Abstract

Chitosan crosslinked with glutaraldehyde or oxidised dextran was studied as a potential scaffold material in tissue engineering for cartilage regeneration. By mixing two solutions of both components it became a gel, which was frozen. After lyophilisation a scaffold was generated with interconnected pores with diameters ranging between 120–350 μm. The mechanical properties (yielding point, elastic and viscous moduli), absolute porosity, pore morphology were determined depending on the ratio of chitosan to crosslinker. ATDC5 (murine cell line) and bovine articular chondrocytes (primary cells) were cultured for 14 days on the scaffolds. Cultivation with ATDC5 cells and bovine chondrocytes showed no negative influence of glutaraldehyde on cell vitality and growth.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

There are several conditions, which a scaffold for tissue engineering has to fulfil. For a start interconnecting pores are important to ensure the supply of the cells with nutrients and to favour tissue integration and vascularization. Furthermore, the pore size and shape are important for cell infiltration and tissue regeneration. Another aspect of the used material should be the biocompatibility and biodegradability. In addition the mechanical properties of the scaffold should have similar values as the natural tissue.

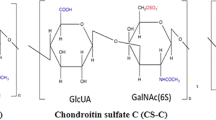

Chitosan is a well-known biodegradable polysaccharide with antibacterial properties used in biomedical and cosmetic applications [1, 2]. It is a linear polysaccharide based on glucosamin units, whereby the acetylation degree changes in a great range. For generating a scaffold material the polymer has to be crosslinked to raise its stability [3]. Chitosan can be crosslinked either ionically [3, 4] or covalently [3, 5–9]. As ionic crosslinkers polyanions are used like, triphosphate [3, 10], citrate [10] or natural polymers like hyaluronic acid or chondroitin sulfate [11]. In this connection the polyanion can interact with chitosan via electrostatic forces to form an ionic crosslinked network. The other possibility is the formation of a covalently network. The amino and hydroxy-groups of chitosan can react with functional groups of crosslinker molecules. Covalently crosslinked networks can be formed by di- or polyaldehydes (glutaraldehyde [3, 5, 7], oxidised starch [8] and oxidised cylcodextrin [9]). Also, to date, carboxylic acids [12], azides [13], epoxides [7, 14], diisocyanates [15] and silanes [16] are compounds used up to date as covalent crosslinker.

Another advantage of using chitosan is its biocompatibility and degradability. It can be degraded by enzymes in human body. For example lysozyme, an ubiquitous enzyme in the body, hydrolyse the glycosidic bond between neighbour N-acetylglucosamine residues [17]. The degradation depends on the degree of acetylation [2, 12, 18] and also varies by crosslinking [6, 19].

The crosslinking reaction with dialdehydes occurred at room temperature in aqueous media without requiring another chemical compound to activate the reaction. After mixing both solutions a gel is formed while the crosslinking reaction took place. By final freezing and lyophilisation a porous structure can be formed easily. This study compares glutaraldehyde and oxidised dextran as crosslinker agents for chitosan whereby the composition of chitosan and crosslinker were varied. By using glutaraldehyde and oxidised dextran two crosslinkers with different lengths and different amount of aldehyde groups located on one chain were chosen. Additionally three different oxidation degrees of dextran were used, so that different amounts of aldehyde groups are located on the polymer chain.

2 Experimental

2.1 Materials and instruments

Chitosan of low molecular weight (Mol wt = 50.000–190.000; degree of deacetylation: 75–85%) was purchased from Sigma-Aldrich. Glutaraldehyde (50% in water) was supplied by Merck. Dextran (Mol wt = 15.000–20.000) was supplied from Fluka and was oxidised with periodic acid [20]. The amount of aldehyde groups depends on the oxidation time. Dextran which is oxidised for ½, 1 and 24 h, respectively posses 16, 39 and 42% of oxidised sugar units. FTIR-ATR measurements were carried out with an instrument from Thermo Nicolet (AVATAR 370 FT-IR).

2.2 Preparation of chitosan scaffolds

Different concentrations of chitosan solution (0.5–2.5 wt%) were used. The requisite amount of chitosan was dissolved in 0.1N HCl (pH was set to a value of 5 with 1 N NaOH). Different glutaraldehyde solution (0.5–3.5 wt%) or 3.5 wt% oxidised dextran solution (oxidation time ½, 1 and 24 h) were used as crosslinker. Both solutions were dissolved overnight to obtain clear solutions. The scaffolds were fabricated by mixing 1 ml of chitosan solution and 1 ml of aldehyde solution (glutaraldehyde or oxidised dextran) in a small plastic tube with a diameter of 1.5 cm. After mixing both components the solution become a gel and was stored at −32°C, whereby the PE-tubes were surrounded with polystyrene to reduce the cooling down rate. After storing the samples for 10 h at –32°C the frozen chitosan scaffolds were lyophilised for 24 h.

2.3 Porosity and pore size

The porosity of the scaffold was determined by water absorption by weighing the amount of water, which is incorporated in the pores [14, 21]. This was done by weighing the scaffold before and after soaking for 30 min into deionised water. Porosity can be estimated according to the following equation:

where w wet is the hydrated mass and w dry the dry scaffold.

The pore size and geometry was determined by SEM-microscopic images. Before examining the scaffolds were sputter-coated with graphite as well as gold. Hereby 50 pores of each sample were measured.

2.4 Determining the crosslinking amount

The amount of amino groups was measured for each scaffold combination by using pH-titration [1, 20]. In this method 25 ml of a 0.1N HCl solution are added in excess to approximately 0.02 g crosslinked chitosan scaffolds (reduced to small pieces), allowing enough time (20 h) to charge all proton binding groups. Subsequently, the solution was titrated with 0.1N NaOH solution with enough time between each interval. Pure chitosan (0.2 g) was dissolved in HCl and titrated with NaOH. In case of free amino groups two steps could be recognised. The percentage of amino groups is calculated by Eq. 2:

in which M NaOH is the molarity of the NaOH solution, V 1 and V 2 the volume to neutralise the excess of HCl and the protonated amino groups, 161 is the molecular weight of the monomeric unit of chitosan and W is the mass of the sample in dry state before titration.

2.5 Determining the amount of free aldehyde groups

A total of 20 ml 0.25 M Na2SO3-solution was added to a special amount of glutaraldehyde. Hereby one sulfit ion reacts with one aldehyde group forming a hydrogensulfonate (RCH(OH)SO3Na) and NaOH. By conductivity titration with H2SO4 the amount of formed NaOH is determined, and thus the amount of aldehyde groups is determined indirectly.

2.6 Rheolocial measurements

The rheological properties of the scaffolds were measured by a rheometer (Rheo Stress 600, Thermo Electron Corporation, Germany) in oscillatory mode by using two parallel profiled plates (diameter 20 mm). The scaffolds were stored during the measurement in PBS-medium. For each composition three samples were tested. The tests were performed at controlled temperature of 20°C, at the equilibrium swollen state in physiological phosphate buffered solution (PBS). Preliminary strain sweep tests were performed to evaluate the region of deformation in which the linear viscoelasticity is valid. The oscillatory tests were performed from 0.1 to 100 Hz.

The yielding point was measured as follows: The shear stress was increased until the scaffold was destroyed. The deformation was determined depending on the shear stress. By graphical analysis of the intersection point of two tangents, which were fitted on this graph, the yielding point was determined.

2.7 Cell culture

Prior to cell seeding, the scaffolds were disinfected with 70 vol.% ethanol, then rinsed with distilled water and phosphate buffered saline several times before being stored in expansion medium for 3 days. ATDC5 cells (ECACC, No. 99072806) were cultivated in expansion medium, consisting of DMEM/F12 with Glutamax®, supplemented with 10 μg/ml recombinant human transferring (Gibco), 3 × 10−8 M sodium selenite (Aldrich), 1 g/l AlbuMAX® Serum Albumin, 1 vol.% Penicillin/Strepotmycin mix (both Gibco) and 1 vol.% fetal bovine serum (FBS), trypsinised using TrypLEExpress® (Gibco) enzyme solution and seeded at 1 million cells/scaffold (N = 4) onto the constructs. Scaffolds were cultivated under standard conditions (5% CO2, sat. moisture, 37°C) for 14 days in 12-well plates, with perpetual medium changes when necessary. Differentiation medium for scaffold cultivation was modified from expansion medium as follows: FBS was omitted, 0.1 μM Dexamethasone, 10 ng/ml rhIGF (Roche) and 2.5 ng/ml rhTGFβ3 (HISS Diagnostics, Freiburg) were added. Bovine articular chondrocytes were isolated from fetlocks of 1–2 year old cattle, obtained from the local abattoir, and cultivated with expansion medium as above, except that 10 vol.% FBS was used. Further processing and differentiation medium were the same.

Four days after seeding, the scaffolds were turned upside down and the cells which adhered to the bottom of the well were trypsinated and applied on top of the scaffold again. After another 3 days the scaffolds were placed in a new plate and the expansion medium was exchanged for differentiation medium. After 14 days the cell cultures were parted in half, one half being fixed in formalin/glutaraldehyde buffer containing cacodylate, dehydrated and critical-point dried for SEM investigation. For histological investigations, the other half was fixed in phosphate buffered 4% formaline solution (Roth) and embedded in paraffin for thin-sectioning. 10 μm thin sections were stained with Sirius Red, Giemsa (both Chroma) or Alcian blue 8GX (Fluka) at pH 1.0. All samples were viewed with a Zeiss Axioplan 2 microscope in transmission, Sirius Red staining for collagen being analysed under crossed polarisation filters in order to visualise collagen fibres.

3 Results and discussion

3.1 Physical and chemical characterisation of chitosan scaffolds

3.1.1 Degree of crosslinking capacity

The amount of free amino groups can be calculated by pH-titration [1, 5, 20]. Starting with an excess of HCl the addition of NaOH increases the pH-value. The first sharp increase corresponds to the excess of HCl. The amount of NaOH between the first and the second jumping point corresponds to the amount of free amino groups. Figure 1 shows the pH-titration of the chitosan. The two steps at 12 and 25 ml of 0.1N NaOH in the diagram indicate 77% of free amino groups of chitosan, used as basis material. The pH-titration of two crosslinked species, one with the crosslinker glutaraldehyde and the other one with oxidised dextran, were carried out (Fig. 1). The chitosan crosslinked either with glutaraldehyde or oxidised dextran does not present significant amounts of amino groups. This result indicates a complete reaction of the amino groups and is comparable with measurements of crosslinked chitosan membranes with glutaraldehyde [14]. The FTIR measurements (Fig. 2) of chitosan and crosslinked chitosan incorporated in the scaffolds confirm a complete reaction of the amino groups, too. Both the NH2 stretching bands at 3352 and 3289 cm−1 and the NH2 bending frequency at 1586 cm−1, which are observed in the chitosan spectrum, could not be observed in both spectra of the scaffolds. Furthermore, a band belonging to imine binding at 1624 and 1635 cm−1, respectively, can recognize the crosslinking of glutaraldehyde or oxidised dextran and chitosan.

3.1.2 Pore size and pore geometry

Porous chitosan structures are formed by freezing and lyophilisation the solution. During the freezing process, ice crystals are formed. By removing these crystals by lyophilisation a porous material remains. The kind of porosity depends, to a greater extent, on the freezing conditions. Both the temperature, the thermal gradient and the cooling rate have an effect on the pore structure [3, 12, 22–25]. High porosity and interconnectivity pore structure are necessary for tissue-guided scaffold materials. The pore diameter should be in the range of cell diameters to enable cell infiltration and vascularisation of the scaffold. Figure 3a, b shows scanning electron images of both kinds of scaffolds, whereas both scaffolds posses a homogeneous pore size geometry. The shape of the pores is nearly round and the ratio of horizontal and vertical axis varies between 0.8 and 1.2. Figure 3a, b show the graphical analysis of pores formed in scaffolds with different composition. The diameter of glutaraldehyde crosslinked chitosan scaffolds ranges from 120 to 340 μm with an average diameter of 140 μm independent from chitosan and glutaraldehyde concentration (Fig. 4a). The pores of the scaffolds crosslinked with oxidized dextran are a little bit higher in diameter and range from 150 to 280 μm with an average diameter of 190 μm (Fig. 4b). In the case of glutaraldehyde as crosslinker, a reduction could be observed of the pore diameter in the series of 1 up to 2.5% chitosan crosslinked with 0.5% glutaraldehyde and also in the series of 1 up to 2% chitosan crosslinked with 1% glutaraldehyde. In the case of oxidized dextran as crosslinker no dependence between chitosan concentration and pore diameter could be observed. By using the oxidized dextran with the least amount of aldehyde groups (Dex-0.5 h, 15% oxidized sugar units) the pore sizes are in general higher compared to the oxidized dextran species with higher amount of aldehyde groups (Dex-1 h and 24 h, oxidation degree of 39 and 41%, respectively) (Fig. 4b). By freezing uncrosslinked chitosan solution Madihally and Matthew [22] found a decrease of pore sizes by lower freezing temperature and also by higher chitosan concentration. This different observation could be caused by different freezing procedures. In our experiments we allowed the solution to form a gel before freezing, thereby a network of covalently crosslinked chitosan is formed, which should have an influence of the final pore structure.

The absolute porosity of the scaffolds was determined by the water uptake ability (Fig. 5). This was done by weighing the dry and wet scaffolds. The crosslinked chitosan scaffolds show an absolute porosity between 95 and 98%, corresponding to scaffolds formed from 0.3% chitosan solutions [26]. The chitosan scaffolds crosslinked with glutaraldehyde show a small decrease of porosity by using higher amount of crosslinker, this could be explained by smaller pore radii. This trend was also seen by Silva et. al. [19] who found a decrease of water uptake of chitosan/soy blend membranes by using higher amounts of glutaraldehyde crosslinker. The porosity of 95–98% is slightly higher as in the natural cartilage. The main part of 60–80% of the natural hyaline cartilage consists of water and only 20–40% are organic components (like collagen and proteoglycane) [27].

3.1.3 Mechanical properties

The mechanical properties of the lyophilized scaffolds stored in PBS-solution were determined. On the one hand the yielding point was measured, which gave an idea of the strength of the network formed by crosslinking. On the other hand the storage (G′) and loss modulus (G′′) were determined. G′ gives information about the elasticity or the energy stored in the material during deformation and G′′ describes the viscous character or the energy dissipated as heat. Figure 6a shows the yielding point of the chitosan scaffolds crosslinked with glutaraldehyde. By increasing the concentration of crosslinker and chitosan the yielding point increases, indicating a stronger network based on more crosslinking points. In case of the scaffolds crosslinked with oxidized dextran an increase of the yielding point can also be recognized by increasing chitosan concentration (Fig. 6b). The same trend could be observed in the oscillatory measurements (Fig. 7) in case of glutaraldehyde using as crosslinker. The storage and loss modulus (plateau values at low frequency) increase by higher amount of crosslinker and chitosan concentration. The differences between both crosslinkers could be explained by the different networks of both scaffold types. Glutaraldehyde is much shorter than oxidized dextran and differs additionally in its aldehyde groups, so that a stiffer network is formed. Supplementary, the main component of the scaffolds crosslinked with oxidized dextran is not chitosan as in the scaffolds crosslinked with glutaraldehyde. Furthermore it could be seen that the storage modulus G′ is in each case higher than the loss modulus G′′, which indicates that the elastic property of the material predominates in the case of both crosslinkers. By using higher amounts of crosslinker the storage and loss modulus increase. This trend was also observed by Draget [28] who investigated chitosan gels. Hsieh et al. [3] compared the mechanical properties of ionically (tripolyphosphate) and covalently crosslinked chitosan scaffolds. The glutaraldehyde crosslinking show higher values of tensile stress and strain and also an increase of tensile stress and strain with increasing concentration of glutaraldehyde.

3.1.4 Analysis of unreacted glutaraldehyde

If glutaraldeyde is used as crosslinker it is often mentioned as undesirable, because a toxic aldehyde is incorporated in the scaffold. Glutaraldehyde, which is either non reacted or set free by degradation, is discussed as potential danger [17, 29, 30]. By conductivity titration we were able to detect in the case of scaffolds crosslinked with 3.5% glutaraldehyde (combination with the highest part of glutaraldehyde) 2–3.5 μl glutaraldehyde released from one scaffold of 0.045 g weight. After rinsing with water no glutaraldehyde could be detected even if the scaffold was stored for 5 days in distilled water (5 ml). By rinsing with distilled water unreacted glutaraldehyde could be removed completely. An in vitro study which examined the releasing of glutaraldehyde from crosslinked tendon was carried out by Huang-Lee et al. [30]. In this study the release of glutaraldehyde was found over a time of 10 weeks, whereas they could not distinguish if the release of the aldehyhde came from reversibility of the Schiff bases or from the breakdown of the collagenous matrix. In comparison to our porous scaffold material the tendon is a dense material, therefore, the removal of excess glutaraldehyde in our chitosan scaffold by rinsing is done easier and perhaps more complete.

3.2 Biological investigations of the chitosan scaffolds

Three different scaffolds were chosen for cell tests, 1 wt.% chitosan crosslinked with 0.5 and 1.5 wt.% glutaraldehyde and 1.5 wt.% chitosan crosslinked with 0.5 wt.% glutaraldehyde. Other combinations were either not suited for cell seeding or lacked sufficient stability for handling in culture. Especially the dextran-crosslinked scaffolds could not be used in cell cultivation.

Figure 8 shows SEM images of 1% chitosan/1.5% glutaraldehyde cultivated with ATDC5 (a) or chondrocytes (b). Abundant cell growth with fibroblastic morphology can be found, without evidence of adverse effects on the material. Cell growth was limited to the outer scaffold regions due to nutrient limitations. The respective histological images are given in Fig. 9. Strong matrix formation with dense layers of collagen in the outer region is demonstrated by Sirius red (a, d) and Giemsa (b, e) staining, especially for bovine chondrocytes. The presence of sulphated GAG is shown by Alcian blue stain at pH 1.0 (c, f) for both cell types.

Histological images of ATDC5 cells (a, c, e) and chondrocytes (b, d, f) cultured for 14 days on chitosan (1%) scaffolds crosslinked with 1.5% glutaraldehyde. a, b Sirius red stain under crossed polarization filters for collagen fibres (red). c, d Giemsa stain for general matrix production (blue, chitosan stained red). e, f Alcian blue stain at pH 1.0 for sulphated GAG (blue)

4 Conclusion

Two different reagents for crosslinking chitosan covalently were determined. By using these crosslinker agents a porous structure with interconnecting pores could be obtained in both cases. Hereby the diameter of the pores received by using oxidized dextran was a little bit higher. The yielding point and the storage and loss moduli of glutaraldehyde crosslinked scaffolds show in comparison with oxidised dextran a dependence of the chitosan concentration. While oxidised dextran crosslinked scaffolds were unsuitable for cell cultivation due to strong swelling, selected glutaraldehyde crosslinked scaffolds showed no obvious toxic effects on cells and supported a lush cell growth, indicating a good suitability for tissue culture. Apparently, all aldehyde groups had reacted before cell seeding and no toxic concentrations of glutaraldehyde were liberated within the 14 days of cultivation.

The cell culture experiments of chitosan scaffolds crosslinked with glutaraldehyde show in the case of chondrocytes a good cell seeding even to the inner part of the scaffold and also collagen production could be recognized after 14 days of culturing. A publication of a more detailed investigation of cell tests is in preparation.

References

Khor E. Chitin: Fulfilling a biomaterials promise. 1st ed. Amsterdam: Elsevier; 2001.

Di Martino A, Sittinger M, Risbud MV. Chitosan: a versatile biopolymer for orthopaedic tissue-engineering. Biomaterials. 2005;26(30):5983–90.

Hsieh CY, Tsai SP, Ho MH, Wang DM, Liu CE, Hsieh CH, et al. Analysis of freeze-gelation and cross-linking processes for preparing porous chitosan scaffolds. Carbohydr Polym. 2007;67(1):124–32.

Peniche C, Fernadez M, Rodriguez G, Parra J, Jimenez J, Lopez Bravo A, et al. Cell supports of chitosan/hyaluronic acid and chondroitin sulphate systems Morphology and biological behaviour. J Mater Sci Mater Med. 2007;18(9):1719–26.

Gupta KC, Jabrail FH. Glutaraldehyde cross-linked chitosan microspheres for controlled release of centchroman. Carbohydr Res. 2007;342(15):2244–52.

Adekogbe I, Ghanem A. Fabrication and characterization of DTBP-crosslinked chitosan scaffolds for skin tissue engineering. Biomaterials. 2005;26(35):7241–50.

Ngah WSW, Endud CS, Mayanar R. Removal of copper(II) ions from aqueous solution onto chitosan and cross-linked chitosan beads. React Funct Polym. 2002;50(2):181–90.

Baran ET, Mano JF, Reis RL. Starch-chitosan hydrogels prepared by reductive alkylation cross-linking. J Mater Sci Mater Med. 2004;15(7):759–65.

Paradossi G, Cavalieri F, Crescenzi V. H-1 NMR relaxation study of a chitosan-cyclodextrin network. Carbohydr Res. 1997;300(1):77–84.

Shu XZ, Zhu KJ. Controlled drug release properties of ionically cross-linked chitosan beads: the influence of anion structure. Int J Pharm. 2002;233(1–2):217–25.

Montembault A, Tahiri K, Korwin-Zmijowska C, Chevalier X, Corvol MT, Domard A. A material decoy of biological media based on chitosan physical hydrogels: application to cartilage tissue engineering. Biochimie. 2006;88(5):551–64.

Mao JS, Zhao LG, Yin YJ, Yao KD. Structure and properties of bilayer chitosan-gelatin scaffolds. Biomaterials. 2003;24(6):1067–74.

Zhu AP, Zhang M, Wu J, Shen J. Covalent immobilization of chitosan/heparin complex with a photosensitive hetero-bifunctional crosslinking reagent on PLA surface. Biomaterials. 2002;23(23):4657–65.

Vieira RS, Beppu MM. Interaction of natural and crosslinked chitosan membranes with Hg(II) ions. Colloids Surf A Physicochem Eng Asp. 2006;279(1–3):196–207.

Lin-Gibson S, Walls HJ, Kennedy SB, Welsh ER. Reaction kinetics and gel properties of blocked diisocyinate crosslinked chitosan hydrogels. Carbohydr Polym. 2003;54(2):193–9.

Liu YL, Su YH, Lai JY. In situ crosslinking of chitosan and formation of chitosan-silica hybrid membranes with using gamma-glycidoxypropyltrimethoxysilane as a crosslinking agent. Polymer. 2004;45(20):6831–7.

Mi FL, Tan YC, Liang HF, Sung HW. In vivo biocompatibility and degradability of a novel injectable-chitosan-based implant. Biomaterials. 2002;23(1):181–91.

Tomihata K, Ikada Y. In vitro and in vivo degradation of films of chitin and its deacetylated derivatives. Biomaterials. 1997;18(7):567–75.

Silva SS, Santos MI, Coutinho OP, Mano JF, Reis RL. Physical properties and biocompatibility of chitosan/soy blended membranes. J Mater Sci Mater Med. 2005;16(6):575–9.

Hoffmann B, Volkmer E, Kokott A, Weber M, Hamisch S, Schieker M, et al. A new biodegradable bone wax substitute with the potential to be used as a bone filling material. J Mater Chem. 2007;17(38):4028–33.

Chow KS, Khor E. Novel fabrication of open-pore chitin matrixes. Biomacromolecules. 2000;1(1):61–7. Spring.

Madihally SV, Matthew HW. Porous chitosan scaffolds for tissue engineering. Biomaterials. 1999;20(12):1133–42.

Suh JK, Matthew HW. Application of chitosan-based polysaccharide biomaterials in cartilage tissue engineering: a review. Biomaterials. 2000;21(24):2589–98.

Mao JS, Liu HF, Yin YJ, Yao KD. The properties of chitosan-gelatin membranes and scaffolds modified with hyaluronic acid by different methods. Biomaterials. 2003;24(9):1621–9.

Chen DC, Lai YL, Lee SY, Hung SL, Chen HL. Osteoblastic response to collagen scaffolds varied in freezing temperature and glutaraldehyde crosslinking. J Biomed Mater Res A. 2007;80A(2):399–409.

Aliakbar Moshfeghian JT, Sundararajan V, Madihally. Characterization of emulsified chitosan-PLGA matrices formed using controlled-rate freezing and lyophilization technique. J Biomed Mater Res A. 2006;79(2):418–30.

Martinek V. Anatomy and pathophysiology of articular cartilage. Dtsch Z Sportmed. 2003;54(6):166–70.

Draget KI. Associating phenomena in highly acetylated chitosan gels. Polym Gel Netw. 1996;4(2):143–51.

Lee CR, Grodzinsky AJ, Spector M. The effects of cross-linking of collagen-glycosaminoglycan scaffolds on compressive stiffness, chondrocyte-mediated contraction, proliferation and biosynthesis. Biomaterials. 2001;22(23):3145–54.

Huang-Lee LL, Cheung DT, Nimni ME. Biochemical changes and cytotoxicity associated with the degradation of polymeric glutaraldehyde derived crosslinks. J Biomed Mater Res. 1990;24(9):1185–201.

Acknowledgments

This work was supported by the “Friedrich-Baur-Stiftung”, Altenkunstadt, Germany. We would like to express our thanks to Dipl.-Ing. Sabine Hamisch for her advice and guidance with the rheological measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hoffmann, B., Seitz, D., Mencke, A. et al. Glutaraldehyde and oxidised dextran as crosslinker reagents for chitosan-based scaffolds for cartilage tissue engineering. J Mater Sci: Mater Med 20, 1495–1503 (2009). https://doi.org/10.1007/s10856-009-3707-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3707-3