The effect of treatment with various chemical modifiers on the physicomechanical properties of polyacrylonitrile (PAN) fibers was studied. The structures of the finished reinforcing systems were analyzed. The hardening kinetics of an epoxide binder in the presence of the modified fibrous systems were studied. It was found that modification of PAN filament improved the mechanical properties of epoxide composites based on it.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Modification of reinforcing fillers that improves the boundary adhesion of a fibrous system to a polymer matrix is given special attention when designing polymer-matrix composites based on chemical fibers. Such modification strengthens and optimizes the mechanical and other functional properties of the composites, which enables their areas of application to be expanded [1, 2].

The goal of the present work was to study the effect of polyacrylonitrile (PAN) fibers treated with various chemical modifiers on the hardening kinetics and properties of epoxide composites based on them.

The modifiers were a mixture of fatty acid glycol esters (Dyron OS 3151) and 3-aminopropyltriethoxysilane (AGM-9). PAN technical filament (PAN-TF) was modified by finishing additives at solution concentrations of 2, 5, and 10% and treatment time 60 s. Modified fibers were dried in two steps at 50°C in the first and 100°C in the second.

The effect of the conditions for treating PAN-TF with the modifiers on its physicomechanical properties showed that its strength characteristics improved by 40 and 49% as a result of modification of the fibrous filler by AGM-9 and Dyron OS 3151 solutions (5%) (Table 1).

The tendency of the strength properties of the PAN precursor modified by solutions of the used finishers to increase was related to the formation on the fiber surface of a film coating that “cured” PAN-TF microcracks and defects. This was confirmed by optical microscopy (Fig. 1).

IR spectra of finished reinforced systems were studied in order to characterize the interaction of PAN-TF with the modifiers. Spectra were interpreted using literature data [4, 5].

An analysis of the IR spectra (Fig. 2) confirmed that bands at 800-850 cm–1 for SiOCH3 (curve 2) and at 1300 cm–1 for COO (curve 3) that were characteristic of the modifiers appeared in the spectrum of the PAN-TF fibrous filler modified by the finishing compositions. The spectrum of fibrous filler modified by Dyron OS 3151 solution (curve 3) changed significantly because it was a non-binding modifier that could be adsorbed on the polar surfaces of the filler to form a monolayer [2]. The spectrum of fiber treated with AGM-9 (curve 2) was characteristic of a Si-containing group and had a weaker peak for –CN in the region of 2240 cm–1 than the spectrum of unmodified PAN-TF. This also indicated that the modifier might have reacted chemically with the reinforcing system.

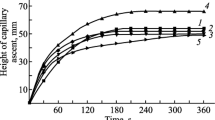

The change in the chemical composition of the fibrous filler surface necessitated an assessment of the effect of the finished PAN fibers on the epoxide-resin hardening process (Fig. 3, Table 2).

The study of the hardening kinetics of the epoxide binder in the presence of the studied fibrous systems showed that unmodified (curve 2) and modified PAN-TF (curves 3 and 4) had analogous effects on the hardening of the epoxide binder (curve 1). The gel-formation time decreased by 2-2.2 times; hardening time, by 1.6-1.8 times. The maximum hardening temperature dropped by 57-76°C with a simultaneous increase of the degree of hardening to 97-99%.

However, an analysis of the hardening kinetics of the epoxide binder in the presence of the modified fibrous systems showed that they had a more pronounced effect on structure formation in the polymer matrix that was obviously due to the introduction of the new functional groups. As a result, the physicochemical compatibility of the epoxidebinder—modified-reinforcing-filler system improved. This increased the strength properties of the polymer-matrix composite (Table 3).

Thus, modification of PAN-TF altered the surface chemical composition of the fibrous filler. This enhanced its effect on structure formation in the polymer matrix and increased the mechanical properties of epoxide composites based on the modified PAN fiber.

References

K. E. Perepelkin, Reinforcing Fibers and Fibrous Polymer Composites: Textbook [in Russian], Nauchnye Osnovy i Tekhnologii, St. Petersburg, 2009, 380 pp.

M. Xanthos (ed.), Functional Fillers for Plastics, Wiley-VCH, Weinheim, 2010 [Translated from English by V. N. Kuleznev (ed.), Nauchnye Osnovy i Tekhnologii, St. Petersburg, 2010, 462 pp].

L. V. Korchina, N. G. Zubova, and T. P. Ustinova, in: Proceedings of the Vth All-Russian Scientific Conference (with International Participation) “Physical Chemistry of Polymer Processing” [in Russian], Ivanovo, 2013, pp. 79-80.

A. N. Del Fanti, Infrared Spectroscopy of Polymers [translated from English by B. N. Tarasevich, electronic resource, http://www.biblus.ru/Default.aspx?book=1b466g1b1; accessed Mar. 14, 2014.

B. N. Tarasevich, IR Spectra of Principal Classes of Organic Compounds [in Russian], electronic resource, http://www.biblus.ru/Default.aspx?book-1b466g1b1, accessed Mar. 14, 2014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 6, pp. 28-30, November—December, 2014.

Rights and permissions

About this article

Cite this article

Korchina, L.V., Zubova, N.G., Popova, N.E. et al. Effect of Polyacrylonitrile Fibers Modified by Various Chemical Finishes on the Hardening Kinetics and Properties of an Epoxide Composite Based on Them. Fibre Chem 46, 360–362 (2015). https://doi.org/10.1007/s10692-015-9621-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-015-9621-1