Abstract

This paper describes the synthesis of a novel chelating material derived from cellulose, and its heavy metal ion adsorption properties from aqueous solution. The first section of this paper reports the chemical grafting of cellulose, that amino acetic acid groups were grafted onto the cellulose by in situ synthesis, a novel yet unreported modified cellulose derivative N,N-(dicarboxymethylaminoethyl, carboxymethyl)aminoethylamine carboxymethyl cellulose amide was synthesized. This obtained adsorbent was characterized by elemental analysis, infrared spectroscopy (IR) and Solid State Nuclear Magnetic Resonance (SSNMR) 13C NMR spectroscopy. In the second section, the adsorption of Cu2+and Pb2+ from single metal ion aqueous solutions onto this adsorbent were evaluated and analyzed by the Freundlich and Langmuir models. Further more, adsorption capacity for Ba2+, Mg2+, Mn2+, Co2+, Zn2+, Pb2+, Ni2+ and Cu2+, and the competitive adsorption of this adsorbent between ions were also evaluated by ICP spectroscopy. The results indicated that this modified cellulose exhibited adsorption properties similar to those of EDTA, and showed good adsorption capacity for a wide range of metal ions.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Environmental issues have always been a important research topic. Among all of the pollutant species, heavy metal ion pollution has a large proportion, and it is related to everyone's health. For example, Cu2+, Hg2+, Ag+ and other trace amounts of heavy metals enter human body through food and drinking water and then accumulated, resulting in heavy metal poisoning (Bhalla et al. 2007; Pereira et al. 2016). The Cu2+ content in drinking water must not exceed 20 μM, the normal concentration of copper ion in blood is 15.7–23.6 μM (100–150 μg/dL) (Carver 2013; Kirsipuu et al. 2020; Lim et al. 2007). Therefore, heavy metal ion removal from water with low cost and high efficiency has been an important endeavor.

At present, the removal methods of heavy metal ions mainly include chemical precipitation, electrolysis, ion exchange, reverse osmosis, and membrane separation etc. (Barakat 2011; Chauhan et al. 2005; Xu 2014). Among them, electrolysis and chemical precipitation are not suitable for the treatment of trace heavy metal wastewater, ion exchange and membrane separation have better effect on the treatment of trace heavy metal ions, but the treatment capacity is limited and the maintenance cost is relatively high. Therefore, the materials with large adsorption capacity, high selectivity, wide range of sources, and are cheap and renewable have been paid more and more attention in the field of heavy metal removal (Barakat 2011).

Cellulose meets the above demands. It has a wide range of sources and biodegradability, and there is a large number of easily reactive chemical groups in the molecules, which are widely used as modified matrix of various metal ion pollutant adsorbents (Cao et al. 2017; Chauhan et al. 2005; Gao et al. 2018; Lin et al. 2021; Mengxuan et al. 2016; Nongbe et al. 2018). Cellulose-based adsorbents have great potential for the adsorption and removal of heavy metal ions in water.

Many studies have been reported about cellulose chemically modified by esterification with EDTA for metal ion recovery, such as adsorption and removal of Cu2+, Co2+, Ni2+; metal ion removal in aqueous solution by cellulose EDTA solid phase extractant reported by Satoshi Tsukinoki (Tsukinoki et al. 2008), and the preparation of hydrophilic filter paper which can filter and remove heavy metal ions, and the preparation of metal ion adsorption materials which connect EDTA to cellulose derivatives by Issam Jilal (Jilal et al. 2018) and Martin d`Halluin (d’Halluin et al. 2017). In other reports (Singh et al. 2012; Huang et al. 2015), EDTA analogue of amino triacetic acid was grafted onto cellulose. These materials have good adsorption properties for metal ions.

These reported adsorption materials based on cellulose matrix (such as microcrystalline cellulose, bagasse, cotton), EDTA, as well as its analogues, were grafted onto cellulose by ester bond. By using microcrystalline cellulose as raw material, we report the feasibility of a new strategy for in situ synthesis groups of similar structure to EDTA on cellulose and the complete synthesis process. This method might also be used for the synthesis of other amino carboxymethyl adsorbent based on matrix such as bagasse, cotton etc..

The first section of this work describes the chemical grafting of cellulose by amino acetic acid functions.The second section of this work evaluates the conditions of adsorption of Cu2+ and Pb2+ by this grafted cellulose from aqueous solutions, and adsorption capacity for Ba2+, Mg2+, Mn2+, Co2+, Zn2+, Pb2+, Ni2+ and Cu2+, and the adsorption competition of this adsorbent between ions was also evaluated by ICP spectroscopy.

Experimental

Materials

Microcrystalline cellulose was purchased from Huzhou Linghu Xinwang Chemical Co.,Ltd. Polyamine diethylenetriamine was from Shanghai Aladdin Biochemical Technology Co.,Ltd. Chloroacetic acid was bought from Sinopharm Chemical Reagent Co.,Ltd. Dichlorosulfoxide(SOCl2), methanol, ethanol, N,N-Dimethyl formamide(DMF), Na2CO3 were purchased from Chengdu Chron Chemicals Co.,Ltd, and were used without further purification.

Synthesis of carboxymethyl cellulose 1

According to literature method (Ardiyanita et al. 2020; Wilpiszewska et al. 2020), the microcrystalline cellulose was suspended in 25% NaOH (mass fraction) and etherified with chloroacetic acid at 65 °C. After the reaction completed, a solid particles were obtained by cooling, acidified, filtrated and washed with ethanol.

Synthesis of Methyl carboxymethyl cellulose ester 2

In a 250 mL bottom flask, 10 g of carboxymethyl cellulose, 100 mL anhydrous methanol, 1 mL DMF were added, cooled by ice bath, with magnetic stirring, 12 mL of SOCl2 was added slowly with a drop funnel and reaction temperature was controlled below 5 °C. And then the reaction was continued at room temperature for another 24 h. After the reaction completed, a white small granular solid was obtained by vacuum filtration, washed with anhydrous ethanol until no HCl was detected, and dried with vacuum.

Synthesis of diethylenetriamine carboxymethyl cellulose amide 3

Methyl Carboxymethyl cellulose ester 5 g, anhydrous ethanol 50 mL, 5 mL (0.0465 mol) diethylenetriamine was added respectively into a 100 mL round bottom flask, and sealed in 75 °C water bath for about 48 h. After cooled to room temperature, filtered, and washed with anhydrous ethanol to neutral, dried, a white solid was obtained, which has weak ammonia smell.

Synthesis of N,N-(dicarboxymethylaminoethyl, carboxymethyl)aminoethylamine carboxymethyl cellulose amide 4

9.0 g Chloroacetic acid (about 0.1 mol) was dissolved in 20 mL distilled water in a 250 mL round bottom flask, with stirring, Na2CO3 powder was added to adjust the pH value to 9–10. And then 100 mL anhydrous ethanol, 4.9 g diethylenetriamine carboxymethyl cellulose amide were added, and the reactant was stirred for 72 h at room temperature. The pH value was detected and adjusted with anhydrous Na2CO3 during the reaction and maintained between 9–10. After filtering, it was washed with ethanol and dried; a white solid was obtained.

Kinetic study of metal ion adsorption of 4

Adsorption equilibrium time of adsorbent with metal ions were determined within 50 min in several min intervals. 10 mg of adsorbent was placed in a 50 mL round bottom flask, and then 10.0 mL of 500 ppm metal ion solution was added with continuous stirring. The absorption process were carried out at pHs 5.0 for Cu2+and Pb2+, optimal contact time to get the best adsorption. During the process, pH values should be adjusted and maintained at 5.0, and NaOH solution (0.01 mol/L) could be added. After filtration, the concentration of metal ion remained in aqueous solution was determined by ICP spectroscopy.

pH study of metal ion adsorption of 4

The effect of pHs on metal ion (Cu2+ and Pb2+) adsorption was performed by experiments. 10 mg of adsorbent 4 was added into a 50 mL round bottom flask, and then under continuous stirring, 10.0 mL of 500 ppm metal ion solution was added. pH was adjusted when needed with NaOH or HCl solutions (0.1–1.0 mol/L). The contact time in experiments was 30 min. After filtered, the remaining metal ion concentration of the solution was determined by the ICP spectroscopy. No significant change in the pH values in the solution were observed in the course of experiments.

Saturated adsorption and ion adsorption competition experiments

According to the conditions obtained from adsorption for Pb2+ and Cu2+, the contact time was 30 min, a maximum pHs value before ion hydrolysis was chosen, pHs 7.0 for Ba2+, Mg2+ and Mn2+, pHs 6.0 for Co2+and Ni2+, pH 4.0 for Zn2+. In the ion adsorption competition experiments, a lower pH was selected for preventing the hydrolysis of the easily hydrolyzed metal ion, for example, ion adsorption competition between Mg2+ and Zn2+, pH 4.0 was chosen. Initial concentration of all metal ions were 300 ppm.

Saturated adsorption for ions. 10 mg of adsorbent 4 was added into a 50 mL round bottom flask, and then under continuous stirring, 10.0 mL of 300 ppm metal ion solution was added. pH was adjusted when needed with NaOH or HCl solution (0.1–1.0 mol/L). The contact time in experiments was 30 min. After filtered, the remaining metal ion concentration of the solution was determined by the ICP spectroscopy.

Ion adsorption competition. 20 mg of adsorbent 4 was added into a 50 mL round bottom flask, and then under continuous stirring, 20.0 mL of mixed solution (300 ppm metal ion 1 and 300 ppm metal ion 2) was added. pH was adjusted when needed with NaOH or HCl solution (0.1–1.0 mol/L). The contact time in experiments were 30 min. After filtered, the remained metal ion concentration of the solution was determined by the ICP spectroscopy. No significant change in the pH values in the solution were observed in the course of experiments.

Characterization for materials obtained

The characterization of materials 1, 2 and 3 were carried out by IR spectroscopy in a iS10 FT-IR spectrometer from Thermo Nicolet Corporation equipment with KBr. And the terminal adsorbent 4 was characterized by IR spectroscopy, Elemental analyses were accomplished in Vario EL cube from Elementar Trading (shanghai) Co.,Ltd, and Solid State Nuclear Magnetic Resonance (SSNMR) 13C NMR spectroscopy was recorded by a Bruker AVANCE III 600 M equipment. Metal ion concentration was determined by ICP spectroscopy with an ICP-OES 5110 spectrometer produced by Agilent Technologies Inc.

Results and discussion

Synthesis of N,N-(dicarboxymethylaminoethyl, carboxymethyl)aminoethylamine carboxymethyl cellulose amide 4

The route used to synthesize terminal adsorbent 4 is presented in Fig. 1.

Carboxymethyl cellulose 1 was synthesized by conventional method reported in the literature.

The esterification of carboxymethyl cellulose has not been reported before. The esterification reaction is a solid–liquid heterogeneous reaction, in this paper, SOCl2/CH3OH/DMF (Hosangadi et al. 1996) were used as reagents. The optimized reaction conditions were obtained through many experiments. Initially, for a higher conversion rate and accelerating the reaction speed, heating was carried out as described in the literature, thus leading to the degradation of cellulose. Satisfactory results were obtained when reaction conditions (temperature, time) were controlled. The optimized reaction conditions were that, SOCl2 was added very slowly and ice bath was used to keep low temperature, during the next stage, the reaction was carried out at room temperature.

Ammonolysis of methyl carboxymethyl cellulose ester 2, and then, carboxymethylation of amino groups with chloroacetic acid for the terminal product 4 are also solid–liquid heterogeneous reactions. A large excess of diethylenetriamine and chloroacetic acid was added to increase the conversion ratio of groups.

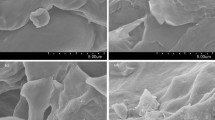

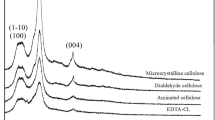

Characterization of 1, 2, 3 and 4

Carboxymethyl cellulose 1 was characterized by IR spectroscopy. The spectrum of 1 and unmodified cellulose is displayed in Fig. 2. Compared with unmodified cellulose, a strong band at 1733 cm−1 in 1 was found, and it is the evidence that carbonyl functions were introduced onto cellulose.

The IR spectra of 2, 3, and 4 are shown in Fig. 3. Product of esterification of carboxymethyl cellulose 2 showed a very wide and strong new band at 1630 cm−1, Here is the stretching vibration of C = O of the carbonyl in ester. Accompanied by the disappearance of C = O double bonds stretching vibration in carboxylic acid at 1733 cm−1, indicate the successful esterification.

In IR spectrum of material 3, one band found at 1747 cm−1 was assigned to C = O for stretch vibration. A very strong band found at 1615 cm−1 was assigned for the presence of axial deformation vibration of C = O in the amide and angular deformation vibration of N–H in amine. The band appears at 1419 cm−1 was assigned to C–N bond in the amide (Karnitz et al. 2007).

Terminal material 4 was got by carboxymethylation from 3, one band found at 1748 cm−1 assigned to C = O for stretch vibration is much stronger than material 3 for the increase of carbonyl groups, and bands of axial deformation of C = O in the amide and the N–H bond angular deformation in amine appear at 1635 cm−1, which became weaker for the substitution of N–H by chloroacetic acid.

The main bands observed in 1, 2, 3 and 4 are presented in Table 1.

Solid State Nuclear Magnetic Resonance (SSNMR) 13C NMR spectrum of material 4 is presented in Fig. 4, and the chemical shift and its assignments are listed in Table 2.

The elemental analysis data of material 4 is listed in Table 3. A larger percentage of nitrogen was found for the introduction of amino carboxylic group onto cellulose. A minor portion of sulfur was found remained for result of the esterification process.

According to the infrared spectrum analysis, Solid State Nuclear Magnetic Resonance (SSNMR) 13C NMR spectrum analysis, and the results of elemental analysis, a possible structure of material 4 was given in Fig. 5. Its calculated values of the elemental analysis are listed in Table 3.

Adsorption study of 4 to Cu2+and Pb2+

Cu2+ and Pb2+, as common heavy metal pollutant ions, were always used as target adsorbed ions (Jilal et al. 2018; Júnior et al. 2009; Tsukinoki et al. 2008; Vaughan et al. 2001). Started with Cu2+ and Pb2+, the conditions and adsorption capacity of adsorbent 4 obtained could compare with literature, and the adsorption properties of adsorbent 4 could be evaluated. Conditions of the solution effect on adsorption were first carried out as functions of time and pH.

Contact time effect on absorption

Contact time effect (kinetic study) of adsorbent 4 on adsorption to Cu2+ and Pb2+ are shown in Fig. 6. Time to reach the equilibrium was within 30 min for adsorption Cu2+ and Pb2+. So, 30 min was used as contact time to study the absorption effect of adsorbent 4 with ions.

pH Effect

Solution pH is a very important factor that affect on adsorbent for the removing metal ions in water by adsorption, because it affects the protonation of amino acetic acid groups, the ionization degree of chelating group and the type of adsorption functional group. In general, with a higher pH value, the adsorption capacity is greater, but, it can not exceed the limit pH value of hydrolysis of metal ion, so pH range of 2–5 was chosen, and adsorption capacity was carried out as function of pH. Of course, a pH range of 2–5, is also the expected range of polluted acid water.

Under the condition of contact time 30 min, the influence of the pH value on the adsorption of metal ions were studied. As shown in Fig. 7, when the pH value increases, the adsorption amount of metal ion by adsorbent 4 has a greater value. When the solution pH was 5, the adsorbent observed a maximum adsorption amount to Cu2+ and Pb2+, and pH 5, does not exceed the limit value of hydrolysis of metal ions.

Adsorption isotherms

Under optimal conditions (equilibrium time 30 min and pH 5.0), adsorption experiments were carried out for evaluation with Langmuir (Eq. (1)) and Freundlich (Eq. (2)) isotherms (Ho et al. 2005; Karnitz et al. 2007), that manifests function relationship between adsorption effect and the initial concentration of metal ion. The results are displayed in Fig. 8 and Fig. 9, and the data is listed in Table 4.

In Eqs. (1) and (2), q(mg/g) is an amount of metal ion adsorbed by the unit adsorbent, c(mg/L) is the concentration of the remaining metal ion in the solution when adsorption reaches equilibrium, Qmax and b are parameters unique in Langmuir equation, and k and n are parameters unique in Freundlich equation.

In Figs. 8 and 9, it can be seen that the data in the diagram are fitted by using Langmuir and Freundlich equations with good linear relations and high correlation coefficients, and thus the equations can well be used to explain the adsorption properties of this adsorbent to metal ions.

Qmax in Langmuir isotherm equation is a parameter that manifests the largest adsorption capacity of adsorbent when the target metal ion in higher concentrated solution. In Table 4, It is clear that adsorbent 4 exhibits the maximum adsorption capacity for Cu2+ was 80.3 mg/g (1.264 mmol/g), while for Pb2+ was 266.7 mg/g (1.287 mmol/g), and the maximum adsorption capacity of the two ions were almost the same in molar per gram. Parameter b manifests the bond energy in the coordination reaction between adsorbent and metal ion. Through the results listed in Table 4, It can be concluded that adsorbent 4 shows a larger bond energy with Cu2+ than Pb2+, the possible explanation is that Cu belongs to transition metal and nitrogen atom have a stronger bond with copper ion.

In Freundlich equation, parameter k is a index for adsorption capacity at the condition when metal ion concentration in equilibrium is unitary, and the case is 1 mg/L, feature closer to the industrial wastewater. So that the parameter k could be used for adsorption capacity assessment of metal ion in diluted contaminated solution. The value of k for Cu2+ was 55.45 mg/g (0.873 mmol/g), and 187.06 mg/g (0.903 mmol/g) for Pb2+, the values were almost the same when calculated into molar per gram. This indicates the adsorption superiority of adsorbent 4 when target metal ion in solution at very low concentration.

These results were compared with some Qmax for Cu2+ and Pb2+ of adsorbents reported in literature, data is listed in Table 5. Duolite GT-73, a purchasable macroreticular adsorbent which having thiol groups, reported by Vaughan(Vaughan et al. 2001), the adsorbent 4 described in this paper exhibited double Pb2+ Qmax and higher Cu2+ Qmax than those of Duolite GT-73. Compared with other adsorbents, which contain EDTA group connected to cellulose by ester bond, the Qmax for Cu2+ and Pb2+ of adsorbent 4 were far more larger.

Saturated adsorption and ion adsorption competition

Adsorbent 4 exhibited fast visible color change when adsorbed ions were Cu2+, Co2+ and Ni2+, this is shown in Fig. 10. According to the conditions obtained from Pb2+ and Cu2+, saturated adsorption capacity (mmol/g) were determined for Ba2+, Mg2+, Mn2+, Co2+, Zn2+, Ni2+, Pb2+ and Cu2+. The data is presented in Fig. 11. The minimum adsorption capacity among them was 0.87 mmol/g for Ba2+. By comparing saturated adsorption capacity (mmol/g) of metal ions, the values differ each other at a rather low level, it could be concluded that there is fixed binding sites in adsorbent 4 and through which metal ion were adsorbed, proposed chelating center is presented in Fig. 5. In the adsorbent 4, the adsorption binding site was amino acetic acid functions, It has similar feature to the EDTA, and the results indicated that, the adsorbent 4 showed a good adsorption capacity to a wide range of metal ions.

For a further comparing the adsorption properties of adsorbent 4 with EDTA, three different metal ions Mg2+, Co2+ and Pb2+ were selected as reference ions, and ion adsorption competition experiments were conducted firstly. The data are presented in Figs. 12, 13 and 14.

In Fig. 12, adsorption competition was carried out between Mg2+ and other ions. In the competition between Mg2+ and Ba2+, the adsorbent 4 showed a greater adsorption amount for Mg2+. Adsorption competition between Mg2+ and other metal ions, the adsorbent 4 was more inclined to adsorb other metal ions, such as Mn2+, Co2+, Zn2+, Pb2+ and Ni2+. Few Mg2+ was absorbed in the competition with Cu2+.

In Fig. 13, adsorption competition was conducted between Co2+ and other ions. The adsorbent 4 showed a much larger adsorption amount for Co2+ in competition with Ba2+ and Mg2+, and a small larger amount than Mn2+. In the solution of Co2+ mixed with Zn2+, Pb2+, Ni2+ respectively, the adsorbent 4 was more inclined to adsorb Zn2+, Pb2+ and Ni2+. Few Co2+ was absorbed in competition with Cu2+.

In Fig. 14, adsorption competition was conducted between Pb2+ and other ions. The amount of metal ion adsorbed by adsorbent 4 vast majority was Pb2+ in the mixed solution of Pb2+ with Ba2+, Mg2+ respectively. In the adsorption competition between Pb2+ and Co2+, Ni2+, the adsorbent 4 was inclined to adsorb Pb2+. In the adsorption competition between Pb2+ and Cu2+, adsorbent 4 exhibited a larger adsorption amount for Cu2+, and it was the evidence that adsorbent 4 shows a larger bond energy with Cu2+ than Pb2+ manifested by Parameter b in Langmuir isotherm equation.

According to the results presented in Figs. 12, 13 and 14, it could be concluded that the adsorption properties of the adsorbent 4 is similar to that of EDTA, and the formation constant lgK(ML) of EDTA with ions were used to explain the adsorption properties of adsorbent 4. From data listed in Table 6, it could be seen that, among all metal ions, formation constant lgK(ML) of EDTA with Ba2+ and Mg2+ are much smaller, so in ion adsorption competition experiments, the adsorbent 4 prefer to absorb other metal ions than Ba2+ and Mg2+. Formation constant lgK(ML) of EDTA with Co2+ is bigger than Ba2+, Mg2+ and Mn2+, thus the adsorbent 4 tends to adsorb Co2+ in competition experiments. Zn2+, Pb2+, Ni2+ and Cu2+ have bigger lgK(ML) with EDTA than Co2+, so the adsorbent 4 tends to absorb these metal ions. lgK(ML) of Ba2+ and Mg2+ with EDTA are much smaller than Pb2+, so the metal adsorbed mainly was Pb2+. When Pb2+ competition with Co2+, the amount of Pb2+ adsorbed was bigger because its larger lgK(ML) with EDTA. The lgK(ML) of EDTA with Cu2+ is slightly bigger than Pb2+, and therefore the amount of Cu2+ adsorbed is slightly greater than Pb2+.

Conclusions

A novel chelating material modified from cellulose was synthesized in situ for the first time, it was a new possible strategy for introducing chelating groups (amino acetic acid) onto the cellulose. Modified cellulose exhibited good adsorption capacity for a wide range of metal ions, such as Ba2+, Mg2+, Mn2+, Co2+, Zn2+, Pb2+, Ni2+ and Cu2+, ion adsorption competition experiments reveal its similar feature to EDTA, and it has potential use in the removal of heavy metal ions and recovery of useful ions from aqueous solution.

Availability of data and materials

Data listed in this paper are available once you send a request e-mail to the communications contacts at 441430968@qq.com.

References

Ardiyanita PZ, Sutriyo S, Suryadi H (2020) Preparation and characterization of sodium carboxymethyl cellulose from kapok (Ceiba Pentandra) alpha-cellulose. Int J Appl Pharm 12:9–14. https://doi.org/10.22159/ijap.2020.v12s1.25840

Barakat MA (2011) New trends in removing heavy metals from industrial wastewater. Arab J Chem 4:361–377. https://doi.org/10.1016/j.arabjc.2010.07.019

Bhalla V, Kumar R, Kumar M, Dhir A (2007) Bifunctional fluorescent thiacalix[4]arene based chemosensor for Cu2+ and F− ions. Tetrahedron 63:11153–11159. https://doi.org/10.1016/j.tet.2007.08.021

Cao J, Fei D, Tian X, Zhu Y, Wang S, Zhang Y, Mao Q, Sun M (2017) Novel modified microcrystalline cellulose-based porous material for fast and effective heavy-metal removal from aqueous solution. Cellulose 24:5565–5577. https://doi.org/10.1007/s10570-017-1504-6

Carver PL (2013) Metal ions and infectious diseases: an overview from the clinic. In: Sigel A, Sigel H, Sigel RKO (eds) Interrelations between essential metal ions and human diseases: metal ions in life sciences. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-7500-8_1

Chauhan GS, Guleria L, Sharma R (2005) Synthesis, characterization and metal ion sorption studies of graft copolymers of cellulose with glycidyl methacrylate and some comonomers. Cellulose 12:97–110. https://doi.org/10.1007/s10570-004-2720-4

d’Halluin M, Rull-Barrull J, Bretel G, Labrugère C, Le Grognec E, Felpin F-X (2017) Chemically modified cellulose filter paper for heavy metal remediation in water. ACS Sustain Chem Eng 5:1965–1973. https://doi.org/10.1021/acssuschemeng.6b02768

Gao X, Zhang H, Chen K, Zhou J, Liu Q (2018) Removal of heavy metal and sulfate ions by cellulose derivative-based biosorbents. Cellulose 25:2531–2545. https://doi.org/10.1007/s10570-018-1690-x

Ho YS, Chiu WT, Wang CC (2005) Regression analysis for the sorption isotherms of basic dyes on sugarcane dust. Biores Technol 96:1285–1291. https://doi.org/10.1016/j.biortech.2004.10.021

Hosangadi BD, Dave RH (1996) An efficient general method for esterification of aromatic carboxylic acids. Tetrahedron Lett 37:6375–6378. https://doi.org/10.1016/0040-4039(96)01351-2

Huang Y, Yang C, Sun Z, Zeng G, He H (2015) Removal of cadmium and lead from aqueous solutions using nitrilotriacetic acid anhydride modified ligno-cellulosic material. RSC Adv 5:11475–11484. https://doi.org/10.1039/C4RA14859B

Jilal I, El Barkany S, Bahari Z, Sundman O, El Idrissi A, Abou-Salama M, Romane A, Zannagui C, Amhamdi H (2018) New quaternized cellulose based on hydroxyethyl cellulose (HEC) grafted EDTA: Synthesis, characterization and application for Pb (II) and Cu (II) removal. Carbohyd Polym 180:156–167. https://doi.org/10.1016/j.carbpol.2017.10.012

Júnior OK, Gurgel LVA, de Freitas RP, Gil LF (2009) Adsorption of Cu(II), Cd(II), and Pb(II) from aqueous single metal solutions by mercerized cellulose and mercerized sugarcane bagasse chemically modified with EDTA dianhydride (EDTAD). Carbohyd Polym 77:643–650. https://doi.org/10.1016/j.carbpol.2009.02.016

Karnitz O, Gurgel LVA, de Melo JCP, Botaro VR, Melo TMS, de Freitas Gil RP, Gil LF (2007) Adsorption of heavy metal ion from aqueous single metal solution by chemically modified sugarcane bagasse. Biores Technol 98:1291–1297. https://doi.org/10.1016/j.biortech.2006.05.013

Kirsipuu T, Zadorožnaja A, Smirnova J, Friedemann M, Plitz T, Tõugu V, Palumaa P (2020) Copper(II)-binding equilibria in human blood. Sci Rep 10:5686. https://doi.org/10.1038/s41598-020-62560-4

Lim MH, Lippard SJ (2007) Metal-based turn-on fluorescent probes for sensing nitric oxide. Acc Chem Res 40:41–51. https://doi.org/10.1021/ar950149t

Lin X, Jin J, Guo X, Jia X (2021) All-carboxymethyl cellulose sponges for removal of heavy metal ions. Cellulose 28:3113–3122. https://doi.org/10.1007/s10570-021-03685-1

Mengxuan Hu PX, Wang L, Liu Y (2016) Research progress of heavy metal ions removal in desulfurization wastewater. Water Pollut Treat 4:85–90

Nongbe MC, Bretel G, Ekou T, Ekou L, Yao BK, Le Grognec E, Felpin FX (2018) Cellulose paper grafted with polyamines as powerful adsorbent for heavy metals. Cellulose 25:4043–4055. https://doi.org/10.1007/s10570-018-1833-0

Pereira TCB, Campos MM, Bogo MR (2016) Copper toxicology, oxidative stress and inflammation using zebrafish as experimental model. J Appl Toxicol 36:876–885. https://doi.org/10.1002/jat.3303

Singh AV, Singh R et al (2012) Synthesis, characterization and application of cellulose nitrilotriacetic acid (CNTAA) resin for removal of heavy metal ions from industrial effluent. J Indian Chem Soc 89:77–84

Tsukinoki S, Yamada K, Ito O, Nanbu N, Belles-lettre A (2008) Solid phase extration of Cu, Ni and Co by EDTA type chelating cellulose. Jpn Soc Anal Chem 57:1033–1038. https://doi.org/10.2116/bunsekikagaku.57.1033

Vaughan T, Seo CW, Marshall WE (2001) Removal of selected metal ions from aqueous solution using modified corncobs. Biores Technol 78:133–139. https://doi.org/10.1016/S0960-8524(01)00007-4

Wilpiszewska K, Antosik AK, Schmidt B, Janik J, Rokicka J (2020) Hydrophilic films based on carboxymethylated derivatives of starch and cellulose. Polymer 12:2447. https://doi.org/10.3390/polym12112447

Xu C, Liu F, Ling C et al (2014) Research progress in adsorption performance of heavy metal ion with polyamine chelating adsorbents: a review. Ion Exch Adsorpt 30:87–96. https://doi.org/10.16026/j.cnki.iea.2014.01.003

Acknowledgments

We should grant our great thanks to Sichuan University of Arts and Science (2018SCL006Y, 2018SCL007Y and 2019BS012Z) and Science and Technology Bureau of Dazhou City Sichuan Province (20YYJC0001) for financial supports.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, T., Hu, X., Tang, C. et al. Adsorbent grafted on cellulose by in situ synthesis of EDTA-like groups and its properties of metal ion adsorption from aqueous solution. Cellulose 29, 941–952 (2022). https://doi.org/10.1007/s10570-021-04324-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-04324-5