The effect of the modification parameters on the structure and properties of polyacrylonitrile technical filament (PAN-TF) used to reinforce an epoxide matrix was studied. It was found that treatment of PAN-TF with aqueous solutions of hydrated Cu(II) sulfate could produce modified reinforcing fillers for which the physicomechanical properties tended to increase. The operating properties of composites with the studied PAN-TF were evaluated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Components for polymer composites are selected taking into account the individual properties of the fibers and polymeric binder (polymer matrix) and their mutual interaction due to several factors such as strength, bending properties, heat resistance, fiber structure and orientation, wetting at the interface, etc. [1]. The reinforcing materials are modified in order to optimize the bending and strength properties of the polymer composites. Chemical metallization based on treatment of fibers with freshly prepared formulations containing a solution of CuSO4"5H2O that can increase the strength characteristics is an accessible and effective method among many methods for modifying fibrous materials [2].

The goal of the work was to study the effect of the modification parameters on the structure and properties of polyacrylonitrile technical filament (PAN-TF) used to reinforce an epoxide matrix.

PAN fibers were treated for 60 s with a formulation containing hydrated Cu(II) sulfate at concentrations of 2%, 5%, and 10%. The samples were additionally heat treated at 100°C for 15 min after the soaking and drying (T dry = 50°C) were finished.

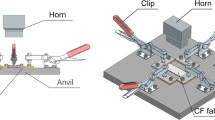

Treatment of PAN-TF with aqueous Cu(II) sulfate solutions produced a modified reinforced filler that characteristically tended to have increased physicomechanical properties (Fig. 1). Testing was conducted according to the literature [3].

Raman spectra of finished reinforcing systems were studies in order to establish the nature of the PAN-TF interaction with CuSO4·5H2O (Fig. 2).

Raman spectra of the fibers showed that starting PAN-TF (curve 1) had characteristic peaks at 2960 and 2928 cm–1 that corresponded to –OH and –CH vibrations. The strongest absorption band occurred at 2240 cm–1 and was due to –C≡N vibrations. The region near 1453 cm–1 contained a peak corresponding to –CH2 vibrations. Treatment with 2 (curve 2), 5 (curve 3), and 10% (curve 4) salt solutions increased slightly the intensity of the –CN peak of the modified PAN fibers. However, the surface of the modified fibers did not change in principle even after treatment with 10% CuSO4·5H2O solution.

Optical microscopy (Fig. 3) found that increasing the Cu(II) sulfate concentration in the modifying bath to 10% led to the formation of copper microcrystals on the PAN-TF surface and its incomplete binding to the fibers (Fig. 3d), in contrast with fibers treated with 2% and 5% salt solutions (Fig. 3b and 3c). This allowed PAN-TF modified with these formulations to be further studied.

Adhesion of the polymer and fiber is an important factor in producing the operational properties of polymer composites [4]. The ability of the fibers to be wetted by an epoxide oligomer was studied in order to determine the adhesive properties of PAN filaments modified by 5% Cu(II) sulfate solution (Fig. 4).

Results from the assessment of the adhesive properties indicated that treatment of PAN-TF by the studied modifier decreased the wettability of the fibers by the epoxide oligomer. This was confirmed by optical microscopy (Fig. 3).

Modification of the fibrous filler necessitated an evaluation of the effect of the decorated PAN fibers on curing of the epoxide resin (Fig. 5, Table 1).

The curing kinetics of the epoxide resin in the presence of the reinforced systems showed that starting (curve 2) and modified PAN-TF (curve 3) had analogous effects on the process. The gelation time was shortened by 2-3 times; curing, by 1.8-2 times. The maximum curing temperature decreased by 57-69°C. The degree of curing increased simultaneously to 98-99%.

Table 2 compares the operational characteristics of modified PAN-TF that was pressed to produce samples of an epoxide composite. Tests were conducted according to the literature methods [5–7]. The results showed that the tensile breaking stress increased by 10-11%; the bending breaking stress, by 16-27%; and the Brinell hardness by 55-90% for PAN-TF modified with CuSO4·5H2O as compared with unmodified fibers.

Thus, the study of the effect of modification on the PAN-TF structure and properties allowed the optimum treatment parameters for the fibers used to reinforce the epoxide composite to be selected.

References

K. E. Perepelkin, Reinforcing Fibers and Fiber Polymer Composites [in Russian], Nauchnye Osnovy i Tekhnologii, St. Petersburg, 2009, 380 pp.

Metallization of Textile Items [in Russian], http://www.textile-press.ru [accession date Aug. 21, 2014].

GOST 10213.2-2002. Staple Chemical Fibre and Tow. Methods for Determination of Breaking Strength and Breaking Elongation. [in Russian], issued Nov. 1, 2002 in replacement of GOST 10213.2-73, Izd. Standartov, Moscow, 2003, 8 pp.

S. E. Artemenko, Composites Reinforced with Chemical Fibers [in Russian], Izd. Sarat. Gos. Univ., Saratov, 1989, 160 pp.

GOST 11262-80. Plastics. Tensile Test Method. [in Russian], issued Dec. 1, 1980 in replacement of GOST 11262-76, Izd. Standartov, Moscow, 1980, 23 pp.

GOST 4648-71. Plastics. Method of Static Bending Test. [in Russian], issued Jan. 1, 1973 in replacement of GOST 4648-63, Izd. Standartov, Moscow, 1971, 22 pp.

GOST 4670-91. Plastics. Determination of Hardness. Ball Indentation Method. [in Russian], issued Jan. 1, 1993 in replacement of GOST 4670-77, Izd. Standartov, Moscow, 1991, 20 pp.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskie Volokna, No. 6, pp. 57-60, November—December, 2015.

Rights and permissions

About this article

Cite this article

Korchina, L.V., Markin, A.V., Zubova, N.G. et al. Properties and Structural Features of Modified Pan Filament and Composites Based on It. Fibre Chem 47, 478–481 (2016). https://doi.org/10.1007/s10692-016-9717-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-016-9717-2