Abstract

This paper presented many improvements of polypropylene (PP) grafted maleic anhydride (MAH), including how to increase graft degree (G) and graft efficiency (G E ) of MAH onto PP and how to reduce side reactions during grafting. Three grafting methods ultrasonication, pre-irradiation and co-irradiation were employed, and a lot of additives were adopted in our research, such as styrene (St), ethyl benzoate, dibutyl phthalate (DBP), 2,2′-bipyridine, divinylbenzene (DVB), benzoyl peroxide (BPO) and p-hydroquinone. The effects of the different grafting methods and additives were determined by G and G E values, viscosity, FTIR and DSC. Experimental results showed that the highest G value was obtained in co-irradiation method in the presence of St, and side reactions could be also reduced. The best reflux time for G value measuring, the storage time on G and batch feeding times of MAH on G in pre-irradiation method, and the mechanism of PP grafted MAH were all studied.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polypropylene (PP) grafted maleic anhydride (MAH) has been widely studied over the past several decades because of the product PP-g-MAH, which can be used as a compatilizer in polymer blends, as an adhesion promoter with glass or carbon fiber, and even as a processing aid for recycling of plastics waste [1]. The grafting reaction is generally performed chemically [2], photochemically [3] or by melt reactive extrusion [4] in solution [5], melt [6], or solid [7] state in the presence of an initiator. In recent decades, ultrasound [8] and irradiation [9] technologies have been also successfully employed to achieve the grafting reaction with or without an initiator.

In our previous researches, PP-g-MAH was prepared with ultrasonication [10], pre-irradiation [11] and co-irradiation [12] methods respectively. In ultrasonication, the grafting reaction was initiated by ultrasound at an ambient temperature and a pressure in the absence of an initiator, but the G obtained was not high. In pre-irradiation, PP was first irradiated by gamma Co60 in solid state, and then the grafting reaction was performed in solution state without an initiator. The homopolymerization of MAH was largely avoided, but the radicals generated by irradiation had a very short storage time. In co-irradiation, PP and MAH were mixed to form a micro-suspension first, and then irradiated together. The G obtained was high, but there were also some side reactions during grafting.

In order to reduce the chain degradation/cross-linking of PP and achieve higher G values at the same time, effective improvements have been carried out in this paper. The employed methods ultrasonication, pre-irradiation and co-irradiation were compared with each other, and the effects of different additives were studied by characterizations of G and G E values, viscosity, FTIR and DSC. Besides, the effects of reflux time for G value measuring, the storage time on G and batch feeding times of MAH on G in pre-irradiation method, and the mechanism of PP grafted MAH were all discussed.

Experimental

Materials

Isotactic PP with a number-average molecular weight (Mn) of 10,000 and a density of 0.89 g/cm3 was supplied by Qingdao Sinoplase I & Co., Ltd, China. MAH obtained from Tianjin Guangfu Ltd., China was used without further treatment. Styrene (St), ethyl benzoate, dibutyl phthalate (DBP), 2,2′-bipyridine, divinylbenzene (DVB), benzoyl peroxide (BPO) and p-hydroquinone were also supplied by Tianjin Guangfu Ltd., China and used as received.

Grafting methods

Pre-irradiation grafting: PP was first irradiated in solid state by gamma Co60 supplied by Tianjin Institute of Technological Physics, China, with a total dose of 14.4 kGy under air/nitrogen circumstance at room temperature. Then the grafting was performed in a solution of xylene with a MAH concentration of 20 w.t.%, a reaction time of 3 h and a temperature of 90 °C. Details were in literature [11].

Ultrasonication grafting: MAH and PP were heated to dissolve in xylene at 130 °C, and then cooled to room temperature to form a micro-suspension. Ultrasonication grafting was carried out by using an ultrasonic generator (model JY92-II) supplied by Ningbo Scientz Biotechnology Co., Seisakusho Ltd., China, with an ultrasonic time of 2.5 h, an ultrasonic intensity of 300 W and a MAH concentration of 20 w.t.%. Details were in literature [10].

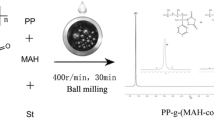

Co-irradiation grafting: the above ultrasonicated micro-suspension was further irradiated directly by gamma Co60 with a total dose of 14.4 kGy under air circumstance at room temperature. Details were in literature [12].

Definition of grafting parameters

The graft degree (G) of MAH onto PP was determined by chemical titration [10–12]. Then the graft efficiency (G E ) of MAH could be calculated by equation (1):

where W gMAH , W MAH and W PP were the weights of MAH grafted (g), MAH added in reactants (g) and PP added (g), respectively.

Characterizations

FTIR

Fourier-transform infrared spectroscopy (FTIR; Nicolet, FTS3000) of PP and grafted products were used to get some qualitative information about the functional groups. FTIR spectra were obtained from kBr pellets at room temperature under the same test conditions.

DSC

A Perkin-Elmer differential scanning calorimeter (DSC) was used for the thermal analysis. Thermal history of the products was removed by scanning to 200 °C with a heating rate of 10 °C/min under nitrogen circumstance. After cooling down it was reheated from room temperature to 200 °C, and then cooled to room temperature again to obtain the melting peaks and crystallization peaks. The heating/cooling rate was always 10 °C/min.

Viscosity measurements

Apparent viscosity: NDJ-79 rotary viscosimeter was used to perform the apparent viscosity measurements of dilute solutions of PP-xylene mixture. They were carried out at the same shearing rate (640 rpm) at room temperature. The results were used for qualitative analysis.

Intrinsic viscosity: Calibrated Ubbelohde viscometer was used to perform the intrinsic viscosity ([η]) measurements of dilute solutions of PP-xylene mixture. They were carried out in a constant-temperature bath at 80 °C, and the temperature of the bath was controlled by a thermostat with 0.1 °C precision. The [η] of each sample could be calculated by measuring the flow time of a solution with a definite concentration.

Results and discussion

Improvement in G determination

It’s always the most important and difficult point to determine the G value of the product because of the very small amount of MAH grafted onto PP. Many quantitative approaches have been employed, such as chemical titration [13], viscosimetric titration [14], potentiometric and conductimetric titration [15], and FTIR spectroscopy [14]. Gaylord et al. [16, 17] have carried out systematic research on chemical acid–base titration, but many negative factors were occurred during titration, such as precipitation, suspended solids, low repeatability, uncertainties of the titration stoichiometric ratio and so on. In order to overcome those problems, one way is to use an organic alkali tetrabutyl ammonium hydroxide titration [14]; another way is to improve the conditions of titration. The reflux time should be long; the titration should be carried out quickly and at a high temperature.

Figure 1 showed the effects of reflux time on G value measuring of grafted samples. G values first increased fast and then went stable with the increase of reflux time in all three grafting methods pre-irradiation, ultrasonication and co-irradiation. This was because in chemical acid–base titration, it took several hours for inorganic base to react with MAH groups grafted on organic PP chain. High accuracy and repeatability could be obtained by this improvement. So the reflux time in our experiments was 6 h.

Storage time in pre-irradiation

While solid PP is pre-irradiated under N2 circumstance, only trapped radicals with high chemical reactivity and low chemical stability are generated. But under air circumstance, peroxide (hydrogen peroxide) are also obtained, which are relatively stable and can be decomposed to form peroxy radicals at a high temperature. The MAH grafting reaction can be induced by both of the above radicals, but mainly by trapped radicals at room temperature.

Figure 2 showed the effects of storage time on G in pre-irradiation method. Four statements could be obtained. First, G values gradually decreased for all of the four curves with the increase of storage time, which indicated that the trapped radicals were unstable and slowly inactivated. Second, the G obtained under air circumstance was higher than that under N2 circumstance (Fig. 2a versus b, c versus d). This was due to the peroxide (hydrogen peroxide) under air circumstance. Third, the G obtained from a high temperature was higher than that of a low temperature (Fig. 2a versus c, b versus d). This was because trapped radicals and peroxide (hydrogen peroxide) had higher chemical reactivity at a high temperature. At a low temperature peroxide (hydrogen peroxide) could hardly decompose, and the grafting reaction solution was a non-homogeneous system. Fourth, when the storage time was more than 170 h, the G values became zero at a low temperature (Fig. 2c and d); but it still had certain G values at a high temperature (Fig. 2a and b). This result proved that the peroxide (hydrogen peroxide) was more stable than trapped radicals, although there might be a possibility of MAH grafting by thermal initiation.

MAH concentration in pre-irradiation

In our previous research, there existed an optimal G value under different MAH concentrations, which was explained by the homopolymerization of MAH at a high concentration. In pre-irradiation method, the amount of trapped radicals and peroxide (hydrogen peroxide) was fixed under a certain irradiation dose. In order to achieve the highest G value, the concentration of MAH must be consistent with the concentration of the active grafting point. One suggested way is to add MAH batch by batch with the same total weight. Figure 3 showed the effects of batch feeding times of MAH on G and G E in pre-irradiation. Not as expected, G and G E values decreased with the increase of batch feeding times. This implied that the grafting reaction took place at the very beginning because of the high chemical activity of the trapped radicals and peroxide (hydrogen peroxide) at a high temperature. Although homopolymerization of MAH was weakened by this way, some other side reactions would occur besides MAH grafting. One batch feeding time was relatively better in our experiments.

Effects of St as a co-monomer

G and GE

In order to increase the G of the grafted product, St was adopted as a co-monomer in MAH grafting reaction. Figure 4 showed the effects of molar ratio of St to MAH on G (Fig. 4 left) and G E (Fig. 4 right) in ultrasonication, pre-irradiation and co-irradiation methods. The G and G E of MAH in the presence of St were always higher than that in the absence of St (St: MAH = 0.0, molar ratio). The maximum G and G E of MAH were obtained when the molar ratio of St to MAH was approximately 1:1 in all experimental conditions. This implied that the interaction of MAH and St played an important role in the grafting reaction. St improved the grafting reactivity of MAH [18], and it was also reacted with MAH to form a St-MAH copolymer (SMA), which might react with PP macroradicals to generate grafted products with long branches [19]. Therefore, the G of MAH could be significantly increased in the presence of St. When the molar ratio of St to MAH was 1:1, the main grafting reaction in the system was the grafting of SMA to PP, yielding relatively long branch. Then the G and G E of MAH were the highest. When the mole of St was lower than that of MAH, the amount of the resulting SMA was less than that in St: MAH = 1:1 system. So the G of MAH decreased, although the left MAH could directly graft onto PP macroradicals. When the mole of St was higher than that of MAH, some St reacted with MAH to form the SMA, and the left might preferentially react with PP macroradicals to form more stable styryl macroradicals. As a result, the G of MAH was also lower than that in St: MAH = 1:1 system.

Figure 5 showed the comparisons of maximum G and G E of MAH for PP-g-MAH and PP-g-(MAH + St) in different conditions. It clearly revealed that maximum G and G E of MAH could be achieved in co-irradiation method in the presence of St (Fig. 5f). Higher G and G E were obtained in co-irradiation (Fig. 5e and f) than that in pre-irradiation (Fig. 5c and d) and ultrasonication (Fig. 5a and b) methods. Higher G and G E were also obtained in the presence of St (Fig. 5b, d and f) than that in the absence of St (Fig. 5a, c and e). The reasons were discussed above.

FTIR

Figure 6 showed the FTIR spectra of pure PP (Fig. 6e), PP-g-(MAH+St) (Fig. 6a) and PP-g-MAH (Fig. 6b–d) in different methods. The absorption at 2,839 cm−1 was the characteristic peak of -CH3 for PP (Fig. 6e) [20], the absorption at 1,720 cm−1 corresponding to the C = O stretching of anhydride groups was the most characteristic peak of MAH grafted PP (Fig. 6a–d) [14], and the absorption at 704 cm−1 could be assigned to the characteristic peak of the grafted St (Fig. 6a) [19]. From the intensities of the carbonyl absorption peaks at 1,720 cm−1, it obviously showed that the grafting reactions occurred and the intensities became more and more stronger from method ultrasonication (Fig. 6d), pre-irradiation (Fig. 6c) to co-irradiation (Fig. 6b), and achieved its strongest intensity in co-irradiation method in the presence of St (Fig. 6a). It meant that the addition of St could significantly increase the G of MAH. The FTIR results were consistent with the results in Fig. 5: a higher G value corresponded to a stronger intensity.

DSC

Figure 7 showed the DSC curves of melting peaks (Fig. 7 left) and crystallization peaks (Fig. 7 right) of pure PP, PP-g-MAH and PP-g-(MAH+St) in pre-irradiation method respectively. Pre-irradiation grafting products were chosen here, and the conclusions were the same as that in other two methods.

Melting process is endothermic with a negative heat flow, and crystallization process is exothermic with a positive heat flow. For melting process in Fig. 7 (left), the melting point of PP-g-MAH (141.15 °C) was lower than that of pure PP (143.93 °C), but the melting heat (61.68 J/g) was higher with a wider melting peak. This was because the grafted MAH on the PP chain increased the intermolecular distance and the entropy, reducing the intermolecular forces, leading to the decreasing of melting point and a broader melting peak. Because of the higher G of MAH in the presence of St, the melting point of PP-g-(MAH+St) (140.91 °C) was even lower than that of PP-g-MAH.

For crystallization process in Fig. 7 (right), the crystallization temperature (105.07 °C) of PP-g-MAH was lower than that of pure PP (105.95 °C), and the crystallization heat (69.22 J/g) was lower too. The depression of crystallization temperature was due to the side grafted MAH groups on the PP chain, which led to a reduction in the amount of perfect crystals, and retarded the crystallization of the PP molecules. The addition of St could also minimize the crystal capability of PP [21]. So the crystallization temperature of PP-g-(MAH+St) (102.12 °C) was even lower than that of PP-g-MAH. These results were consistent with what Baotong Huang [22] proposed. He found that the melting point and crystallization temperature of grafted products were both a little lower than that of pure materials.

In order to estimate the influences of St on thermal performance of the products PP-g-(MAH+St) in detail, Fig. 8 showed the effects of molar ratio of St to MAH on DSC curves of melting peaks (Fig. 8 left) and crystallization peaks (Fig. 8 right). The melting point and crystallization temperature of grafted products with St were all a little lower than that of grafted products without St (molar ratio, St: MAH = 0.0). It was also proved that the changes of the melting point and crystallization temperature were corresponded to the trends of G in Fig. 4. The melting point and crystallization temperature of grafted products decreased with the increase of G values, and obtained the minimums in St: MAH = 1:1 system. There was a very small endothermic peak appeared at about 130 °C around the melting peak in some curves (Fig. 8 left). This was due to the evaporations of small amount of bound water/crystal water in some grafted products.

Apparent viscosity

Effects of irradiation dose on apparent viscosity of PP

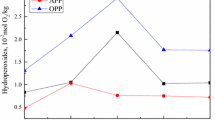

It is reported [23] that there is a certain degree of cross-linking/degradation for polyolefin under irradiation conditions. Polypropylene tends to degrade and polyethylene tends to cross-link. Figure 9 illustrated the effects of total irradiation dose on apparent viscosity of PP irradiated in solid state. The apparent viscosity of the PP-xylene solutions first decreased and then increased with the increase of total dose, indicating that the molecular weight of PP first decreased and then increased. It meant that in our experiments (total dose was 14.4 kGy), the chain degradation of PP occurred, and it caused the decrease of viscosity. When the total dose went above a certain value, PP exhibited cross-linking. However, the irradiated PP could be absolutely dissolved in hot xylene, the cross-linking of PP was not serious. It was also showed that the atmosphere was an important factor during irradiation. PP went cross-linking more favorable in air than in N2. This was due to the peroxide (hydrogen peroxide) generated under O2 circumstance, which could induce the cross-linking of PP macromolecules.

Influences of additives on apparent viscosity of PP

In order to reduce the chain degradation of PP in our experiments and achieve high G at the same time, a lot of additives were used. Figure 10 showed the effects of different treatments on apparent viscosity of PP. Sample Fig. 10a was pure PP with the highest apparent viscosity. Samples Fig. 10c–g were co-irradiated in 10 w.t.% PP-xylene solutions, and the additives added were all 2 w.t.% in PP: blank (Fig. 10c), St (Fig. 10d), MAH (Fig. 10e), ethyl benzoate (Fig. 10f) and DBP (Fig. 10g) respectively. The apparent viscosity of sample Fig. 10c without any additives decreased a lot than that of sample Fig. 10a, but that of sample Fig. 10g only decreased a little. The additives St and MAH played a role as electron accepters and grafting monomers; the additives ethyl benzoate and DBP played a role as electron donors. They could all reduce the chain degradation of PP to some extent. Besides, the chain degradation of PP irradiated in solid state (Fig. 10b) was better than that in solution state (Fig. 10c–g).

Influences of additives on G and G E

Firstly, the effects of amount of additives on G and G E of MAH in co-irradiation method were studied. DBP was chosen as an example in Fig. 11. The G and G E of MAH first increased and then decreased with the increase of amount of DBP in PP. The optimum values were obtained at a DBP concentration of 2.0 w.t.%. It was conceivable that the additive (electron donor) could activate MAH by rendering its structure unsymmetrical and its π bond of radical-anion character [19]. With the aid of DBP, the chain degradation of PP decreased and the MAH activity was improved, so G and G E increased. But, if DBP was added too much, it would also induce the homopolymerization of MAH, leading to a slight decrease of G and G E .

Secondly, different additives at the same 2.0 w.t.% (in PP) level were studied. Figure 12 showed the effects of different additives on G and G E of MAH in co-irradiation method. Sample Fig. 12a was PP-g-MAH without any additives, other samples were PP-g-MAH (+DVB) (Fig. 12b), PP-g-MAH (+DBP) (Fig. 12c), PP-g-MAH (+2,2′-bipyridine) (Fig. 12d) and PP-g-MAH (+ethyl benzoate) (Fig. 12e) respectively. It showed that samples Fig. 12b–e with additives had higher G and G E values than that of sample Fig. 12a, and PP-g-MAH (+ethyl benzoate) had higher G and G E values than PP-g-MAH (+2,2′-bipyridine), PP-g-MAH (+DBP) and PP-g-MAH (+DVB). These additives were all effective to increase the G and G E of MAH in our experimental conditions.

Influences of additives on intrinsic viscosity of grafted products

The best additive is the one that not only increases the G of MAH, but also reduces the chain degradation of PP and other side reactions. So the intrinsic viscosity of the grafted products was measured to see the molecular weight changes. Figure 13 showed the effects of different additives on intrinsic viscosity of grafted products in co-irradiation method, and the additives added were 2 w.t.% in PP (except Fig. 13f). Sample Fig. 13a was PP-g-MAH without any additives, samples Fig. 13b–e were PP-g-MAH (+DVB) (Fig. 13b), PP-g-MAH (+2,2′-Bipyridine) (Fig. 13c), PP-g-MAH (+ethyl benzoate) (Fig. 13d) and PP-g-MAH (+DBP) (Fig. 13e) respectively, sample Fig. 13f was PP-g-(MAH+St) in St: MAH = 1:1 system. It could be seen from the figure that the intrinsic viscosities of PP-g-MAH (+DVB), PP-g-MAH (+2,2′-Bipyridine) and PP-g-MAH (+ethyl benzoate) were a litter lower than that of PP-g-MAH, which meant that these three additives could not reduce the chain degradation of PP. The intrinsic viscosity of PP-g-MAH (+DBP) was a litter higher than that of PP-g-MAH. So DBP was effective to reduce the chain degradation of PP. All of the above additives with electron-donating groups were considered to reduce the free radical transfer reactions inner and inter the PP molecules. They worked as the negative catalysts, reducing the side reactions of PP during MAH grafting. St played a role as a co-monomer. The intrinsic viscosity of PP-g-(MAH+St) was much higher than that of PP-g-MAH. So the addition of St could not only greatly improve the G value of MAH, but also effectively reduce chain degradation of PP [19].

Mechanism of PP grafted MAH

The mechanism of PP grafted MAH is normally considered as a free-radical grafting reaction [24–26]. In order to check or prove this mechanism, a free-radical initiator and a free-radical inhibitor were separately added as additives, and the amount each was still 2 w.t.% in PP. Figure 14 showed the effects of initiator BPO and inhibitor p-hydroquinone on G and G E of MAH in co-irradiation method. The middle one (Fig. 14b) was PP-g-MAH, the left one (Fig. 14a) with BPO had significantly higher G and G E than that of PP-g-MAH, and the right one (Fig. 14c) with p-hydroquinone had nearly zero G and G E values. The free-radical grafting mechanism of PP grafted MAH was strongly supported by our experiments. When a free-radical initiator was added, G and G E improved, enhancing the grafting reaction; when a free-radical inhibitor was added, G and G E decreased to zero, preventing the grafting reaction.

Conclusions

Many improvements of PP grafted MAH with ultrasonication, pre-irradiation and co-irradiation methods have been successfully carried out in our experiments. The best reflux time on G values measuring was 6 h. In pre-irradiation, storage time was important to G values, but batch feeding times of MAH was not important. In co-irradiation, the additives ethyl benzoate, DBP, 2,2′-bipyridine and DVB all could increase the G values to some extent, but only DBP could slightly reduce the PP degradation reaction. However, St could not only greatly improve the G of MAH, but also effectively reduce PP degradation in all three methods. The higher the G values, the stronger the characteristic peak absorption intensity in FTIR spectra, and the lower the melting point and crystallization temperature in DSC curves. Although the free-radical grafting mechanism has been proved by adding additives BPO and p-hydroquinone, there are still many works to do. For example, the detailed mechanisms of different grafting methods employed and different additives adopted, the exactly structures and the stabilities of the grafted products.

References

Ehrig RJ (1992) Plastics recycling, products and processes. Carl Hanser Verlag, Munchen

Wang ZM, Hong H, Chung TC (2005) Synthesis of maleic anhydride grafted polypropylene with high molecular weight using borane/O2 radical initiator and commercial PP polymers. Macromolecules 38:8966–8970

Nito K, Suzuki SI, Miyasaka K et al (1982) Photoinduced acrylamide graft polymerization onto extended hard elastic polypropylene. J Appl Polym Sci 27:637–643

Zhu LC, Tang GB, Shi Q et al (2006) Neodymium oxide co-catalyzed melt free radical grafting of maleic anhydride onto co-polypropylene by reactive extrusion. React Funct Polym 66:984–992

Ruggeri G, Aglietto M, Petragnani A et al (1983) Some aspects of polypropylene functionalization by free radical reactions. Eur Polym J 19:863–866

Bratawidjaja AS, Gitopadmoyo I, Watanabe Y et al (1989) Adhesive property of polypropylene modified with maleic anhydride by extrusion molding. J Appl Polym Sci 37:1141–1145

Rengarajan R, Parameswaran VR, Lee S et al (1990) N.M.R. analysis of polypropylene-maleic anhydride copolymer. Polymer 31:1703–1706

Gonzalez DA, Lozano GM, Concepcion GM (1998) Modification of polypropylene with maleic anhydride: Ultrasonic irradiation effects. J Appl Polym Sci 68:45–52

Jung CH, Choi JH, Lim YM et al (2007) Preparation of polypropylene compatibilizer by radiation grafting and its effect on PP/Nylon 6 blend. Macromol Symp 249–250:573–579

Tan XM, Xu YS, Jia GW et al (2007) Ultrasonically initiated grafting of maleic anhydride onto polypropylene. Macromol React Eng 1:185–190

Tan XM, Xu YS, Wang CL (2006) Pre-irradiation-induced graft reaction of maleic anhydride onto polypropylene. Radiat Eff Defects Solids 161:529–535

Tan XM, Xu YS, Qian J et al (2007) Study on grafting maleic anhydride onto polypropylene in micro-colloid systems by co-irradiation. Polym Eng Sci 47:1703–1707

Sclavons M, Carlier V, De Roover B et al (1996) The anhydride content of some commercial PP-g-MA: FTlR and titration. J Appl Polym Sci 62:1205–1210

Sclavons M, Franquinet P, Carlier V et al (2000) Quantification of the maleic anhydride grafted onto polypropylene by chemical and viscosimetric titrations, and FTIR spectroscopy. Polymer 41:1989–1999

Trivedi BC, Culbertson BM (1982) Maleic anhydride. Plenum, New York

Gaylord NG (1989) High density polyethylene-g-maleic anhydride preparation in presence of electron donors. J Appl Polym Sci 38:359–371

Gaylord NG, Mishra MK (1983) Nondegradative reaction of maleic anhydride and molten polypropylene in the presence of peroxides. J Polym Sci Polym Lett Ed 21:23–30

Xie XM, Chen NH, Li S (1999) The effect of comonomer in the melt grafting PP system. Acta Polym Sin 3:351–354

Li Y, Xie XM, Guo BH (2001) Study on styrene-assisted melt free-radical grafting of maleic anhydride onto polypropylene. Polymer 42:3419–3424

Yazdani-Pedrama M, Vegaa H, Quijada R (2001) Melt functionalization of polypropylene with methyl esters of itaconic acid. Polymer 42:4751–4758

Rao HX, Zhang ZY (2008) Graft copolymerization of maleic anhydride/styrene onto isotactic polypropylene using supercritical. Polym Adv Technol 19:770–774

Wang YL, Ji DQ, Yang CL et al (1994) Structure and properties of maleated high-density polyethylene. J Appl Polym Sci 52:1411–1417

Chapiro A (1988) Chemical modifications in irradiated polymers. Nucl Instrum Methods Phys Res B 32:111–114

De Roover B, Sclavons M, Carlier V (1995) Molecular characterization of maleic anhydride-functionalized polypropylene. J Polym Sci Part A Polym Chem 33:829–842

Ho RM, Su AC, Wu CH et al (1993) Functionalization of polypropylene via melt mixing. Polymer 34:3264–3269

Thompson MR, Tzoganakis C, Rempel GL (1998) Terminal functionalization of polypropylene via the Alder Ene reaction. Polymer 39:327–334

Acknowledgements

The authors would like to thank Chonglin Wang, Director of Tianjin Institute of Technical Physics, China, for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qian, J., Huang, Z., Dang, S. et al. Improvements of polypropylene grafted maleic anhydride with ultrasonication, pre-irradiation and co-irradiation methods. J Polym Res 18, 1557–1565 (2011). https://doi.org/10.1007/s10965-010-9560-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10965-010-9560-8