Abstract

The present study reports a simple all microbial-based consolidated bioprocess for the conversion of poplar parings into ethanol. The bacterium Bacillus cereus G9241 CP 026,376 and the yeast Candida tropicalis MF 289,181 were employed for this purpose. Potential of the cellulolytic B. cereus for saccharification of the substrate and bioethanol fermentation was unveiled by employing the separate hydrolysis and fermentation (SHF) as well as simultaneous saccharification and fermentation (SSF) processes. The bacterium as well as yeast grew well in the 2% substrate hydrolyzate and the cell counts reached up to 19,701 × 107 and 852 × 106/ml at 96 h, respectively. For the bacterially fermented saccharified substrate, the HMF content reduced from 489 ± 38.1 µg/L at 24 h to 232 µg/L (52.56%) at 96 h. In case of the yeast fermented poplar hydrolyzate, the HMF content dropped down to 351.3 ± 48.6 µg/L right at first sampling point and thereafter became un-detectable. In case of SSF, HMF could appear only at 72 and 96 h of fermentation with respective values of 260.3 ± 25.8 and 243 ± 8.66 µg/L. Acetic acid content among the differently fermented substrates ranged from 460 ± 230 to 5360 ± 503 mg/L. The bacterial cellulases yielded up to 6.742 and 8.561 mg/ml of glucose and xylose of 2% substrate, respectively. In case of yeast monoculture, the glucose and xylose contents reduced down to 34.17% and 85.28%, respectively, at 24 h post-inoculation with concomitant ethanol production of 634 ± 159 mg/L. Following 24 h of co-culturing of the microbes in the substrate hydrolyzate, the glucose and xylose reduced down to 39.69% and 82%, respectively, with accompanying ethanol level of 501.38 ± 46.7 mg/L. Glucose content of 24 h incubated SSF fluids was 1568 ± 226 mg/L, whereas the xylose remained non-detectable throughout the study period. Ethanol productions at 24, 48, 72 and 96 h of incubations for the SSF experiment were 140.43 ± 44.8, 60.18 ± 13.5, 177.78 ± 23.9 and 83.48 ± 10.3 mg/L, respectively. The simple experiments reported here provide a workable model to assess the potential of suitable microbes for bioethanol production from plants’ biowastes by a consolidated bioprocess without any drastic pretreatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Second-generation bioethanol fermentations have targeted lignocellulosic matter; the most abundantly available renewable biomass resource. However, either the substrate is physicochemically pretreated and/or is attacked directly by cellulases. In any case, the processes of saccharification and subsequent ethanologenesis are interrupted for their efficiencies by the inhibitors compounds. Origin of the inhibitors molecules is the breakdown of lingo-cellulosic material. After pretreatment of the implicated waste, it can be converted into a useful biotechnological product by microorganisms. Studies have shown the productive implication of different microbes for the production of various biotechnological products from different wastes (Hussain et al., 2012, ; Jabeen et al., 2019; Saleem et al., 2020; Saleh et al., 2020). Application of cellulolytic/ethanologenic bacteria and ethanol fermenting yeasts resistant to or capable of concomitant detoxification (degradation) of the inhibitors molecules may improve the efficiency of the catalytic saccharification processes.

The substrate poplar is well known for its rich cellulosic content, which have been reported as cellulose up to 43.2%, hemicelluloses 26.6%, lignin 1.3%, xylan, arabinan, acetate, other sugars 26.2%, other 6.1% and ash 1.5% (Esteghlalian et al., 1997). The poplar biomass is a very popular substrate for development of biofuels’ generation processes through different pretreatments and bioconversion strategies (Antczak et al., 2021; Crawford et al., 2016). The present study employed pulverized leaves and small twigs of poplar as lignocellulosic feedstock. The substrate’s acid and alkali pretreatments were optimized. Autoclaved substrate was used as major resource of nutrients for cultivation of a cellulolytic/ethanologenic bacterium. A yeast isolate capable of fermenting the bacterially saccharified substrate was also employed. The simplicity of the medium allowed initial bacterial growth in the substrate, but the microbial biomass was then soon checked by depletion of certain essential micro-nutrients. Production by the cells and activities of already formed hydrolytic enzymes may continue to saccharify the cellulose and hemicellulosic complexes. This model lays the foundation for self-controlled system of microbial growth and saccharification with optimum yields of sugars. Ethanologenesis of the sugar streams thus obtained was then managed by two routes, i.e., by interrupting O2 supply which shifted oxidative metabolism toward the ethanologenesis. Alternatively, the bacterially saccharified substrate was fermented by ethanologenic yeast. This very simple to follow model appears important for conserving microbial biodiversity as well recognizing suitable lignocellulosic substrates. Regarding the techno-economic feasibility of the poplar substrate, availability of its leaves and twigs is not an issue in this agricultural country. As the tree is planted on large scale to provide wood for making boxes for industrial products’ packaging. Resultantly, its shaving, remnants, leaves and twigs represent a solid waste problem. Their utility for bioethanol production will be welcomed by solid waste management authority. After separating the bioethanol, the residual fermentation mass can be evaporated through solar insolation in this country to reduce the amount of industrial effluent and to supply/sale the single-cell protein-rich solid as animal feed supplement. This auxiliary income will be a positive factor for techno-economic feasibility of the process development.

Sustainability of a bioprocess depends on un-interrupted supply of raw materials, process economics and demand of the produce. Regarding the availability, lignocellulosic agri-wastes are generated in huge amounts in Pakistan. Less developed post-harvesting storage facilities further add to the generation of waste biomass resource in the form of millions of tons of vegetables and fruit wastes. Lignocellulosic wastes can be collected easily and inexpensively in the form of agricultural residues from crops, peels of different fruits and vegetables, certain industrial and municipal effluents, forest wastes and fast-growing grasses and trees (Chang & Yao, 2011; Claassen et al., 1999; Wyman, 1996). It is noteworthy that crystalline cellulose is more resistant to hydrolysis than its amorphous portion. Woody biomass is generally more resistant to degradation than other types of lignocelluloses. Softwood is typically more difficult to hydrolyze than hardwood or agricultural residues (Arantes & Saddler, 2011; Mabee et al., 2006). Bioethanol production from wastes is advantageous as majority of ligno-wastes are still considered waste products in many parts of the world and are often disposed of by burning (Levine, 1996). Ethanol from wood has been investigated since the beginning of nineteenth century. However, yields of sugars from wood for ethanol production were considered only at start of the twentieth century. Some of the earliest processes using dilute sulfuric acid produced 72 L ethanol (100%) per ton of dry matter, i.e., 24% of the theoretical yield (Brownlie, 1940). Through the use of percolation-type reactors employing Scholler processes, yield of ethanol was increased from 55 to 64% (Harris et al., 1945; Jones & Semrau, 1984; Krumbein, 1938).

Conclusively, second-generation biofuels productions are in their infancy and there is much room for development toward attaining economically viable routes. All microbial-based processes must be developed for the bioconversion of the largest renewable resource (lignocellulosic) into low volume/mass but high energy containing fuels essentially in an environmentally and economically sound scenario. Jouzani and Taherzadeh (2015) have reviewed that recent advances in production of biofuel from lignocellulosic biomass including consolidated bioprocessing (CBP) have increased hope for a viable solution to the energy. A CBP would utilize a single substrate and product-tolerant microorganism(s) that perform hydrolysis and fermentation process concomitantly in one reactor.

If all the mechanisms of consolidated or different steps of multiphasic bioprocesses are governed by microbially inoculated routes, the processes developed will have promising yields defined by environmental conditions. Importance of the inhibitors resistant cellulolytic and/or ethanologenic microorganisms cannot be overemphasized. Search of such microorganisms from local environments is promising for designing lignocellulosic ethanol fermentation units with improved process economics in this country. The present study reports the cellulolytic/ethanologenic potential of the bacterium Bacillus cereus and ethanologenic yeast Candida tropicalis while employing steam treated substrate.

2 Materials and methods

2.1 Collection and processing of biomass

Fresh poplar (Populus euramericana) leaves and twigs were collected from local trees of Quaid-e-Azam Campus, University of the Punjab, Lahore, Pakistan. Leaves and twigs were washed thoroughly with tap water to remove dust particles and then sun-dried. Thereafter, the biomass was oven-dried at 70 °C till constant weight. The dried leaves and twigs were finally ground into powder in a grinding mill and then passed through a 1 mm sieve to save the fine pulverized biomass which was subsequently stored in air-tightened plastic jars at room temperature for further use.

2.2 Steam pretreatment of the substrate:

For different experiments, 1% each of pulverized leaves and twigs of poplar were suspended in water along with other ingredients of medium when required. The flasks were then autoclaved at 15 pound/inch2 pressure for a period of 20 min. The substrate was sterilized as well as steam pretreated concomitantly.

2.3 Cellulase producing and ethanol fermenting bacterium

Bacillus cereus strain was employed in this study. This bacterium had been isolated from the gut of Labeo rohita and had already been identified by 16S rRNA gene sequencing technology. The bacterium was revived in nutrient broth [Oxoid (England)] from the microbial conservatory of Microbial Biotechnology Lab., Department of Zoology, University of the Punjab, Lahore, Pakistan. The strain was revived in nutrient broth and its culture was maintained on nutrient agar slants and kept at 4 °C for further use. Its cellulase production potential was verified in carboxymethyl cellulose medium.

2.4 Isolation of yeast

For isolation of yeast, soil which had been impregnated with sugarcane juice was sampled from a sugarcane juice extraction unit near Jinnah Hospital Lahore, Pakistan, in sterile containers and immediately brought to the laboratory. Two g of the sample was dispensed in a test tube containing 10 ml of autoclaved distilled water and mixed on a gyro-mixer for 20 min. Then, 0.5 ml of the suspension was poured and spread on (YPD) [Oxoid (England)] agar fortified with 0.02% chloramphenicol (Sigma). After 24 h of incubation at 37 °C, separated colonies of yeast from three YPD agar plates were shifted to nutrient agar plates to obtain the pure culture. The pure culture was then preserved in the form of glycerol stocks.

2.5 DNA preparation of the yeast by boiling process

One ml of cell suspension of 24 h old culture was shifted to microtube and kept in a water-bath at 90 °C for 5 min. The suspension (containing DNA) was vigorously homogenized by vortexing for 10 s and the tube was frozen on ice. The DNA sample was incubated at −180 °C until ice formation. The samples were then allowed to thaw at room temperature and homogenized by vortexing for 10 s.

2.6 Precipitation with isopropanol

After boiling and freeze-thawing as mentioned above, the cell debris was separated by centrifugation at 10,000 × g for 15 min and re-suspended in 100 µl TE buffer. The supernatant was precipitated with cold isopropanol and again centrifuged at 10,000 × g for 15 min. The DNA present in the supernatant and cell debris was subjected to 25 and 30-cycle PCR for amplification, separately.

2.7 PCR procedure

Fungal primers [forward (5´-TACTGTGAAACTGCGAATGGCTC-3´) and reverse (5´-TGATCCTTCCGCAGGTTCACCTA-3´)] targeting the conserved region of 18S rDNA were used to amplify a 375-bp segment. PCR amplification was performed at final volume of 25 µl. One microliter of DNA sample (from boiling and freeze-thawing) was added to the PCR master mixture, which consisted of buffer Taq DNA polymerase enzyme 1x (Invitrogen Corporation, USA), 1.5U Platinum® Taq DNA polymerase (Invitrogen Corporation, USA) and 100 µmol each dNTP (Invitrogen Corporation, USA), 0.8 pmol/µl (0.8 µM) of each primer (Integrated DNA Technologies Inc., USA), 2.5 mM MgCl2. Amplification consisted of an initial denaturation step at 94 °C for 5 min, followed by 25, 30 or 35 cycles comprising a denaturation step at 94 °C for 30 s, an annealing step at 68 °C for 45 s and an extension step at 72 °C for 30 s, followed by a final extension at 72 °C for 5 min. A PTC-100 Peltier thermal cycler (Bio-Rad Life Sciences, USA) was used.

2.8 DNA quantification

DNA was quantified with help of dsDNA high sensitivity kit (Qubit, Cat # Q32851) using Qubit fluorometer. DNA quantity was normalized to a concentration of 0.2 µg/ µL using standard protocol. The study was approved by the Institutional Review Board (IRB) at Rehman Medical Institute (RMI), Peshawar, Pakistan. Subsequent procedures of sequencing including library preparation, amplification and clean-up of libraries, etc., were accomplished commercially from RMI, where MiSeq machine is used. From the 18S rRNA gene sequence, the yeast was identified as Candida tropicalis.

2.9 Sequence data analysis

Once sequencing completed, raw sequence NGS data were processed to remove adapter sequences. De-multiplexing was done with the help of CASAVA to separate FASTQ files for each individual. The individual data file was then analyzed according to Genome Analysis Toolkit (GATK) Best Practices recommendation (Auwera et al., 2013). Processing steps were employed using Trimmomatic tool (Bolger et al., 2014). in order to remove technical biases/artifacts from reads various data clean-up operations such as removal of adapters sequences and filtering of low-quality reads on basis of quality scores (Q > 30) were applied.

All the sequences were submitted to GenBank for obtaining accession numbers.

2.10 Genome sequences of the microorganisms

After submitting the bacterial as well as yeast genomic sequences to the GenBank, following accession numbers were obtained:

-

Bacillus cereus: G9241 CP026376.

-

Candida tropicalis: MF289181.

2.11 Separate hydrolysis and fermentation (SHF) and simultaneous saccharification and fermentation (SSF) of the untreated substrate

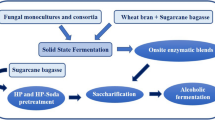

Ethanol fermentations were conducted by two separate routes which are depicted as Fig. 1.

As can be seen from this figure that for route No. 1 for separate hydrolysis and fermentation, the substrate 2% poplar was first saccharified by the bacterial crude cellulase preparation and was then fermented with the help of microorganism(s). Whereas for the route No. 2., i.e., simultaneous saccharification and fermentation, the substrate, without enzymatic saccharification, was directly co-cultured with 1% inocula each of the bacterium as well as yeast.

2.12 Separate hydrolysis and fermentation (SHF)

The bacterium Bacillus cereus had been reported to produce maximum cellulase at 0.5% yeast extract (Oxoid), 0.09% MgSO4 (Merck, BDH), 0.03% peptone (Oxoid) and 0.1% carboxymethyl cellulose (MP Biomedicals, LLC) at pH 9 and 37 °C with 2% inoculum size (Tabssum et al., 2018). In the present study, the bacterium was cultivated under the same conditions except the substrate which was 2% Poplar.

In separate hydrolysis and fermentation method, 200 ml of the optimized medium for cellulase production was taken in experimental bottles and 2% inoculum of B. cereus prepared in nutrient broth was added. Then, the experimental bottles were kept in shaking incubator at 37 °C at 120 rpm. After 24 h of incubation, the culture was centrifuged to save crude enzyme. Then, 2% of the substrate was added in the supernatant and incubated at 50 °C for 6 h. After the incubation, the enzyme substrate mixture was centrifuged and the supernatant containing sugars was separated and divided into three categories of triplicates. To one set, 2% of yeast inoculum prepared in YPD medium was added. The second set of the hydrolyzate was inoculated with 2% bacterial inoculum, whereas the third set was inoculated with 1% each of the bacterial and the yeast inocula. All categories of the cultures were incubated at 37 °C. Samples were taken after 24, 48, 72 and 96 h of the incubation. Contents of a culture were shaken well, and then, the samples without centrifugation as well as after centrifugation (14,000 rpm for 6 min) were transferred to 1.5 ml Eppendorf tubes separately. The Eppendorf tubes were kept in freezer at − 20 °C till further analysis.

2.13 Simultaneous saccharification and fermentation (SSF)

In SSF method, 200 ml of already optimized medium for cellulase production was taken in experimental bottles and 1% inocula each of the bacterium and the yeast, raised in their respective media, were added and incubated at 37 °C up to 96 h. The samples were taken and preserved for analyses as mentioned in SHF process.

2.14 Counting of bacterial and yeast cells during the SHF and SSF processes

After thorough vertexing the samples, Eppendorf tubes were kept in stand for few minutes. Then, the fluid portion of the sample was introduced into the Helber bacterial counting chamber (Thoma ruling) and observed under microscope at 400X employing the 40X objective. The bacterial cells visible within 16 small squares measuring (in total) 0.05 × 0.05 × 0.02 mm had volume of 0.00005mm3. Total number of bacterial cells counted within the containments described above were then calibrated as No./ml with the help of following formula.

For counting the yeast cells, the samples were introduced into hemocytometer and the cells were then counted falling within one small square, measuring 0.05 × 0.05 × 0.1 mm. Total count within one square was then multiplied by 4 × 106 to obtain number of yeast cells/ml of a sample. For bacterial as well as yeast counts, cells touching or crossing the upper and right borders were taken into account, whereas those touching or crossing the bottom and left borders were not counted.

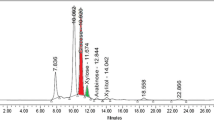

2.15 Estimation of sugars

Standard solutions of glucose as well as xylose (Sigma ultra pure) 20 mg/ml were employed in this study. The standards as well as the samples were filtered through 0.2 µm (Sartorius) filters. Then, 10 µl each of a sample as well as standard was injected through autosampler (PerkinElmer). The analytes were then resolved through Aminex HPX–87 H column (300 × 7.8 mm) by using 5 mM sulfuric acid as mobile phase at 1.00 ml/min flow rate. Temperature of the column was maintained at 50 °C by using column oven. The unit sugars were then detected with R1 detector. Peak areas of the standards and the samples of same retention times were then used to calculate amount of sugars in the samples with the help of following formula.

2.16 Estimation of ethanol

Ethanol concentration of fermented broths was determined by gas chromatograph (GC): Agilent Technologies 7890B GC system using Agilent J & W GC capillary column DB-5 (length 30 m, diameter 0.32 nm with film thickening of 0.25 µm having temperature limit of −60–325 °C) and FID detector. Column oven temperature was set at 90 °C, whereas injection and detector temperatures were 170 °C and 175 °C, respectively. The N2 was used as carrier gas, whereas the H2 was employed as flame gas. H2 flow was 30 ml/min, whereas air flow was 40 ml/min. Then, 0.5 µl of standard (10%) ethanol (Riedel–de Haen ®) as well as samples was injected to the GC capillary injector with the help of microinjecting syringe. (Agilent Manual syringe 5 µl RN, 23 g cone tip facility). The ethanol concentration of the experimental samples was determined with the help of following formula.

2.17 Estimation of inhibitors formed during the SSF and SHF processes

HMF (5-Hydroxymethyl-furfural Ark Pharm, Inc (No. AK26249) 1840 Industrial Dr. Suite 120 Libertyville, IL 60,048, USA) pure acetic acid (Merck) was used as standards. Standard solutions were prepared through serial dilutions. Hydroxymethyl-furfural (HMF) standard solution contained 1.00 µg of HMF dissolved in 1.00 ml of methanol + acetonitrile + double-distilled water (1:1:1). Likewise one ml of the solvent contained 0.001 µl of acetic acid. The experimental samples were centrifuged at 6000 rpm for 6 min. The supernatants were then filtered through 0.21 µm Millipore filters (Sartorius). Then, 20 µl each of a standard and sample was injected into Agilent 1100 series HPLC (USA), fitted with C18 Merck column (4.6 × 250 mm; 5 µm particle size). The inhibitors were resolved by using 0.1% H2SO4, CAN and double-distilled methanol (1:1:1) as mobile phase at 1 ml/min flow rate with 170 bar pressure and employing the diode array detector. Quantifications of HMF and acetic acid were then achieved by incorporating peak areas into the following formulae:

-

I.

Conc. of HMF; µg/ml of sample = \(\frac{\mathrm{Peak\;area\;of\;sample }}{\mathrm{Peak\;ares\;of\;standard}}\)

-

II.

Conc. of acetic acid; µg/ml of sample = \(\frac{\mathrm{Peak\; area\; of\; sample }}{\mathrm{Peak\; ares \;of\; standard}}\) × 1050

2.18 Statistical analysis

The data regarding the different fermentation experiments were analyzed using ANOVA (Tukey’s test) to estimate the significance. Means were compared by using multiple range tests. All the analyses were performed using MINITAB 16 (Pennsylvania State University, USA, 1972).

3 Results

3.1 Ethanol fermentation from poplar substrate

Sugars, cell biomass, ethanol and inhibitors’ contents of poplar substrate subjected to following different saccharification and fermentation conditions were determined.

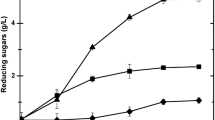

3.2 SHF with bacteria

Two percent substrate which was saccharified enzymatically under pre-determined optimized conditions revealed the presence of glucose and xylose up to 6742 and 8561 mg/L, respectively. Likewise the enzymatically saccharified substrate had 14.0 µg/L and 2263.72 mg/L of HMF and acetic acid contents, respectively. When the 2% hydrolyzate of the poplar substrate was inoculated with the bacterium Bacillus cereus and incubated at 37 °C for 24 h the glucose and xylose reduced down to 3267 and 1894 mg/L, respectively. Ethanol produced at 24 h post-fermentation was 80.5 mg/L (Tables 1 and 3, Fig. 2). The ethanol production reduced down to 58.26, 68.91 and 63.64 mg/L at 48, 72 and 96 h of the fermentation, respectively. Further incubation of the bacterial culture did not reduce the glucose content of the cell-free culture fluid, rather it increased up to 32.73% at last sampling period (Table 1, Fig. 2). On the other hand, xylose contents at all the sampling points remained more or less same (Table 2, Fig. 2). The bacterial growth continued to increase throughout the experimental period from 29.65 ± 4.64 × 109 at 24 h stage to 197.00 ± 49.1 × 109/ml at the last sampling point (Table 4, Fig. 2). HMF content of the bacterially fermented poplar hydrolyzate was recorded as 489.0 ± 38.1, 659.3 ± 17.2, 533.7 ± 20.2 and 232.00 µg/L at 24, 48, 72 and 96 h of the incubation, respectively. Respective amounts of the second inhibitor worked out in this study, i.e., acetic acid, were 961.85 ± 67.8, 1019.33 ± 44.6, 982.1 ± 63.9 and 705.96 mg/L (Tables 6 and 7, Fig. 2).

3.3 SHF with yeast

Glucose and xylose contents of the enzymatically saccharified substrate went down from their initial levels of 6742 and 8561 mg/L to 4438 ± 368 and 1260 ± 85.00 mg/L, respectively (Tables 1 and 2). These 34.17 and 85.28% reductions in the glucose and xylose contents, respectively, in the poplar hydrolyzate at 24 h post-incubation were accompanied with the yeast cell mass and ethanol production of 513 ± 17 × 106 cells/ml and 634 ± 159 mg/L, respectively. Thereafter, the glucose content reduced to 4256 ± 375, 0.840, 1766 ± 926 and 1167.33 (mg/L) with accompanying ethanol levels of 134.12 ± 37.9, 138.8 ± 23.1 and 71.51 ± 15.2 mg/L, respectively (Tables 1 and 3, Fig. 3). The xylose contents of the cell-free culture fluids at the remaining sampling points ranged from 1182 ± 104 to 1381.3 ± 96.6 mg/L (Table 2). The yeast cell counts appeared as 485 × 106, 514 × 106 and 852 × 106/ml at 48, 72 and 96 h of the incubation, respectively (Table 5, Fig. 3).

Only 24 h yeast fermented hydrolyzate contained HMF content of 351.3 ± 48.6 µg/L, whereas at the remaining sampling points the inhibitor became non-detectable (Table 6, Fig. 2). Acetic acid contents of 24, 48, 72 and 96 h fermented cell-free culture fluids were 777.53 ± 345, 857.00 ± 108, 664 ± 107 and 512.20 ± 93.8 mg/L, respectively (Table 7, Fig. 3).

3.4 Bacterial and yeast co-fermented poplar hydrolyzate

Glucose and xylose contents of the poplar hydrolyzate went down from their initial levels of 6742 and 8561 mg/L to 4066 ± 678 and 1223.7 ± 75.4 mg/L, respectively, following 24 h of incubation (Tables 1 and 2, Fig. 4). These 39.69% and 82% reductions in glucose and xylose contents, respectively, were accompanied with 101.87 ± 6.78 × 109 and 166.7 ± 20.8 × 106 cells/ml of the bacterium and yeast, respectively. The bacterial cells density went down to 80.85 ± 1.05 × 109, 90.77 ± 8.3 × 109 and 80.96 ± 9.64 × 109 cells/ml at 48, 72 and 96 h, respectively, whereas the yeast cells progressively increased from 194.7 ± 28.9 × 106 through 394.7 ± 82.7 × 106 to 507 ± 165 × 106 cells/ml at 48, 72 and 96 h, respectively (Tables 4 and 5). The ethanol productions were 501.04 ± 46.7, 380.2 ± 71.0, 201.00 ± 12.8 and 173.2 ± 5.63 mg/L at 24 through 96 h of incubations, respectively (Table 3, Fig. 4).

HMF contents of the co-fermented cell-free culture fluids were 488.7 ± 31.1, 709.0 ± 16.7, 450.0 ± 36 and 381.67 ± 2.19 µg/L at 24, 48, 72 and 96 h of incubations, respectively (Table 6, Fig. 3). The corresponding values for the acetic acid were 765.00 ± 74.4, 1168.00 ± 30.7, 646.64 ± 9.22 and 689.37 mg/L (Tables 6 and 7, Fig. 3).

3.5 SSF

In this experiment, the un-saccharified but autoclaved substrate (2%) was co-inoculated with the bacterium and yeast cells. Following 24 h of the incubation, the bacterial and yeast cells grew up to 23.04 ± 9.30 × 109 and 382.7 ± 208 × 106 cells/ml. Thereafter, the bacterial growth reduced down to 17.49 ± 2.99 × 109, 15.25 ± 1.36 × 109 and 19.31 ± 5.48 × 109 cells/ml at 48, 72 and 96 h post-incubation, respectively. The yeast cells too showed a comparable trend having the corresponding values of 106.7 ± 21.5 × 106, 141.3 ± 26.3 × 106 and 248 ± 40.5 × 106 cell/ml (Tables 4 and 5, Fig. 4). Glucose content of the cell-free culture fluid appeared as 1568 ± 226, 1529 ± 182, 571.5 ± 7.50 and 696 ± 24.0 mg/L at 24, 48, 72 and 96 h of incubation, respectively (Table 1). The xylose could not be detected throughout the study periods. Ethanol productions at 24, 48, 72 and 96 h of incubations were 140.40 ± 44.4, 60.6 ± 13.5, 177.8 ± 23.9 and 83.5 ± 10.3 mg/L, respectively (Table 3, Fig. 5).

In case of simultaneous saccharification and fermentation, HMF could appear only after 48 h of the incubation and values of the inhibitor were 260.3 ± 25.8 and 243.0 ± 8.66 µg/L at 72 and 96 h of incubation, respectively (Table 6). However, acetic acid appeared in highest amounts so that 24, 48, 72 and 96 h fermented cell-free fluids contained 3470 ± 1666, 5360 ± 503, 5013 ± 721 and 4746 ± 694 mg/L of it, respectively (Table 7, Fig. 5).

Values represent mean ± S.E.M. of triplicates/duplicates, unless mentioned otherwise. The means were compared by multiple range tests (ANOVA). Values having different superscripts are significantly different from each other. Capital alphabetic superscripts indicate comparison within a respective column, whereas small alphabetic superscripts indicate comparison within a respective row.

4 Discussion

In the present study, B. cereus was employed for saccharification of the poplar feedstock. The best cellulase efficiency of the bacterium in untreated poplar feedstock was employed for SHF as well as SSF processes. The latter fermentation was attempted to have insight for the possibility of developing consolidated bioprocess to obtain bioethanol from the feedstock. The enzymatic saccharification of 2% poplar substrate yielded glucose and xylose up to 6.742 and 8.561 mg/mL, respectively. The yield of 337.1 mg/g of the steam pretreated subset in the present study is apparently 50% that of 764.4 mg/g pretreated biomass reported by Antczak et al. (2021). However, these authors subjected the poplar wood for steam explosion also for 15 minutes but at 190 °C. Whereas in the present study, the steam explosion was achieved at 121 °C. This relatively mild treatment may compensate for the lesser glucose yield. Incubation of the hydrolyzate with 2% inoculum of the same bacterium (SHF + Bacterium) resulted into 51.65% and 77.8% reductions of glucose and xylose, respectively, at 24 h. The glucose content did not reduce at subsequent study points rather it increased up to 32.73% at 96 h post-incubation. However, excepting the initial decrease at 24 h stage, the xylose contents remained more or less consistent for rest of the study points. It appears that the enzymatic hydrolyzate of the substrate possibly contained cellulo-oligosaccharides such as cellobiose. The plant biomass hydrolyzates are known to contain cellulo-oligosaccharides. For instance, Katahira et al. (2006) have reported that wood chip hydrolyzate prepared by a modified concentrated sulfuric acid hydrolysis method contained up to 10.2 g/L cellulo-oligosaccharides in addition to varying amounts of different monosaccharides. In the present study, subsequent bacterial (cellulolytic) growth might had saccharified the cellulo-oligosaccharides into glucose and besides conversion to cell biomass and ethanol its amount increased at end of the experiment compared to the level measured at 24 h stage.

The initial (within 24 h) 77.88% reduction in the xylose content of the hydrolyzate indicated the pentose sugar utilization potential of the B. cereus. But when growth of this bacterium attained the level which secreted sufficient amount of cellulase which in turn yielded glucose from cellulo-oligosaccharides, thereafter the bacteria preferred glucose and did not utilize xylose. The cellulo-oligosaccharides-based explanation of glucose increase and non-utilization of xylose excepting the first study point by the bacterium was further supported by the yeast fermentation of the hydrolyzate in which case the glucose content reduced up to 98% at 72 h stage to complete consumption at end of the experiment. As the yeast did not express cellulolytic potential and the cellulo-oligosaccharides were accordingly not saccharified, accordingly the glucose of the hydrolyzate got consumed totally. In case of co-culturing of the yeast with bacterium, the glucose content could fluctuate only from 4070 ± 17.2 to 5472 ± 1053 mg/L throughout the study period. This indicated continuous bacterial cellulolytic activity and consumption of the glucose by both the microbes either did not allow or reduced the phenomenon of the enzyme inhibition. Again for the co-fermentation experiments, the xylose contents remained more or less consistent throughout the study period. In case of simultaneous saccharification and fermentation, the glucose content appeared as 1568 ± 226 and 1529 ± 182 mg/L at 24 and 48 h post-incubation, respectively. Thereafter at third and fourth sampling points, the monosaccharide decreased down to 63.43% and 55.53%, respectively, as compared to their levels at first sampling point.

In the present study, ethanol productions ranged from 58.26 to 80.52 ± 24.2, 71.51 ± 15.2 to 633.91 ± 159, 173.2 ± 5.63 to 501.4 ± 46.7 and 60.6 ± 13.5 to 140.43 ± 44.8 mg/L for the SHF with the bacterium, SHF with the yeasts, SHF with the bacterium and the yeast and SSF experiments, respectively. Tran et al. (2013) employed Bacillus sp. THLA0409 as a dominant cellulose-degrading bacterium and klebsiella oxytoca THLC0409 as a dominant sugar utilizing bacterium to develop a single-step process for converting lignocelluloses to ethanol. These authors also reported comparable ethanol productions. The K. oxytoca THLC0409 produced ethanol in the range of 424–475 mg/L from alpha cellulose + xylan, purified bamboo + xylan, raw bamboo, Napiergrass and rice straw, whereas the Bacillus sp. THLA0409 could yield ethanol in the range of 243–306 mg/L. Co-culturing of these bacteria produced ethanol in the range of 732–1309 mg/L. However, relatively low ethanol yields in the present study as compared to the ones reported by other workers might be due to low (2%) substrate employment. For example, Zhang et al. (2015) have documented an ethanol titer of 41 g/L employing approximately 20% of sulfite pretreated poplar without detoxification with a low cellulase loading of 15 FPU/g glucan. In the present study, no inhibitors detoxification attempt was made as well as the experiments employed the bacterial cellulase(s) instead of commercial enzymes. For these reasons, low concentration of the substrate was employed. The low product yield may prove economical into account while bypassing the steps of detoxification and saving the environment from the associated pollutants’ generation. However, the processes needs further optimization including the substrate loading and retention time.

When the saccharified poplar syrup was co-fermented employing the bacterium as well as yeast, the ethanol production increased up to 523% at 24 h post-incubation as compared to the corresponding sampling point of the bacterially fermented hydrolyzate. However, highest ethanol production up to 634 ± 159 mg/L was obtained when the hydrolyzate was fermented by the yeast monoculture. It is to be noted that highest ethanol in all the four categories of the fermentations was obtained at 24 h post-incubation. Drastic decreases in the ethanol contents of the cell-free culture fluids at all the subsequent fermentation periods were possibly the outcomes of product inhibition, evaporation effects and the poor performance of the fermenting cells following longer exposure to the inhibitory compounds.

The simultaneous saccharification and fermentation (SSF) experiments could yield ethanol up to 140.43 ± 44.8 mg/L at first sampling point and the production was 74.40% higher but 77.85% and 72.02% lower than the corresponding ethanol productions in case of SHF with bacteria, SHF with yeast and SHF co-fermented by the bacterium and the yeast. Phwan et al. (2018) have documented that this process accomplished simultaneous hydrolysis and fermentation in the same unit and its advantages include faster production rates, higher bioethanol yield and lower risk of contamination.

In separate hydrolysis and fermentation (SHF), the pretreated feedstock biomass is first saccharified and then the monosaccharides rich syrup is subjected to ethanol fermentation usually by employing Saccharomyces cerevisae. This process is well practiced and has the advantage of practicing differential optima for the steps of saccharification and fermentation. On the other hand, the process of simultaneous saccharification and fermentation implies the bioconversion of monosaccharides to ethanol soon after their liberation from the polysaccharide feedstock. The SSF can yield higher levels of the product by reducing the inhibition of cellulases by concomitant consumption of soluble sugars and not allowing their concentrations to attain the threshold level of inhibition. This benefit can accommodate the compromised optima for the process of saccharification and fermentations. For example, S. cerevisae required 32 °C for best fermentation yield, whereas the cellulases may need 50 °C incubation temperature for optimum saccharification (Hgren et al., 2007; Menon & Rao, 2012). To compromise the mismatch between the optimal temperature of yeast fermentation and the enzymatic saccharification, the SSF is commonly conducted at lower temperature which results into poor hydrolysis of the substrate (Hasunum & Kondo, 2012). Application of thermoduric ethanologenic microbial strains is expected to improve the efficiency of SSF process (Lin & Tanaka, 2006). Dahnum et al. (2015) have reported yield of ethanol from empty fruit bunch following 72 h of SHF as 4.74%, whereas following 24 h of SSF it increased to 6.05%.

Better performance of SSF over SHF has been established by several workers. SHF is a two-stage process for which separate optimal operating conditions of each step may be maintained with minimal interaction between hydrolysis and fermentation. End-product inhibition and likelihood of contamination may decrease ethanol yield (Sarkar et al., 2012), whereas in SSF, the processes of hydrolysis and fermentation are combined to reduce product inhibition to enzymes as well as chances of contamination (Olofsson et al., 2008). However, formation of substances inhibitory to the lignocellulose hydrolysis and the sugars’ fermenting microorganisms cannot be ruled out during the SSF process.

In the present study, HMF content of the bacterially fermented poplar substrate hydrolyzate fluctuated between 232 and 659.3 ± 17.2 µg/L, whereas for the co-fermented hydrolysate, the HMF ranged from 381.67 ± 2.19 to 709 ± 16.7 µg/L. For both the above cited cases, the lowest values appeared at end of the experimental period. However, when the hydrolyzate was fermented by the yeast only the HMF measured up to 351.3 ± 48.6 µg/L only at first sampling point. Thereafter, the inhibitory compound became un-detectable. More or less consistent values of glucose were observed for both the bacterial (mono) and co-cultured fermentations throughout the study period. Similar pattern of HMF indicated the continual of saccharification activity of the bacterium together with the generation of HMF, whereas in case of yeast fermented broth, the HMF did not appear after the first sampling point. The yeast cells probably detoxified the HMF before the next sampling point (48 h). Recently, Yee et al. (2018) have documented that biological detoxification of the inhibitors can use enzymes or whole cells. It was interesting to note that HMF did not appear up to 48 h of the SSF. Later on at the 3rd and 4th sampling points, the inhibitory compound approached only 260.3 ± 25.8 and 243 ± 8.66 µg/L levels, respectively. As the highest ethanol production was recorded at 24 h post-incubation, it appears that SSF can be accomplished following the batch fermentation well before the generation of HMF. However, the acetic acid contents of the SSF fluids appeared several folds higher than the three categories of SHF throughout the study periods. And in contrast to the case of HMF, the acetic acid became vivid right from the first sampling point in all the fermentations. For the SHF with bacteria, SHF with yeast and the co-fermentation experiments, the acetic acid contents ranged from 705.96 to 1019.33 ± 44.6, 512.24 ± 93.8 to 777.3 ± 34.5 and 646.64 ± 9.22 to 1168.011 ± 30.7 mg/L, respectively. In all the experiments, acetic acid, in general, decreased with progression of fermentation period and became non-detectable at 96 h of bacterial separate hydrolysis and fermentation.

Lowest (80.5 mg/L) and lower (140.4 mg/L) ethanol productions for the bacterial SHF and SSF might be due to the inhibitory effect of acetic acid being faced by the still growing bacterial and yeast cells and the bacterial cells alone, respectively. It is well known that being highly acetylated poplar woods’ cell walls yield high concentration of acetic acid following pretreatment which inhibit processes of bacterial as well as yeast fermentations (Gille & Pauly, 2012; Klinke et al., 2004; Tian et al., 2011). Inhibitors’ detoxification, removal or application of inhibitors’ tolerant cellulolytic and/or ethanologenic microbes will improve ethanol yields from the lignocellulosic un-exhaustible feedstocks. The genomic sequences of the microorganisms employed in the present study, i.e., Bacillus cereus and the Candida tropicalis, are available at public database of GenBank for molecular level comparison and bioinformatic-based insight for exploring their further biotechnological potentials under diverse conditions.

A variety of compounds which are formed during pretreatment and hydrolysis process are inhibitory to subsequent fermentation (Liu, Ma, et al., 2009; Palmqvist et al., 1999). Any detoxification strategy to detoxify/remove inhibitors will obviously increase price of the product. Therefore, search and application of inhibitors’ tolerant fermenting microorganisms would decrease total cost. And in case of SSF, the inhibitory compounds may also prove detrimental to the saccharifying microbes too. Therefore to develop consolidated bioprocess in addition to their efficient cellulolytic and/or ethanologenic nature, the microorganisms must also be screened for tolerating the inhibitory molecules. Another strategy would be optimizing pretreatment processes at varying physicochemical conditions while considering well the techno-economical feasibility in terms expenditure incurred and the amounts of inhibitors’ formation in the process. In this regard, Brethauer et al. (2020) while studying steam explosion pretreatment of beech wood have documented that total inhibitors content increased with increase in temperature and pretreatment time. Briefly for a given substrate, pretreatment and the microbes recruited process optimizations will define the economic feasibility.

5 Conclusion

The steam pretreated substrate was found best for the growth as well as cellulolytic activity of the bacterium. The mild pretreatment would prove cost-effective as well as environmental friendly. A consolidated bioprocess in which the cellulolytic bacterium Bacillus cereus and the ethanologenic yeast Candida tropicalis were co-cultured in a single chamber bioreactor is reported. Separate saccharification and fermentation yielded better up to 634 mg/L ethanol production, whereas simultaneous saccharification and fermentation process could yield ethanol up to 140.43 ± 44.8 mg/L of first sampling point. The low ethanol yield is to be improved by concomitant product recovery and application of more robust microbes. Further work is required to screen different feedstocks employing the microorganisms reported here for widening their applications and to identify more feasible consolidated bioprocess for second-generation bioethanol production.

References

Antczak, A., Szadkowski, J., Szadkowska, D., & Zawadzki, J. (2021). Assessment of the effectiveness of liquid hot water and steam explosion pretreatments of fast-growing poplar (Populus trichocarpa) wood. Wood Science and Technology, 1–23.

Arantes, V., & Saddler, J. N. (2011). Cellulose accessibility limits the effectiveness of minimum cellulase loading on the efficient hydrolysis of pretreated lignocellulosic substrates. Biotechnology for Biofuels, 4, 3.

Bolger, A. M., Loshe, M., & Usadel, B. (2014). Trimmomatic: A flexible trimmer for Illumina sequence data. Bioinformatics, 30(15), 2114–2120.

Brethauer, S., Antczak, A., Balan, R., Zielenkiewicz, T., & Studer, M. H. (2020). Steam explosion pretreatment of beechwood. Part 2: Quantification of Cellulase inhibitors and their effect on avicel hydrolysis. Energies, 13(14), 3638.

Brownlie, D. (1940). Wood as a chemical raw product: Latest developments in sugar and alcohol production. Chemistry and Industry, 59, 671–675.

Chang, T., & Yao, S. (2011). Thermophilic, lignocellulolytic bacteria for ethanol production: Current state and perspectives. Applied Microbiology and Biotechnology, 92, 13–27.

Claassen, P. A. M., van Lier, J. B., Lopez Contreras, A. M., van Niel, E. W. J., Sijtsma, L., Stams, A. J. M., de Vries, S. S., & Weusthuis, R. A. (1999). Utilisation of biomass for the supply of energy carriers. Applied Microbiology and BiotechnolOgy, 52, 741–755.

Crawford, J. T., Shan, C. W., Budsberg, E., Morgan, H., Bura, R., & Gustafson, R. (2016). Hydrocarbon bio-jet fuel from bioconversion of poplar biomass: Techno-economic assessment. Biotechnology for Biofuels, 9(1), 1–16.

Dahnum, D., Tasum, S. O., Triwahyuni, E., Nurdin, M., & Abimanyu, H. (2015). Comparison of SHF and SSF processes using enzyme and dry yeast for optimization of bioethanol production from empty fruit bunch. Energy Procedia, 68, 107–116.

Esteghlalian, A., Hashimoto, A. G., Fenske, J. J., & Penner, M. H. (1997). Modeling and optimization of the dilute sulphuric acid pretreatment of corn stover, poplar and switchgrass. Bioresource Technology, 59, 129–136.

Gille, S., & Pauly, M. (2012). O-acetylation of plant cell wall polysaccharides. Frontiers of Plant Science, 3, 12.

Harris, E. E., Beglinger, E., Hajny, G. J., & Sherrard, E. C. (1945). Hydrolysis of wood-treatment with sulfuric acid in a stationary digester. Industrial & Engineering Chemistry, 37(1), 12–23.

Hasunuma, T., & Kondo, A. (2012). Consolidated bioprocessing and simultaneous saccharification and fermentation of lignocelluloses to ethanol with thermotolerant yeast strains. Process Biochemistry, 47, 1287–1294.

Hgren, K. O., Bura, R., Lesnicki, G., Saddler, J., & Zacch, G. (2007). A comparison between simultaneous saccharification and fermentation and separate hydrolysis and fermentation using steam pretreated corn stover. Process Biochemistry, 42, 834–839.

Hussain, A., Iqbal, M. A., Javid, A., Razaq, A., Aslam, S., Hasan, A., Akmal, M., & Qazi, J. I. (2019). Application of fruit wastes as cost-effective carbon sources for biological sulphate reduction. Iranian Journal of Science and Technology Transactions, a: Science, 43(1), 33–41.

Hussain, A., & Qazi, J. I. (2012). Biological sulphate reduction using watermelon rind as a carbon source. Biologia (pakistan), 58(1–2), 85–92.

Hussain, A., Shakir, H. A., & Qazi, J. I. (2014). Anaerobic biodegradation of sulphate employing animal manure as a cost effective growth substrate. Journal of Animal and Plant Sciences, 24(3), 913–918.

Jabeen, F., Hussain, A., Younis, T., Manzoor, M., & Samiullah, K. (2019). Isolation of thermophilic Anoxybacillus beppuensis JF84 and production of thermostable amylase utilizing agro–dairy wastes. Environmental Progress and Sustainable Energy, 38(2), 417–423.

Jones, J. L., & Semrau, K. T. (1984). Wood hydrolysis for ethanol production—previous experience and the economics of selected processes. Biomass, 5(2), 109–135.

Jouzani, G. S., & Taherzadeh, M. J. (2015). Advances in consolidated bioprocessing systems for bioethanol and butanol production from biomass: A comprehensive review. Biofuel Research Journal, 5, 152–195.

Katahira, S., Mizuike, A., Fukuda, H., & Kondo, A. (2006). Ethanol fermentation from lignocellulosic hydrolysate by a recombinant xylose- and cellooligosaccharide-assimilating yeast strain. Applied Microbiology and BiotechnolOgy, 72, 1136–1143.

Klinke, H. B., Thomsen, A. B., & Ahring, B. K. (2004). Inhibition of ethanol producing yeast and bacteria by degradation products produced during pretreatment of biomass. Applied Microbiology and BiotechnolOgy, 66, 10–26.

Krumbein, W. C. (1938). Size frequency distribution of sediments and the normal phi curve. Journal of Sedimentary Petrology, 8, 84–90.

Levine, J. S. (1996). Biomass burning and global change: Remote sensing and inventory development and biomass burning in Africa (pp. 35). The MIT Press, Cambridge, Massachusetts, USA.

Lin, Y., & Tanaka, S. (2006). Ethanol fermentation from biomass resources: Current state and prospects. Applied Microbiology and Biotechnology, 69, 627–642.

Liu, L., Sun, J., Li, M., Wang, S., Pei, H., & Zhang, J. (2009). Enhanced enzymatic hydrolysis and structural features of corn stover by FeCl3 pretreatment. Bioresource Technology, 100, 5853–5858.

Liu, Z. I., Ma, M., & Song, M. (2009). Evolutionary engineered ethanologenic yeast detoxifies lignocellulosic biomass conversion inhibitors by reprogrammed pathways. Molecular Genetics and Genomics, 282, 233–244.

Mabee, W. E., Gregg, D. J., Arato, C., Berlin, A., Bura, R., Gilkes, N., Mirochnik, O., Pan, X., Pye, E. K., & Saddler, J. N. (2006). Updates on softwood-to-ethanol process development. In Twenty-Seventh Symposium on Biotechnology for Fuels and Chemicals (pp. 55–70). Humana Press.

Menon, V., & Rao, M. (2012). Trends in bioconversion of lignocellulose: Biofuels, platform chemicals & biorefinery concept. Progress in Energy and Combustion Science, 38(4), 522–550.

Olofsson, K., Bertilsson, M., & Liden, G. (2008). A short review of SSF an increasing process option for ethanol production from lignocellulosic feedstocks. Biotechnology for Biofuels, 1, 1–14.

Palmqvist, E., Grage, H., Meinander, N. Q., & Hahn-Hägerdal, B. (1999). Main and interaction effects of acetic acid, furfural, and phydroxybenzoic acid on growth and ethanol productivity of yeasts. Biotechnology and Bioengineering, 63, 46–55.

Phwan, C. K., Ong, H. C., Chen, W. H., Ling, T. C., Ng, E. P., & Show, P. L. (2018). Overview: Comparison of pretreatment technologies and fermentation processes of bioethanol from microalgae. Energy Conversion and Management, 173, 81–94.

Saleem, A., Hussain, A., Chaudhary, A., Ahmad, Q. A., Iqtedar, M., Javid, A., & Akram, A. M. (2020). Acid-hydrolysis optimization of pomegranate peels waste using response surface methodology for ethanol production. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-01117-x

Saleh, F., Hussain, A., Younis, T., Ali, S., Rashid, M., Ali, A., Mustafa, G., Jabeen, F., & AL-Surhaneee, A. A., Alnoman, M. M., & Qamer, S. (2020). Comparative growth potential of thermophilic amylolytic Bacillus Sp. on unconventional media food wastes and its industrial application. Saudi Journal of Biological Sciences, 27(12), 3499–3504.

Sarkar, N., Ghosh, S. K., Bannerjee, S., & Aikat, K. (2012). Bioethanol production from agricultural wastes: An overview. Renewable Energy, 37, 19–27.

Tabssum, F., Irfan, M., Shakir, H. A., & Qazi, J. I. (2018). RSM based optimization of nutritional conditions for cellulase mediated Saccharification by Bacillus cereus. Journal of Biological Engineering, 12(1), 1–10.

Tian, S., Zhu, W., Gleisner, R., Pan, X. J., & Zhu, J. Y. (2011). Comparisons of SPORL and dilute acid pretreatments for sugar and ethanol productions from aspen. Biotechnology Progress, 27, 419–427.

Tran, D. T., Yet-Pole, I., & Lin, C. W. (2013). Developing co-culture system of dominant cellulolytic Bacillus sp. THLA0409 and dominant ethanolic Klebsiella oxytoca THLC0409 for enhancing ethanol production from lignocellulosic materials. Journal of the Taiwan Institute of Chemical Engineers, 44, 762–769.

Van der Auwera, G. A., Carneiro, M. O., Hartl, C., Poplin, R., Del Angel, G., Levy-Moonshine, A., Jordan, T., Shakir, K., Roazen, D., Thibault, J., & Banks, E. (2013). From FastQ data to high-confidence variant calls: The genome analysis toolkit best practices pipeline. Current Protocols in Bioinformatics, 43(1), 11–10.

Wyman, C. E. (1996). Handbook on bioethanol: Production and Utilization. Washington, DC, Taylor & Francis.

Yee, K. L., Jansen, L. E., Lajoie, C. A., Penner, M. H., Morse, L., & Kelly, C. J. (2018). Furfural and 5-hydroxymethyl-furfural degradation using recombinant manganese peroxidase. Enzyme and Microbial Technology, 108, 59–65.

Zhang, J., Gu, F., Zhu, J. Y., & Zalesny, R. S., Jr. (2015). Using a combined hydrolysis factor to optimize high titer ethanol production from sulfite-pretreated poplar without detoxification. Bioresource Technology, 186, 223–231.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tabssum, F., Khan, M.N. Microbial-based separate and simultaneous saccharification and ethanol fermentation of poplar (Populus euramericana) substrate. Environ Dev Sustain (2022). https://doi.org/10.1007/s10668-022-02143-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10668-022-02143-7