Abstract

With the increase of global energy consumption, bioenergy from microalgae has been recognized as a potential alternative choice. A novel carbohydrate-rich microalgal strain, isolated from Xisha Islands (China), was identified as Rhodosorus sp. SCSIO-45730. To accumulate biomass for bioenergy production, strategies of phosphate optimization and chitosan flocculation were used to evaluate its potential for the production of biomass, total carbohydrates, and β-glucans. The biomass of this alga reached 12.3 ± 0.1 g L−1 in vertical bubble column photobioreactors at the phosphate concentration of 120 mg L−1, and the productivities of total carbohydrates and β-glucans maximized up to 242.6 ± 2.3 mg L−1 day−1 and 108.1 ± 4.0 mg L−1 day−1, respectively. Simultaneously, flocculation results demonstrated that the recovery rate of the biomass, total carbohydrates, and β-glucans were over 90% at a low chitosan concentration of 3 mg L−1. The flocs were easily collected and washed through a 300-mesh bolting cloth, presenting an ultralow harvest cost of 2.93 US$ per tonne of biomass. In summary, addition of suitable phosphate and flocculation with low chitosan concentration could be effective strategies to enhance the commercial potential of Rhodosorus sp. SCSIO–45730 as a feedstock for biofuel and β-glucans.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of fossil fuels is causing environmental pollution such as the greenhouse effect and climate change (Sivakumar et al. 2010; Ho et al. 2011). Thus, biofuels from biomass are considered to be one of the ways through which energy and environmental issues could be avoided due to being biodegradable, nontoxic, and carbon neutral (Ho et al. 2010; Toor et al. 2019). Among biofuels, bioethanol is being preferred because of its higher heat of vaporization and higher octane than conventional fuels (Formighieri 2015). In recent decades, the carbohydrate-rich microalgae have received great attention as promising feedstocks for biofuels (Jones and Mayfield 2012; Bobadilla et al. 2013). Moreover, the carbohydrate-rich microalgae are also promising feedstocks for β-glucans (Jones and Mayfield 2012; Bobadilla et al. 2013). β-Glucans are polysaccharides, consisting of D-glucose monomers linked by β-glycosidic bonds and are mainly found in yeast, fungi, bacteria, plants, and algae (Du et al. 2014). β-Glucans show extensive biological activities, including immunoregulatory, anticancer, anti-inflammatory, antioxidant, and hypolipidemic (Zhou et al. 2016; Zhu and Wu 2019). Several microalgae are considered important source of β-glucans, such as Nannochloropsis and Porphyridium purpureum (Schulze et al. 2016; Rojo-Cebreros et al. 2017).

Phosphorus is one of the essential elements which regulate algal growth and metabolism. It approximately constitutes 1% of microalgal dry weight (DW) (Borchardt and Azad 1968). Phosphorus plays a key role in processes involving in energy and information storage and transfer (Raghothama 2000). It has been reported that phosphorus levels significantly affected microalgal growth and biomass composition (Lai et al. 2011; Wu et al. 2014). Adenan et al. (2016) found the biomass of Chlorella sp., and Chaetoceros calcitrans in phosphorus-deprived cultures were lower than that in non-deprived cultures. According to Roopnarain et al. (2014), varying levels of phosphorus had effects on the cell growth and lipid accumulation in Isochrysis galbana U4. The effects of phosphorus on microalgal carbohydrates vary with species. For example, carbohydrate content of Prorocentrum donghaiense increased in phosphorus-limited conditions, while it decreased for Chlorella sp. (Lai et al. 2011; Liang et al. 2012).

Microalgae harvesting contributes approximately to 20–30% of the total cost of biomass and is considered a bottleneck for the commercial production of microalgae (Grima et al. 2003). Therefore, a cost-effective manner for harvesting microalgae to reduce the total production cost is very important. Nowadays, flocculation is becoming the most cost-efficient and convenient method in harvesting microalgal biomass due to the rapid treatment of a large amount of microalgal cultures (Vandamme et al. 2013). There are various flocculation technologies, such as chemical flocculation, physical flocculation, and bio-flocculation (Vandamme et al. 2013). Bio-flocculation has been demonstrated to be effective for wastewater treatment and environmentally friendly for microalgae harvesting (Kim et al. 2011; Hende et al. 2014).

Chitosan is one of the most promising bio-flocculants. It is a linear poly-amino-saccharide obtained by partial deacetylation of chitin—a waste product from shellfish sources. Chitosan has been proved very effective in flocculating microalgae (Divakaran and Pillai 2002). Generally, flocculation using chitosan has been indicated to be effective for freshwater microalgae harvesting (Divakaran and Pillai 2002; Ahmad et al. 2011), while the results are unpredictable for harvesting of marine microalgae. It was reported that chitosan was not effective for flocculating marine species (Sukenik et al. 1988; 't Lam et al. 2016). 't Lam et al. (2016) also found that chitosan performed poorly in seawater. On the other hand, Morales et al. (1985) reported that chitosan flocculation was effective for five marine microalgae. Garzon-Sanabria et al. (2013) and Farid et al. (2013) found good results in chitosan flocculation of the marine microalgae Nannochloropsis. More recently, Yamin et al. (2019) also indicated that chitosan was valid for the marine diatom C. gracilis, especially in alkaline conditions (pH = 9).

In this research, a novel microalgal strain Rhodosorus sp. SCSIO-45730 was isolated and characterized. Its potential as a feedstock for bioethanol and β-glucan production under different phosphate concentrations was evaluated. Moreover, flocculation of the microalgal biomass using chitosan was investigated, and the cost and effect of chitosan flocculation on carbohydrates and β-glucans of the microalga were also assessed.

Materials and methods

Algal strain and culture conditions

The microalga was isolated and purified by the streak plate method from the seawater samples collected from Xisha Islands, South China Sea (111°45.000′ E, 16°28.471′ N). The plate contained the modified ASW medium (ASW medium) comprising 1% agar. The ingredients of the ASW medium were composed of NaNO3 (1500 mg L−1), K2HPO4 (120 mg L−1), NaHCO3 (40 mg L−1), FeCl3·6H2O (3.15 mg L−1), EDTANa2·2H2O (4.36 mg L−1), MnCl2·4H2O (0.18 mg L−1), ZnSO4·7H2O (0.022 mg L−1), Na2MoO4·2H2O (0.006 mg L−1), CoCl2·6H2O (0.01 mg L−1), and CuSO4·5H2O (0.01 mg L−1) in 28‰ sea water (Li et al. 2019). Then, this strain was cultured in 300-mL vertical bubble column photobioreactors (3.0 cm × 60 cm) containing the ASW medium. Illumination was provided with fluorescent lamps located at one side of the photobioreactor, and the photoperiod was 24 h:0 h (light:dark). The light intensity gradually increased from 30 to 180 μmol photons m−2 s−1 in the first 4 days of cultivation and then kept at 180 μmol photons m−2 s−1. The growth temperature was maintained at 25 ± 1 °C. The carbon source and agitation were supplied by bubbling CO2-enriched compressed air (1% CO2, v/v).

Morphological and molecular identification of the microalga

Morphological characterization was examined under a light microscope (BX53, Olympus, Japan). Genomic DNA of the microalgal cells was extracted using HP Plant DNA Kit (OMEGA Bio-Tech Co. Ltd., USA). The 18S rRNA gene was amplified by polymerase chain reaction (PCR) using primers 16F (forward, 5′-TGCGGCTGGATCACCTCCTT-3′) and 23R (reverse, 5′-TCTGTGTGCCTAGGTATCC-3′) (2720, Thermo Fisher Scientific, China). The PCR program for amplification was 94 °C for 5 min, 36 cycles of 94 °C for 80 s, 52 °C for 1 min, and 72 °C for 2 min, followed a final 10-min extension step at 72 °C. The PCR products were purified and sequenced by Tian Yi Hui Yuan Gene Technology Inc. (Guangzhou, China). The obtained sequence was aligned and compared to those in GenBank database of the National Center for Biotechnology Information (NCBI) by a BLAST search. Kimura’s two-parameter neighbor-joining algorithm was used to construct the phylogenetic tree through MEGA6 software with 1000 bootstraps.

Different phosphate concentrations treatment

To investigate the effects of phosphate concentrations on the growth, carbohydrates, and β-glucan production, the isolated strain was cultivated in ASW medium containing different phosphate concentrations (0, 60, 120, and 240 mg L−1) in 300-mL vertical bubble column photobioreactors. Each treatment has three independent biological replicates. Then, the microalga was cultivated with optimized concentration of phosphate in 1.5-L vertical bubble column photobioreactors (6.0 cm × 60 cm) for harvesting experiment. For each batch of cultivation, the microalga was activated by subculturing the stock culture twice.

Harvesting of microalga

Chitosan solution preparation

Commercial chitosan with 90% degree of deacetylation was used. One percent chitosan stock solution was prepared by dissolving chitosan in 1% acetic acid solution under magnetic stirring at room temperature until fully dissolved.

Effect of chitosan concentrations on flocculation efficiency

The microalgal culture at the stationary growth phase was used for flocculation experiments. Specifically, aliquots of 50 mL microalga suspensions were rapidly mixed in a 50-mL beaker for 5 min using a magnetic stirrer under room temperature. Certain volumes of chitosan solution were added slowly to reach a final concentration of 0, 1, 3, 5, 10, 20, 50, 80, and 120 mg L−1, respectively. The stirring was continued for 2 min, and the suspensions were then allowed to settle for the specified time. An aliquot of the microalgal suspension at the height of two-thirds from the bottom was taken to measure the optical density at 750 nm (OD750). The flocculation efficiency (%) of Rhodosorus sp. SCSIO-45730 was calculated using the following equation:

where OD750,initial is the OD750 of the initial culture medium and OD750,sample is the OD750 of the sample. All the flocculating experiments were conducted in duplicate.

Effect of pH on the flocculation efficiency of microalga

The effect of pH on the flocculation efficiency of the isolated microalga was investigated under the optimal chitosan concentration. For this test, 4 N HCl and 4 N NaOH were added to the algae cultures (pH of untreated culture was 7.7) until the desired pH was achieved. Then the chitosan was added to the algal suspensions. The suspensions were mixed immediately by magnetic stirring, allowed to settle for the specified time and measured as above.

Biomass and composition measurement

Growth of the isolated strain was monitored every other day by measuring the biomass dry weight (DW, g L−1) of each culture system. Briefly, a known volume sample of each culture system was filtered through a pre-weighed 0.45-μm membrane filter and washed by deionized water. Each filter was dried overnight in a dry oven at 80 °C and reweighed.

The total carbohydrates were extracted with 10 mg lyophilized cell samples using 1 N H2SO4 at 80 °C in a water bath. The total carbohydrate content was measured by the phenol-sulfuric acid method described in Dubois et al. (1956). For β-glucan content determination, the enzymatic kit “Mushroom and Yeast Beta-Glucan Assay Procedure” (K-YBGL 12/16, Megazyme, Bray, Ireland) was used, following the manufacturer’s instructions.

The crude protein content of the microalga was analyzed by Kjeldahl method and was calculated using a nitrogen-to-protein conversion factor of 6.25 (Barbarino and Lourenço 2005; Santizo-Taan et al. 2020). Lipid extraction and content determination was performed with a modified Khozin-Goldberg method (Khozin-Goldberg et al. 2005). The fatty acid composition and the phycobiliproteins content were determined as described by Li et al. (2019).

Zeta potential measurements

Zeta potential of the microalgal strain was measured using Malvern Zetasizer Nano system (ZEN3600; Malvern instruments Ltd., UK). The untreated microalgal suspension and treated samples at different chitosan concentrations and pH were quickly mixed and rapidly measured at room temperature. All the measurements were conducted in duplicates, and the readings were taken from the mean values of three repetitions.

Statistical analysis

All measurements were conducted in duplicates, and the results were expressed as the mean ± SD. One-way analysis of variance (ANOVA) (p < 0.05) with Tukey’s test was used to analyze the statistically significant differences between treatments. The data were tested for normality (Shapiro-Wilk test) and for homogeneity of variance (F test or Brown-Forsythe test) at the 0.05 significance level. When non-normality or non-homogeneity of variance was found, non-parametric Mann-Whitney test was used. All results analysis and visualization were performed by GraphPad Prism 5 and Origin 8.1 software.

Results and discussion

Identification and characterization of the microalga

Microscopic observation revealed that the isolated microalgal strain was a unicellular red alga. The cells were coccoid and easy to aggregate, ranging from 4 to 8 μm in diameter (Fig. 1a). A single pyrenoid is located in the middle of each cell. The strain reproduced by cell division forms two or four autospores. These morphological features were similar to the Rhodosorus species as reported by Wilson et al. (2002) and Krayesky-Self et al. (2020). For further identification of the isolated strain, phylogeny analysis was performed using the 18 rRNA sequence (Fig. 1b). This strain showed close genetic similarity with Rhodosorus marinus UTEX1538 (FJ595493.2). According to the results of morphological and molecular identification, the isolated strain was identified as Rhodosorus sp. SCSIO-45730.

Morphological and molecular identification of the microalga a microscopic images of isolated Rhodosorus sp. SCSIO-45730 at different state of cell division. Scale bar indicates 10 μm; b phylogenetic tree for isolated Rhodosorus sp. SCSIO-45730 strain constructed by neighbor-joining algorithm based on 18S rDNA sequences through MEGA6 software with 1000 bootstraps

Rhodosorus sp. SCSIO-45730 could grow well in ASW medium (Fig. 2a). The dry weight reached over 10 g L−1. Analysis of main components of Rhodosorus sp. SCSIO-45730 (Fig. 2b) indicated that carbohydrates were the dominant compound of this strain, accounting for over 40% of dry weight. Moreover, β-glucan determination showed the high β-glucan content of Rhodosorus sp. SCSIO-45730, which was about 21% of dry weight. Therefore, this research focused on phosphate optimization and chitosan flocculation to enhance the commercial potential of Rhodosorus sp. SCSIO-45730 for total carbohydrate and β-glucan production.

Effect of different phosphate concentrations on Rhodosorus sp. SCSIO-45730

Microalgal biomass

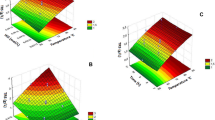

The effect of different phosphate concentrations on the growth of Rhodosorus sp. SCSIO-45730 is shown in Fig. 3a. From day 0 to day 4, there were no obvious differences in dry weight of the microalga at different phosphate concentrations (p > 0.05). However, the dry weight of the microalga improved with the increase of phosphate concentrations after day 6. The growth of the microalga was significantly inhibited under phosphate-deprived condition (0 mg L−1 K2HPO4) (p < 0.05), and the biomass at the end of the culture was 2.9 ± 0.1 g L−1. With the increase of phosphate concentration to 120 mg L−1, the biomass of Rhodosorus sp. SCSIO-45730 increased to 12.3 ± 0.1 g L−1, which was consistent with the results from a previous study by Kalla and Khan (2016) who studied Chlorella vulgaris. There were no obvious differences in the microalgal biomass of Rhodosorus sp. SCSIO-45730 when the phosphate concentration was increased to 240 mg L−1 (p > 0.05).

Phosphorus is a crucial element requirement for general growth and development of algal cells (Juneja et al. 2013). Phosphorus limitation reduces the combination and regeneration of substrates in the Calvin-Benson cycle and decreases the light usage required for carbon fixation (Kalla and Khan 2016).

The biomass of Rhodosorus sp. SCSIO-45730 at 120 mg L−1 phosphate is much higher than those for many microalgae cultured in a photobioreactor, the later could reach 4 g L−1 (Sero et al. 2020). Li et al. (2019) reported that the biomass of Porphyridium purpureum SCS-02 reached 5.54 g L−1 under the similar condition. The results indicated that Rhodosorus sp. SCSIO-45730 is a promising raw material for biomass production.

Total carbohydrate and β-glucan production

The content of total carbohydrates was distinctly enhanced from 24.2 ± 0.2 to 43.8 ± 0.3% DW (p < 0.05) with the increase of phosphate concentrations from 0 to 120 mg L−1 (Fig. 3b). Simultaneously, the total carbohydrate productivity improved from 20.4 ± 0.1 to 242.6 ± 1.3 mg L−1 day−1. A similar result was reported by Said (2009) who found that carbohydrate content of Dunaliella parva was significantly reduced in response to phosphorus limitation. However, when the phosphate concentration was increased to 240 mg L−1, the content and productivity of the total carbohydrates in Rhodosorus sp. SCSIO-45730 decreased to 37.3 ± 0.5% DW and 219.7 ± 2.3 mg L−1 day−1, respectively. These results suggested the phosphate concentration of 120 mg L−1 was beneficial for carbohydrate production by this strain.

It has been reported that high microalgal carbohydrates production could be used for ethanol production. For example, C. vulgaris FSP-E was reported to produce 51% carbohydrate per dry weight after nitrogen starvation, and its bioethanol yield (g g−1 substrate) was 0.23 (Ho et al. 2013). Chng et al. (2017) found that the carbohydrate-rich microalga Scenedesmus dimorphus (49% w/w of carbohydrate) can potentially be utilized as biomass for fermentation to produce bioethanol. Moreover, Scenedesmus elongatus PCC 7942 has been genetically modified to increase its carbohydrate content from 28 to 35% (DW) for the production of bioethanol. In this study, the high content and productivity of total carbohydrates of Rhodosorus sp. SCSIO-45730 at 120 mg L−1 phosphate concentration indicated that the microalga strain may also be used as a feedstock for bioethanol production.

Microalgal carbohydrates are a suitable biomass compound for the production of several biofuels. The greatest potential, however, lies in their application as immunostimulants because most of microalgal carbohydrates are generally β-glucans (Rojo-Cebreros et al. 2017). β-Glucans have been considered storage components in several microalgae such as Nannochloropsis (Rojo-Cebreros et al. 2017). The effect of phosphate concentrations on the content and productivity of β-glucans of Rhodosorus sp. SCSIO-45730 is shown in Fig. 3c. The variation tendency was similar as that of total carbohydrates. The content and productivity of β-glucans of Rhodosorus sp. SCSIO-45730 were 6.6 ± 0.2% DW and 8.3 ± 0.3 mg L−1 day−1, respectively, when phosphate was deprived (0 mg L−1 phosphate). When the phosphate concentrations changed from 0 to 120 mg L−1, the content and productivity of β-glucans significantly improved to 19.4 ± 0.8% DW and 108.1 ± 4.0 mg L−1 day−1, respectively (p < 0.05). When the phosphate concentration was 240 mg L−1, the content and productivity of β-glucans reduced to 14.5 ± 2.2% DW and 86.1 ± 12.7 mg L−1 day−1, respectively. These results suggest that the phosphate concentration of 120 mg L−1 was also helpful for the production of β-glucans in Rhodosorus sp. SCSIO-45730. Schulze et al. (2016) found four algal species with high β-glucan content from 16 to 24% by analyzing forty-seven microalgae, among which Scenedesmus ovalternus SAG 52.80 exhibited the highest β-glucan content of 24%, while the productivity of β-glucans was low due to the low biomass. To our knowledge, the maximum β-glucans productivity of 108.1 ± 4.0 mg L−1 d−1 in Rhodosorus sp. SCSIO-45730 is the highest among reported microalgal strains.

According to the above results, the phosphate concentration of 120 mg L−1 was beneficial for the production of biomass, total carbohydrates, and β-glucans in Rhodosorus sp. SCSIO-45730. High biomass and high productivities of total carbohydrates and β-glucans of Rhodosorus sp. SCSIO-45730 could have great potential for bioenergy (such as bioethanol) and β-glucan production in large scale.

Harvesting of the microalga

Effect of chitosan concentrations on flocculation efficiency of Rhodosorus sp. SCSIO-45730

Rhodosorus sp. SCSIO-45730 was cultivated in ASW medium with the phosphate concentration of 120 mg L−1, which was the optimized amount for the maximization of carbohydrate and β-glucan production. At the end of 22-day cultivation, the culture with the maximal biomass of 7.3 ± 0.1 g L−1 was used for exploring the effect on harvesting Rhodosorus sp. SCSIO-45730 by chitosan flocculation.

Figure 4a shows the flocculation efficiency of Rhodosorus sp. SCSIO-45730 at different chitosan concentrations. Rhodosorus sp. SCSIO-45730 has the peculiarity of auto-flocculation, and the flocculation efficiency was about 20% at the first 10 min and reached over 90% after 120 min settling when the microalgal culture was treated with 0 mg L−1 chitosan. It was assumed that the auto-flocculation of Rhodosorus sp. SCSIO-45730 might be due to the secretion of exopolysaccharides (EPS) which led to the aggregation of the microalgal cells (Básaca-Loya et al. 2008). The flocculation efficiency was similar when the culture was treated with 1 mg L−1 chitosan. When chitosan concentration increased to 3 mg L−1, the flocculation efficiency was notably improved to 97.7 ± 1.2% after 10 min of sedimentation (p < 0.05), and it reached over 95% after 3-min treatment with 5 to 120 mg L−1 chitosan.

The effect of chitosan flocculation for Rhodosorus sp. SCSIO-45730 harvesting a the effect of different chitosan concentrations on flocculation efficiency of the strain at different sedimentation time; b zeta potential of the microalgal culture at different chitosan concentrations; and c the microalgal cultures treated with different chitosan concentrations after 120-min sedimentation

Figure 4c showed the microalgal cultures treated with different chitosan concentrations after 120-min sedimentation. The microalgal flocs became larger and fluffier, and the volume of microalgal sludge also increased with the increase of chitosan concentration. It was found that all the flocs could be effectively collected with 300-mesh bolting cloth and there was almost no biomass leakage observed when the collected flocs were rinsed with water after treatment with 3 to 120 mg L−1 chitosan. However, a considerable amount of biomass passed through the cloth mesh when the flocs were collected and washed after treatment with 0 or 1 mg L−1 chitosan. Consequently, centrifugation was required for fully harvesting and purification of the flocs treated with 0 or 1 mg L−1 chitosan. Considering the high energy-consuming of centrifuge operation when treated with 0 or 1 mg L−1 chitosan, as well as the high harvest cost and chitosan pollution when treated with excessive chitosan, chitosan concentrations of 3 or even 5 mg L−1 were deemed to be favorable for flocculating of Rhodosorus sp. SCSIO-45730.

Zeta potential is frequently used to investigate the flocculation process. It is a measure of the magnitude of the electrostatic or charge attraction/repulsion between particles. Figure 4b shows the zeta potential of the microalgal suspension treated with different chitosan concentrations. The zeta potential of initial culture was − 24.9 ± 2.7 mV, which was similar with that observed by Corrêa et al. (2018) who reported a value of − 23.19 ± 0.3 mV for Desmodesmus subspicatus. The surface charge of microalga was negative because of the presence of anion, such as carboxylic groups (Brady et al. 2014). As chitosan concentrations were increased from 0 to 5 mg L−1, the zeta potential remained at the same level and was about − 25 mV, suggesting that small dosage of chitosan had little influence on the surface charge of the microalga. With an increase of chitosan concentrations, the negative zeta potential of the microalgal cells was elevated sharply, indicating the occurrence of charge neutralization. This increase of zeta potential was also found in C. vulgaris for chitosan harvesting (Gerchman et al. 2017).

Several flocculation mechanisms were reported by Gupta et al. (2018), such as bridging, charge neutralization, sweeping, and precipitation. Based on the above results, the flocculation mechanism for Rhodosorus sp. SCSIO-45730 with 0 mg L−1 chitosan might be associated with the secretion of EPS and the gravity sedimentation of the microalgal cells. Nevertheless, the elevating zeta potential with the increase of the chitosan concentrations in the microalgal suspension suggested that partial charge neutralization and adsorption bridging occurred during flocculation.

Effect of pH on chitosan flocculation of the microalgal culture

pH plays an important role in chitosan flocculation, because it can influence the molecular structure of chitosan. Several pH values of initial culture were designed for this test, and the pH of untreated culture was 7.7. Chitosan concentrations of 3 and 5 mg L−1 were used for this study according to the results above. As shown in Fig. 5a, similar tendency was found for both concentrations at different pH conditions. Poor flocculation efficiency (< 70%) was observed at pH 3.7 and 5.7 after 30 min of sedimentation, while valid flocculation was obtained at high pH (pH > 7). The flocculation efficiency was over 98% at pH 7.7 and 10.7, and it was about 88% at pH 9.7. The variation trends of zeta potential of microalgal culture with 3 and 5 mg L−1 chitosan at different pH conditions were similar (Fig. 5b). The effect of pH on chitosan flocculation of the microalgal culture could be seen in Fig. 5c.

The effect of pH on the flocculation of Rhodosorus sp. SCSIO-45730 harvested by 3 and 5 mg L−1 chitosan. a The effect of different pH conditions on flocculation efficiency of the two chitosan dosage after 10-min sedimentation; b zeta potential of the microalgal culture treated with two chitosan dosage at different pH conditions; and c the microalgal cultures treated with two chitosan concentrations after 30-min sedimentation at different pH conditions, respectively

The zeta potential was raised when pH was increased from 3.7 to 5.7, while it was reduced when pH increased from 5.7 to 10.7. This result can be ascribed to the gradual disappearance of the positive charge of chitosan and its decrease in solubility, as well as the character of precipitation at high pH. Sweeping might be the possible mechanism for chitosan flocculation at different pH (Blockx et al. 2018).

These results suggested that there were no obvious differences for the flocculation efficiency of 3 and 5 mg L−1 chitosan in pH-adjusted microalgal culture. A wide range of pH (7.7–10.7) was favorable for chitosan flocculation, which was in accordance with the results of Blockx et al. (2018). Algal biomass is generally pretreated with acids and alkalis to deliver the stored carbohydrates within the cells. Then, enzymes and acids hydrolysis are usually used to release fermentable sugars from algal carbohydrates for bioethanol production (Chen et al. 2013). Thus, high pH of culture medium might influence the carbohydrate quality in the harvested microalgal biomass. In summary, the initial culture pH (7.7) in this study was suitable for the harvest of Rhodosorus sp. SCSIO-45730 through chitosan flocculation, and there was no need to adjust the pH of the cultures.

Total carbohydrate and β-glucan content in the harvested Rhodosorus sp. SCSIO-45730

Figure 6 shows the content of total carbohydrates and β-glucans of Rhodosorus sp. SCSIO-45730 harvested using different concentrations of chitosan. The total carbohydrate content of the control (centrifugation) was 39.7 ± 0.4%. The total carbohydrate content of the chitosan-harvested biomass notably decreased from 39.5 ± 1.5 to 24.0 ± 0.2% with the increase of chitosan concentrations from 0 to 120 mg L−1 (p < 0.05). When the concentration was 3 and 5 mg L−1, the total carbohydrate content of the chitosan-harvested biomass was 39.6 ± 0.2 and 39.5 ± 0.4%, respectively.

The high contents of carbohydrates of microalgal biomass can be easily converted to fermentable sugars for bioethanol production (Chen et al. 2013). There are several carbohydrate-rich microalgae species suitable for bioethanol production, such as Tetraselmis sp. CS-362, Porphyra, S. obliquus CNW-N, Chlorococum sp., and Chlamydomonas reinhardtii UTEX90, in which the content of carbohydrates vary from 26 to 60% (Chen et al. 2013). Therefore, Rhodosorus sp. SCSIO-45730 might be a promising feedstock for bioethanol product due to its higher carbohydrate productivities compared with many carbohydrate-rich microalgae species.

The centrifuged biomass exhibited the highest β-glucan content of 20.5 ± 0.2%. The β-glucan content decreased from 20.5 ± 0.2% to 10.3 ± 0.0% with the increase of chitosan concentrations from 0 to 120 mg L−1. The β-glucan contents of 3 and 5 mg L−1 chitosan-harvested biomass were 18.9 ± 0.1 and 18.7 ± 0.0%, respectively.

The productivities of the total carbohydrates and β-glucans of the centrifuged biomass were 128.5 ± 2.3 and 67.5 ± 0.2 mg L−1 day−1, respectively. There were no significant differences in productivities of the total carbohydrates and β-glucans between the centrifuged biomass and chitosan-harvested biomass treated with 3 or 5 mg L−1. All results suggested that chitosan would not disadvantageously affect the quality of total carbohydrates and β-glucans in the harvested biomass at the concentrations of 3 or 5 mg L−1, so the concentration of 3 mg L−1 is more applicable for harvesting of Rhodosorus sp. SCSIO-45730. Moreover, chitosan would not influence the bioethanol production from this microalgal biomass since it is a saccharide. The recovery of the biomass and total carbohydrates was over 98% at 3 mg L−1 chitosan and that of β-glucans was 90%, suggesting that 3 mg L−1 chitosan has the great potential for large-scale harvest of Rhodosorus sp. SCSIO-45730 to produce carbohydrates and β-glucans.

Cost analysis

There are two choices, centrifugation and chitosan flocculation, for Rhodosorus sp. SCSIO-45730 biomass harvesting (Fig. 7). The estimated cost of centrifugation and chitosan flocculation for Rhodosorus sp. SCSIO-45730 and the estimated cost of chitosan flocculation for C. vulgaris and N. oculata are shown in Table 1. Rhodosorus sp. SCSIO-45730 was collected and washed three times with deionized water by centrifugation. Auto-flocculation of the microalga made it easier to harvest by centrifugation with less energy and time (5000 rpm for 5 min) than many other unicellular microalgae in our lab. The price for harvesting 1 t of biomass dry weight by centrifuging was estimated to be about US$ 12,123, which was far more than that of chitosan flocculation. The cost of chitosan flocculation was evaluated according to the initial biomass, flocculant concentration, and flocculation efficiency. The cost for harvesting 1 t of Rhodosorus sp. SCSIO-45730 biomass dry weight using 3 mg L−1 chitosan was estimated to be US$ 2.9, which was calculated with a cost of 7 US$ kg−1 for chitosan (Garzon-Sanabria et al. 2013). This cost was much less than those for harvesting the same mass of biomass for C. vulgaris and N. oculata using chitosan, which have been reported to be US$ 2198 and US$ 510, respectively (Vandamme et al. 2014; Garzon-Sanabria et al. 2013). It can be estimated that the biomass dry weight of Rhodosorus sp. SCSIO-45730 in outdoor large-scale cultivation might be reduced to one-tenth of that cultivated in lab condition. Consequently, the harvest cost with 3 mg L−1 chitosan would be increased to US$ 29 per ton of biomass. Even so, the harvest cost would be considerably low and acceptable for the commercial production of Rhodosorus sp. SCSIO-45730. These results indicated that chitosan is a potentially economically and ecologically friendly bio-flocculant to harvest Rhodosorus sp. SCSIO-45730.

Conclusions

Two strategies were used to evaluate the potential of a novel carbohydrate-rich microalgal strain, isolated and identified as Rhodosorus sp. SCSIO-45730, for carbohydrate and β-glucan production. The highest contents and productivities of carbohydrates and β-glucans of the alga were obtained at 120 mg L−1 K2HPO4. Furthermore, favorable recovery of biomass, carbohydrates, and β-glucans was observed at 3 mg L−1 chitosan, providing an ultralow cost of US$ 2.9 per tonne of biomass. In conclusion, addition of suitable phosphate and flocculation at low chitosan concentration could be valid for commercial cultivation of the alga as the feedstock for biofuel and β-glucans.

References

Adenan NS, Yusoff FM, Medipally SR, Shariff M (2016) Enhancement of lipid production in two marine microalgae under different levels of nitrogen and phosphorus deficiency. J Environ Biol 37:669–676

Ahmad AL, Mat Yasin NH, Derek CJC, Lim JK (2011) Optimization of microalgae coagulation process using chitosan. Chem Eng J 173:879–882

Barbarino E, Lourenço SO (2005) An evaluation of methods for extraction and quantification of protein from marine macro- and microalgae. J Appl Phycol 17:447–460

Básaca-Loya A, Burboa MG, Valdez MA, Gámez R, Goycoolea FM, Gutiérrez-Millán LE (2008) Aggregation behavior and rheology of culture broths of Rhodosorus marinus. Rev Mex Fish Sci 54:119–126

Blockx J, Verfaillie A, Thielemans W, Muylaert K (2018) Unravelling the mechanism of chitosan-driven flocculation of microalgae in seawater as a function of pH. ACS Sustain Chem Eng 6:11273–11279

Bobadilla F, Rodriguez-Tirado C, Imarai M, Galotto MJ, Andersson R (2013) Soluble beta-1,3/1,6-glucan in seaweed from the southern hemisphere and its immunomodulatory effect. Carbohydr Polym 92:241–248

Borchardt JA, Azad HS (1968) Biological extraction of nutrients. Water Pollution Control Federation 40:1739–1754

Brady PV, Pohl PI, Hewson JC (2014) A coordination chemistry model of algal autoflocculation. Algal Res 5:226–230

Chen CY, Zhao XQ, Yen HW, Ho SH, Cheng CL, Lee DJ, Bai FW, Chang JS (2013) Microalgae-based carbohydrates for biofuel production. Biochem Eng J 78:1–10

Chng LM, Lee KT, Chan DJC (2017) Synergistic effect of pretreatment and fermentation process on carbohydrate-rich Scenedesmus dimorphus for bioethanol production. Energ Convers Manag 141:410–419

Corrêa DO, Duarte MER, Noseda MD (2018) Biomass production and harvesting of Desmodesmus subspicatus cultivated in flat plate photobioreactor using chitosan as flocculant agent. J Appl Phycol 31:857–866

Divakaran R, Pillai VNS (2002) Flocculation of algae using chitosan. J Appl Phycol 14:419–422

Du B, Bian Z, Xu B (2014) Skin health promotion effects of natural beta-glucan derived from cereals and microorganisms: a review. Phytother Res 28:159–166

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Farid MS, Shariati A, Badakhshan A, Anvaripour B (2013) Using nano-chitosan for harvesting microalga Nannochloropsis sp. Bioresour Technol 131:555–559

Formighieri C (2015) Bioethanol from algae polysaccharides. In: Solar-to-fuel conversion in algae and cyanobacteria. Springer, Cham, pp 13–17

Garzon-Sanabria AJ, Ramirez-Caballero SS, Moss FE, Nikolov ZL (2013) Effect of algogenic organic matter (AOM) and sodium chloride on Nannochloropsis salina flocculation efficiency. Bioresour Technol 143:231–237

Gerchman Y, Vasker B, Tavasi M, Mishael Y, Kinel-Tahan Y, Yehoshua Y (2017) Effective harvesting of microalgae: comparison of different polymeric flocculants. Bioresour Technol 228:141–146

Grima EM, Belarbi EH, Acién Fernández FG, Medina AR, Chisti Y (2003) Recovery of microalgal biomass and metabolites: process options and economics. Biotechnol Adv 20:491–515

Gupta SK, Kumar NM, Guldhe A, Ansari FA, Rawat I, Nasr M, Bux F (2018) Wastewater to biofuels: comprehensive evaluation of various flocculants on biochemical composition and yield of microalgae. Ecol Eng 117:62–68

Hende SVD, Carre E, Cocaud E, Beelen V, Boon N, Vervaeren H (2014) Treatment of industrial wastewaters by microalgal bacterial flocs in sequencing batch reactors. Bioresour Technol 161:245–254

Ho SH, Chen WM, Chang JS (2010) Scenedesmus obliquus CNW-N as a potential candidate for CO2 mitigation and biodiesel production. Bioresour Technol 101:8725–8730

Ho SH, Chen CY, Lee DJ, Chang JS (2011) Perspectives on microalgal CO2-emission mitigation systems - a review. Biotechnol Adv 29:189–198

Ho SH, Huang SW, Chen CY, Hasunuma T, Kondo A, Chang JS (2013) Bioethanol production using carbohydrate-rich microalgae biomass as feedstock. Bioresour Technol 135:191–198

Jones CS, Mayfield SP (2012) Algae biofuels: versatility for the future of bioenergy. Curr Opin Biotechnol 23:346–351

Juneja A, Ceballos RM, Murthy GS (2013) Effects of environmental factors and nutrient availability on the biochemical composition of algae for biofuels production: a review. Energies 6:4607–4638

Kalla N, Khan S (2016) Effect of variable salinity and phosphorus culture conditions on growth and pigment content of Chlorella vulgaris. Indian J Sci Technol 9:93941

Khozin-Goldberg I, Shrestha P, Cohen Z (2005) Mobilization of arachidonyl moieties from triacylglycerols into chloroplastic lipids following recovery from nitrogen starvation of the microalga Parietochloris incisa. Biochim Biophys Acta 1738:63–71

Kim DG, La HJ, Ahn CY, Park YH, Oh HM (2011) Harvest of Scenedesmus sp. with bioflocculant and reuse of culture medium for subsequent high-density cultures. Bioresour Technol 102:3163–3168

Krayesky-Self S, Phung D, Schmidt W, Sauvage T, Butler L, Fredericq S (2020) First report of endolithic members of Rhodosorus marinus (Stylonematales, Rhodophyta) growing inside rhodoliths offshore Louisiana, Northwestern Gulf of Mexico. Front Mar Sci 7:1–8

Lai J, Yu Z, Song X, Cao X, Han X (2011) Responses of the growth and biochemical composition of Prorocentrum donghaiense to different nitrogen and phosphorus concentrations. J Exp Mar Biol Ecol 405:6–17

Li T, Xu J, Wu H, Jiang P, Chen Z, Xiang W (2019) Growth and biochemical composition of Porphyridium purpureum SCS-02 under different nitrogen concentrations. Mar Drugs 17:E124

Liang K, Zhang Q, Gu M, Cong W (2012) Effect of phosphorus on lipid accumulation in freshwater microalga Chlorella sp. J Appl Phycol 25:311–318

Morales J, Noüe JDL, Picard G (1985) Harvesting marine microalgae species by chitosan flocculation. Aquac Eng 4:257–270

Raghothama KG (2000) Phosphate transport and signaling. Curr Opin Plant Biol 3:182–187

Rojo-Cebreros AH, Ibarra-Castro L, Martínez-Brown JM, Velasco-Blanco G, Martínez-Téllez MA, Medina-Jasso MA, Nieves-Soto M, Quintana-Zavala D (2017) Potential of Nannochloropsis in beta glucan production. In: Jan M, Kazik P (eds) Nannochloropsis: biology. Biotechnological. Nova Sciences Publishers Inc., New York, pp 181–225

Roopnarain A, Gray VM, Sym SD (2014) Phosphorus limitation and starvation effects on cell growth and lipid accumulation in Isochrysis galbana U4 for biodiesel production. Bioresour Technol 156:408–411

Said HA (2009) Changes in levels of cellular constituents of Dunaliella parva associated with inorganic phosphate depletion. Middle East J Sci Res 4:94–99

Santizo-Taan R, Bautista-Teruel M, Maquirang JRH (2020) Enriched Ulva pertusa as partial replacement of the combined fish and soybean meals in juvenile abalone Haliotis asinina (Linnaeus) diet. J Appl Phycol 32:741–749

Schulze C, Wetzel M, Reinhardt J, Schmidt M, Felten L, Mundt S (2016) Screening of microalgae for primary metabolites including β-glucans and the influence of nitrate starvation and irradiance on β-glucan production. J Appl Phycol 28:2719–2725

Sero ET, Siziba N, Bunhu T, Shoko R, Jonathan E (2020) Biophotonics for improving algal photobioreactor performance: a review. Int J Energy Res. https://doi.org/10.1002/er.5059

Sivakumar G, Vail DR, Xu JF, Burner DM, Lay JO, Ge XM, Weathers PJ (2010) Bioethanol and biodiesel: alternative liquid fuels for future generations. Eng Life Sci 10:8–18

Sukenik A, Bilanovic D, Shelef G (1988) Flocculation of microalgae in brackish and sea waters. Biomass 15:187–199

't Lam GP, Giraldo JB, Vermue MH, Olivieri G, Eppink MH, Wijffels RH (2016) Understanding the salinity effect on cationic polymers in inducing flocculation of the microalga Neochloris oleoabundans. J Biotechnol 225:10–17

Toor M, Kumar SS, Malyan SK, Bishnoi NR, Mathimani T, Rajendran K, Pugazhendhi A (2019) An overview on bioethanol production from lignocellulosic feedstocks. Chemosphere 242:125080

Vandamme D, Foubert I, Muylaert K (2013) Flocculation as a low-cost method for harvesting microalgae for bulk biomass production. Trends Biotechnol 31:233–239

Vandamme D, Muylaert K, Fraeye I, Foubert I (2014) Floc characteristics of Chlorella vulgaris: influence of flocculation mode and presence of organic matter. Bioresour Technol 151:383–387

Wilson S, West J, Pickett-Heaps J, Yokoyama A, Hara Y (2002) Chloroplast rotation and morphological plasticity of the unicellular alga Rhodosorus (Rhodophyta, Stylonematales). Phycol Res 50:183–191

Wu YH, Yu Y, Hu HY (2014) Effects of initial phosphorus concentration and light intensity on biomass yield per phosphorus and lipid accumulation of Scenedesmus sp. LX1. BioEnerg Res 7:927–934

Yamin WA, Shaleh SRM, Ching FF, Othman R, Manjaji-Matsumoto M, Mustafa S, Shigeharu S, Kandasamy G (2019) Harvesting Chaetoceros gracilis by flocculation using chitosan. IOP Conference Series: Earth and Environmental Science 236:012123

Zhou X, Lin W, Tong L, Liu X, Zhong K, Liu L, Wang L, Zhou S (2016) Hypolipidaemic effects of oat flakes and beta-glucans derived from four Chinese naked oat (Avena nuda) cultivars in Wistar-Lewis rats. J Sci Food Agric 96:644–649

Zhu Q, Wu S (2019) Water-soluble beta-1,3-glucan prepared by degradation of curdlan with hydrogen peroxide. Food Chem 283:302–304

Funding

The authors appreciatively acknowledge financial support from Science and Technology Planning Project of Guangdong Province (2019B030316027), the National Natural Science Foundation of China (31602182), the 13th Five-Year Plan Marine Economy Innovation Development Demonstration Project (BHSFS004), the Key deployment projects of Chinese Academy of Sciences (ZDRW-ZS-2017-2-1), and the Guangdong Province Engineering Technology Center for molecular Probe & Bio-medical Imaging.

Author information

Authors and Affiliations

Contributions

Lumei Dai designed and performed the experiment, analyzed the experimental data, and drafted the manuscript. Li Tan carried out the identification of Rhodosorus sp. SCSIO-45730. Xuejie Jin participated in the isolation of Rhodosorus sp. SCSIO-45730. Hualian Wu and Houbo Wu assisted in flocculation experiment and data analysis. Tao Li guided the experiment, helped to draft the manuscript, and revised this manuscript. Wenzhou Xiang took part in designing the study and coordinating the study and assisted with revisions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dai, L., Tan, L., Jin, X. et al. Evaluating the potential of carbohydrate-rich microalga Rhodosorus sp. SCSIO-45730 as a feedstock for biofuel and β-glucans using strategies of phosphate optimization and low-cost harvest. J Appl Phycol 32, 3051–3061 (2020). https://doi.org/10.1007/s10811-020-02139-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-020-02139-8