351–2360

Ruan C, Yang Z, Hallowita N, Rodgers MT (2005) Cation–π interactions with a model for the side chain of tryptophan: structures and absolute binding energies of alkali metal cation–indole complexes. J Phys Chem A 109:11539–11550

Murray JS, Lane P, Politzer P (1995) Relationships between impact sensitivities and molecular surface electrostatic potentials of nitroaromatic and nitroheterocyclic molecules. Mol Phys 85:1–8

Lu T (2014) Multiwfn: a multifunctional wavefunction analyzer, version 3.3.5. Beijing Kein Research Center for Natural Sciences, Beijing

Weiner JH (1983) Statistical mechanics of elasticity. Wiley, New York

Pugh SF (1954) XCII. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos Mag 45(367):823–843

Zhang CY (2007) Computational investigation on the desensitizing mechanism of graphite in explosives versus mechanical stimuli: compression and glide. J Phys Chem B 111:6208–6213

Hu L, Hu S, Cao X (2012) Study on the initiation capacities of two booster pellets. Cent Eur J Energ Mat 9(3):261–272

Hu L, Hu S, Cao X (2014) Initiation capacity of a new booster pellet. Cent Eur J Energ Mat 11(1):157–170

Hu L, Hu S, Cao X, Zhang J (2014) Initiation capacity of a specially shaped booster pellet and numerical simulation of its initiation process. J Energ Mater 32:27–36

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical statement

We have full control of all primary data and the journal was allowed to review all the data. This work was not submitted to more than one journal, and it was not published previously. This manuscript has not been split into several parts to increase the number of papers submitted. None of the data included in this paper were copied from other papers.

Electronic supplementary material

ESM 1

(DOC 1259 kb)

Rights and permissions

About this article

Cite this article

Xue, Zq., He, J., Zhang, J. et al. Theoretical investigation of the safety of nitroguanidine-based PBXs containing the nonpolar desensitizing agent polytetrafluoroethylene. J Mol Model 23, 346 (2017). https://doi.org/10.1007/s00894-017-3519-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00894-017-3519-1