Abstract

Polypropylene (PP) film activated by corona discharge treatment was grafted with methyl methacrylate (MMA) and acrylic acid (AA). The grafted PP was characterized by spectral, thermal analysis and swelling behavior which confirmed the occurrence of the grafting. The water vapor and oxygen permeability (OTR and WVTR) as well as the mechanical properties have been enhanced by grafting with both AA and MMA. The grafted PP was further immobilized with chitosan (CS) using ceric ammonium nitrate (CAN) as an initiator under ultraviolet radiation. The chitosan immobilized grafted film was characterized by FTIR, mechanical properties, thermal properties and swelling measurements. Scanning electron microscope (SEM) confirmed that the CS is bonded to the grafted PP film. The CS modified PP film has acquired enhanced antibacterial and antifungal properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polypropylene (PP) films are widely used in food packaging industry because of its low cost, good mechanical and thermal properties, and chemical stability that makes it a star among the polyolefin resins. PP has a slippery surface which makes it difficult to bond to other surfaces. To overcome this problem, some techniques have been adapted, like Corona, UV irradiation [1], flame, plasma photons [2], electron beams, ion beams, X-rays and γ-rays’ treatment which create active sites and improve the surface properties of the PP. Another approach is grafting with another monomer (polymer) containing functional groups which can offer a vast opportunity for further modification of the PP surface [3]. Graft-polymerization of polyethylene glycol acrylate (PEGA) on polypropylene (PP) films was conducted in order to obtain surfaces with a reduced protein adsorption for possible biomedical applications [4]. By applying gamma irradiation, PP film was grafted by a mixture of monomers, for example N-vinylpyrrolidone, acrylamide and their mixtures [5]. The obtained membranes can be used for the removal of heavy metals from solution.

Polypropylene (PP) films were grafted with N-p-hydroxyphenylmaleinide using γ-radiation. The effect of both monomer concentration and dose rate on the degree of grafting was measured [3]. To overcome disadvantage of polypropylene induced by its low surface energy, poly(methyl methacrylate) was grafted onto polypropylene and entrapped into polypropylene as macromolecular surface modifier. The effects of copolymer structures, were studied by attenuated total reflection infrared spectroscopy (ATR-FTIR), contact angle measurements (CDA) and scanning electron microscopy (SEM) [4]. PP modified by grafting monomer, Pentaerythritol tetra-acrylate (PETeA) a polyfunctional monomer was grafted onto PP in a Haake mixer at 180 °C in the presence of 2,5-dimethyl-2,5-di(tert-butylperoxy) hexane peroxide (DDHP) to enhance the melt strength and suppress formation of β crystal and α-β transition [5].

Several set of monomer mixtures were grafted onto PP using gamma radiation; Vinylimidazole (VI) and acrylic acid (AA) monomer mixture[6], acrylic acid (AAc) and styrene (S) [7], N, N′-dimethyl acrylamide (DMAAm) and N-isopropyl acrylamide (NIPAAm) (two-step method)] [8], and N-isopropyl acrylamide and acrylic acid [9]. A mixture of acrylic acid (AA) and 2-acrylamido-2-methyl-1-propanesulfonic acid (AMPS) was grafted onto PP by two-steps electron beam irradiation for filtration of cigarette smoke [10]. PP fibers grafted with 2-(dimethyamino)ethyl mathacrylate (DMAEMA) by UV- irradiation has been used for removal of Cr(VI) and as(V) [11].

Most of these grafting trials were undertaken to provide effective interfacial agents that improve the compatibility of polyolefin with other materials [12]. In order to render more suitable PP films to be used in the packaging applications, a composite of PP with a series of plasticized polysaccharide has been prepared by simple casting method. High glossy surfaces were observed on the coated films with chitosan and κ-carrageenan, with the sucrose-plasticized chitosan coating giving the highest gloss [13]. The results suggest that coatings based on chitosan and κ-carrageenan with proper plasticizers possess excellent visual and mechanical characteristics and have great potential for acting efficiently as antimicrobial agent carriers in active packaging systems [13], however, no data were given in this direction. The water vapor and oxygen-barrier characteristic of PP have been improved when a novel corn–zein coating structure on polypropylene (PP) films was applied [14]. Water vapor permeability (WVP) of the coated films decreased significantly with increasing corn-zein concentration [14]. Antimicrobial active films based on PP was made by melt blending followed by compression molding of carvacrol and thymol on the PP films [15]. The antimicrobial activity of the films was evaluated against two food borne pathogens.

Antimicrobial films were obtained after plasma treatment of PP films in the presence of N2, NH3, and CO2 + N2 to create amino and carboxyl groups which were then used to attach the antimicrobial enzyme, glucose oxidase by covalent bonds [16]. Immobilization was carried out with glutaraldehyde at temperatures of 4-75 °C and pH 5.6–7.2. This treatment produced enzymatically active films which inhibited the growth of Escherichia coli and Bacillus subtilis. The authors suggested that such films could have antimicrobial packaging applications.

Polypropylene nonwoven fabric has been graft modified with N-isopropyl acrylamide and acrylamide by radiation to be used as a drug releasing matrix. The drug release was found to increase with increasing the grafting percent. The resulting grafted membranes exhibited temperature-triggered drug release behavior, and have potential for use as drug carriers [17].

The quality of food product depends on organoleptic, nutritional, and hygienic characteristics, but these properties may suffer many changes during storage and commercialization [18, 19]. Such changes are mainly due to exchanges between foods and the surrounding media, or migrations between the different components in a composite food. Many physical and chemical processes, such as sterilization, high pressure, radiations or actives agents, were developed to preserve food quality [20]. However, the use of a performing package is necessary for the ultimate step of the preservation process. Therefore, the packaging is preponderant for the conservation of food quality. The performance of synthetic packaging materials is appraised by their efficiency to reduce mass transfers between food and storage medium, that is, by the determination of their permeability [21].

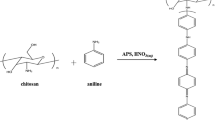

In order to achieve a suitable and dependable packaging material, PP was chosen due to its versatile mechanical properties and stability, however, it lacks antimicrobial capacity which highly desirable for such purpose. As it is well documented, chitosan is a partially deacetylated polymer of acetyl glucosamine obtained after alkaline deacetylation of chitin [22]. It displays interesting properties such as biodegradability biocompatibility and its degradation products are non-toxic, non-carcinogenic and non-immunogenic [23,24,25] besides having antimicrobial properties which are required for food preservation [26, 27].

Microbial contamination of ready-to-eat products such as refrigerated meats and intermediate moisture foods is a serious concern to human health [28, 29]. A traditional method used to control the growth of microorganism has been the application of antimicrobial dips or sprays on the surface of products. However this have had limited success because the antimicrobial substances may interact with food components by evaporating or diffusing into the bulk food [30]. One new approach to overcome these limitations could be the use of antimicrobial packaging technique [31], or the application of antimicrobial edible coating [32].

Recent food-borne microbial outbreaks are driving the search for innovative ways to inhibit microbial growth in the foods while maintaining quality, freshness, and safety. One option is to use packaging to provide an increased margin of safety and quality. The next generation of food packaging may include materials with antimicrobial properties. These packaging technologies could play a role in extending shelf-life of foods and reduce the risk from pathogens [33].

The combination of both chitosan attractive properties and graft copolymers properties for surface modification of polypropylene films is a promising way for food preserving packaging which is mainly the aim of the present work.

Herein, polypropylene films were graft copolymerized with acrylic acid and methyl methacrylate using benzoyl peroxide. The grafted PP films were characterized in term of their surface, thermal and mechanical properties. The grafted films were further treated with chitosan solution under UV irradiation using ceric ammonium nitrate. In this way, a chemical bond between the PP surface and chitosan will be formed thus making the chitosan attachment stronger than mere electrostatic attachment. The antimicrobial activity of these modified PP films was investigated against different bacterial and fungal species.

Experimental

Materials

A polypropylene film (40 μm thickness) commercial grade of (melt flow index (MFI) = 3.2 g/10 min; ρ = 0.905 g/cm3) was cut into small stripes of size (25 × 25 mm2) and then washed with distilled water followed by extraction in Soxhlet using acetone as a solvent for about 16 h and dried in vacuum oven at 60 °C. Methylmethacrylate (MMA) with purity 99% was purchased from Acros Organics, Geel, Belgium. Acrylic acid (AA) was supplied by research lab India. MMA and AA were distilled under reduced pressure before use. Benzoyl peroxide (Merck, Germany) was purified by recrystallization in methanol. Chitosan was prepared by alkaline deacetylation of chitin which was extracted from shrimp [34]. It has molecular weight 17,875 and the deacetylation degree is 77.25%.

Graft polymerization

The grafting polymerization processes on the PP film was carried out according to the method described previously [35]. The PP film (about 0.24 g) was put into a solution containing methyl methacrylate and deionized water (10%, v/v), followed by ferrous sulfate (1.0 × 10−3 M) as an inhibitor, sulphuric acid (H2SO4, 0.1 M) and initiator BPO (0.5 mol% of MMA). The reaction mixture was purged by freshly nitrogen gas for 15 min and then immersed in water bath at 65 °C for 2 h. After grafting reactions, the samples were washed with distilled water, acetone in Soxhlet for 6 h to remove the produced homopolymers.

The grafting of AA onto PP film was carried out by immersing PP film in a solution of acrylic acid (0.5 mol) in toluene (10%, v/v) and benzoyl peroxide and then purged by nitrogen gas for 5 min. The reaction mixture was heated in water bath at 95 °C for 2 h. Then, the acrylic acid grafted polypropylene film was removed from the flask and washed with distilled water and extracted in a Soxhlet using acetone as a solvent for 24 h to remove PAA homopolymer.

The degree of the grafting of the modified PP film was determined by the following equation:

where Wg and W0 are the weights of the grafted and PP film, respectively.

Chitosan immobilization on modified PP films

The PP grafted PMMA (PP-g-PMM) and PP grafted PAA (PP-g-PAA) film was attached with chitosan according to the method described before [36]. A solution of 2.0% chitosan in 5.0% acetic acid mixed with 0.1 M ceric ammonium nitrate (CAN) dissolved in nitric acid were stirred, added onto PP-g-PMMA as well as PP-g-PAA film and then irradiated with UV (λ= 254 nm) at 60 °C for 35 min. After irradiation, the film was taken out from the reaction vessel and washed at least 3 times with distilled water many times to remove the residual chitosan. The amount of chitosan was determined gravimetrically and the value was 2.2% and 3.8% for the MMA and the AA graft, respectively.

Measurements

IR measurements were performed using IR-Affinity SHIMADZU spectrophotometer in the range 500–4000 cm−1.

Thermogravimetric analysis (TGA) was measured using SDT Q600 V20.9 (United States of America) Build 20 instrument from room temperature to 550 °C at a heating rate 10 °C/min under nitrogen atmosphere.

Stress-strain curves of the samples of modified films were measured using a Zwick Tensile Testing machine 1999/GmbH +G (Germany) according to ASTM D882–90 [37]. The reported values are the average of five measurements.

The surface morphology of chitosan on PP-g-PMMA and PP-g-PAA was studied with FE- SEM, QUANTA FEG 250 microscope. The sample surface was coated with gold to avoid charging under an electron beam then fixed on a plate holder with a silver paste after that investigated using back scattered electron to detect the image of the surface with high resolution accelerated voltage 20 KV.

Swelling properties

The swelling behaviors of PP grafted films and chitosan on PP grafted films were studied as a function of time in the distilled water at 25 °C according to [38].

Permeability behavior of oxygen and water vapor

Oxygen and water vapor transmission rates through the film samples were determined by a Systech Illinois – 7000 (United Kingdom) Tester according to Testing was performed at 38 °C in a dry environment (0% RH) for the determination of oxygen transmission rate and 100% relative humidity for the determination of water vapor transmission rate.

Pathogenic microorganisms and culture conditions

All strains of fungi and bacteria used in this study were obtained from the Northern Regional Research laboratory (NARRL) and American Type Culture Collection (ATCC) and maintained as pure culture. The Fungi Fusarium oxysporum SCHL f. sp. Lycopersici (SACC.) Snyder Hansen ATCC 64987), causing Fusarium wilt [38] and Fusarium solani (MART.) SACC. were isolated from diseased roots of sugar beet plants [39]. Verticillium albo-atrum Reinke and BerthoLd (NARRL 1204), causing Verticillum wilt were maintained on Sarcina agar. Alternaria alternate (ELL. And MART.) Jones and Grout (NARRL 2168), causing early bright, was maintained on Czapek-Dox agar. Cladosporium herbarum and Fusarium moniliforme were maintained on Czapek-Dox agar. The rest of the tested fungal strains, Aspergillus niger, A. flavus, A. terreus, A. ochraceus and A. sydowii, were provided from the “National Center of Fungi” at Botany Department, Faculty of Science, Assuit University, Egypt, and were maintained on potato dextrose agar medium (PDA).

The pathogenic bacteria Clavibacter michiganensis ssp. Michiganensis (E.F. Smith) (NARRL B-33), causing bacterial canker and Pseudomonas solanacearum (E.F. Smith) (NARRL B-3312), causing bacterial wilt, was maintained on nutrient agar. The bacteria Escherichia coli and Staphylocccus aureus were maintained on nutrient agar.

Bioassay for antifungal activity

The susceptibilities of the test fungal spores of Fusarium oxysporum, F. solani, F. monilforme, Verticillium albo-otrum, Alternaria alternate, Cladosporium herbarum, Aspergillus niger, A. flavus, A. terreus and A. ochraceus as seeded in Dox’s medium on sterilized discs (2 mm) of different kind of films (PP-g-MMA/CS and PP-g-AA/CS), were determined according to the method proposed by Olurinola et al. [40]. The sterilized membrane discs were placed on the surface of the seeded Dox medium in triplicates. Then, the plates were incubated at 28 ± 1 °C for 96 h, after which the susceptibility of each fungal organism to each film was estimated by measuring the diameter of the inhibition zones.

Antibacterial activity

The antibacterial activity of the films (PP-g-MMA/CS and PP-g-AA/CS) was determined using the agar diffusion method, according to Pellissari et al. [41]. The films were aseptically cut into 2-mm discs and placed on Muller Hinton agar plates which had been previously spread with 0.1 ml of inoculum, each, containing 105–106 CFU/ml of bacterial culture previously standardized using the McFarLand scale. The plates were incubated at 37 ± 1 °C for 48 h. The diameter of the growth inhibition zones around the discs was measured using a digital caliper (VWR, USA). The growth under the film discs (area of contact with the agar surface) was visually examined. The measurements were made in triplicate for each film.

Statistics

All measurements are the mean of three replicates; the results obtained were processed by analysis of variance and the significance was determined at the least significant difference (LSD) Levels of 1% and 5% [42].

Results and discussion

Characterization of graft polymerization

Grafting percentage depends upon different number of reaction parameters such as monomer concentration, initiator concentration, reaction temperature, and reaction time. Since the purpose of this study was to promote the immobilization of chitosan onto modified PP film via grafting technique, several experiments were carried out by changing monomer concentration to obtain reasonable and comparable amounts of PMMA and PAA grafted chains onto PP without altering the transparency, gloss and shape of PP films. Figures 1 and 2 display the effect of MMA and AA concentrations on the percentage of grafting onto PP film, respectively. It can be seen that the grafting percentage of MMA increases initially with increasing monomer concentration giving maximum percentage around 43.4% at a monomer concentration of 1.5 M and then decreases on further increasing the concentration of MMA may be due to preferential homo- over graft copolymerization another possibility is increased chain transfer to the polymer chains and to increasing of the viscosity of the medium which lowered chain movements rendering grafting less likely than homo-polymerization [3, 43].

For grafting of AA onto PP, the grafting percentage increases gradually with increasing the concentration of AA. Here two grafted PP films with 20% PMMA and 28.7% AA were chosen for the study because the transparency, gloss and sh3ape of PP films did not change at this monomer concentration.

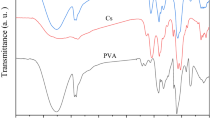

FTIR

The FTIR spectra of PP, PP-g-PMMA and PP-g-PAA are shown in Fig. 3. The corona treated PP films shows characteristic peaks due to the formation of several peroxy, carboxylic and carbonyl groups as a result of the interaction of corona with atmospheric oxygen. The IR spectrum of the PP-g-PMMA shows a characteristic peak at 1712 cm−1 which is due to CO stretching of the PMMA, and another peak appeared at 1150–1250 cm−1 due to the C–O–C stretching vibration. Furthermore, there are two weak absorption bands at 3437 cm−1 and 1636 cm−1, which can be attributed to the –OH stretching and bending vibrations, respectively, of the adsorbed water. The IR spectrum of PP-g-PAA reveals the presence of a broad band from 3000 to 3600 cm−1 due to OH stretching, and bands at 1712 cm−1 and 1249 cm−1 due to C=O and C–O stretching vibrations, respectively. The peak at 1172 cm−1 refers to the existence of C–C asymmetric stretching which is present in the original polypropylene at 1165 cm−1.

TGA

Figure 4 shows the TGA trace of PP, PP-g-PMMA and PP-g-PAA films. As can be seen, a considerable change in the thermal behavior of PP has occurred upon grafting. In the case of PP-g-PMMA, the thermal degradation occurs via two steps and the onset degradation temperature shifts to lower temperature by about 160 °C compared to the virgin PP. The first step occurs in the range of 100-320 °C with a maximum decomposition at 315 °C (~ 19.8%. weight loss) which is ascribed to the degradation of PMMA chains grafted on PP. The other in the range 310-480 °C is ascribed to the degradation of PP. In the case of PP-g-PAA, the onset degradation temperature is lowered by 230 °C compared to virgin PP and two distinct stages of thermal degradation are observed. The first ranges between 100 and 380 °C (~ 27.9% weight loss) with a maximum at 296 °C corresponds to the thermal degradation of PAA grafted chains. The second stage of degradation takes place in the range 410 to 505 °C with a maximum at 451 °C due to degradation of PP. The weight loss in the range 32–120 °C, which is related to the elimination of water adsorbed to the polymer films, becomes more pronounced in the case of PP-g-AA sample due to the hydrophilic character of PAA grafted chains.

Swelling behavior

Figure 5 shows the swelling behavior of PP and the grafted film, the greater extent of swelling of the grafted film compared with that of PP may be due to the hydrophilic character of PAA and PMMA grafted chains. Generally, the existence of hydrophilic moieties such as carboxylic and hydroxyl groups tends to increase the hydrophilicity of the polymeric material and consequently increases its swelling capacity.

Mechanical properties

Grafting of PP film may cause some deterioration of the polymer therefore care must be taken to ensure that the mechanical properties of the PP copolymers did not suffer after such treatment. The tensile strength, elongation and Young’s modulus for virgin PP, PP-g-PMMA and PP-g-PAA films are depicted in Table 1. The results show that the mechanical properties of the films have on the contrary increased after the treatment. Such behavior could potentially be due to the formation of a crosslinked membrane of the grafted polymer on the surface which will increase the tensile strength no doubt. In the next section it will be shown that the gas and water vapor permeability are both drastically decreased after grafting which could safely support a network structure of the graft polymer on the surface, reducing thus the pores.

These data indicate that these grafted copolymers can be used for the fabrication of useful packaging materials with commercial applications.

Permeability properties of different gases (oxygen and water vapor)

Oxygen permeability

The oxygen barrier property of a food packaging container for the fresh product (e.g., fruits, salad, and ready-to-eat meals) plays an important role in its preservation [44].The oxygen transmission rate (OTR) value of virgin PP film (928.2cm3/m2/day) should not exceed 1100 cm3/m2/day according to [45]. The mean oxygen permeability of PP-g-PMMA and PP-g-PAA were found to be 410.6cm3/m2/day and 22.2cm3/m2/day, respectively as shown in Fig. 6. These values illustrate a great improvement of the barrier properties after grafting. This important result is further indication of the validity of this grafting technique of PP for packaging applications.

Water vapor permeability

The water vapor barrier properties of the packaged food product are of great importance for maintaining or extending its shelf-life since the physical and chemical deteriorations of the food stuff are related to the equilibrium moisture content [44]. For fresh food, it is important to avoid dehydration while for bakery or delicatessen it is important to avoid water permeation. The water vapor transmission rate (WVTR) of virgin PP, PP-g-PMMA and PP-g-PAA are displayed in Fig. 7. WVTR is expressed in (g/m2/day). The WVTR value of virgin PP film is found to be 3.7 g/m2/day which lies below the maximum acceptable value of 4.1 g/m2/day according to [46]. The WVTR values of PP-g-PMMA (0.345 g/m2/day) and PP-g-AA (0.320 g/m2/day) are lower than that of virgin PP, indicating that grafting of the surface of PP provides a dramatic improvement of the barrier properties. This decreasing behavior of oxygen and water vapor permeability may be due to a decrease in the porous microstructure caused by grafting.

Properties of the PP grafted films with attached chitosan

FTIR

The FTIR spectra of PP-g-PMMA/CS and PP-g-PAA/CS are shown in Fig. 8. In the IR spectrum of the PP-g-PMMA/CS, a characteristic peak of the amide II (N-H deformation in plane) at 1600 cm−1is due to the remaining acetamide groups in the chitosan. The broad peak appeared in the range of 3100–3600 cm−1 is due to the O-H and N-H stretching. The absorption peak appearing at 1736 cm−1is assigned to the carbonyl absorption of the methacrylate groups.

The IR spectrum of PP-g-PAA/CS shows characteristics peaks at 1652 cm−1 for amide I and 1545 cm−1 for amide II which is sufficient indication of chitosan immobilization on the grafted film. A loss of carboxyl group is due to the formation of amide bond. The IR data provide therefore evidence for the attachment of CS with the PP grafted surface.

Thermal properties behavior (TGA)

The TGA thermograms of PP grafted films with chitosan attachment are shown in Fig. 9. As can be seen the thermogram of the grafted PP films with and without chitosan exhibit the same profile. The loss peak due to the elimination of adsorbed water (100-200 °C) becomes more significant in the case of PP grafted films attached with chitosan due to the increased hydrophilicity of the polymer. There is a slight lowering in the thermal stability of the grafted polymers after the attachment of chitosan.

Mechanical properties

The tensile strength, elongation and Young’s modulus for PP-g-PMMA/CS and PP-g-PAA/CS films (Wet and dry state) are depicted in Table 2. As can be seen from Table 2, the wet samples have lower mechanical values compared with the corresponding dry samples. From Tables 1 and 2 the attachment of chitosan to the grafted films leads to slight decrease in the mechanical parameters.

Scanning electron microscope (SEM)

The scanning electron micrographs of virgin PP, PP-g-PMMA and PP-g-PAA/CS are shown in Fig. 10. By comparing the surface morphology of the grafted PP (Fig. 10b, c) with the virgin PP (Fig. 10a), it can be seen that the grafted chains with and without chitosan drastically change the morphology of the surface of PP. As shown in the figure, the surface of the grafted PP has more spongy structure than that of virgin PP. On the other hand, the inactivated side of films appears smooth, indicating that the grafting and immobilization of chitosan occur on the activated surface.

Swelling behavior

The dependency of swelling capacity in distilled water was studied and the results were represented in Fig. 11. As seen in the figure, swelling % increases with increase in time, after that tends to equilibrium. The greater extent of swelling of PP-g-PAA/chitosan compared with that of PP-g-PMMA may be more likely due to the hydrophilic character of PAA grafted chains. Generally, the existence of hydrophilic moieties such as carboxylic and hydroxyl groups tends to increase the hydrophilicity of a polymeric material and consequently increases its swelling values. By comparing the result of Fig. 5 to that of Fig. 11, one can see an increase in the swelling extent of chitosan attached polymers which confirm the immobilization of chitosan on the grafted films. The hydrophilic nature of chitosan may explain such increase in swelling trends.

Antimicrobial activity

The antimicrobial activity of virgin PP, PP-g-PMMA and PP-g-PAA films without and with chitosan as biocide was evaluated against the growth of different bacterial and fungal species.

From Table 3, one can see that the virgin polymer film did not show any bactericidal property. The polypropylene grafted with PMMA showed a very little antibacterial behavior. On the other hand, the PP/PAA graft film showed a considerable antibacterial activity. Immobilization of chitosan onto PP-g-PMMA (20% grafting percentage and 2.2% chitosan ratio) showed a pronounced increase in the inhibition zone of all tested bacterial species. The chitosan immobilized PP-g-PAA film (28.7% grafting percentage and 3.8% chitosan ratio) shows the best bactericidal behavior, with dramatic enhancement of bactericidal activity over samples without CS attachment. Figure 12 shows the antifungal efficacy of the PP films; PP-g-PMMA; PP-g-PAA; PP-g-PMMA/CS and PP-g-PAA/CS. The film of PP-g-PAA/CS has the largest inhibition zone indicating highest antifungal efficacy.

Mean values of the diameter of the inhibition zone in mm.

As expected, the PP grafted films associated with chitosan have better antibacterial activity than that of PP grafted films. In addition, PP-g-PAA/CS films are more reactive compared with that of PP-g-PMMA/CS films at the same time of incubation. The antimicrobial properties of chitosan due to its positively charged of the amino group which interacts with the negatively charged microbial cell membranes, lead to the leakage of proteinaceous and other intracellular constituents of the microorganisms [47]. Thus, the presence of molecular PAA grafted chains with hydrophilic groups (carboxylic groups) and chitosan enhances the antimicrobial activity.

Conclusions

In the present work, a trial has been taken to enhance the mechanical and the barrier properties (OTR and WVTR) of the polypropylene films by grafting with AA and MMA using corona discharge and benzoyl peroxide followed by immobilization with chitosan onto the surface of PP films. The modified films showed excellent antimicrobial properties. The microbicide effect was found to depend on the sensitivity of the microorganism, the chitosan concentration as well as on the type of grafted polymer. These modified PP films may be used as innovative antimicrobial packaging materials for preserving food stuff.

References

Fasce LA, Costamagna V, Pettarin V, Strumia M, Frontini PM (2008) Poly (acrylic acid) surface grafted polypropylene films: Near surface and bulk mechanical response. Express Polym Lett 2(11):779–790. https://doi.org/10.3144/expresspolymlett.2008.91

Saxena S, Ray AR, Gupta B (2010) Chitosan immobilization on polyacrylic acid grafted polypropylene monofilament. Carb Polym 82:1315–1322. https://doi.org/10.1016/j.carbpol.2010.07.014

Mokhtar SM, Mostafa TB (2000) Gama radiation-induced graft copolymerization of N-p-hydroxyphenylmaleimide onto polypropylene films. J Polym Res 7(4):215–219. https://doi.org/10.1007/s10965-006-0122-z

Chen HJ, Zhu YF, Zhang Y, Xu JR (2007) Surface enrichment of polypropylene-graft-poly(methyl methacrylate) on polypropylene. J Polym Res 14:489. https://doi.org/10.1007/s10965-007-9134-6

Wang Y, Ni Q, Liu Z, Zou J, Zhu X (2011) Grafting modification and properties of polypropylene with pentaerythritol tetra-acrylate. J Polym Res 18(6):2185–2193. https://doi.org/10.1007/s10965-011-9629-z

Naguib HF, Aly RO, Sabaa MW, Mokhtar SM (2003) Gamma radiation induced graft copolymerization of vinylimidazole-acrylic acid onto polypropylene films. Polymer Testing 22(7):825–830. https://doi.org/10.1016/S0142-9418(03)00018-7

El-Salmawi KM, El-Naggar AM, Said HM, Zahran AH (1997) Graft copolymers of polypropylene films. 1. Radiation-induced grafting of mixed monomers. Polymer International 42(2):225–234. https://doi.org/10.1002/(SICI)1097-0126(199702)42:2<225::AID-PI703>3.0.CO;2-E

Contreras-García A, Burillo G, Aliev R, Bucio E (2008) Radiation grafting of N,N′-dimethylacrylamide and N-isopropylacrylamide onto polypropylene films by two-step method. J Rad Phys Chem 77(8):936–940. https://doi.org/10.1016/j.radphyschem.2008.02.007

Ramírez-Fuentes YS, Bucio E, Burillo Burillo G (2007) Radiation-induced grafting of N-isopropylacrylamide and acrylic acid onto polypropylene films by two step method. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 265(1):183–186. https://doi.org/10.1016/j.nimb.2007.08.046

Wang H, Wei J, Li S, Chen Y, Ren Z, Qiu S (2013) Preparation and characterization of acrylic acid(AA) and 2-acrylamido-2-methyl-1-propanesulfonic acid (AMPS) grafted polypropylene by two-steps electron beam irradiation for filtration of cigarette smoke. J Polym Res 20:44. https://doi.org/10.1007/s10965-012-0044-x

Kong Z, Wu X, Wei J, Zhang H, Cui L (2016) Preparation and characterization of hydrophilicity fibers based on 2-(dimethyamino)ethyl mathacrylate grafted polypropylene by UV- irradiation for removal of Cr(VI) and as(V). J Polym Res 23:199. https://doi.org/10.1007/s10965-016-1079-1

Yin F, Chen Q, Lin J, Deng Y, Mao X (2014) Effect of different peroxide initiators on the reaction extrusion of polypropylene-graft-cardanol and its compatibilization on PP/PC. J Polym Res 21:411. https://doi.org/10.1007/s10965-014-0411-x

Hong SI, Lee JW, Son SM (2005) Properties of polysaccharide-coated polypropylene films as affected by biopolymer and plasticizer types. Packag Technol and Sci 18(1):1–9. https://doi.org/10.1002/pts.667

Tihminlioglu F, Atik İD, Özen B (2010) Water vapor and oxygen-barrier performance of corn–zein coated polypropylene films. J Food Eng 96(3):342–347. https://doi.org/10.1016/j.jfoodeng.2009.08.018

Ramos M, Jimenez A, Peltzer M, Garrigos MC (2012) Characterization and antimicrobial activity studies of Polypropylene films with carvacrol and thymol for active packaging. J Food Eng 109:513–519. https://doi.org/10.1016/j.jfoodeng.2011.10.031

Vartiainen J, Rättö M, Paulussen S (2005) Antimicrobial Activity of Glucose Oxidase-immobilized Plasma-activated Polypropylene Films. Packag Technol Sci 18:243–251. https://doi.org/10.1002/pts.695

Gupta B, Kumari M, Ikram S (2013) Drug release studies of N-isopropyl acrylamide/acrylic acid grafted polypropylene nonwoven fabric. J Polym Res 20:95. https://doi.org/10.1007/s10965-013-0095-7

Swallow AJ (1991) Wholesomeness and Safety of Irradiated Foods. Adv. Exp. Med. Biol. 1:11–31 Part of the "Advances in Experimental Medicine and Biology" book series (AEMB, Vol 289)

Méndeza C, López T (2014) Use of mild irradiation doses to control pathogenic bacteria on meat trimmings for production of patties aiming at provoking minimal changes in quality attributes. Meat Sci. 98:383–391. https://doi.org/10.1016/j.meatsci.2014.06.037

Debeaufort F, Quezada-Gaao J, Voilley A (1998) Edible films and coatings: Tomorrow’s packaging: A Review. Critical Reviews in Food Science 38(4):299–313. https://doi.org/10.1080/10408699891274219

Henriques M, Santos G, Rodrigues A, Gomes D, Pereira C, Gil M: Replacement of conventional cheese coating by natural whey protein edible coatings with antimicrobial activity. J. Hyg. Des., 34–47 (2013). UDC637.3.045.055, URL: http://www.jhed.mk/filemanager/JHED%2

Muzzarelli RA (1997) Human enzymatic activities related to the therapeutic administration of chitin derivatives. Cell Mol Life Sci 53(2):131–140. https://doi.org/10.1007/PL00000584

Song JS, Such CH, Park YB, Lee SH, Yoo NC, Lee JD, Kim KH, Lee SK (2001) A phase I/IIa study on intra-articular injection of holmium-166-chitosan complex for the treatment of knee synovitis of rheumatoid arthritis. Eur J Nucl Med 28:489–497. https://doi.org/10.1007/s002590000470

Shahidi F, Abuzaytoun R (2005) Chitin, chitosan, and co-products: chemistry, production, applications, and health effects. Adv. Food Nutr. 49:93–135. https://doi.org/10.1016/S1043-4526(05)49003-8

He P, Davis SS, Illum L (1998) In vitro evaluation of muco adhesive properties of chitosan microspheres. Int. J. Pharm. 166:75–88. https://doi.org/10.1016/S0378-5173(98)00027-1

Tripathi S, Mehrotra GK, Dutta PK (2009) Physicochemical and bioactivity of crosslinked chitosan-PVA film for food packaging applications. Inter J Biolog. Macromol. 45:372–376. https://doi.org/10.1016/j.ijbiomac.2009.07.006

Siripattrawan U, Vitchayakitti W (2016) Improving functional properties of chitosan films as active food packing by incorporating with propolis. Food Hydrocolloids 61:695–702. https://doi.org/10.1016/j.foodhyd.2016.06.001

Cárdenas FC, Giannuzzi L, Zaritzky NE (2008) Mathematical modeling of microbial growth in ground beef from Argentina: Effect of lactic acid addition, temperature and packaging film. Meat Science 79:509–520. https://doi.org/10.1016/j.meatsci.2007.12.003

Benavides S, Villalobos-Carvajal R, Reyes JE (2011) Physical, mechanical and antibacterial properties of alginate film: Effect of the crosslinking degree and oregano essential oil concentration. J Food Eng 110:232–239. https://doi.org/10.1016/j.jfoodeng.2011.05.023

Kerry JP, O’Grady MN, Hogani SA (2006) Past, current and potential utilization of active and intelligent packaging systems for meat and muscle-based products: A review. Meat Science 74:113–130. https://doi.org/10.1016/j.meatsci.2006.04.024

Appendini P, Hotchkiss JH (2002) Review of antimicrobial food packaging. Innov Food Sci Emerg Technol 3:113–126. https://doi.org/10.1016/S1466-8564(02)00012-7

Elsabee MZ, Abdou ES (2013) Chitosan based edible films and coatings: A Review. Material Science and Engineering C 33(4):1819–1841. https://doi.org/10.1016/j.msec.2013.01.010

Aymerich T, Picouet PA, Monfort JM (2008) Decontamination technologies for meat products. Meat Sci. 78(1–2):114–129. https://doi.org/10.1016/j.meatsci.2007.07.007

Abdou ES, Nagy K, Elsabee MZ (2008) Extraction and characterization of chitin and chitosan from local sources. Bioresource Technology 99:1359–1367. https://doi.org/10.1016/j.biortech.2007.01.051

Sehgal T, Rattan S (2010) Synthesis, characterization and swelling characteristics of graft copolymerized Isotactic polypropylene film. Int. J. Polym. Sci. 2010 (2010), Article ID 147581, 9 pages. https://doi.org/10.1155/2010/147581.

Shanmugapriya A, Srividhya A, Ramya R, Sudha PN (2011) Graft copolymerization of chitosan with acrylic acid used in waste water treatment. International Journal of Environmental Science 1(7):2086–2095. www.ipublishing.co.in

(ASTM D882–90) Standard test methods for tensile properties of thin plastic sheeting. D882–90. In: Annual book of ASTM standards. Vol 15, Philadelphia, American Society for Testing and Materials, pp. 31–39.

Elsabee ME, Abdou ES, Nagy KS, Eweis M (2008) Surface modification of polypropylene films by chitosan and chitosan/pectin multilayer. Carbohydrate Polymers 71(2):187–195. https://doi.org/10.1016/j.carbpol.2007.05.022

Eweis M, Elkholy SS, Elsabee MZ (2006) Antifungal Efficacy of chitosan and its thiourea derivatives upon the growth of some sugar-beet pathogens. International J of Biological Macromolecules 38:1–8. https://doi.org/10.1016/j.ijbiomac.2005.12.009

Olurinola PF, Ehinmidu JO, Bonire JJ (1992) Antifungal activity of n-tributyl tin acetate against some common yam rot fungi. Appl Environ Microbiol 58(2):758–760

Pellissari FM, Grossmann MVE, Yamashita F, Pineda EAG (2009) Antimicrobial, mechanical and barrier properties of Cassava starch-chitosan films incorporated with oregano essential oil. J Agriculture and Food Chem 57:7499–7504. https://doi.org/10.1021/jf9002363

Snedecor GW, Cochran WG (1967) Statistical Methods6th edn. Oxford and IBH Publishing Co, New Delhi, p 593

Qian J, Huang Z, Dang S, Xu Y (2011) Improvements of polypropylene grafted maleic anhydride with ultrasonication, pre-irradiation and co-irradiation methods. J Polym Res 18:1557–1565. https://doi.org/10.1007/s10965-010-9560-8

Siracusa V (2012) Food packaging permeability behavior: a report. Int J Polym Sci:1–11. https://doi.org/10.1155/2012/302029

ASTM D3985 "Standard Test Method for Oxygen Gas Transmission Rate through Plastic Film and Sheeting using a Coulometric Sensor". Annual Book of ASTM Standards (1995) American Society for Testing and Materials. USA, Philadelphia, pp 491–496

ASTM F1249 "Standard Test Method for Water Vapor Transmission Rate through Plastic Film and Sheeting using a Modulated Infrared Sensor". Annual Book of ASTM Standards (1990) American Society for Testing and Materials. USA, Philadelphia, pp 1131–1135

Bhadra S, Dora KC, Sarkar S, Chowdhury S, Ganguly S (2012) Effect of chitosan coating on shelf life of black tiger shrimp (Penaeus monodons). Explor Anim. Med. Res. (2) Issue-II: 155–165. ISSN 2277-470X (Print) ISSN 2319-247X (Online).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abudonia, K.S., Saad, G.R., Naguib, H.F. et al. Surface modification of polypropylene film by grafting with vinyl monomers for the attachment of chitosan. J Polym Res 25, 125 (2018). https://doi.org/10.1007/s10965-018-1517-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1517-3