Abstract

Subcritical water extraction (SWE) technology has become useful as a green extraction technology for generating various biochemical and bioactive compounds from a wide range of biomass feedstocks, including microalgae. SWE processes result in two different product phases: an aqueous phase containing solubilized or immiscible bioactive compounds from the extract, and solid-phase biomass debris containing residual or unextracted bioactive molecules in the matrix. While most SWEs of microalgal biomass focus on maximizing lipid production for biofuel application, the present work seeks to explore opportunities to identify and characterize compounds obtained from both the aqueous and solid phases. SWE of Chlorella pyrenoidosa biomass was carried out under varying conditions of temperature (170–370 °C), extraction time (1–20 min), and microalgal biomass loading (1–15%). Analysis of aqueous and solid-phase samples collected under varying SWE conditions showed a higher protein concentration of 4.13 mg mL−1 in the aqueous phase compared with carbohydrate (1.35 mg mL−1) for the optimum extraction conditions. About 17.52 mg g−1 of amino acids and 12.72 mg g−1 of organic acids were obtained from the aqueous phase with glutamic acid and lactic acid being the highest. The findings from this work would be useful in identifying and harnessing important microalgal biochemical from SWE process to develop new and improved bioproduct technologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgal biomass contains a wide range of biochemicals including lipids, proteins, and carbohydrates. Lipids extracted from microalgae have been widely studied for biodiesel production (Miao and Wu 2006; Halim et al. 2011). However, commercial-scale production and processing of microalgal biomass into biodiesel under optimum economy as an alternative to fossil fuels has been challenging due to high cost of production (Medipally et al. 2015; Sánchez et al. 2016). As a result, researchers are switching their interests to the production of omega-3 polyunsaturated fatty acids (PUFA) from microalgal biomass (Cheung 1999; Andrich et al. 2005; Spolaore et al. 2006). Apart from lipids, microalgae are also rich in proteins which can be extracted for human consumption as food supplements as well as for animal feed (Becker 2007). Also, the carbohydrate content of microalgae has been widely studied for biofuel production, including bioethanol and biobutanol (Harun and Danquah 2011; Ho et al. 2013).

The lipid, protein, and carbohydrate molecules are located either in the cell wall or within the microalgal cells. For example, proteins are part of the composition of the cell wall, cytoplasm, chloroplast, and organelles inside the barrier of the cell wall (Safi et al. 2015). Microalgal cell walls also contain carbohydrate (polysaccharides, cellulose, glucose), proteins, lipids, and minerals (Safi et al. 2015; Rashidi and Trindade 2018; Alhattab et al. 2019). To extract these molecules from microalgae, different pre-treatment methods such as mechanical (expeller, bead beating, high-pressure homogenizer, and sonication) and chemical extraction have been widely applied (Halim et al. 2012; Li et al. 2014). Although these two techniques are well established, there are still many drawbacks such as high energy input and the use of an organic solvent that continue to pose sustainability and environmental concerns.

Subcritical water extraction (SWE) technology or sometimes known as pressurized liquid extraction (Azmir et al. 2013) is a green extraction method that uses water as the solvent. This makes it more favorable compared with solvent-based methods. Several studies on SWE of different types of feedstock such as rice bran, squid waste, and fish meat have been reported (Yoshida et al. 1999; Yoshida and Tavakoli 2004; Sereewatthanawut et al. 2008; Awaluddin et al. 2016). A summary of SWE performance characteristics includes short extraction time, environmentally friendly technology, and ease of extraction of polar and non-polar compounds with water under subcritical conditions. SWE technology works under milder operating conditions (T < 374 °C, P < 22.1 MPa) and can offer a lower production cost compared with other extraction methods (Thiruvenkadam et al. 2015).

Several parameters that are known to affect the performance of SWE technology include temperature, time, and biomass loading to water ratio, with the temperature being the most studied parameter (Zhu et al. 2008, 2010, 2011b; Reddy et al. 2014). An increase in extraction temperature leads to a decrease in dielectric constant, which increases the solubility of organic compounds in water. The dielectric constant is important in SWE as it determines the solubility or degree of interaction between the solvent and the organic molecule of interest (Halim et al. 2011). Water is polar in nature; hence, only polar lipid such as phosphoglycerides, glycosylglycerides, and sphingolipids present in microalgae can dissolve in water. In addition, water as a medium can lead to co-extraction of proteins and carbohydrates from microalgal biomass. As the temperature of water increases, its polarity changes from polar to moderately polar, allowing non-polar compounds such as triglycerides lipid to be dissolved.

Furthermore, when the temperature of the water is elevated, the hydrogen bond that holds the water molecule cleaves, increasing the number of hydrogen ions and potential use as an acid catalyst (Thiruvenkadam et al. 2015). Besides temperature, time and biomass loading are also essential parameters in SWE. Previous studies showed that shorter times are sufficient and preferable for extraction as longer reaction times could result in degradation of compounds (Zhu et al. 2011a; Kouchaksaraie et al. 2016). Biomass loading affects the operating cost, extraction time, and the interaction between the biomass and the solvent. To date, different yields and product types have been reported for SWE operations under various operating conditions. Hence, process optimization is important to determine the optimum conditions for an enhanced yield of the molecule of interest.

SWE processes result in two different product phases: an aqueous phase containing solubilized or immiscible bioactive compounds from the extract, and solid-phase biomass debris containing residual or unextracted bioactive molecules in the matrix. The liquid layer obtained after SWE can be divided into two fractions. The upper fraction is known as the oil phase, which contains lipids as well as lipophilic pigments such as carotenoids and chlorophyll a. The middle fraction is known as the aqueous phase, and this phase usually contains proteins (including peptides and amino acids), carbohydrates (including monosaccharides, disaccharides, oligosaccharides, and polysaccharides), and organic acids. The solid phase occupies the bottom fraction and consists of solid residue or microalgal cell debris.

Most of the reported studies on SWE of microalgal biomass focus more on maximizing lipid yields for biofuel application (Reddy et al. 2014; Zakaria et al. 2017a; Ho et al. 2018; Thiruvenkadam et al. 2018). Other reports focused on the efficiency of SW in extracting phenolic compounds and the assessment of antioxidant activity (Meizoso et al. 2010; Zakaria et al. 2017b). There are limited reports and discussions that explore the potential application of by-products that could be developed from residues after SWE lipid extraction. These by-products include solid residue, protein, carbohydrate, and other biomolecules. Therefore, the present work explores comprehensive use of holistic approach to determine the presence of potential biomolecules products from both the aqueous/liquid and solid phases obtained after the extraction of microalgal Chlorella pyrenoidosa lipids by SWE. A central composite design (CCD) was employed to determine the effect of three factors: microalgal biomass loading, extraction time, and extraction temperature towards the protein and carbohydrate generation via SWE. The work is important to support complete utilization of microalgal biomass towards the development of commercially viable bioproduct strategies from microalgae.

Materials and methods

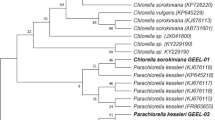

Microalgal cell

Dried green cells of Chlorella pyrenoidosa, with an average particulate size between 50 and 100 μm, were obtained from Sunrise Nutrachem Group, China. The microalgal cells were stored in a desiccator until further use.

Chemicals and reagents

The chemicals and reagents used in this study are as follows: sodium carbonate (Na2CO3, R&M Chemicals Ltd., MW 105.99, 99.5%), sodium hydroxide (NaOH, Merck Pty Ltd., MW 40, 99%), copper sulfate (CuSO4.5H2O, R&M Chemicals Ltd., MW 249.68, 99.6%), sodium potassium tartrate (C4H4KNaO6.4H2O, R&M Chemicals Ltd., MW 283.23. 99%), Folin Ciocalteu (R&M Chemicals Ltd.), bovine serum albumin (BSA, R&M Chemicals Ltd.), glucose (C6H12O6, R&M Chemicals Ltd.), phenol (R&M Chemicals Ltd.), sulfuric acid (H2SO4, R&M Chemicals Ltd., MW 98.079, 99%), p-toluenesulfonic acid (Sigma-Aldrich), Bis-Tris (CalbioChem), Ethylenediamine tetraacetic acid (EDTA, R&M Chemicals Ltd.), hydrochloric acid (HCl), α-Aminobutyric acid (AABA), acetonitrile, AccQ Tag Eluent A (Waters), derivatization reagent kit (borate buffer, acetonitrile and ACCQ fluor reagent, Waters). Formic acid, lactic acid, levulinic acid, acetic acid, succinic acid, and malic acid were obtained from R&M Chemicals Ltd.

Characterization of the microalga C. pyrenoidosa

Physical, biochemical (protein, fat, and carbohydrate), and elemental characterizations of C. pyrenoidosa were conducted to determine its moisture, ash, and nutrient contents. The moisture content was analyzed via oven drying at 105 °C, while the ash content was analyzed by incinerating the microalgae at 550 °C. The weights of microalgae before and after oven drying and incineration were determined. The protein content was determined using Kjeltec System 2300 analyzer (FOSS, Denmark), and the lipid content was determined using Soxtec Avanti 2055 (FOSS, Denmark). Carbohydrate content of the microalgae was determined using Eq. 1:

Elemental analysis of C. pyrenoidosa was conducted using a CHNS analyzer (LECO True Spec CHNS628, USA). Approximately 0.2 g of the microalgal biomass was weighed into a tin capsule and transferred to an autosampler. The samples were combusted at 1000 °C, and carbon (C), hydrogen (H) and nitrogen (N) were determined by comparing with calibrated values. The characterization results for C. pyrenoidosa are shown in Table 1.

SWE experiment

SWE experiments were conducted in a batch mode at different temperatures (170–370 °C), microalgal biomass loading concentrations (1–15%), and time (1–20 min). The operating conditions for each experiment were generated based on CCD, shown in Table 2. The pressure within the reaction tube was estimated from the steam table under subcritical conditions. The reaction pressure that corresponds to the saturated vapor pressure of water at each temperature is 0.79 MPa at 170 °C, 2.32 MPa at 220 °C, 5.5 MPa at 270 °C, 11.28 MPa at 320 °C, and 21.04 MPa at 370 °C. The parameters (extraction temperature, extraction time, and biomass loading) were selected for this study as they have been reported to have a significant influence on SWE processes (Ho et al. 2018; Thiruvenkadam et al. 2018). The range of temperature (170–370 °C) in this study was selected, as 170 °C is the minimum temperature allowable for the salt bath and 370 °C is the subcritical threshold temperature before the reaction goes into the supercritical phase. The extraction time and microalgae loading had minimum values of 1 min and 1%, while the maximum values were selected based on preliminary studies in which results are not shown.

The dried microalgal biomass was initially mixed with Milli-Q water at a specific loading concentration. For 1% loading concentration, 0.25 g of the biomass was mixed with 25 mL water. The same approach was used to obtain the remaining biomass loading concentrations. The biomass was loaded into a stainless steel reaction tube with one side closed. The reactor has an inner diameter of 19.05 mm and a length of 150 mm. The reactor was purged with argon gas for a few minutes to release trapped air inside the reactor. The reactor was tightly closed with Swagelok caps. The schematic diagram of the experimental setup is shown in Fig. 1. The salt bath containing a mixture of potassium nitrate and sodium nitrate (1:1) was heated to the desired temperature and the reactor was individually immersed for the extraction process to commence according to the experimental design shown in Table 2. After the extraction process duration, the reactor was quenched with cooling water to stop the reaction. The reactor pressure was allowed to reduce and the samples were collected for further analysis.

Analysis of SWE samples

The generated extracts were transferred into a 50-mL centrifuge tube and centrifuged (KUBOTA 2420, Japan) at 2540×g for 5 min. Three different layers of the samples formed after centrifugation, representing the lipids, aqueous phase, and solid residue. About 1.5 mL of n-hexane was added to separate the lipid fraction, and the mixture was incubated at room temperature for a few minutes before recovering the lipid fraction. The lipid recovery process was repeated several times to achieve complete lipid separation. The residual mixture was re-centrifuged at 2540×g for 5 min. The supernatant was separated by filtration and stored at − 20 °C. On the contrary, the solid residue was dried in the oven at 60 °C overnight and stored in a desiccator until further analysis.

Aqueous phase analysis

The supernatant obtained after the second stage centrifugation (aqueous phase) was analyzed to determine total protein, carbohydrate, amino acid, and organic acid contents.

Total protein analysis

Lowry assay (Lowry et al. 1951) was used to determine the total crude protein content of the samples. Eight different standards with varying protein concentrations ranging from 0.05 to 1 mg mL−1 were prepared using bovine serum albumin (BSA) solution to generate a linear calibration curve. A plot of absorbance against protein concentration was generated and used to determine the protein concentrations of the unknown samples. About 0.4 mL of each standard and the aqueous solution of SWE was pipetted into test tubes followed by 4 mL of the alkaline copper sulfate reagent. The solution was mixed and incubated for 10 min at room temperature. A total of 0.4 mL of the Folin Ciocalteu reagent was added to each test tube and incubated for an additional 30 min. Folin reagent is photosensitive, so the incubation was performed in the dark at room temperature. The absorbance of the solutions was measured at 660 nm using a UV/VIS spectrophotometer (UV-160A, Shimadzu, Japan). Protein yield via SWE process was determined using Eq. 2:

Total carbohydrate analysis

Total carbohydrate content was determined using the phenol-sulfuric acid method (Dubois et al. 1956). A set of five glucose standards with varying concentrations (0, 10 mg L−1, 25 mg L−1, 50 mg L−1, and 100 mg L−1) was prepared. About 600-μL aliquot of each standard was transferred to a glass tube followed by 600 μL of 5% phenol. Three milliliter sulfuric acid was pipetted into the tube and incubated under ambient conditions for 30 min. The absorbance was measured at 480 nm. The absorbance values of the standards were used to create a calibration curve and used to determine the carbohydrate contents of the unknown samples.

About 600 μL of the sample mixture was put in a glass tube followed by 600 μL of 5 % phenol and 3 mL sulfuric acid. The solution was incubated for 30 min, and the absorbance was measured to determine the carbohydrate content using the calibration curve. The carbohydrate yield from the SWE process was determined using Eq. 3:

Amino acid and organic acid contents analysis by high-pressure liquid chromatography

The aqueous phase sample was mixed with 5 mL of 6 N HCl and heated at 110 °C for 24 h. About 4 mL of α-aminobutyric acid (AABA) stock solution (2.5 mM) was added, and the solution was made up to 100 mL with distilled water. A total of 10-μL aliquot of the solution was transferred to a 1.5-mL centrifuge tube for derivatization after mixing with 70 μL of borate buffer and 20 μL of AccQ reagent. The mixture was incubated for 1 min at room temperature and 5 μL (50 pmole of AABA = 5.156 ng AABA) of the contents was injected into the HPLC (Waters, Water 2475 model e2695) for amino acid analysis. AccQ Tag Column (3.9 × 150 mm) was used for the analysis and AccQ Tag Eluent A concentrate and 60% acetonitrile was the mobile phase. The flow rate was 1 mL min−1, and the column temperature was 36 °C. Fluorescence Detector (Waters 2475) was used to detect the amino acids.

The organic acid content was analyzed using HPLC (Shimadzu Corporation, Japan) Organic Acid Analysis System. Separation and detection of organic acids were performed at 45 °C and a flow rate of 0.8 mL min−1 using Shim-pack SCR-102H (8 mm I.D. × 300 mm L) column. The mobile phase was 5 mM p-toluenesulfonic acid aqueous solution. The reagent used for detection was 20 mM Bis-Tris aqueous solution containing 5 mM p-toluenesulfonic acid and 100 μM EDTA. The detector CDD-6A with a positive polarity and slow response was used in this analysis. Several types of organic acid standards (formic acid, lactic acid, levulinic acid, acetic acid, succinic acid, and malic acid) were used to identify and quantify the type of organic acids produced at a specific retention time. The organic acid yield from the SWE process was determined based on Eq. 4:

Fourier-transform infrared spectroscopic experiment

FTIR analysis was carried out using Perkin Elmer, Spectrum 100 FTIR Spectrometer (USA). An attenuated total reflection (ATR) system was used for this analysis (Schmitt and Flemming 1998). The ATR diamond crystal was cleaned at the beginning of each experiment. A small amount of the sample (in this case, a drop of aqueous phase or a few milligram of powder algae sample) was placed on the crystal. The pressure arm was positioned over the crystal/sample area. Force was applied to the sample, pushing it onto the diamond surface, and the IR scanning was performed. Measurements were carried out in the spectral range of 650–4000 cm−1 with a resolution of 4 cm−1 at a constant temperature of 25 °C. Each spectrum was recorded three times and the average spectrum was calculated. Data analysis was performed using Spectrum v 10.03.07 and Origin Pro 8 software.

Solid residue analysis

The solid residue was analyzed for elemental (Carbon, Hydrogen, and Nitrogen) composition using a CHNS analyzer (Leco True Spec CHNS628, USA). First, the solid residue was weighed into a tin capsule and transferred to an autosampler. The combusted temperature of the solid residue was set to 1000 °C and carbon, hydrogen, and nitrogen were determined by comparing with calibrated values. The multiplying factor of 4.78 was used to calculate the nitrogen-protein conversion, and it was assumed that the nitrogen is associated with proteins (Lourenço et al. 2004).

Statistical analysis

All statistical analyses were performed using Design-Expert 7.0.0 software (Stat-Ease Inc., USA). The interactions of three factors (temperature, time, and microalgae loading) on the protein and carbohydrate composition were studied using response surface methodology (RSM). The RSM approach was carried out using the 3-factor 5-level CCD. The protein and carbohydrate contents of data obtained were considered as dependent variables, while temperature, time, and microalgal biomass loading were the independent variables. A set of 20 experiments was performed in the study. Analysis of variance (ANOVA) was applied to evaluate the fitness of the model and identify the interactions between the independent and dependent variables. The agreement between the model and the experimental data was expressed by the coefficient of determination (R2), which indicated the quality of the model. Empirical models correlating protein and carbohydrate contents to the three independent variables were developed. The independent variables are designated as A (temperature), B (time), and C (microalgae loading), while the dependent variable (response) is designated as Y. The extraction conditions using a combination of independent variables and the dependent variable were correlated using a second-order polynomial Eq. 5:

where β0 is the model constant coefficient; β1, β2, and β3 are linear coefficients; β12, β13, and β23 are interaction coefficients; and β11, β22, , and β33 are quadratic coefficients.

Results

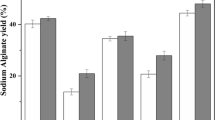

Yield of protein and carbohydrate in the aqueous phase of SWE

The experimental design matrix and their corresponding protein and carbohydrate concentration are shown in Table 2. The highest protein concentration of 4.13 mg mL−1 was obtained at temperature 270 °C, extraction time of 10 min, and 15% microalgae biomass loading (run 12), while the highest carbohydrate concentration of 1.35 mg mL−1 was achieved at 220 °C, 5 min, and 10% microalgae loading (run 17). The concentration of carbohydrates obtained in the aqueous phase was lower than proteins. However, the temperature, time, and biomass loading needed for the highest carbohydrate concentration were lower than the operating conditions required for protein production. The yield of protein and carbohydrate obtained via SWE in this study was calculated by dividing the concentration of protein or carbohydrate in the aqueous phase with the initial concentration of microalgae loading based on the design matrix in Table 2. The highest yield of protein (18.773%) was produced under the conditions of 270 °C, 10 min extraction time, and 1% of microalgae loading, while only 2.403% carbohydrate was produced under the condition of 170 °C, 10 min extraction time, and 5% biomass loading. The quantity of protein and carbohydrate obtained in the aqueous phase of SWE was lower than the initial composition of proteins (62.7%) and carbohydrate (22.8%) that is present in the C. pyrenoidosa biomass.

Analysis of model

ANOVA analysis in Tables 3 and 4 shows the models generated for protein and carbohydrate are significant. No transformation has been done on both response, and the quadratic model was used for both responses. The significance of the terms in the quadratic model was determined based on the p value (< 0.05). The p value of extraction time (B) and microalgal biomass loading (C) were less than 0.05, indicating these parameters mostly affected the protein extraction (Table 3). Other significant terms that affected protein production via SWE included AB, A2, B2, and C2. A value greater than 0.100 indicates the model terms are not significant. The ANOVA analysis of carbohydrate showed that the extraction temperature (A), microalgal biomass loading (C), AC, and A2 were the significant terms that affected carbohydrate production. The coefficient of determination or R2 value of the ANOVA model for protein was 0.9247, while carbohydrate was 0.9633. Both of the models showed adequate signals (the adequate precision ratio was larger than 4) and non-significant lack of fit (lack of fit was more than 0.05). The uncoded (actual) equations for optimum protein and carbohydrate extraction via SWE extraction of C. pyrenoidosa biomass are:

Figure 2 a–c shows the 3-D surface relationship of the extracted protein with each independent variable. The response variables in all figures are dependent on the three variables analyzed in this study. It can be seen that a decrease in temperature and an increase in both extraction time and microalgal biomass loading result in an increase in protein concentration. Figure 3 a–c show the relationship between the independent process variables and the extracted carbohydrate. Compared with the extraction temperature and microalgal biomass loading, the extraction time does not affect carbohydrate yield. In addition, Fig. 3 b and c show that increasing microalgae biomass loading leads to increasing sugar production as more biomass is available for conversion. The carbohydrate production decreased as the temperature increased from 170 to 370 °C.

Analysis of solid residue from SWE lipid extracted microalgal biomass

The elemental analysis of the microalgal biomass before and after SWE was conducted to determine the amount of nitrogen (N) reduction. The data is presented in Table 1. The N analysis indicates the protein content of the microalgae. A multiplying factor of 4.78 is used to calculate the N to proteins conversion. Runs 12 and 19 were selected because the samples produce the highest amounts of protein in the SWE process. The initial N analysis of the original microalgae biomass was 9.8% N, equivalent to 46.8% of protein. After the extraction, analysis on run 12 (270 °C, 10 min, 15% biomass loading) indicated that around 6.6% N was still present in the solid residue, meaning only about 3.2% of N was extracted, equivalent to about 15.3% protein in the aqueous phase.

The analysis of run 19 (220 °C, 15 min, 10% biomass loading) showed that about 8.2% N was present in the solid residue, indicating only 1.6% of N was extracted, corresponding to 7.6 % protein released to the aqueous phase. Based on Table 2, only 2.7% (run 12) and 4.1% (run 19) proteins were detected using the Lowry method. This indicates that there are still about 12.6 and 3.5% of protein undetected in runs 12 and 19, respectively.

Figure 4 a summarizes the N contents of the microalgal biomass before and after SWE. It should be noted that a complete mass balance analysis was not achieved in the present study due to the limitation of the instrument used to analyze the gases such as nitrogen and ammonia that contribute to the total N. Furthermore, the N content present in the biocrude was not included in this study (Fig. 4b). Also, the multiplying factor used for the conversion of N to proteins may have been slightly overestimated since the work did not include a detailed structural and molecular analysis of the proteins present in the C. pyrenoidosa biomass.

The carbon (C) and hydrogen (H) contents of the microalgal biomass residue after SWE were high, as shown in Table 1. A higher C (62.53%) and H (8.33%) contents were observed in run 12 compared with run 19 (C 58.35% and H 7.84%).

Amino acids and organic acids analysis

About 16 different types of amino acids were detected from the SWE process, as listed in Fig. 5. The total concentration of amino acids produced from runs 12 and 19 was 17.515 mg g−1 and 11.04 mg g−1. In this study, glutamic acid was the highest amino acid produced in run 12 (4.96 mg g−1) and run 19 (2.42 mg g−1). This was followed by proline (1.99 mg g−1), alanine (1.95 mg g−1), valine (1.83 mg g−1), leucine (1.64 mg g−1), glycine (1.35 mg g−1), isoleucine (1.19 mg g−1), phenylalanine (0.61 mg g−1), methionine (0.52 mg g−1) lysine (0.455 mg g−1), tyrosine (0.415 mg g−1), arginine (0.38 mg g−1), histidine (0.175 mg g−1), and aspartic acid (0.05 mg g−1) for run 12. As for run 19, aspartic acid, serine, arginine, and lysine were produced in higher concentrations than run 12. Hydroxyproline was not detected in both runs, while threonine and serine were not detected in run 12. Based on Fig. 5, the concentrations of alanine and glycine obtained were higher than serine. Alanine, leucine, and phenylalanine were present in the aqueous phase of runs 12 and 19. On the contrary, aspartic acid and serine were less detected in the aqueous phase. The aspartic acid in run 12 (270 °C) was lower in concentration than run 19 (220 °C), while serine was not detected in run 12 but present in run 19.

Organic acids analysis was performed to investigate the earlier hypothesis on the degradation of protein, carbohydrate, and amino acids that generate organic acids at high temperatures and high pressures. The organic acids identified from run 12 consist of lactic acid, formic acid, acetic acid, and succinic acid. Lactic acid (796.22 mg L−1) was the highest organic acid produced from run 12 followed by acetic acid (757.54 mg L−1), formic acid (179.14 mg L−1), succinic acid (126.03 mg L−1), and malic acid (49.11 mg L−1). However, there are some unaccounted organic acids, which limits the ability to identify the loss of 12.6% protein, as discussed above.

FTIR spectroscopic analysis

Figure 6 shows the FTIR spectrographs obtained for the raw/original C. pyrenoidosa biomass and the aqueous phase of runs 12 and 19 after SWE. It can be observed that there are differences in the functional groups and peak intensities before and after SWE. However, there are no significant differences in the functional groups of the aqueous phases of runs 12 and 19. Table 5 shows the wavenumbers of peaks identified from the original sample as well as their functional groups. The functional groups profile of the original microalgae biomass consists of water (O–H) or protein (N–H) at 3288 cm−1, lipid (2963 and 2933 cm−1), protein (1739 cm−1, 1646 cm−1, 1542 cm−1, 1452 cm−1, and 1383 cm−1), carbohydrate (1061 and 1038 cm−1), cellulose fatty acids (1739 cm−1), and nucleic acid (1228 cm−1).

Fewer functional groups were present in the aqueous phase after SWE, as shown in Table 5 and Fig. 6. The broad peak (3360 cm−1) could be observed in the aqueous phase of both runs. However, the intensity of the peaks at wavenumber (1000–1800 cm−1) of the aqueous phase samples 12 and 19 were less after extraction as compared with the original biomass. The functional groups of lipids (2809–3012 cm−1) were not detected in the aqueous phases of runs 12 and 19. The intensity of the carbohydrate groups (980–1072 cm−1) from both runs was lower compared with the original biomass.

Discussion

Protein and carbohydrate produced via SWE

CCD was used to identify and optimize the significant parameters that affect protein and carbohydrate production from SWE of C. pyrenoidosa biomass. The maximum protein generated from the present study is higher than the protein generated from the hydrolysis of Scenedesmus sp. biomass (3.184 mg mL−1) operated at 325 °C and 20.7 MPa (Moscoso et al. 2013). The difference in protein concentration of other microalgae could be attributed to the initial protein content of the biomass and the rigidity of the cell wall to subcritical water permeation. The concentration of carbohydrates was lower than proteins due to the initial amount of proteins (62.7%) in the biomass was higher compared with carbohydrates (22.8%) as shown in Table 1. It is also important to note that some of the carbohydrate molecules may still reside in the solid residue after SWE. The SWE temperature needed for the highest carbohydrate concentration in this study is lower than protein due to the presence of this carbohydrate in the microalgal cell wall. At room temperature, this cell wall has not yet disrupted; hence, none or limited amount of compounds are allowed to diffuse from the microalgae cell. As the temperature increase, the pressure of water also increases to maintain the water in liquid conditions. The rise in temperature and pressure cause the microalgae cell wall to swell and rupture, hence release the carbohydrate that mostly located in the cell wall and in the cell. Further increase in temperature could degrade the carbohydrate to organic acids.

SWE optimal operating conditions for maximum protein and carbohydrate extraction were different, indicating that extraction conditions are only tailored for a specific biochemical and it is difficult to identify a single best-operating condition for extracting all components (lipid, carbohydrate, and protein) from microalgal biomass. Ho et al. (2007) also identified different optimal conditions for protein and carbohydrate extractions from flaxseed meal. The optimal protein production was obtained at pH 9, 160 °C extraction temperature, and 210 mL g−1 meal solvent to solid ratio, while the optimal conditions for carbohydrates were obtained at 150 °C, 210 mL g−1 meal, and pH 4 or 6.5 (Ho et al. 2007). Hence, each biochemical component has its own optimal SWE operating conditions for extraction.

The efficiency of the SWE approach was evaluated by comparing the yields of protein and carbohydrate with other biomass feedstock as well as other extraction techniques. Awaluddin et al. (2016) obtained 31.2% protein and 14.2% carbohydrate under SWE conditions of 277 °C, 5% C. vulgaris biomass, and 5 min of extraction time, while Sereewatthanawut et al. (2008) obtained 21.9% protein of deoiled rice bran using SWE technology. The low yields of protein and carbohydrate in the present study reflect the SWE process was designed for lipid extraction; hence, proteins and carbohydrates are considered as by-products of the extraction process. In addition, the presence of the microalgae cell wall creates additional challenges to extract large protein molecules that trapped in the cell wall. The yield of proteins could be improved by pre-treating the microalgae biomass via mechanical, chemical, and/or enzymatic action (Safi et al. 2014; Bleakley and Hayes 2017). These treatments are intended to disrupt the cell wall of the microalgae biomass to make the proteins more accessible for extraction (Rodrigues et al. 2016). The protein yields obtained from other extraction techniques (manual grinding, ultrasonication, chemical extraction, and high-pressure homogenization) (Safi et al. 2014) were compared with that of SWE of C. pyrenoidosa biomass obtained in this study. The protein yield from the SWE (18.77%) in this study was higher (more efficient) than manual grinding (9.0%) and about the same as ultrasonication (18.1%), but lower (less efficient) than chemical extraction (33.2%) and high-pressure homogenization (52.8%). However, it should be noted that the use of chemicals for protein extraction is time-consuming and heavily associated with toxic waste management, and high-pressure homogenization requires high energy demands.

Interactions and influences of process variables

The 3-D surface relationship (Fig. 2a) indicates total protein concentration decreases with increasing temperature due to thermal denaturation of protein molecules under high-temperature conditions. The molecular kinetic energy of the protein molecules increases with increasing temperature, causing rapid vibration and intermolecular collisions that destroy the tertiary structure of the protein through the cleavage of its hydrogen bonds and non-polar hydrophobic interactions (Awaluddin et al. 2016). The amount of protein increased during extraction when increasing the solid loading from 1 to 15 wt%. This might be due to an increased rate of compound mass transfer resulting from the increased solid loading during the extraction. This phenomenon was attributed to the mass transfer principle. Higher solid-to-solvent ratios gave higher concentration gradients, leading to the increased diffusion and extraction of protein. In terms of extraction time, it was found that the protein extracted increased when the time was increased from 1 to 20 min. This might be due to the time required for the exposure of solute or compounds to the release medium when the water penetrates the microalgae, dissolves the solute and then diffuses out from the microalgae.

It is known that the degradation of carbohydrate, protein, and other components in microalgal cells is a temperature- and time-dependent process. As the microalgal biomass is mainly cellulose in the cell wall and starch in the plastids without lignin and low hemicelluloses contents, they could easily and readily leach out under milder subcritical water conditions compared with protein composition that mostly entrapped inside the cells. This is aligned with the findings from this study where the time taken to release carbohydrate was shorter than protein and the same pattern for the effect of temperature. It is believed that the carbohydrates compositions reported in this study were majorly obtained from the degradation of carbohydrates from the microalgae cell wall instead of the carbohydrates that entrapped inside the cells. Sereewatthanawut et al. (2008) observed in their work that the reaction time did not affect sugar production at a certain temperature (120–140 °C). However, at a higher temperature (220 °C), the extraction time affected sugar production (Sereewatthanawut et al. 2008). There are also studies that report that the microalgal rigid cell walls are hard to break. Hence, longer exposure/extraction time is necessary to increase the efficiency of extraction (Ursu et al. 2014; Awaluddin et al. 2016). The yield of carbohydrate decreased as temperature increase because the extreme temperatures probably caused the carbohydrate to degrade into other products such as ketones and aldehydes as well as organic acids (Sereewatthanawut et al. 2008).

Potential applications of solid residue after SWE

The elemental analysis of the microalgal biomass solid residue after the SWE showed the amount of N content was still significant, indicating the presence of proteins in the microalgal residue. Some of the extracted proteins cannot be detected by the Lowry method as this method only detects soluble proteins, and therefore, some undetected proteins could be found in the solid phase. Also, it is believed that those proteins may have been degraded into amino acids and organic acids at high temperature. At high temperatures, the ionization constant (Kw) increases from 1 × 10−14 at ambient temperature to 7 × 10−12 at 220 °C, and this elevates the concentrations of hydroxide and hydronium ions. These ions then interact with the protein molecules in the aqueous phase and induce molecular cleavage at the sites of the peptide bonds, generating smaller molecules of soluble protein or amino acids, which could further be degraded to form low molecular weight organic acids (Sereewatthanawut et al. 2008). Besides protein and peptide, carbohydrates compound also react with hydronium and hydroxide ions to generate reducing sugars (Sereewatthanawut et al. 2008). As mentioned earlier, the high temperature could also lead to degradation of these sugars into other products, including aldehydes and ketones, and from which organic acids could be produced (Sereewatthanawut et al. 2008). Therefore, further studies were conducted to determine the yields and types of amino acids and organic acids generated from the SWE of the C. pyrenoidosa biomass.

High-quality solid fuels should have high C and H contents to provide high heating values. A higher C and H contents were observed in run 12, showing the solid residue obtained from SWE of C. pyrenoidosa biomass has a great potential to be used as a solid fuel. As the C, H, and N contents of solid residue were high, it could be highly beneficial for gasification to produce syngas. The solid residue from the SWE process could also be used for pyrolysis to generate bio-oil (Maddi et al. 2011). However, the presence of N compounds in the solid residue could likely reduce the bio-oil value as the N would be converted to nitrogen-containing compounds such as amide, amine, and indole. This could potentially create secondary pollutants like NOx gases during combustion. Besides being used as feedstock for gasification and pyrolysis, the solid residue from the SWE process could be used as soil amendments to improve soil fertility, especially for acidic and nitrogen-deficient soils (Kiatsiriroat 2012). Furthermore, the solid residue could be processed as animal feed due to the high N contents.

Potential applications of amino acids and organic acids from microalgae C. pyrenoidosa via SWE

Amino acids are produced via protein hydrolysis. The concentration of amino acids obtained from the SWE process in this study is higher than the amino acids produced from deoiled rice bran (8.0 mg g−1), in which the SWE process was performed at 200 °C and 30 min extraction time (Sereewatthanawut et al. 2008). However, the concentration of the amino acids produced in this study is lower than the amino acids produced from subcritical water hydrolysis treatment of waste squid entrails and dried fish meat (Yoshida and Tavakoli 2004). About 103.1 mg g−1 amino acids were produced from SWE of the waste squid, and the total amount of cysteine, alanine, glycine, and leucine produced from SWE of fish meat was 50 mg g−1 of dry fish meat (Yoshida et al. 1999).

Hydroxyproline, threonine, and serine were not detected in run 12 due to high SW temperature (270 °C). Serine and threonine can be decomposed into other amino acids depending on the extraction conditions (Sato et al. 2004; Abdelmoez et al. 2010). Abdelmoez et al. (2010) reported that serine could be decomposed into glycine and alanine at the range of 230–290 °C, and pressure of 2.8–7.44 MPa. The formation of glycine is caused by retro-aldol condensation of serine, while threonine also undergoes retro-aldol condensation to produce glycine and acetaldehyde (Sato et al. 2004).

Amino acids have specific decomposition temperatures (Sato et al. 2004). The decomposition temperature of amino acids such as glycine, alanine, leucine, phenylalanine, serine and aspartic acid was 290 °C, 297 °C, 294 °C, 283 °C, 228 °C, and 271 °C (Sato et al. 2004). Hence, alanine, leucine, and phenylalanine could be detected present in the aqueous phase of runs 12 and 19 as these amino acids could withstand high temperatures. Sato et al. (2004) reported that alanine degradation rate is the slowest, followed by leucine and phenylalanine. On the contrary, aspartic acid and serine have higher degradation rates; thus, lower concentrations were detected in the aqueous phase. The yield of aspartic acid in run 12 (270 °C) was lower compared with run 19 (220 °C) due to the decomposition of aspartic acid at 271 °C. Serine was not detected in run 12 as serine decomposes at 228 °C. However, it was present in run 19 as the SWE was performed at a lower temperature of 220 °C.

Amino acids have many industrial applications. They are useful additives in the food industry and very important as flavor enhancers. Glutamic acid is used as an additive for spices, soups, sauces, meat, and fish in concentrations of 0.1–0.4% (Rogalinski et al. 2005). Beside glutamic acid, alanine and glycine are also considered as the main components of seaweed flavor (Mišurcová et al. 2014). It is noticeable that some essential amino acids (EAAs) such as valine, leucine, histidine, isoleucine, threonine, lysine phenylalanine, and methionine were produced from SWE of C. pyrenoidosa biomass. These EAAs are very important for protein supplement as humans cannot synthesize these EAAs. Besides nutrition, amino acids are also being used in medical, cosmetic, and other industrial applications, including agriculture (Rogalinski et al. 2005).

The general reaction pathway of amino acids degradation under SWE conditions takes two main paths: (1) deamination pathway to produce ammonia and organic acid and (2) decarboxylation pathway to produce carbonic acid and amines (Zhu et al. 2011a). Studies conducted by Yoshida et al. (1999) and Yoshida and Tavakoli (2004) showed a high amount of pyroglutamic acid generated from the hydrolysis of fish meat and squid. Other organic acids identified from fish meat and squid included lactic, formic, acetic, citric, malic, and succinic acids. A maximum of 0.055 kg kg−1 of organic acids was produced from SWE of squid operated at 280 °C for 40 min (Yoshida and Tavakoli 2004), while only 12.72 mg g−1 organic acids were obtained from the present study (270 °C, 10 min and 15% microalgal biomass loading). Besides amino acids, organic acids are also used in various industries such as food, pharmaceutical, and cosmetics. Examples of organic acids that are commonly used include citric, tartaric, malic, lactic, succinic, and gluconic acids. These organic acids are degradable and can be used for the production of biodegradable polymers. Lactic acid (2-hydroxypropanoic acid) was the highest organic acid produced in this study and can be used in the food industry for mild acid flavoring, for pH-regulation, or as a preservative (Bicker et al. 2005). In addition, lactic acid is used in medical, pharmaceutical, leather, and textile industries (Laopaiboon et al. 2010). Malic and succinic acids were also detected in this study and are widely used as an acidulant in soft drinks and as chelating agents (Taing and Taing 2007).

FTIR of protein and carbohydrate in the aqueous phase of SWE

The functional groups detected from FTIR analysis of this study are almost similar to the functional groups identified from C. vulgaris and S. obliques biomass (Duygu et al. 2012). The broad peak at 3360 cm−1 indicates the presence of water (O–H) functional groups, while the reduction in the intensity of peak at 1000–1800 cm−1 indicating a lesser amount of proteins in the aqueous phases compared with the original biomass. The functional groups of lipids were not detected in the aqueous phases, indicating most of the extracted lipids were recovered from the aqueous phase and probably some of the lipids still present in the solid residue. Most of the functional groups detected in the aqueous phase belong to proteins, showing proteins are a major component of runs 12 and 19. The FTIR data obtained validates the presence of protein and carbohydrate in the aqueous phase.

Overall, various potential biochemical compounds such as proteins, carbohydrates, amino acids, and organic acids were obtained from the aqueous phase of SWE of C. pyrenoidosa biomass in addition to the extracted lipid. The solid residue from the SWE process also demonstrated high C, H, and N contents. The present work shows a comprehensive strategy to harness new bioproducts from SWE of microalgal biomass. The amino acids (glutamic acid) and organic acids (lactic acid) produced could be further purified and commercialized as these two compounds have numerous applications in food industries. It was also found that the optimal SWE operating conditions for the highest protein, carbohydrate, and lipid production are different. However, it is evident that SWE can be used to extract lipids, proteins, and carbohydrates from microalgal biomass via a single extraction process with no biomass treatment, hence demonstrates the promising nature of SWE as a future green extraction technology.

References

Abdelmoez W, Yoshida H, Nakahasi T (2010) Pathways of amino acid transformation and decomposition in saturated subcritical water conditions. Int J Chem React Eng 8:1–19

Alhattab M, Kermanshahi-Pour A, Brooks MS-L (2019) Microalgae disruption techniques for product recovery: influence of cell wall composition. J Appl Phycol 31:61–88

Andrich G, Nesti U, Venturi F, Zinnai A, Fiorentini R (2005) Supercritical fluid extraction of bioactive lipids from the microalga Nannochloropsis sp. Eur J Lipid Sci Technol 107:381–386

Awaluddin SA, Thiruvenkadam S, Izhar S, Hiroyuki Y, Danquah MK, Harun R (2016) Subcritical water technology for enhanced extraction of biochemical compounds from Chlorella vulgaris. Biomed Res Int 2016:1–10

Azmir J, Zaidul ISM, Rahman MM, Sharif KM, Mohamed A, Sahena F, Jahurul MHA, Ghafoor K, Norulaini NAN, Omar AKM (2013) Techniques for extraction of bioactive compounds from plant materials: a review. J Food Eng 117:426–436

Becker EW (2007) Micro-algae as a source of protein. Biotechnol Adv 25:207–210

Bicker M, Endres S, Ott L, Vogel H (2005) Catalytical conversion of carbohydrates in subcritical water: a new chemical process for lactic acid production. J Mol Catal A 239:151–157

Bleakley S, Hayes M (2017) Algal proteins: extraction, application, and challenges concerning production. Foods 6:1–34

Cheung PCK (1999) Temperature and pressure effects on supercritical carbon dioxide extraction of n − 3 fatty acids from red seaweed. Food Chem 65:399–403

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Duygu DY, Udoh AU, Ozer TB, Akbulut A, Erkaya IA, Yildiz K et al (2012) Fourier transform infrared (FTIR) spectroscopy for identification of Chlorella vulgaris Beijerinck 1890 and Scenedesmus obliquus (Turpin) Kützing 1833. Afr J Biotechnol 11:3817–3824

Halim R, Gladman B, Danquah MK, Webley PA (2011) Oil extraction from microalgae for biodiesel production. Bioresour Technol 102:178–185

Halim R, Harun R, Danquah MK, Webley PA (2012) Microalgal cell disruption for biofuel development. Appl Energy 91:116–121

Harun R, Danquah MK (2011) Enzymatic hydrolysis of microalgal biomass for bioethanol production. Chem Eng J 168:1079–1084

Ho CHL, Cacace JE, Mazza G (2007) Extraction of lignans, proteins and carbohydrates from flaxseed meal with pressurized low polarity water. Food Sci Technol 40:1637–1647

Ho S-H, Huang S-W, Chen C-Y, Hasunuma T, Kondo A, Chang J-S (2013) Bioethanol production using carbohydrate-rich microalgae biomass as feedstock. Bioresour Technol 135:191–198

Ho BCH, Mustapa Kamal SM, Danquah MK, Harun R (2018) Optimization of subcritical water extraction (SWE) of lipid and eicosapentaenoic acid (EPA) from Nannochloropsis gaditana. Biomed Res Int 2018:1–11

Kiatsiriroat T (2012) Biochar production from freshwater algae by slow pyrolysis. Maejo Int J Sci Technol 6:186–195

Kouchaksaraie ZA, Niazmand R, Najafi MN (2016) Optimization of the subcritical water extraction of phenolic antioxidants from Crocus sativus petals of saffron industry residues: Box-Behnken design and principal component analysis. Innov Food Sci Emerg 36:234–244

Laopaiboon P, Thani A, Leelavatcharamas V, Laopaiboon L (2010) Acid hydrolysis of sugarcane bagasse for lactic acid production. Bioresour Technol 101:1036–1043

Li Y, Ghasemi Naghdi F, Garg S, Adarme-Vega TC, Thurecht KJ, Ghafor WA et al (2014) A comparative study: the impact of different lipid extraction methods on current microalgal lipid research. Microb Cell Factories 13:14

Lourenço SO, Barbarino E, Lavín PL, Lanfer Marquez UM, Aidar E (2004) Distribution of intracellular nitrogen in marine microalgae: calculation of new nitrogen-to-protein conversion factors. Eur J Phycol 39:17–32

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the folin phenol reagent. J Biol Chem 193:265–275

Maddi B, Viamajala S, Varanasi S (2011) Comparative study of pyrolysis of algal biomass from natural lake blooms with lignocellulosic biomass. Bioresour Technol 102:11018–11026

Medipally SR, Yusoff FM, Banerjee S, Shariff M (2015) Microalgae as sustainable renewable energy feedstock for biofuel production. Biomed Res Int 2015:1–13

Meizoso IR, Jaime L, Santoyo S, Señoráns FJ, Cifuentes A, Ibáñez E (2010) Subcritical water extraction and characterization of bioactive compounds from Haematococcus pluvialis microalga. J Pharmaceut Biomed 51:456–463

Miao X, Wu Q (2006) Biodiesel production from heterotrophic microalgal oil. Bioresour Technol 97:841–846

Mišurcová L, Buňka F, Vávra Ambrožová J, Machů L, Samek D, Kráčmar S (2014) Amino acid composition of algal products and its contribution to RDI. Food Chem 151:120–125

Moscoso JLG, Obeid W, Kumar S, Hatcher PG (2013) Flash hydrolysis of microalgae (Scenedesmus sp.) for protein extraction and production of biofuels intermediates. J Supercrit Fluids 82:183–190

Rashidi B, Trindade LM (2018) Detailed biochemical and morphologic characteristics of the green microalga Neochloris oleoabundans cell wall. Algal Res 35:152–159

Reddy HK, Muppaneni T, Sun Y, Li Y, Ponnusamy S, Patil PD, Dailey P, Schaub T, Holguin FO, Dungan B, Cooke P, Lammers P, Voorhies W, Lu X, Deng S (2014) Subcritical water extraction of lipids from wet algae for biodiesel production. Fuel 133:73–81

Rodrigues IM, Carvalho MG, Rocha JM (2016) Increase of protein extraction yield from rapeseed meal through a pretreatment with phytase: rapeseed meal: enhancing alkaline protein extraction with phytase pretreatment. J Sci Food Agric 97:2641–2646

Rogalinski T, Herrmann S, Brunner G (2005) Production of amino acids from bovine serum albumin by continuous sub-critical water hydrolysis. J Supercrit Fluids 36:49–58

Safi C, Ursu AV, Laroche C, Zebib B, Merah O, Pontalier P-Y, Vaca-Garcia C (2014) Aqueous extraction of proteins from microalgae: effect of different cell disruption methods. Algal Res 3:61–65

Safi C, Frances C, Ursu A, Laroche C, Pouzet C, Vaca-Garcia C, Pontalier P-Y (2015) Understanding the effect of cell disruption methods on the diffusion of Chlorella vulgaris proteins and pigments in the aqueous phase. Algal Res 8:61–68

Sánchez NFS, Valadez-Blanco R, Hernández-Carlos B, Torres-Ariño A, Guadarrama-Mendoza PC, Salas-Coronado R (2016) Lipids rich in ω-3 polyunsaturated fatty acids from microalgae. Appl Microbiol Biotechnol 100:8667–8684

Sato N, Quitain AT, Kang K, Daimon H, Fujie K (2004) Reaction kinetics of amino acid decomposition in high-temperature and high-pressure water. Ind Eng Chem Res 43:3217–3222

Schmitt J, Flemming H-C (1998) FTIR-spectroscopy in microbial and material analysis. Int Biodeterior Biodegradation 41:1–11

Sereewatthanawut I, Prapintip S, Watchiraruji K, Goto M, Sasaki M, Shotipruk A (2008) Extraction of protein and amino acids from deoiled rice bran by subcritical water hydrolysis. Bioresour Technol 99:555–561

Spolaore P, Joannis-Cassan C, Duran E, Isambert A (2006) Commercial applications of microalgae. J Biosci Bioeng 101:87–96

Taing O, Taing K (2007) Production of malic and succinic acids by sugar-tolerant yeast Zygosaccharomyces rouxii. Eur Food Res Technol 224:343–347

Thiruvenkadam S, Izhar S, Yoshida H, Danquah MK, Harun R (2015) Process application of subcritical water extraction (SWE) for algal bio-products and biofuels production. Appl Energy 154:815–828

Thiruvenkadam S, Izhar S, Hiroyuki Y, Harun R (2018) Subcritical water extraction of Chlorella pyrenoidosa: Optimization through response surface methodology. Biomed Res Int 2018:1–10

Ursu A-V, Marcati A, Sayd T, Sante-Lhoutellier V, Djelveh G, Michaud P (2014) Extraction, fractionation and functional properties of proteins from the microalgae Chlorella vulgaris. Bioresour Technol 157:134–139

Yoshida H, Tavakoli O (2004) Sub-critical water hydrolysis treatment for waste squid entrails and production of amino acids, organic acids, and fatty acids. J Chem Eng Jpn 37:253–260

Yoshida H, Terashima M, Takahashi Y (1999) Production of organic acids and amino acids from fish meat by sub-critical water hydrolysis. Biotechnol Prog 15:1090–1094

Zakaria SM, Mustapa Kamal SM, Harun MR, Omar R, Siajam SI (2017a) Extraction of antioxidants from Chlorella sp. using subcritical water treatment. Mater Sci Eng 206:12035

Zakaria SM, Mustapa Kamal SM, Harun MR, Omar R, Siajam SI (2017b) Subcritical water technology for extraction of phenolic compounds from Chlorella sp. microalgae and assessment on its antioxidant activity. Molecules 22:1105

Zhu X, Zhu C, Zhao L, Cheng H (2008) Amino acids production from fish proteins hydrolysis in subcritical water. Chin J Chem Eng 16:456–460

Zhu G, Zhu X, Fan Q, Liu X, Shen Y, Jiang J (2010) Study on production of amino acids from bean dregs by hydrolysis in sub-critical water. Chin J Chem 28:2033–2038

Zhu G, Zhu X, Fan Q, Wan X (2011a) Kinetics of amino acid production from bean dregs by hydrolysis in sub-critical water. Amino Acids 40:1107–1113

Zhu G, Zhu X, Fan Q, Wan X (2011b) Recovery of biomass wastes by hydrolysis in sub-critical water. Resour Conserv Recycl 55:409–416

Funding

The authors would like to thank the Malaysia Ministry of Higher Education (MOHE) and Universiti Putra Malaysia (Putra IPS grant no.: 9573400) for the financial and infrastructural supports to pursue this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zainan, N.H., Thiruvenkadam, S., Danquah, M.K. et al. Biochemical analysis and potential applications of aqueous and solid products generated from subcritical water extraction of microalgae Chlorella pyrenoidosa biomass. J Appl Phycol 32, 111–126 (2020). https://doi.org/10.1007/s10811-019-01960-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-019-01960-0