Abstract

Cell disruption is an essential pre-treatment for the efficient extraction of many types of intracellular metabolites such as proteins, carbohydrates, DNAs or lipids; but the high process energy requirement becomes an important issue for low valued commodities such as biofuels. Current mechanical cell disruption methods such as high-pressure homogeniser or sonication require energy input in the order of hundreds of MJ kg−1 of the dry mass; in addition, these methods do not have the capacity suitable for biofuel production where daily processing volumes are in order of mega litres. This study investigated hydrodynamic cavitation (HC) as a cell disruption technique, with levels of disruption determined by i) lipids extracted and ii) the chlorophyll released. It was found that for the lipid extraction, HC has a disruption energy requirement of 3 MJ kg−1. This amount of energy requirement is more efficient than sonication by a factor of 10; however, it still represents nearly 13 % of the total energy in the biomass and is too high for the production of biofuels. The cell disruption by HC is essentially periplasmic, i.e. mainly confined to the cell wall and membrane. This result suggests that damage to the outer cell barrier such as the cell wall was sufficient to allow for the diffusion of solvents for lipid extraction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Many species of microalgae have high biomass productivity in the order of 60 t ha−1 y−1 in particular; marine species have the added advantage of not competing with farm produce for fresh water or arable land (Moheimani and Borowitzka 2006). These advantages make microalgae attractive as a feedstock for biodiesel or a source of animal feed (Ward and Kumar 2010). For the production of microalgal biofuels such as biodiesel or ethanol, the intracellular lipid and/or carbohydrate needs to be extracted before they can be converted to fuel. Cell disruption can increase the amount of intracellular lipids extractable from some species of microalgae by up to threefold (Halim et al. 2012; Keris-Sen et al. 2014; Lee et al. 2010b; Olmstead et al. 2013; Samarasinghe et al. 2012). However, these inclusions and other cell structures are bound by a cell membrane and/or wall (Barsanti et al. 2007) with tensile strength in the order of 109 Pa (Allard et al. 2002; Carpita 1985). The barrier makes cell disruption an energy intensive process and the disruption energy requirement an important consideration especially in the case of low valued commodities such as biofuels.

Microorganism disruption methods can broadly be divided into two categories, namely, mechanical and non-mechanical. Mechanical methods have lower risk of contaminating the target product and are the preferred option (Middelberg 1995). Current industrial scale mechanical cell disruption techniques include bead mills, sonication, high-speed homogenisers (HSH) or high-pressure homogenisers (HPH). These processes are highly energy intensive; for example, the use of HSH or HPH for the extraction of the enzyme, invertase, has an energy consumption rate of approximately 0.6 to 1 MJ L−1 of the culture media while that by sonication is approximately three times higher (Lee et al. 2012). The majority of energy input is not consumed by cell disruption but rather dissipated as heat (Lee et al. 2013) and it is clear that such high level of energy consumption is not sustainable for biofuel productions. Finally, the commercial production of biofuels requires an economy of scale with processing capability in the order of mega litres per day (Lee et al. 2010a; Erkelens et al. 2014), and it will be technically challenging for HPH or sonication to be operated on such a large scale.

Cell disruption by hydrodynamic cavitation (HC) may offer a viable option to solve such problems; this study aims to evaluate this technique for the microalgal cell disruption as a pre-treatment for the extraction of lipids from microalgae.

Cavitation refers to the creation of cavities inside homogeneous liquid media. The generation of cavitation can be ultrasonic (Feliu et al. 1998), optic (Vogel and Lauterborn 1988) or hydrodynamic (Yu et al. 1995). For liquids with high boiling point and low viscosity, the collapse of these cavities can be very violent with extremely localised zones of pressure as high as 100 MPa and temperature up to 5000 °C (Gogate and Pandit 2005). HC has been shown to disrupt yeast cells (Save et al. 1997) with an energy efficiency one order of magnitude better than those from HSH or HPH. It should be noted that yeast membrane consists mainly of glucan and chitin (Cabib et al. 2001), while those from microalgae such as Chlorella are reinforced with tri-laminar layers of algaenan (Allard et al. 2002); hence, the disruption efficiency may be different. Finally, the location of lipids within the cell as to whether they are periplasmic or cytoplasmic may also affect the subsequent lipid extractability.

During a liquid flow where the flow velocity, \( v \), is increased to a sufficiently high level, as in the case of a small orifice or constriction, the pressure, P, will drop below the vapour pressure of the liquid and cavitation will be formed. The formation of the cavitation bubble is characterised by the dimensionless cavitation number, σ, in Eq. 1 (Moholkar and Pandit 2001).

where P 0 is the atmospheric pressure, Pa; P v is vapour pressure of the liquid, Pa; ρ m is the mass density of the liquid, kg m−3 and u is flow velocity of the liquid, m s−1.

Cavitations collapse shortly downstream from the orifice where the flow slows down and the pressure recovers. Under proper conditions, the collapse pressure can be high enough to rupture the suspending particles (Eq. 2). In theory, cavitation will be formed when σ ≤ 1; in practice, the cavitation inception is somewhat independent of flow velocity due to the presence of various suspended particles and dissolved gases (Yan and Thorpe 1990). In theory, u should be the value at the vena contracta (Fig. 1) where the flow rate is highest; however, it appears that neither the vena contracta nor the discharge coefficient is mentioned in many of the literature on the topics of cell disruption and hydrodynamic cavitation; therefore, in this study, for the convenience in comparison with previous publications, u is taken as the average value over the orifice rather than at the vena contracta.

The collapse pressure can be estimated by the empirical Eq. 2 (Gogate and Pandit 2000).

where P collapse is the collapse pressure of a single cavity, Nm−2; R 0 is the initial radius of the bubbles, μm; P in is the inlet pressure, bar, and (d 0/d p) is the orifice to pipe diameter ratio. The value of P collapse will be estimated in section ‘Lipids release and FAME conversion’

The efficiency of cell disruption by HC depends on a number of factors, including:

-

Cavitation number, σ: from Eq. 1, a higher linear flow velocity, u, and a lower viscosity, μ, will result in a lower σ and a higher collapsing pressure.

-

Presence of dissolved gases: the dissolved gases inside a cavitation will resist its collapse and reduce the resultant collapse pressure.

-

Viscosity of the liquid: low viscosity is essential for a faster cavitation collapse.

-

Vapour pressure: a volatile liquid will exert a higher outward pressure and reduce the overall collapse pressure.

-

Design of the orifice: orifice holes arranged radially have higher cell disruption efficiencies than those set in a circular fashion (Balasundaram and Harrison 2011).

Material and methods

Tetraselmis suecica starting culture was obtained from Australian National Algae Culture Collection, CSIRO, Tasmania, Australia. The microalga was grown in 2 × 400 L open outdoor ponds located in the University of Adelaide, SA, Australia. F medium (Guillard and Ryther 1962) was used as culture medium with components dissolved in sand-filtered natural seawater. The culture was mixed by paddlewheels and enriched with commercial carbon dioxide at 34.5 kPa (gauge). The microalga was harvested during stationary phase with the biomass collected by centrifugation (Veronesi, 2 kW, 12,000×g, 700 L h−1) to a semi-solid consistency then frozen and stored at −10 °C.

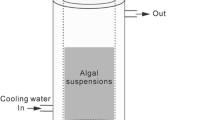

Hydrodynamic cavitation rig

The pilot scale HC rig was set up as a loop reactor open to the atmosphere (Fig. 2a); it consisted of a fibre glass holding tank of volume 200 L, A; a 3-phase, 11 kW motor, B (Lowara SV16-12) and a centrifugal pump, C; the pump and motor were coupled to the power inverter, D, (Fuji-Eco FRN 11, 23 amp, 3-phase) which controlled the flow through the orifice. The volumetric flow rate was measured by an electromagnetic flow meter, F (Krohne, Optiflux Magflo). An orifice plate, with 33 × 1 mm diameter circular holes (Fig. 2b) was housed in a flange located downstream from the pump exit. The section of tube (inner diameter 3.0 × 10−3 m) from the pump exit to the holding tank was made of stainless steel while the low pressure section from the holding tank to the inlet of the pump was made of PVC. Other accessories included a pressure relief valve, drain valve, safety shield around observation tube, flange reinforcement and mobile trolley.

a Hydrodynamic cavitation rig, showing T 200-L holding tank; C centrifugal pump; P1 and P2 pressure gauges for downstream and upstream of orifice, respectively; O orifice and flange housed inside safety shield; F flow meter; V1, V2 and V3 valves for main line, pressure release and drain, respectively. b Orifice plate design

From Eq. 2, with an average initial bubble diameter of 20 μm, which is of a similar order of magnitude to that of microalgal cells (Sharma et al. 2008), an inlet pressure of 1 MPa and a (d 0 /d p ) ratio of 0.66, Eq. 2 shows that P collapse has an estimated collapse pressure of 3.7 × 109 Pa. Such value is approximately 3.5 times the tensile strength of a typical cell wall and appears to be sufficient for the cell disruption. However, there are a number of factors that will affect the disruption: firstly, this calculation does not take into account of the vapour present in the bubbles which will reduce the cavitation collapsing speed; secondly, the collapse pressure generated may not be the actual pressure exerted on the cell surface due to the random distance of separation between the algal cell and cavitation, and finally, depending on the distance from the solid surface, the cavitation collapse mechanism may either be spherical (Shah et al. 1999), water jet impingement (Tomita and Shima 1986) or cluster (Kanthale et al. 2003). Therefore, the effect of P collapse on cell disruption can only be used as a guide.

For the disruption experiment, a calculated amount of the harvested algal biomass was mixed with filtered seawater to form a suspension with a dry mass concentration of 1.5 to 2 % w/w shortly before being used. Each run required an average of 40 L, and the equivalent of 0.9 kg of the algal dry mass was required. This amount was equivalent to 3 weeks of continuous culturing and harvesting from the 2 × 400 L open ponds. During the HC trial, a 200 mL aliquot sample was taken at time, t = 0, then again at 4-min intervals until the end of the treatment. Sealed bags of ice were immersed in the holding tank to keep the temperature of the algal suspension below 35 °C. The flow through the orifice and hence the cavitation number was adjusted by varying the current supplied via the power inverter coupled to the centrifugal pump (Fig. 2a, item C).

Determination of the degree of disruption

The level of cell disruption can be quantified by measuring the release of cellular metabolites (such as protein or enzymes), cell counting or particle size distribution (Middelberg 1995). As lipids were the target product for the study of microalgal biofuels, the efficiency of disruption was determined gravimetrically by the mass of lipid released from HC and compared with that from sonication.

The extent of disruption by HC on yeast cells had been determined by the release of proteins or enzymes (Balasundaram and Harrison 2006). The process involved the centrifugation of disrupted samples and measurement of specific enzymatic activities from the supernatant. Solvent was not used during the extraction as it would denature the protein or enzymes extracted. For microalgae, the level of disruption can similarly be measured by the release of chlorophyll (Kuboi et al. 1995). Although chlorophyll is not the target product in this study, its measurement can be used to demonstrate the differences in the product release mechanism and characteristics.

Gravimetric

The amount of lipids from the sonicated sample, W s, was chosen arbitrarily for comparison. It was determined by sonicating 10 mL of the algal concentrate for 4 × 10 s in a Branson Sonifier (power consumption of 700 W, coupled to Branson 102C converter with 2 mm horn probe). Five millilitres of the disrupted sample was mixed with 10 mL of hexane, and the other 5 mL was mixed with 10 mL of a 1:2 mixture of methanol and chloroform. They were mixed in a water bath at 40 °C for 4 h for extraction. This was followed by the addition of 2 mL of 0.88 % w/v KCl solution to each sample to improve the phase separation. Samples were then centrifuged at 1000×g for 5 min; the aqueous phase was then solvent extracted and centrifuged again. The lipid phase from the two extractions was combined, then filtered and dried at 70 °C by a gentle stream of nitrogen gas until a constant weight was obtained. The weight of crude lipid W s was recorded at 0.1 mg. The amount of lipids from HC samples, W t , and untreated samples, W o , were determined similarly but without sonication.

The level of disruption as measured gravimetrically, D g , is determined by Eq. 3a.

where W o is mass of the lipid extracted from untreated samples, W t is mass of the lipid extracted from samples at time t of HC and W s is mass of the lipid extracted from completely sonicated samples.

Chlorophyll UV-VIS absorption

The procedure was carried out as follows: 10 mL aliquot from each sample was centrifuged at 1000×g for 2 min (Beckman-Coulter, Allegra X-12), and then, 3 × 1 mL aliquots from the supernatant were taken for spectrophotometer readings (Shimadzu, UV1700). No extraction solvent was used, and absorption readings were repeated three times with the average recorded. The level of disruption, D c, as measured by the optical density, O d (no unit) of the chlorophyll released, is determined by Eq. 3b:

where O do is the optical density (no unit) of the chlorophyll released from untreated samples at time 0, O dt is optical density at time t of HC and O ds is optical density of chlorophyll released from sonicated samples.

Gas chromatography

Many types of intra-cellular chemicals can be extracted by solvents such as methanol or chloroform; many of these chemicals may not be true lipids, for example, the phospho- or glyco-lipids found in the cell membrane. Such problem in the determination of the content and nature of lipids has been investigated by Sukhija and Palmquist (1988) and Palmquist and Jenkins (2003). Their study showed that the preferred method of lipid analysis is to use esterification to determine the total fatty acid concentration by first converting the fatty acids to methyl esters. These esters are then quantified by chromatography to provide information on both fatty acid quantity and profile. The determination of lipid content was carried out as below:

The crude lipids were first dissolved in toluene, then extracted by Florisil (Sigma-Aldrich Australia), followed by the trans-esterification in a mixture of H2SO4 and methanol in the volume ratio of 1: 50 for 3 h at 70 °C. After cooling, the resulting fatty acid methyl esters (FAMEs) were extracted with n-hexane and washed with KHCO3 solution (40 g L−1) prior to being evaporated to dryness under a stream of nitrogen. The FAMEs were re-dissolved in n-hexane analysed with a Perkin Elmer Claus 500 gas chromatograph equipped with a flame ionisation detector and a BP20 Forté (30 m × 0.32 mm ID × 0.25-μm film thickness) capillary column (SGE Pty Ltd, Australia). Hydrogen gas was used as carrier with a column flow rate of 2.4 mL min−1. The injector and detector were set at 250 °C. One microlitre samples were injected with a split ratio of 50:1. The initial oven temperature was programmed at 155 °C for 10 min then raised to 180 °C at a rate of 2 °C min−1, followed by a further temperature rise to 220 °C at a rate of 4 °C min−1 and held steady for 7.5 min. FAMEs were identified and quantified by comparison of retention times to internal standards C19 (Nu-Chek Prep, USA). FAMEs were selectively bind to Florisil (Sigma-Aldrich Australia) and washed with n-hexane and then eluted from the column with a solvent consisting of 10 % v/v diethyl ether in n-hexane.

Results and discussion

Cell disruption

Figure 3a, b shows respectively the images of T. suecica cells before and after HC. The cells in Fig. 3a are intact with the outer protective layer of mucilage, cell wall and membrane clearly visible. Figure 3b shows the periplasmic disruption produced by HC where much of the cell’s outer layer has been damaged but the cell body remains essentially intact. In comparison, sonication produced the cytoplasmic type of disruption where cell bodies are split open (Fig. 3c). The significance of these two types of disruption, with respect to the release characteristics of the cellular lipids and chlorophyll, will be explained later in section ‘Disruption energy requirement’.

Lipids release and FAME conversion

Figure 4a, b presents respectively the level of disruption as measured by the mass of lipids extracted and fatty acid methyl ester (FAME) produced. The extraction solvents used were chloroform/methanol (CM) of volume ratio 2:1 and n-hexane (hex) with the latter providing higher crude lipid extraction efficiency (Fig. 4a, items 1 and 2). Figure 4a, b shows that the level of disruption was relatively steady after 4 min of HC, and further HC treatment did not show any significant increase in the crude lipids extracted. The disruption by HC appeared to achieve higher lipid extraction efficiency than sonication with an average D g of 1.5 (Eq. 3a).

Figure 3b, c shows that HC and sonication produce a large difference in the extent of morphological disruption; yet, Fig. 4a, b (items 2 and 4) shows little difference in the amount of lipids extracted by these two processes. These two results show that the combined effects of the disrupted cell wall, small cell size of approximately 8 μm, the use of solvent and a long mechanical mixing time of 4 h (section ‘Gravimetric’), all contributed to the diffusion of solvent into the cell interior for the extraction. Disruption of the whole cell under such conditions does not increase the overall lipid extraction efficiency and may not be necessary. This apparently contradictory result to that obtained by Lee et al. (2010b) is mainly due to the difference in extraction time of 5 min in the former vs. 4 h in this study.

Figure 4b indicates that under the acid esterification conditions (section ‘Gas chromatography’) under 20 % of the extractable crude lipids had been converted to FAME. The gas chromatograph scans for the purified crude lipids and FAME produced is presented in Fig. 5a, b, respectively, with these two scans showing similar peaks. The similarity in peaks shows lipids esterifiability, and the conversion to FAME is roughly related, but the relatively low conversion rate shows that the technique of in situ acid trans-esterification may not be suitable for the biodiesel production. The extracted crude lipids may require further purification and separation to maximise FAME conversion.

Level of disruption measured by chlorophyll released

Figure 6a, b shows the level of cell disruption as measured by the chlorophyll released. For sonication, the optical density reading, O d , and hence the level of cell disruption increased from 0.23 to 0.63 during the first 10 s then plateau off with only a slight increase to about 0.77 at 40 s. For HC, the O d readings increased from 0.20 at process time, t = 0 to 0.82 at t = 20 min. The increase in O d and hence the chlorophyll released with HC time is different from the plateau at 4 min obtained by lipids released. The difference in the release characteristics was mainly due to the use of extraction solvents and mechanical mixing, both of which enhanced the cell wall permeability, solvent diffusion and hence the lipid release from the cells. Under the action of solvents and mechanical mixing, the damage to the outer barrier of cell wall and membrane is deemed to be sufficient for the lipid extraction. In contrast, the release of chlorophyll was not aided by the solvents and mixing. The difference in disruption efficiency as measured by lipid extraction and chlorophyll release shows that the disruption efficiency depends on the release characteristics of the target product such as location within the cell, binding to cell substrates and the difference in measurement techniques.

Disruption energy requirement

A cavitation number value of approximately 0.125 had been chosen for the maximum cell disruption efficiency (Balasundaram and Harrison 2006). The process parameters and their respective values to achieve such a condition are presented in Table 1.

The energy consumption for the disruption of a minimum volume of 40 L of algal concentrate was 7.5 kW for 4 min; this is equivalent to 45 MJ m−3 of the suspension or 3 MJ kg−1 of the dry biomass. In comparison, 10 mL of the algal concentrate required a minimum of 10 s of sonication time at an energy consumption rate of 700 W; this is equivalent to 700 MJ m−3 of the algal suspension or 46.8 MJ kg−1 of the dry biomass. The amount of energy required by sonication is of one order higher than that of HC.

For the cell disruption efficiency as measured by the release of chlorophyll, 40 L of cell suspension would require 20 min of HC treatment time with a power consumption of 7.5 kW, this is equivalent to an energy consumption per unit volume of 225 MJ m−3 or per unit dry biomass of 15 MJ kg−1.

Comparison with literature values

There is no previous study on the HC disruption of microalgal cells; however, the yeast, Saccharomyces cerevisiae, cell suspension (1 % w/w) had been disrupted by HC with an energy consumption of 330 MJ m−3 of the culture media or 33 MJ kg−1 of the biomass (Balasundaram and Pandit 2001). Such value is between eight to ten times of that obtained by lipid extraction in this study but is of similar order of magnitude to that by chlorophyll extraction in this study. The main contributing factor is the use of solvents (hexane or chloroform-methanol) and extraction time during lipid extraction but not the enzyme extraction; other contributing factors include: the bigger cell diameter of Tetraselmis (approximately 8 to 10 μm vs. 3 to 4 μm for the yeast); a higher cell mass concentration (1.5 vs. 1 % w/w), and finally, cell wall structures (algaenan and cellulose in Tetraselmis vs. chitin and glucan in the yeast).

The disruption energy consumption measured by chlorophyll released was approximately half of that obtained by Balasundaram and Pandit (2001), but still of similar order of magnitude. The main reason is the larger cell size of the microalgae in comparison to that of the yeast as indicated previously.

Comments on HC for cell disruption

Apart from the lower energy requirement as previously mentioned, HC also has a lower operating cost. In this study, the operation time for HC is 4 min for 40 L, but it would require a processing time of over 10 h for sonication to disrupt a similar volume. For the production of biofuels where processing volumes of mega litres are required for the economy of scale, HC has the advantage of much shorter processing time over other mechanical disruption methods and the added advantage of disinfecting the media for the purpose of water recycling (Jyoti and Pandit 2001; Erkelens et al. 2014).

A summary of the difference between HC and sonication is presented in Table 2.

HC also has the potential for further energy reduction; this is because the high level of localised turbulence and pressure created during HC can increase the mixing and the diffusion of solvents on a cellular level. Hence, the combination of HC and solvent extraction into one single operation has the potential to further minimise the energy requirement. The major issues with such an operation are the selection of an organic solvent with a high boiling point, low viscosity for the cavitation and a high ignition point for safety.

A high biomass concentration is preferred for an efficient extraction of the target product from the disruptate; however, due to both the relatively high liquid velocity required at the orifice (about 40 m s−1 during this study) for the generation of cavities and a fast cavity wall collapse required for the cell disruption, HC is only suitable for the processing of cell suspensions with a relatively low viscosity. Such requirements put an upper limit on the biomass concentration allowed during the processing. In this study, a dry mass concentration of approximately 2 % w/w has been deemed to be the upper end of the range and the attempt to increase the biomass concentration resulted in excessive pump and motor power requirement and poor cell disruption efficiency.

Although HC can provide a lower energy cell disruption alternative in the order of 3 MJ kg−1 of the dry mass equivalent, such energy is still too high for the production of biofuels for the following two major reasons: firstly, this energy requirement does not include that for solvent extraction and trans-esterification, and secondly, the large amount of fine cell fragments formed during HC lead to extra energy required for the solid-liquid separation. Although the problem with extra separation energy is common to other disruption methods, the low cost of biofuels does become a significant constraint. Finally, comparing with the theoretically calculated cell disruption energy of 673 J kg−1 (Lee et al. 2013), the values obtained during this HC trial still indicate a very low energy efficiency.

Conclusion

Hydrodynamic cavitation can be used as a cell disruption technique with higher energy efficiency than other mechanical ones. The disruption is periplasmic and is more efficient when combined with mechanical mixing and solvent extraction. The energy efficiency also depends on the release characteristics of the target products such as lipids or chlorophyll. The lower energy requirement when comparing with other disruption techniques such as sonication may provide a viable option for biofuel production where energy requirement is a critical consideration.

References

Allard B, Rager M-N, Templier J (2002) Occurrence of high molecular weight lipids (C80+) in the trilaminar outer cell walls of some freshwater microalgae. A reappraisal of algaenan structure. Org Geochem 33:789–801

Balasundaram B, Harrison STL (2006) Disruption of Brewers’ yeast by hydrodynamic cavitation: process variables and their influence on selective release. Biotechnol Bioeng 94:303–311

Balasundaram B, Harrison STL (2011) Optimising orifice geometry for selective release of periplasmic products during cell disruption by hydrodynamic cavitation. Biochem Eng J 54:207–209

Balasundaram B, Pandit AB (2001) Selective release of invertase by hydrodynamic cavitation. Biochem Eng J 8:251–256

Barsanti L, Evangelista V, Frassanito AM, Vesentini N, Passarelli V, Gualtieri P (2007) Absorption microspectroscopy, theory and applications in the case of the photosynthetic compartment. Micron 38:197–213

Cabib E, Roh D-H, Schmidt M, Crotti LB, Varma A (2001) The yeast cell wall and septum as paradigms of cell growth and morphogenesis. J Biol Chem 276:19679–19682

Carpita NC (1985) Tensile strength of cell walls of living cells. Plant Physio 79:485–488

Erkelens M, Ball AS, Lewis DM (2014) The influences of the recycle process on the bacterial community in a pilot scale microalgae raceway pond. Biores Tech 157:364–647

Feliu JX, Cubarsi R, Villaverde A (1998) Optimized release of recombinant proteins by ultrasonication of E. coli cells. Biotech Bioeng 58:536–540

Gogate PR, Pandit AB (2000) Engineering design methods for cavitation reactors II: hydrodynamic cavitation. AICHE J 46:1641–1649

Gogate PR, Pandit AB (2005) A review and assessment of hydrodynamic cavitation as a technology for the future. Ultrason Sonochem 12:21–27

Guillard RRL, Ryther JH (1962) Studies of marine planktonic diatoms: 1. Cyclotella nana Hustedt and Detonula confervacea (Cleve) Gran. Can J Microbiol 8:229–239

Halim R, Harun R, Danquah MK, Webley PA (2012) Microalgal cell disruption for biofuel development. Appl Energy 91:116–121

Jyoti KK, Pandit AB (2001) Water disinfection by acoustic and hydrodynamic cavitation. Biochem Eng J 7:201–212

Kanthale PM, Gogate PR, Pandit AB, Marie Wilhelm A (2003) Cavity cluster approach for quantification of cavitational intensity in sonochemical reactors. Ultrasonics Sonochem 10:181–189

Keris-Sen UD, Sen U, Soydemir G, Gurol MD (2014) An investigation of ultrasound effect on microalgal cell integrity and lipid extraction efficiency. Biorces Tech 152:407–413

Kuboi R, Umakoshi H, Takagi N, Komasawa I (1995) Optimal disruption methods for the selective recovery of β-galactosidase from Escherichia coli. J Ferm Bioeng 79:335–341

Lee AK, Lewis DM, Ashman PJ (2010a) Energy requirements and economic analysis of a full-scale microbial flocculation system for microalgal harvesting. Chem Eng Res Design 88:988–996

Lee AK, Lewis DM, Ashman PJ (2012) Disruption of microalgal cells for the extraction of lipids for biofuels: processes and specific energy requirements. Biomass Bioenergy 46:89–101

Lee AK, Lewis DM, Ashman PJ (2013) Force and energy requirement for microalgal cell disruption: an atomic force microscope evaluation. Biores Tech 128:199–206

Lee JY, Yoo C, Jun SY, Ahn CY, Oh HM (2010b) Comparison of several methods for effective lipid extraction from microalgae. Bioresour Tech 101 (Supplement 1):S75-S77.

Middelberg APJ (1995) Process-scale disruption of microorganisms. Biotech Adv 13:491–551

Moheimani N, Borowitzka M (2006) The long-term culture of the coccolithophore Pleurochrysis carterae (Haptophyta) in outdoor raceway ponds. J Appl Phycol 18:703–712

Moholkar VS, Pandit AB (2001) Modeling of hydrodynamic cavitation reactors: a unified approach. Chem Eng Sc 56:6295–6302

Olmstead ILD, Hill DRA, Dias DA, Jayasinghe NS, Callahan DL, Kentish SE, Scales PJ, Martin GJO (2013) A quantitative analysis of microalgal lipids for optimization of biodiesel and omega-3 production. Biotech Bioenergy 110:2096–2104

Palmquist D, Jenkins T (2003) Challenges with fats and fatty acid methods. J Anim Sci 81:3250–3254

Samarasinghe N, Fernando S, Lacey R, Faulkner WB (2012) Algal cell rupture using high pressure homogenization as a prelude to oil extraction. Renew Energy 48:300–308

Save SS, Pandit AB, Joshi JB (1997) Use of hydrodynamic cavitation for large scale microbial cell disruption. Food Bioprod Pro 75:41–49

Shah Y, Moholkar V, Pandit A (1999) Cavitation reaction engineering. The Plenum Chemical Engineering Series. Kluwer, Dordrecht

Sharma A, Gogate PR, Mahulkar A, Pandit AB (2008) Modeling of hydrodynamic cavitation reactors based on orifice plates considering hydrodynamics and chemical reactions occurring in bubble. Chem Eng J 143:201–209

Sukhija PS, Palmquist DL (1988) Rapid method for determination of total fatty acid content and composition of feedstuffs and feces. J Agr Food Chem 36:1202–1206

Tomita Y, Shima A (1986) Mechanisms of impulsive pressure generation and damage pit formation by bubble collapse. J Fluid Mech 169:535–564

Vogel A, Lauterborn W (1988) Acoustic transient generation by laser-produced cavitation bubbles near solid boundaries. J Acoust Soc Am 84:719–731

Ward AJ, Kumar MS (2010) Bio-conversion rate and optimum harvest intervals for Moina australiensis using digested piggery effluent and Chlorella vulgaris as a food source. Bioresour Tech 101:2210–2216

Yan Y, Thorpe R (1990) Flow regime transitions due to cavitation in the flow through an orifice. Int J Multiphase Flow 16:1023–1045

Yu P-W, Ceccio SL, Tryggvason G (1995) The collapse of a cavitation bubble in shear flows—a numerical study. Phys Fluid 7:2608–2616

Acknowledgments

This project received funding from the Australian Government as part of the Asia-Pacific Partnership (APP) on Clean Development and Climate (Project number: RD-07-26). The views expressed herein are not necessarily the views of the Commonwealth, and the Commonwealth does not accept responsibility for any information or advice contained herein.

The authors would also like to thank Prof. M.A. Borowitzka from Murdoch University, Western Australia, for his overall co-ordination of the APP project and acknowledge the permission granted by Muradel Pty Ltd for the publication of this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, A.K., Lewis, D.M. & Ashman, P.J. Microalgal cell disruption by hydrodynamic cavitation for the production of biofuels. J Appl Phycol 27, 1881–1889 (2015). https://doi.org/10.1007/s10811-014-0483-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-014-0483-3