Abstract

A novel pH- and thermo-responsive poly (ε-caprolactone-b-4-vinyl benzyl-g-2-(dimethyl amino ethyl) methacrylate), poly (CL-b-VB-g-DMAEMA), brush type copolymer has been described. In this study, a reversible addition–fragmentation chain transfer (RAFT) agent, 1,2-propanediol-3-ethyl xanthogenate, was obtained through the reaction of 3-chloro-1,2-propanediol with potassium salt of ethyl xanthogenate. Poly (CL-b-VB) block copolymer was synthesized in one-pot polymerization of ε-caprolactone (CL) and 4-vinyl benzyl chloride (VB) using a new dual macro-RAFT agent. In the second step of the work, chloride side groups of poly-VB in poly (CL-b-VB) block copolymer were reacted with potassium salt of ethyl xanthogenate to obtain another novel macro-RAFT agent, poly (CL-b-VB)-g-xanthate (PCL-PVB-Xa). Controlled free radical living polymerization of 2-(dimethylaminoethyl) methacrylate (DMAEMA) was initiated with this PCL-VB-Xa macro-RAFT agent to obtain new poly (CL-b-VB-g-DMAEMA) comb type pH- and thermo-responsive heterograft copolymer. The homopolymer was soluble in water at pH = 10–11 and not soluble at pH = 12.5. A pH-sensitive feature of the brush type graft copolymer was observed between pH 9.4 and 11.5 in view of their swelling/solution properties depending on the acrylic polymer inclusion. The LCST values of the multiblock brush type copolymers were found to be as low as 42.8 °C, while that of PDMAEMA homopolymer was 46.6 °C. The characterization of the products was achieved using gel-permeation chromatography (GPC), thermal, and spectrometric analysis techniques. pH- and thermo-responsiveness of the copolymers were verified by surface tension and zeta potential measurements.

Synthesis of pH- and Thermo-responsive Poly (Ɛ-Caprolactone-b-4-vinyl benzyl-g-dimethyl amino ethyl methacrylate) Brush Type Graft Copolymers via RAFT Polymerization

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

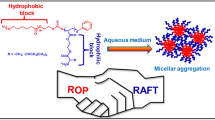

More than ever, there is pressure to offer polymers with tailored property profiles for industrial and medical applications in order to make daily life easy and simple. Block copolymers are two or more different polymer chains linked together and have long been used for this purpose [1–5]. Recent progress in synthetic polymer chemistry has unveiled unprecedented opportunities to prepare tailored block copolymers. Up to now, polymers with various kinds of architectures have been synthesized including linear, star shaped [6], tadpole shaped [7–9], comb type [10], brush type, hyperbranched [11–13], and dendrimer, since the properties of polymers are inherently dependent on their architectures [14, 15]. The increasing diversity in polymer architectures has offered versatility in developing novel polymer materials with unprecedented properties and functions [16]. The term “polymer brush” is broadly used as a synonym of the term “tethered polymer chain”. Polymers with comb-shaped architecture may also undergo microphase separation due to the repulsion between the backbone and the side chains. They may also exhibit the hierarchical structures with two distinct length scales [17–19]. When the distance between neighboring grafting points is small, steric repulsion leads to chain stretching. At lower grafting densities, surface-tethered polymer chains can adopt various other conformations, which are referred to as mushroom or pancake, when the distance between neighboring grafting points is large enough [17]. Reversible addition–fragmentation chain transfer (RAFT) polymerization represents the most recently developed controlled radical-polymerization method and is a powerful technique for the macromolecular synthesis of a broad range of well-defined polymers [20–29]. The versatility of the method is proved by its compatibility with a very wide range of monomers and reaction conditions. Combination pathways of the ring opening polymerization (ROP)/controlled radical polymerization (CRP) have been extensively used in the synthesis of graft copolymers in one step [30–41]. The dual initiators had two functional groups that could initiate ROP and reversible addition-fragmentation chain transfer (RAFT) polymerization independently and selectively.

In this study, a new pH- and thermo-responsive brush type of graft copolymer was synthesized in four steps via controlled living polymerization using a novel macro-RAFT agent based on poly (CL-b-VB). For this purpose, 1,2-propanediol-3-ethyl xanthogenate (RAFT agent) was prepared with the reaction of 3-chloro-1,2-propanediol (CPD) and potassium salt of ethyl xanthogenate (EDTC). Poly (CL-b-VB) triarm block copolymers were synthesized using RAFT agent by the simultaneous RAFT and ROP of the reactants in one step. Macro-RAFT agent was prepared with the reaction of poly (CL-b-VB) triarm block copolymers and EDTC. The newly synthesized macro-RAFT agent initiated the RAFT polymerization of 2-(dimethylaminoethyl) methacrylate, (DMAEMA), in order to obtain poly (CL-b-VB-g-DMAEMA) brush type copolymer. The products obtained in each step were characterized by using spectrometric, thermal, and physicochemical methods.

Experimental

Materials

Potassium salt of ethyl xanthogenate, also referred to as potassium ethyl xanthate and potassium-O-ethyl dithiocarbonate (EDTC), was supplied from Alfa Aesar and used as received. 3-chloro-1,2-propanediol, CPD, was obtained from Sigma-Aldrich and used as received. 2,2'-azobisisobutyronitrile (AIBN) was supplied by Fluka A.G. and used as received. Diethyl ether was obtained from Sigma-Aldrich and used as received. 4-Vinyl benzyl chloride (VBC) was obtained from Sigma-Aldrich and passed through an Al2O3 column to remove the inhibitors before use. Tetrahydrofuran (THF) and toluene were supplied by Sigma-Aldrich and distilled from sodium (Na). Tin (II) 2-ethylhexanoate was supplied by Sigma and used as received. Methanol was obtained from Riedel de Haen and used as received. Sodium (Na) was supplied by Sigma-Aldrich and used as received. 2-(Dimethylamino) ethyl methacrylate (DMAEMA) was obtained from Merck and passed through in Al2O3 column to remove the inhibitors before use. Ɛ-caprolactone (CL) was supplied by Sigma-Aldrich and dried with anhydrous CaSO4, then fractionally distilled. All other chemicals were reagent grade and used as received.

Instrumentation

The molecular weights and molecular weight distributions were measured with a Malvern Viscotek GPC and OmniSEC 4.7 Software Systems with THF as the solvent at a flow rate of 1 mL min−1. A calibration curve was generated with eight polystyrene standards: 1.79 × 106, 9.25 × 105, 1.64 × 105, 1.2 × 105, 6.37 × 104, 2.91 × 104, 5.87 × 103, and 955 g mol−1, of low polydispersity. Fourier-transform infrared spectroscopy (FTIR) spectra were recorded using a Perkin Elmer Pyris model FTIR spectrometer. 1H-nuclear magnetic resonance (1H-NMR) spectra of the samples in CDCl3 as the solvent, with tetramethylsilane as the internal standard, were recorded using a Bruker Ultra Shield Plus, ultra long hold time 400 MHz NMR spectrometer. Thermo gravimetric analyses (TGA) of the polymers were carried out using a SIIQ TG/DTA 7200 model instrument to determine thermal degradation. Dried sample was heated under nitrogen from 25 °C to 650 °C at a heating rate of 10 °C/min. Differential scanning calorimeter (DSC) traces of the polymer samples were obtained using a Perkin Elmer DSC 8000 series thermal analysis system. Dried sample was heated under nitrogen atmosphere from −50 to 250 °C at a rate of 10 °C/min. UV–VIS spectra of the polymer samples were recorded using an Agilent Cary 60 UV–vis Spectrophotometry. Surface tension values of the copolymers were measured via Du Nouy method using PHYWE P2140500 set. The zeta potential ζ of the samples were at 25 °C with a Brookhaven Zeta Plus Zetasizer. pH values were measured with a “Hanna” pH-meter; HI 83141 was used to measure the pH values of the aqueous solution of the polymers.

Synthesis of RAFT agent (1, 2-propanediol-3-ethyl xanthogenate) (RA-1)

The same procedure described in the cited literature was applied to synthesize the RAFT agent [39]. For example, a mixture of 3.01 g of CPD and 6.01 g of EDTC in 45 mL of THF was stirred at 40 °C for 72 h under argon. The solution was filtered to remove the unreacted xanthate, and the solvent was removed by a rotary evaporator. For further purification, the solid product was redissolved in THF and poured into distilled water by continuous stirring with a glass rod. The solid precipitate was collected from the mixture after 24 h, then dried under vacuum at room temperature for 24 h. Melting point of the pale yellow solid RA-1 sample was 38 °C, while the precursor, CPD, was a liquid at room temperature.

One-step polymerization

In a typical example, 0.50 g of RAFT agent, 0.10 g of AIBN, 20 mL of toluene (as solvent), a drop of tin (II) 2-ethylhexanoate, 2.06 g of VBC, and 2.16 g of CL were charged separately into a Pyrex tube, and subsequently, argon was purged into the tube through a needle for 1 min. The tube was tightly capped with a rubber septum and was put into an oil bath at 90 °C for 14 h. Then, the reaction mixture was poured into an excess of methanol to precipitate poly (CL-b-VBC) triarm block copolymer. It was dried at 40 °C under vacuum for 3 days.

Synthesis of macro-RAFT agent, poly (CL-b-VB-Ksent)

In a typical example, 2.00 g of poly (CL-b-VBC) triarm block copolymer was reacted with 2.44 g of EDTC in 10 mL of THF at 40 °C for 72 h. The solution was filtered to remove the unreacted xanthate, and KCl formed. Solvent was removed using a rotary evaporator. The macro-RAFT agent, poly (CL-b-VB) containing xanthate pendant side groups, was precipitated in cold diethyl ether and dried under vacuum at room temperature for 24 h. The yield of macro-RAFT agent was determined gravimetrically.

Synthesis of poly (CL-b-VB-g-DMAEMA) brush type copolymer

In a typical example, 40 mg of AIBN, 5 mL of toluene (as solvent), 0.50 g of macro-RAFT agent, and 1.87 g of DMAEMA were charged separately into a Pyrex tube, and subsequently, argon was purged into the tube through a needle for 1 min. The tube was tightly capped with a rubber septum and was put into an oil bath at 90 °C for 14 h. After the polymerization, the reaction mixture was poured into an excess of methanol to separate the poly (CL-b-VB-g-DMAEMA) heterograft copolymer. The polymers were dried at 40 °C under vacuum for 24 h. The yield of the copolymer was determined gravimetrically.

Fractional precipitations of the block copolymers

Block copolymers can be isolated from their homopolymer impurities using the fractional precipitation method. The formation of block or graft copolymers can also be confirmed via fractional precipitation. Fractional precipitations of the polymers were carried out according to the procedure described in the cited reference [4]. For example, a vacuum-dried polymer sample (approximately 0.5 g) was dissolved in 10 mL of chloroform (solvent). Methanol (nonsolvent) was added drop wise into the solution with stirring until turbidity occurs. When turbidity occurs, an excess of 2 mL of nonsolvent was added to complete the precipitation. The first polymer precipitate was isolated by filtration, and dried under vacuum. The nonsolvent addition into the filtrate solution was continued in order to precipitate the second fraction of the polymer dissolved. The precipitated polymers were dried under vacuum.

Thermo-responsive properties of graft copolymers

In a typical example, 1.5 g poly (CL-b-VB-g-DMAEMA) heterograft copolymer was dissolved in 200 ml water. Primarily, the transmittance values (T%) of these solutions are obtained by their UV measurements at 600 nm from 22 °C to 45 °C. In addition, in order to determine their surface tensions, lower critical solution temperatures (LCST) of heterograft copolymers were measured from 28 °C to 44 °C with ranges of 2 °C. Each value was taken as the average of three readings.

pH sensitivity of graft copolymers

The zeta potential of poly (CL-b-VB-g-DMAEMA) heterograft copolymer was measured with zetasizer. To this aim, aqueous solutions at various pHs of the heterograft copolymers were prepared. The solutions were filtered through a 0.45-μm millipore filter before the measurement. Several solutions were prepared to study the influence of the pH of the solution. The pH was set by adding NaOH and HCl to the solution [42]. In order to obtain an average value for each data point, 30 iterations of the fitting routine were performed for each measurement to get an accurate reading of the phase signal.

Results and discussion

Synthesis of RAFT agent

Synthesis of polymers

In this study, we aimed to synthesize PCL-b-PVB-g-PDMAEMA amphiphilic brush copolymers in four steps for the first time and investigate the effects of structural alterations on their thermal and physicochemical behavior. In the first step, we prepared the dual initiator, (1, 2-propanediol-3-ethyl xanthogenate), RA-1, by the reaction between CPD with EDTC. In the second step, the one-pot RAFT and ROP polymerization of CL and VB was initiated by the dual RAFT-ROP agent in order to obtain the PCL-b-PVBCl block copolymers with pendent chloride groups. In the third step, PCL-b-PVBC was reacted with EDTC in order to obtain PCL-b-PVB-Xa block copolymers containing dithiocarbonate pendent chain transfer agent. In the fourth step, RAFT polymerization of DMAEMA was initiated by the PCL-b-PVB-Xa macro-RAFT agent in order to obtain PCL-b-PVB-g-PDMAEMA amphiphilic brush type graft copolymer. The basic outlines for the synthesis of PCL-b-PVB-g-PDMAEMA amphiphilic brush type graft copolymer starting from CPD the PCL-b-PVB block copolymers are shown in Scheme 1.

RAFT agent (1, 2-propanediol-3-ethyl xanthogenate), RA-1, was synthesized from the substitution reaction between CPD and EDTC with a weight ratio of 1:2, in THF solution at 40 °C for 72 h under argon. The first step of the overall reaction designed for the synthesis of RA-1 can be seen in Scheme 1. The five samples of RAFT agents were synthesized by using the same procedure during this work. The chemical structure of the RA-1 was confirmed using 1H NMR spectrometry, in agreement with the cited literature [35].

The one-step polymerization of a vinyl monomer and a lactone initiated by RAFT agent creates three new active sites—two sites on an equal number of hydroxyl groups for ROP reaction and one on the thiocarbonate group for RAFT polymerization. During this one-pot synthesis, RAFT polymerization of VBC is carried out simultaneously as the ROP of CL proceeds, in order to obtain poly (CL-b-VBC) triarm block copolymer in good yield. Table 1 summarizes results and conditions of the whole synthesis of the graft copolymers. The reactions can be seen in the second step of the Scheme 1.

GPC chromatograms of the fractionated triarm block copolymers were unimodal except the PCL-b-PVBC-10 triarm block copolymers. The molecular weights of the polymers (Mn) changed from 4,132 to 13,439 g/mol. Figure 1 shows the GPC chromatograms of the copolymers. The Mw/Mn values of second fraction samples were lower than those of first fraction samples.

GPC chromatograms of poly (CL-b-VBC) triarm block copolymers in Table 1 (A) PCL-VBC-41; (B) PCL-VBC-71; (C) PVBz-1; and (D) PCL-VBC-51

As shown in the third step of the overall reaction in Scheme 1, macro-RAFT agent with polyvinyl benzyl with pendant ethyl xanthegonate groups and two poly-CL segments was prepared by the reaction of poly (CL-b-VBC) block copolymer and EDTC. The results of the reactions are gathered in Table 2. The Mn values of the macro RAFT agents were slightly lower than those of the precursors. Presumably, biodegradable PCL blocks are slightly degraded during the reaction with EDTC in order to get the macro RAFT agent.

Figure 2 shows the 1H NMR spectra of PCL-b-PVBC-50 and PCL-b-PVB-Ksent-50. The characteristic chemical shifts of the xanthate units were observed at δ ppm: 3.05 for –CH 2-S- C (S)- and 0.80 for CH 3-CH2-O-. Aromatic protons of VB group were also observed at between 7.0 ppm and 7.5 ppm.

The RAFT polymerization of DMAEMA was initiated using macro-RAFT agent in order to obtain poly (CL-b-VB-g-DMAEMA) heterograft copolymers (fourth step in Scheme 1). The results of RAFT polymerization are shown in Table 3. There was an increase in the molecular weights of the heterograft copolymers compared to that of macro-RAFT agent. Increases in the molecular weights of the polymers when compared with the agent confirm the heterograft copolymer formation. Because of the branched structure, more than one propagating centers initiate the polymerizations, and the Mw/Mn values of the heterograft copolymers are relatively higher than expected. RAFT polymerization of DMAEMA were carried out using poly (CL-b-VB) macro-RAFT initiator in good yield. Increase in monomer concentration causes increase in both yield and molecular weight of the heterograft copolymer obtained (Run no.s PCL-b-PVB-g-PDMAEMA-6, −7, and −10 in Table 3).

GPC chromatograms of the PCL-b-PVB-g-PDMAEMA heterograft copolymers were unimodal and the heterograft copolymers indicated the higher molecular weight values than that of the triarm block copolymers, which was a typical confirmation of the heterografting reaction. Fig 3 shows the unimodal GPC curves of the precursor block copolymers and those of the heterograft copolymers.

Structural characteristics of the heterograft copolymers were evaluated using 1H NMR spectrometry. Fig 4 shows 1H NMR spectrum of the PCL-b-PVB-g-PDMAEMA-10 brush copolymer. The characteristic signals of each segment of the heterograft copolymer obtained were observed in this spectrum. The characteristic chemical shift of the xanthate unit was observed at 0.80 ppm for CH3CH2O-. Aromatic protons of vinyl benzyl group were also observed at 7.0 and 7.1 ppm. Chemical shifts in PCL units can be assigned to the signal of independent methylene protons at 1.2-1.3 ppm, at 2.2 ppm to carboxyl groups adjacent to methylene protons, and at 4.0 ppm they can be assigned to oxygen atoms in acyloxy groups adjacent to methylene protons. Nitrogen atoms adjacent to methylene protons in DMAEMA units were observed at 2.2 ppm like the carboxyl groups adjacent to methylene protons in PCL units.

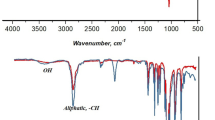

The FTIR spectrum of the PCL-b-PVB-g-PDMAEMA was compared with those of 3-chloro 1,2-propane diol, 1, 2-propane diol-3-ethyl xanthegonate (01RA), and PCL-b-PVB-40-Ksent in Fig. 5. The characteristic halogen signal at 831 cm−1 of the precursor was nearly diminished in that of RAFT agent. Typical xanthate signal at 1,638 cm−1 appeared in three polymer samples, which was confirmed the expected chemical structure. Additionally, −C = O signal at 1,723 cm−1 also confirms the presence of both PCL and PDMAEMA segments.

As an additional confirmation of the styrene units in the multiblock copolymers, UV spectra of the samples were taken, and the sharp peak which belongs to the benzene ring was observed at the wavelength 270 nm (Fig. 6).

Thermal analysis of poly (CL-b-VB-g-DMAEMA) heterograft copolymers

Thermal analysis of the poly (CL-b-VB-g-DMAEMA) heterograft copolymers was done by using DSC and TGA methods. DSC and TGA curves of the PCL-b-PVB-g-PDMAEMA-6, −7, and −10 in Table 3 were studied in view of the thermal analysis. DMAEMA concentration of the initial polymerization solution of PCL-b-PVB-g-PDMAEMA-6, −7, and −10 were 65, 82, and 90 wt.%, respectively. Tg values were obtained from the DSC curves of the heterograft copolymers and PDMAEMA-homopolymer (Fig. 7). Tgs of the heterograft copolymers were all higher than that of PDMAEMA-homopolymer. Probably, polystyrene segments from the macro-RAFT agent increases the Tg of the copolymer.

DSC traces of the brush type graft copolymers: (a) PCL-b-PVB-g-PDMAEMA-6, (b) PCL-b-PVB-g-PDMAEMA-7, (c) PCL-b-PVB-g-PDMAEMA-10, and (d) PDMAEMA-homopolymer in Table 3

The similar TGA curves were obtained in the heterograft copolymer samples except PCL-b-PVB-g-PDMAEMA-6 containing less PDMAEMA (Fig. 8). In this sample, decomposition starts from 202 °C to 403 °C, which can be attributed to the miscibility of the polymer segments in the heterograft copolymer. The others indicated two decomposition temperatures like the PDMAEMA homopolymer. The results of the thermal analysis were listed in Table 4.

In order to determine pH-responsive property of water soluble heterograft copolymer, poly (CL-b-VB-g-DMAEMA)-10, the transmittance values (T%) of its aqueous solution at different pH 10, 11, and 12.5 were measured using UV–VIS spectrometry.

T% values of the aqueous solutions of poly-DMAEMA homopolymer and poly (CL-b-VB-g-DMAEMA)-10 heterograft copolymer at different pHs versus wavelength are plotted in Fig. 9. The turbidity of the solution increased at pH ≥ 12 and the T% values decreased. From here, it was observed that the precipitation of polymer took place. While the homopolymer and copolymer were soluble at pH = 10 and pH = 11, the polymers precipitate at pH = 12.5.

The zeta potential was determined between pH 7–13 for heterograft copolymers. All measurements were performed after 5 min of equilibration time at 25 °C. The zeta potential values are shown in Fig. 10. When pH is increased, the zeta potential decreases. The isoelectric points were at approximately pH 11.1 for PCL-b-PVB-g-PDMAEMA-5, pH 9.4 for PCL-b-PVB-g-PDMAEMA-6, pH 11.5 for PCL-b-PVB-g-PDMAEMA-7, and pH 10.3 for PCL-b-PVB-g-PDMAEMA-10. Under the isoelectric points, copolymers yield a net positive charge at low pH and a negative charge above this value. The surface charge of the heterograft copolymers decreases while the pH increases, which means that the hydrophobic interaction continues. Under acidic conditions, the amine groups on DMAEMA units are protonated, causing the polymer to be hydrophilic. The subsequent addition of the base deprotonates the amine groups [43].

It is observed that the isoelectric points for the PCL-b-PVB-g-PDMAEMA vary with heterograft copolymers composition, with higher isoelectric points obtained for the more DMAEMA-rich copolymers. pH-sensitivity of heterograft copolymers was confirmed by UV and zetasizer measurements. It is seen that zetasizer measurements support the data obtained from UV.

With the UV measurements of the thermo-responsiveness of heterograft copolymers, the transmittance values (T%) at various temperatures were determined at 600 nm. Fig. 11 shows T% values of the copolymers. The LCST of PDMAEMA homopolymer which was 46.6 °C at pH 7 [44] has decreased to 42.8 °C and 44.5 °C due to the PDMAEMA amount in the obtained heterograft copolymer. It was reversible, thermosensitivity was observed during both heating and cooling process.

Normally, the hydrophilic balance is important for thermosensitivity, but in the case of block copolymers, the comonomer composition can be important. In this manner It could be possible to increase the hydrophilicity by increasing the amount of DMAEMA.

The LCST of PDMAEMA homopolymer was 46.6 °C, the LCST of the poly (CL-b-VB-g-DMAEMA) 5 heterograft copolymer sample was obtained to be 42.8 °C from the surface tension measurements of the aqueous solution of the heterograft copolymer (Fig. 12). It is reversible and it is observed that there is no transmittance above 43 °C. It is seen that the LCST value is getting closer to 46.6 °C depending on the increase in the amount of DMAEMA.

Conclusions

Poly (CL-b-VB-g-DMAEMA) pH- and thermo-responsive amphiphilic heterograft copolymers were, for the first time, synthesized in four steps. The proposed procedure for the preparation of heterograft copolymers is simple and efficient. By changing the initial concentrations, the heterograft copolymer compositions can be adjusted. It is observed that the results obtained from both UV and surface tension measurements support each other. The LCST of PDMAEMA homopolymer was 46.6 °C, the LCST of poly (CL-b-VB-g-DMAEMA) 5 heterograft copolymer was obtained to be 42.8 °C with the surface tension measurements which is shown in Fig. 11, with the aqueous solution of the heterograft copolymer. It is reversible and it is observed that there is no transmittance above 43 °C. The hydrophobic moieties of the multiblock copolymers cause the lower Tg than that of the homopolymer [45]. In addition to this, the LCST value is getting closer to 46.6 °C depending on the increase in the amount of DMAEMA. pH-sensitivity of the brush type graft copolymer was observed between pH 9.4 and 11.5. The acrylic polymer inclusion affects their swelling/solution properties in water. At lower pH regions, electrostatic repulsion force and intermolecular hydrogen bonding are principally main factor. At higher pH values, interchain hydrophobic interactions come into prominence. This responsive branched, brush type of the novel pH- and thermo-responsive copolymer can be applied to various areas such as new types of adaptive surfaces, sensors, microfluidics, antibacterial materials, and gene delivery.

References

Bates FS, Fredrickson GH (1990) Annu Rev Phys Chern 41:525–557

Hazer B (1990) Eur Polm J 26:1167–1170

Fei P, Cavicchi KA (2010) ACS Appl Mater Interfaces 2:2797–2803

Wu B, Lenz RW, Hazer B (1999) Macromolecules 32:6856–6859

Hazer B, Çakmak I, Denizligil S, Yağcı Y (1992) Angew Macromol Chem 195:121–127

Hazer B (1991) Eur Polym J 27:975–978

Wang GW, Hu B, Fan XS, Zhang YN, Huang JLJ (2012) Polym. Sci., Part A. Polym Chem 50:2227–2235

Zhang W, Müller AHE (2010) Polymer 51:2133–2139

Li H, Jerome R, Lecomte P (2006) Polymer 47:8406–8413

Kuo W-T, Chen H-L, Goseki R, Hirao A, Chen W-C (2013) Macromolecules 46:9333–9340

Yıldız U, Hazer B, Tauer K (2012) Polym Chem 3:1107–1118

Hazer B (1992) Makromol Chem 193:1081–1086

Voit BI, Lederer A (2009) Chem Rev 109:5924–5973

Hadjichristidis N, Pitsikalis M, Pispas S, Iatrou H (2001) Chem Rev 101:3747–3792

Ruzette AV, Leibler L (2005) Nat Mater 4:19–31

Hizal G, Tunca U, Sanyal AJ (2011) Polym. Sci., Part A. Polym Chem 49:4103–4120

Barbey R, Lavanant L, Paripovic D, Schuwer N, Sugnaux C, Tugulu S, Klok H-A (2009) Chem Rev 109:5437–5527

Nese A, Li Y, Averick S, Kwak Y, Konkolewicz D, Sheiko SS, Matyjaszewski K (2012) ACS Macro Lett 1:227–231

Brittain WJ, Minko SJ (2007) Polym. Sci., Part A. Polym Chem 45:3505–3512

Chiefari J, Chong YK, Ercole F, Krstina J, Jeffery J, Le TPT, Mayadunne RTA, Meijs GF, Moad CL, Moad E, Rizzardo E, Thang SH (1998) Macromolecules 31:5559–5562

Schmidt, B. V. K. J.; Barner-Kowollik, C. Nature Chemistry 2013, 5, 990–992

Pan JL, Miao J, Zhang LF, Si ZY, Zhang CW, Cheng ZP, Zhu XL (2013) Polym Chem 4:5664–5670

Goto A, Tsujii Y, Fukuda T (2008) Polymer 49:5177–5185

Robin MP, Wilson P, Mabire AB, Kiviaho JK, Raymond JE, Haddleton DM, O'Reilly RKJ (2013) Am Chem Soc 135:2875–2878

Ray B, Isobe Y, Matsumoto K, Habaue S, Okamoto Y, Kamigaito M, Sawamoto M (2004) Macromolecules 37:1702–1710

Ozturk T, Goktas M, Hazer B (2011) J Macromol Sci Part A: Pure Appl Chem 48:65–70

Ozturk T, Hazer B (2010) J Macromol Sci Part A: Pure Appl Chem 47:265–272

Patton DL, Mullings M, Fulghum T, Advincula RC (2005) Macromolecules 38:8597–8602

Topuzogullari M, Bulmus V, Dalgakiran E (2014) Dincer. S Polymer. doi:10.1016/j.polymer.2013.12.040

Öztürk, T.; Atalar, M. N.; Göktaş, M.; Hazer, B. J. Polym. Sci., Part A: Polym. Chem. 2013, 51, 2651–2659.

Öztürk, T.; Göktaş, M.; Savas, B.; Işıklar, M.; Atalar, M. N.; Hazer, B. e-Polymer 2014, 14, 27–34.

Ozturk T, Cakmak I (2008) J Macromol Sci Part A: Pure Appl Chem 45:572–577

Ozturk T, Hazer B (2010) J Macromol Sci Part A: Pure Appl Chem 47:265–272

Ozturk T, Cakmak IJ (2010) Appl Polym Sci 117:3277–3281

Ozturk T, Goktas M, Hazer BJ (2010) Appl Polym Sci 117:1638–1645

Momčilović N, Clark PG, Boydston AJ, Grubbs RHJ (2011) Am Chem Soc 133:19087–19089

Dong H, Zhu M, Yoon JA, Gao H, Jin R, Matyjaszewski KJ (2008) Am Chem Soc 130:12852–12853

Yu YC, Li G, Kang HU, Youk JH (2012) Coll Polym Sci 290:1707–1712

Chagneux N, Trimaille T, Rollet M, Beaudoin E, Gerard P, Bertin D, Gigmes D (2009) Macromolecules 42:9435–9442

Nomura R, Endo T (1995) Macromolecules 28:1754–1757

Kang HU, Yu YC, Shin SJ, Kim J, Youk JH (2013) Macromolecules 46:1291–1295

Li X, Zhu L, Xu Y, Yi Z, Zhu B (2011) Journal of Membrane Science 374:33–42

Chen K, Yang Y, Sa Q, Shi L, Zhao H (2008) Polymer 49:2650–2655

Fournier D, Hoogenboom R, Thijs HML, Paulus RM, Schubert US (2007) Macromolecules 40:915–920

A. Allı, B. Hazer (2008) Eur. Polym. J. 44: 1701–1713. Poly(N-isopropylacrylamide) thermoresponsive cross-linked conjugates containing polymeric soybean oil and/or polypropylene glycol”

Acknowledgment

This work was supported by; both the Bulent Ecevit University Research Fund (#BEU-2012-10-03-13) and TÜBİTAK (grant # 211 T016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Şanal, T., Oruç, O., Öztürk, T. et al. Synthesis of pH- and thermo-responsive poly (ε-caprolactone-b-4-vinyl benzyl-g-dimethyl amino ethyl methacrylate) brush type graft copolymers via RAFT polymerization. J Polym Res 22, 3 (2015). https://doi.org/10.1007/s10965-014-0640-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-014-0640-z