Abstract

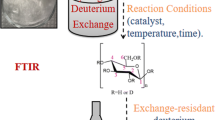

Preparation of deuterium incorporated cellulose is a vital tool to investigate cellulose internal structure and to expand the application fields of cellulose materials. In this study, cellulosic cotton fibers with anti-rehydration (exchange-resistant) deuterium incorporated in cellulose were prepared by chemical hydrogen–deuterium exchange treatment. The chemical hydrogen–deuterium exchange process, along with exchange time, were characterized by nuclear magnetic resonance hydrogen spectroscopy (1H-NMR). The anti-rehydration deuterium incorporation was determined by Fourier Transform infrared spectroscopy (FTIR) and Stable Isotope Ratio Mass Spectrometer (IRSM). The effect of the deuterium hydroxyl substitution on cotton fiber’s spectral data, microstructure, crystalline information, degree of polymerization, as well as it’s thermogravimetric analysis (charcoalization and combustion) are explored. Analysis of the chemical exchange process indicated that the hydrogen–deuterium exchange occurred preferentially in the amorphous cellulose component over the first several minutes. Deuterium exchange in the anti-rehydration crystalline phase took several hours. Increasing the treatment time, enhanced exchange-resistant deuterium incorporation to as high as about 60% of the cotton fibers’ cellulose hydroxyl groups was achieved. The characterization of FTIR, Fourier transform Raman (FT-Raman), and near-infrared spectra (NIR) all exhibited the deuterium spectral isotope effect on cellulose hydroxl groups. While, apart from the effect of reaction temperature, deuterium incorporation isotope effect did not affect the cellulose microstructure, crystalline index and the degree of polymerization properties. Furthermore, the thermogravimetric analysis of deuterated cotton fibers under N2 and air atmosphere were both altered due to the thermodynamic isotope effect. These observations revealed the hydrogen–deuterium exchange treatment process and impacts on cellulose fiber properties, which helped us to better understand the cellulose internal structure and may facilitate the potential utilization of deuterated cellulosic materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose, as one of the most abundant and sustainable polymers in the world, has seen continuing research attention due to its excellent performance in bio-derived materials, chemicals, and fuels (Jiang et al. 2018; Liang et al. 2020). Recently, deuterium labeled cellulose has become a research focus area as it is a key tool for exploring structural features when used with neutron science and imaging technology (Evans et al. 2014). Notably, deuterated cellulose with hydrogen atoms substituted by deuterium atoms facilitates small-angle neutron scattering (SANS) application because deuterium and hydrogen interact with the neutrons very differently (O’Neill et al. 2015). Therefore, cellulose supramolecular structural information (Langan et al. 1999) and hydrogen bonding patterns such as Iα (Nishiyama et al. 2003) and Iβ (Nishiyama et al. 2002) are revealed. Furthermore, the literature shows that deuterium substituted cellulose exhibits isotope effects in cellulose hydrolysis rates (Bhagia et al. 2018) and thermostability (Budarin et al. 2010), which may expand its field of applications. Hence, there is a need to study the preparation and characterization of deuterated cellulose materials.

According to the literature, deuterated cellulose can be acquired by either biological routes or by chemical means. Bio-deuterated cellulose is extracted from plants or bacteria that are cultivated with a deuterium-enriched growth medium (Evans et al. 2019). It was reported that no significant differences were observed in the cellulose microstructural, morphological properties and crystallinity between biological deuterated and protonic cellulose (Evans and Shah 2015). The weight-average degree of polymerization (DPw) value of the deuterium incorporated cellulose was increased by 20% to 30% (Evans and Shah 2015). Furthermore, both the hydrogen atoms from R–O–H and C–H could be substituted with R–O–D and C–D through biological deuteration routes (Evans et al. 2015). However, cellulose C–D substitution with the bio-deuteration remains challenging and plant species specific (Evans and Shah 2015). For some studies, there is a need to solely incorporate deuterium into the proton cellulose hydroxyl groups, which could be accomplished by chemical hydrogen–deuterium exchange treatment.

Currently, the chemical exchange process has been primarily applied to investigate cellulose accessibility. The hydrogen–deuterium exchange is believed to occur solely in the amorphous regions of cellulose under certain conditions, where the deuterium incorporation can be readily exchanged with a proton hydroxyl groups (Lindh and Salmén 2016; Tsuchikawa and Siesler 2003). At the same time, there are also literature results that highlight the deuteration of cellulose crystalline regions, which was mainly used in neutron studies to reveal cellulose crystalline structure and hydrogen bonding patterns (Nishiyama et al. 2010). The deuteration of exchange-resistant cellulose hydroxyl groups via chemical exchange routes is easy and convenient to accomplish. It also has the potential of generating exchange-resistant deuterated hydroxyl groups that could be used as a “tracer” material such as specialty papers or fabrics for anti-counterfeiting purpose. For example, treating cellulose microcrystals with 0.1 N NaOD/D2O at 210 °C for 30 min was able to generate 100% deuteration of intracrystalline OH moieties replaced by ODs (Nishiyama et al. 1999). However, these severe conditions didn’t retain cellulose fiber structure. Thereby, milder parameters should be applied to keep the original structure of cellulose material (such as fibers or films) for better extending its application fields.

To explore the potential utilization of exchange-resistant deuterium incorporation into cellulose material, deuterated cotton fibers with different deuterium incorporation levels were prepared by chemical hydrogen–deuterium exchange treatment. The deuteration process was evaluated using 1H-NMR to determine the replaced exchangeable hydrogen concentration under varying reaction times and temperatures. Then the properties of the deuterated cotton fibers were characterized and summarized. The deuterium substitution was determined by FTIR, FT-Raman and NIR for spectroscopy isotope effect. The effect of deuterated hydroxyl groups on cellulose spectra, micro-morphology, crystalline information, polymerization, and thermogravimetric analysis were also examined. Therefore, it deepened our understanding of the hydrogen–deuterium exchange process and laid foundation for the application of deuterated cotton fibers. Moreover, the kinetic isotope effect on cotton fiber strength also needs to be studied in the future research.

Experimental methods

Materials

The original cotton fibers were acquired from Dezhou Hengfeng Co., Ltd. All chemicals purchased were reagent grade, and used as received from Sigma Aldrich without any further purification. The D2O used for exchange treatment was 99.99% in purity.

Hydrogen–deuterium exchange treatment of cotton fibers

Before the hydrogen–deuterium exchange treatment, the reactor was purged with N2. Then the dried cotton fiber samples were treated in a 4560 series Parr reactor (Parr Instrument Company, USA) with D2O (1:30, w/v) and 10% K2CO3 (based on the samples). This slurry was then heated to a reaction temperature of 25 °C, 65 °C, 105 °C, 145 °C, 185 °C, and 205 °C, respectively. After 8 h, the reaction mixture was filtered and washed with D2O until the effluent was pH neutral. Moreover, H2O was applied instead of D2O during the alkaline treatment as a control. The recovered fibers were dried at 60 °C in a vacuum oven for 24 h before they were stored at constant temperature and humidity (25 ± 2 °C, 65 ± 5% RH, H2O moisture).

Characterization of cotton fibers

Characterization of hydrogen–deuterium exchange process

For the calculation of deuterium incorporation process, deuterium exchange test was also performed using absolutely dry cotton fibers mixed with D2O (1:30, w/v) and 10% K2CO3 (based on the samples), placed in a sealed Teflon tube at 25 °C, 65 °C, 105 °C oil bath (which was preheated to the target temperature and tested by thermometer) for 1 min, 5 min, 10 min, 30 min, 1 h, 2 h, 4 h, 8 h, respectively. These samples were filtered immediately and pressed sufficiently to acquire the residual solution treated for certain time to calculate the replaced hydrogen concentration by 1H-NMR spectroscopy. External dimethyl sulfoxide (DMSO) was applied as a reference. All NMR experiments were performed on a Bruker Avance-III HD 400 MHz spectrometer operating at a frequency of 400.17 MHz. The 1H-NMR experiments utilized a 9.45 μs (90°) 1H pulse, 5 s recycle delay, and 256 scans. The hydrogen concentration in the deuterated reagent was calculated with the ratio of the proton spectrum integration and moles of proton from DMSO and HOD, respectively.

Calculation of anti-rehydration deuterium incorporation

The dried cotton fibers after hydrogen–deuterium exchange treatment were placed in a constant temperature and humidity environment (25 ± 2 °C, 65 ± 5% RH, H2O moisture) for 2 weeks before FTIR and IRSM analysis to determine the anti-hydration deuterium incorporation (Song et al. 2020). FTIR spectra of the cotton fiber samples were recorded with a PerkinElmer Spectrum 100 FTIR spectrometer (Waltham, MA, USA) equipped with an ATR accessory. The spectral data was acquired over the wavelength range of 800–4000 cm−1 with a resolution of 2 cm−1 per spectrum and scanned 64 times. The FTIR spectra of the exchange-resistant deuterated cotton fibers were baseline-corrected with the Origin Pro software with reference to the wave numbers of 3670 cm−1, 3002 cm−1, 2636 cm−1, and 2320 cm−1, respectively, before the deuterium incorporation analysis (Łojewska et al. 2007; Song et al. 2020). Moreover, the calculation of non-exchangeable deuterium (δD) for the resistant deuterated cotton fibers were analyzed using a Thermo MAT 253 mass spectrometer (Flash EA 1112 and Mat 253 IRMS). The δD value is based on the SMOW (Standard Mean Ocean Water) international standard, and the δDVSMOW value is based on the following formula:

In this formula, R(D/HVSMOW) is the hydrogen isotope abundance ratio of the international standard of SMOW. The analysis accuracy of δDVSMOW value is ± 1‰.

Spectral characterization of cotton fibers

Apart from FTIR spectra, the Raman spectra were recorded using a Thermo Scientific Nicolet iS 50 FT-Raman spectrometer (Waltham, MA, USA). The analysis was carried out at room temperature with the Nd:YAG laser set at 1064 nm and 450 mW, with a spot size of 150 μm in diameter. Three samples were used to collect FT-Raman spectra with a resolution of 8 cm−1 and a 5 min/spectrum speed.

The NIR spectra of the cotton fibers were collected using a PerkinElmer Spectrum Two N Fourier transform near infrared spectrometer (Waltham, MA, USA) in a wave number range of 4000–1000 cm−1 with a resolution of 4 cm−1 and 32 scans per sample.

Micro-structure of cotton fibers

A JSM-840 scanning electron microscope (JEOL, Japan) was employed to observe the cotton fibers’ micro-morphology properties for D2O exchange treatment. Platinum was sprayed on the cotton fiber surface before they were observed. All the pictures were taken under an accelerating voltage of 15 kV and magnification of 10,000.

Crystalline index of cotton fibers

A D8 Advanced X-ray diffractometer (Bruker, Germany) was applied to record the cotton fibers’ (H2O and D2O exchange treated) crystalline information. It was scanned in a 2θ range from 5° to 40° with a scan rate of 2°/min at 40 kV and 50 mA, respectively. The crystalline index (CrI) of the cotton fibers was calculated according to the Segal method equation previously reported (French 2014; Segal et al. 1959).The equation was listed as follows:

where I200 connects to the maximum peak intensity of the 200 cellulose crystalline lattice diffraction (around 22.6° for native cotton cellulose). Iamorph is the minimum intensity taken near 2θ = 18°, attributed to the amorphous area in native cotton cellulose (French 2014).

Degree of polymerization of cotton fibers

The degree of polymerization value for cotton fibers exchanged with H2O or D2O were measured using an Agilent GPC SECurity 1200 system (PSS, Germany) after cellulose tricarbanilation, as previously described (Meng et al. 2016). Briefly, shredded cotton fiber samples (~ 15 mg) were derivatized with a solution of anhydrous pyridine (4 mL) and phenyl isocyanate (0.5 mL) stirred in the dark at 70 °C for 72 h. After the derivatization, cellulose was precipitated and washed with a methanol/H2O (7:3, v/v) solution, the dried derivatized cellulose was dissolved in tetrahydrofuran (1.0 mg/mL) and filtered through a 0.45 μm PTFE filter membrane into GPC vials before conducting GPC analysis. Tetrahydrofuran was used as the mobile phase (1.00 mL/min), and the injection volume was 30.0 μL. The weight-average degree of polymerization (DPw) of cotton fibers was obtained by dividing the weight-average molecular weight by 519 g/mol, the molecular weight of the tricarbanilated cellulose repeating unit.

Thermogravimetric analysis of the cotton fibers

The thermogravimetric analysis of the cotton fiber samples (i.e., exchanged with H2O and D2O) was measured with a Pyris TGA analyzer (PerkinElmer, USA). Prior to the TGA test, the samples were placed in a constant temperature and humidity chamber for 24 h to obtain equilibrium moisture stable materials. Approximately 10 mg of shredded cotton fiber samples were applied for the TGA test from room temperature to 700 °C under a nitrogen atmosphere or air environment, respectively. The temperature was increased with a constant heating rate of 10 °C/min.

Results and discussion

Characterization of deuteration process

To avoid the calculation error caused by cellulose degradation under high temperature, cotton fibers were only treated below 105 °C for hydrogen–deuterium exchange process analysis. Figure 1 presents the deuterium substitution process along with treatment time. From Fig. 1, it is clear that there are at least two stages during the deuteration process. The deuterium incorporating into the cellulose fibers occurs rapidly in the first several minutes. This presumably represents the deuteration of cellulose hydroxyl groups in the amorphous regions, which is fast and preferential. This is attributed to the fact that the cellulose chains from amorphous area are arranged disorderly, which made it easier for the dissociation of R–O+ from cellulose molecule. Furthermore, “hydrogen–deuterium exchange” during this period might be mistypography. After 1 h reaction time, a second slower deuterium exchange process occurs, and it almost reaches equilibrium after 4 h, which is consistent with a previous report (Frilette et al. 1948). This latter period is believed to be related to the deuteration of the cellulose in the imperfect crystalline or crystalline surface phase. Furthermore, both the imperfect crystalline and amorphous regions of cellulose experienced greater isotope exchange with increased reaction temperature. Since the cellulose chains in crystalline area are densely arranged, the R–O+ dissociation from cellulose molecule solely occurred preferentially in the transfer regions between crystalline and amorphous phase after the saturation of hydrogen–deuterium in amorphous regions. While, the cellulose chains from semi-crystalline or crystalline area were more and more accessible due the molecular acceleration by high temperature and lower dissociation activation energy resulted from alkaline catalyst. However, the internal crystalline phase are indeed very compact to be exposed to D2O molecule, leading to a platform at the end of the hydrogen–deuterium process. In a word, the hydrogen–deuterium exchange of cellulose fibers occurs fast and preferential in the amorphous area and then slowly moves to the transfer or imperfect crystalline phases.

Calculation of anti-rehydration deuteration incorporation

The anti-rehydration cotton fibers’ deuterium incorporation amount was analyzed by FTIR and IRSM test. Table 1 summarizes the results with FTIR and IRSM deuterium incorporation calculation methods. It is clear from the FTIR results (calculated by the comparison of OD and OH characterization peaks) that the anti-rehydration exchange reaction was more efficiently accomplished at a higher reaction temperature. The trend was consistent with the IRSM deuteration rate (δD/H)% of the cotton fibers also, although the deuterium incorporation results calculated from FTIR is a slightly higher than IRSM. Since there is water molecule inside of the cellulose, the FTIR and IRSM results are inconsistent. This latter result supports the hypothesis that the FTIR technique could be employed to determine the anti-rehydration deuteration component.

To increase the deuteration rate of cotton fibers, Fig. 2 shows the deuterium incorporation into cellulose with increased temperature for hydrogen–deuterium exchange treatment time for 8 h. As can be seen, with the increasing temperature, the replacement of proton hydroxyl groups with deuterium increased in an exponential form. However, the anti-rehydration R–O–D groups calculated by FTIR were decreased dramatically at 205 °C. The reason for this phenomenon was attributed to the degradation of the cellulose crystalline region under high temperature for a long treatment time of 8 h. We have reported previously that the exchange-resistant deuterium signal is related to the cellulose crystalline area (Song et al. 2020). Since the crystalline phase would be degraded with higher treatment temperature, it can be concluded that the highest chemical deuteration rate for cotton fibers is about 60% of the cellulose hydroxyl groups.

Spectral characterization of cotton fibers

Figure 3 summarizes the spectral changes of cellulose fibers upon deuteration, including FTIR, FT-Raman, and NIR spectra of proton and deuteron exchanged fibers. As observed, although the strong characteristic bonds of OH signal shown in the FTIR spectra did not exhibit high intensity in FT-Raman spectra, both samples presented a clear signal for OD groups after deuteration. The OD peak wave number (2480 cm−1) from both FTIR and FT-Raman spectra exhibited at lower wavenumber peaks with a ratio of 1/√2 for OH characteristic wave number (3340 cm−1) due to heavier deuterium atom weight, which was in line with the previous literature (Hofstetter et al. 2006; Reishofer and Spirk 2015). Moreover, the NIR spectral data also confirmed the success of deuterium incorporation, with decreasing peaks around 6500 cm−1 and appearing of peaks at 5400 cm−1 after hydrogen–deuterium exchange treatment, which is also in consistent with the former literature (Inagaki et al. 2010; Whiteside et al. 2008). In conclusion, the spectroscopic effect of the isotope exchange was apparent for the deuterated cotton fibers. These spectra alterations are able to be applied to identify the level of deuterium incorporated into cellulose materials, also able to identify the deuterated and protonic cellulosic materials when deuterated cellulosic fibers are used as “tracer” materials.

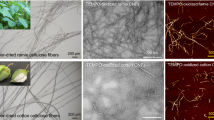

Micro-structure of cotton fibers

Figure 4 demonstrates the micro-morphology of the treated cotton fiber samples. It can be seen that after the hydrogen–deuterium exchange treatment, the cotton fiber surface became smoother. The reason is that the residual gummy materials on the cotton fibers’ surface were dissolved and removed in the high-temperature solutions. Besides these minor structural alterations, no other changes in surface structure were observed, meaning the deuterium incorporation of the cellulose hydroxyl groups via the chemical exchange treatment in this work itself did not affect the surface cellulose morphology structure.

Crystalline information of the cotton fibers

The XRD spectra and the Segal CrI value of the cotton fiber samples are summarized in Fig. 5. It is clear that the treated cotton fibers’ crystalline allomorph still belongs to cellulose I structure (i.e. cellulose I characteristic crystalline lattice peak of 1–10, 100, 200, and 004). Furthermore, the CrI of the cotton fibers was barely altered after the hydrogen–deuterium exchange treatment, meaning the deuterium incorporation of the cellulose hydroxyl groups did not affect the cellulose CrI. Actually, Evans and Bali et al. have reported previously that the bio-deuteration of plant or bacterial cellulose (deuterium substitution of cellulose hydrogen that connects to the carbon and oxygen atoms) will not alter the cellulose crystalline allomorph properties, too (Bali et al. 2013; Evans and Shah 2015).

Degree of the polymerization of cotton fibers

The GPC curves and the DPw value of the cotton fiber samples are presented in Fig. 6. It can be observed that with the increasing of deuterium exchange, the DPw value of the cotton fibers decreased by 12–52%. To investigate the factors contributing to the decrease, the controlled H2O exchanged samples of the cotton fibers were also tested. The DPw value for the deuterated and controlled protonic samples showed a minimum difference which was within the margin of error (5%). Thus, it can be concluded that only the heating temperature caused a decrease of the DPw value for different deuterium incorporation levels of cotton fibers. This effect can be attributed to an increase in cellulose chain hydrolysis with temperature resulting in the lowering of DPw value. This result data means the deuterium incorporation decreased the cellulose DPw value, but it is caused by the temperature rather than deuterium isotope effect.

Thermogravimetric analysis of cotton fibers

The TGA and DTG curves of the cotton fibers under N2 and air atmosphere are shown in Figs. 7 and 8, respectively.

As can be observed from Fig. 7, after deuteration, the thermal stability of cotton fibers under N2 atmosphere has been changed. On one hand, the initial degradation temperature was reduced after deuteration. However, the decreasing rate of the cellulose primary devolatilization process became slower after deuteration. On the other hand, the remaining mass for deuterated cotton fibers was higher than the controlled protonic samples. It may be due to that the similar atomic composition of torrefied char from deuterated sample and that from control sample can be expressed as CxDyOz and CxHyOz, respectively. Since D atom is twice as heavy as H atom, the former is slightly heavier than the latter. Also, this effect may also due to that the deuterium bond is stronger than the hydrogen bond (the vibration frequency of O–D is only 1/√2 of O–H since the D atom is twice as heavy as H atom), which probably resulted in more thermally stable cellulose structure. While, there is a very minimal decrease in the temperature of the maximum decomposition rate between the deuterated and controlled fiber samples. And the differences between different deuterium incorporated cotton fibers were not obvious.

Similar behavior was also observed in the TGA and DTG spectra of cotton fibers in the oxidative environment as shown in Fig. 8. First, deuterated cotton fibers started to degrade at a lower temperature, although the final ash yield was the same to proton cellulose. Another difference was exhibited in the second oxidative degrading region. The maximum decreasing rate for the oxidative degradation process was lowered after deuteration. This effect was attributed to a deuterium isotopic effect, which may have changed the degradation path in oxidative environment. In conclusion, the thermodynamic effect of the isotope effect for the deuterium incorporated cotton fibers was observed. However, the specific mechanism of the different degradation path or pyrolysis products between deuterated and protonic cellulose deserves to be studied in future studies.

In a word, the chemically deuterated cotton fibers exhibited their spectral and thermodynamic isotope effect. While, the alteration of cellulose basic properties including microscopy, crystalline information and degree of polymerization were not caused by the deuterium isotope effect.

Conclusion

The deuterated cotton cellulose fibers from several deuterium incorporation trials were prepared with chemical hydrogen–deuterium exchange treatment and then characterized by FTIR, SEM, XRD, GPC and TGA. The deuteration process with a prolonged reaction time under an enhanced reaction temperature was also explored by 1H NMR. The deuteration of the amorphous regions of cellulose occurred in the initial several minutes, but the incorporation into the semi-crystalline or crystalline area took several hours. With an increasing deuteration exchange temperature, the deuterium content incorporated into cotton fibers increased. The highest level of anti-rehydration deuterium incorporation into cotton fibers was approximately 60% of the cellulose hydroxyl groups. With deuterium incorporated into cellulose, the deuterium isotope effects altered the cellulose spectra and thermogravimetric performance (charcoalization and combustion) without affecting its micro-morphology, crystalline information, and polymerization. These findings will help to understand the internal structure of cellulose and expand its application.

References

Bali G, Foston MB, O’Neill HM, Evans BR, He J, Ragauskas AJ (2013) The effect of deuteration on the structure of bacterial cellulose. Carbohydr Res 374:82–88

Bhagia S, Meng XZ, Evans BR, Dunlap JR, Bali G, Chen JH et al (2018) Ultrastructure and enzymatic hydrolysis of deuterated switchgrass. Sci Rep 8(1):13226–13234

Budarin VL, Clark JH, Lanigan BA, Shuttleworth P, Macquarrie DJ (2010) Microwave assisted decomposition of cellulose: a new thermochemical route for biomass exploitation. Bioresour Technol 101(10):3776–3779

Evans BR, Shah R (2015) Development of approaches for deuterium incorporation in plants. Methods Enzymol 565:213–243

Evans BR, Bali G, Reeves DT, O’Neill HM, Ragauskas AJ (2014) Effect of D2O on growth properties and chemical structure of annual ryegrass (Lolium multiflorum). J Agric Food Chem 62(12):2595–2604

Evans BR, Bali G, Foston M, Ragauskas AJ, O’Neill HM, Shah R et al (2015) Production of deuterated switchgrass by hydroponic cultivation. Planta 242(1):215–222

Evans BR, Foston M, O’Neill HM, Reeves D, Rempe C, Mcgrath K et al (2019) Production of deuterated biomass by cultivation of lemna minor (duckweed) in D2O. Planta 249:1465–1475

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896

Frilette VJ, Hanle J, Mark H (1948) Rate of exchange of cellulose with heavy water. J Am Chem Soc 70(3):1107–1113

Hofstetter K, Hinterstoisser B, Salmén L (2006) Moisture uptake in native cellulose – the roles of different hydrogen bonds: a dynamic FT-IR study using deuterium exchange. Cellulose 13(2):131–145

Inagaki T, Siesler HW, Mitsui K, Tsuchikawa S (2010) Difference of the crystal structure of cellulose in wood after hydrothermal and aging degradation: a NIR spectroscopy and XRD study. Biomacromolecules 11(9):2300–2305

Jiang W, Song Y, Liu S, Ben H, Zhang Y, Zhou C et al (2018) A green degumming process of ramie. Ind Crops Prod 120:131–134

Langan P, Nishiyama Y, Chanzy H (1999) A revised structure and hydrogen bonding system in cellulose II from a neutron fiber diffraction analysis. J Am Chem Soc 121(43):9940–9946

Liang L, Zhang S, Goenaga GA, Meng X, Zawodzinski TA, Ragauskas AJ (2020) Chemically cross-linked cellulose nanocrystal aerogels for effective removal of cation dye. Front Chem. https://doi.org/10.3389/fchem.2020.00570

Lindh EL, Salmén L (2016) Surface accessibility of cellulose fibrils studied by hydrogen–deuterium exchange with water. Cellulose 24(1):21–33

Łojewska J, Missori M, Lubańska A, Grimaldi P, Ziȩba K, Proniewicz LM et al (2007) Carbonyl groups development on degraded cellulose. Correlation between spectroscopic and chemical results. Appl Phys A 89(4):883–887

Meng X, Sun Q, Kosa M, Huang F, Pu Y, Ragauskas AJ (2016) Physicochemical structural changes of poplar and switchgrass during biomass pretreatment and enzymatic hydrolysis. ACS Sustain Chem Eng 4:4563–4572

Nishiyama Y, Isogai A, Okano T, Müller M, Chanzy H (1999) Intracrystalline deuteration of native cellulose. Macromolecules 32(6):2078–2081

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124(31):9074–9082

Nishiyama Y, Sugiyama J, Chanzy H, Langan P (2003) Crystal structure and hydrogen bonding system in cellulose Iα from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 125(47):14300–14306

Nishiyama Y, Langan P, Wada M, Forsyth VT (2010) Looking at hydrogen bonds in cellulose. Acta Crystallogr Sect D Biol Crystallogr 66(11):1172–1177

O’Neill H, Shah R, Evans BR, He J, Urban V (2015) Production of bacterial cellulose with controlled deuterium-hydrogen substitution for neutron scattering studies. Methods Enzymol 565:123–146

Reishofer D, Spirk S (2015) Deuterium and cellulose: a comprehensive review. In: Rojas OJ (ed) Cellulose chemistry and properties: fibers, nanocelluloses and advanced materials. Springer, Berlin, pp 93–114

Segal et al (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794

Song Y, Jiang W, Ben H, Meng X, Ragauskas AJ (2020) The production of hydrogen–deuterium exchanged cellulose fibers with exchange-resistant deuterium incorporation. Cellulose 4(27):6163–6174

Tsuchikawa S, Siesler HW (2003) Near-infrared spectroscopic monitoring of the diffusion process of deuterium-labeled molecules in wood. Part I: softwood. Appl Spectrosc 57(6):675–681

Whiteside PT, Luk SY, Madden-Smith CE, Turner P, Patel N, George MW (2008) Detection of low levels of amorphous lactose using H/D exchange and FT-Raman spectroscopy. Pharmacol Res 25(11):2650–2656

Acknowledgments

This work was supported by the National Science Foundation of China (51706044 and 51903131), the Natural Science Foundation of the Shandong of China (ZR2019QEM007), the Natural Science Foundation of the Jiangsu of China (BK20170666), Special Foundation of “Taishan Scholar” Construction Program and the Recruitment Program for Young Professionals in China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, Y., Jiang, W., Ben, H. et al. The preparation and characterization of chemically deuterium incorporated cotton fibers. Cellulose 28, 5351–5361 (2021). https://doi.org/10.1007/s10570-021-03869-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03869-9