Abstract

In-situ preparation of silver nanoparticles (AgNPs) into plasma-pretreated cotton substrates adds novel functional properties and expands their potential applications. Herein, we report a new approach toward the assembly of multifunctional coated technical textiles. AgNPs was in-situ prepared onto plasma-pretreated cotton fibers using the simple pad-dry-cure method to impart ultraviolet protection, brilliant colors, antimicrobial and photocatalytic self-cleaning properties. AgNPs was produced by thermal reduction of excess Ag+ from an aqueous solution of silver N-(2-ethylhexyl)carbamate on the fibrous cotton surface at 130 °C. The immobilization of the generated AgNPs onto the fibers was improved by plasma activation. Both morphology and elemental content of the treated fabrics were investigated by Fourier-transform infrared spectroscopy, energy dispersive X-ray analysis and scanning electron microscopy (EDX-SEM). The morphology of the generated AgNPs was also investigated by means of transmission electron microscopy (TEM). The generated AgNPs exhibited a homogeneous distribution and high depositing density with a nanoparticle size between 35 and 80 nm. AgNPs incorporated onto cotton fibers endowed with brownish-yellow color for plasma-untreated fibers and brown for plasma-pretreated fibers. The colorfastness and color strength of the AgNPs-coated fabrics were explored. The colored cotton fibers demonstrated persistent antimicrobial performance to S. aureus, E. coli and C. albicans pathogens. AgNPs/cotton displayed excellent photocatalysis and self-cleaning properties to the photochemical decomposition of methylene blue.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

High performance technical textiles are smart materials designed to present significant functionalities toward an improved quality of life (Revaiah et al. 2020; Yasin and Sun 2019). Nanotechnology has been an important, globally emerging and creative practice for a variety of industrial sectors (Shaheen et al. 2016; Abdelgawad et al. 2017; Hussein et al. 2018; Rehan et al. 2018a; El-Naggar et al. 2019; Elshaarawy et al. 2019; Youssef et al. 2019). The application of nanotechnology and nanomaterials in the production of high performance technical textiles can be interpreted with regard to the highly surface area to volume ratio resulting in an improved material activity, lesser cost, less utilization of chemicals, lower consumption of energy as well as lower environmental impacts (Jayathilaka et al. 2019; Abdelrahman et al. 2020; Vigneshwaran and Arputharaj 2020). In addition, the highly surface area to volume ratio results in lesser effects on the textile original mechanical and physical characters, such as handling, strength and air permeability. Recently, the application of metal and metal oxide nanoparticles (NPs) in technical textile manufacturing has been employed to impart novel functionalities (Lund et al. 2018). In technical textiles, a fiber/fabric surface may provide multiple functionalities, such as better color strength brilliant colors, flame-retardant, antimicrobial activity, water-repellent, anti-static, self-cleaning, thermal stability and UV protection as well as other healthcare and hygiene purposes (Yuranova et al. 2006; Textor and Mahltig 2010; Petkova et al. 2014; Abdelrahman and Khattab 2019; Khattab et al. 2019). Such characteristics lead to increasing the fabric's versatility. There have been various techniques reported for the immobilization of metal oxide NPs onto textile fibers, such as exhaustion, dip-coats, pad-batch, sol–gel and sonochemical coating (Perera et al. 2013; Mitrano et al. 2014; Pulit-Prociak et al. 2016). The exhaustion procedure can be recognized as an adsorption of a definite substance into the fibrous textile matrix from aqueous bath through a padding process. Therefore, the concentration of the adsorbed substance in the aqueous medium gradually decreases considering the rate of exhaustion as a function of time. The exhaustion technique has been reported as one of the most utilized adsorption approaches with the capability to provide a uniform distribution of metal oxide NPs as well as being an appropriate method for the simultaneous immobilization of NPs and dyes into the fibrous textile matrix to accomplish a concurrent colored and antibacterial fabric as an effective one-step procedure (Khalil-Abad et al. 2009; OhadiFar et al. 2020). There have been varieties of techniques that have been reported for the posttreatment or in-situ preparation of metal and metal oxide NPs into the surface of fibrous textile matrix. Metal and metal oxide NPs have been immobilized into the fibrous textile matrix through spinning procedure, as well as exo- situ or in-situ preparation procedures of the nanoparticles onto the fiber/fabric surface (Tao et al. 2016; Islam et al. 2018; Rehan et al. 2018b). In-situ preparation of metal and metal oxide NPs into a textile matrix has been recognized recently as a highly favored technique posttreatment as the in-situ method is distinguished by lower time consumption, lesser energy and lower usage of chemicals. Moreover, it has offered better control of the deposition process (Magesh et al. 2018; Rehan et al. 2019).

The application of metallic silver nanoparticles (AgNPs) in technical textile industry has been recently growing (Hebeish et al. 2011, 2014; Yan et al. 2016; El-Naggar et al. 2018; Rehan et al. 2018a; Zhou and Tang 2018; Elshaarawy et al. 2019). Both of ultraviolet shielding and antimicrobial activity are the main functional characteristics under inspection for AgNPs-based finished technical textiles. AgNPs have been utilized to offer medical dressings owing to its antimicrobial activity for extended time periods against a variety of pathogenic organisms (Hebeish et al. 2011, 2014; Yan et al. 2016; Xu et al. 2017; El-Naggar et al. 2018; Rehan et al. 2018a; Shabbir and Mohammad 2018; Elshaarawy et al. 2019). Both of AgNPs and Ag+ have been proved to be very effective antimicrobial substances by damaging the bacterium DNA and RNA, and accordingly inhibiting their replication. In addition, the application of AgNPs on textile fibers has been beneficial due to the presence of surface plasmons that impart distinctive colors depending on their shape and size (Liu et al. 2014). Up to date, silver nanoparticles with varied morphologies (spherical, cubic, rods or wires) and sizes (3–100 nm) can be generated by either the bottom-up or top-down technique. Currently, the development of novel nanomaterials for textile finishing is of great significance to provide functional textile fibers (Butola and Verma 2019; Haslinger et al. 2019). In textile finishes, the thermal reduction of organometallic silver carbamate complex can be utilized to generate AgNPs as photocatalytic and bactericidal material on textile fibers (Kwak et al. 2015a, b; Kim et al. 2018). The thermal reduction has been recognized recently as a facile, cost-effective and direct approach for reducing silver ions in an aqueous media into Ag0 by direct excitation of Ag+ in the precursor solution of silver N-(2-ethylhexyl)carbamate (Kwak et al. 2016). The thermal reduction approach has been widely utilized in different media, such as fibers, polymer films and glasses (Kim et al. 2017). Cellulose has been a well-known natural polymer that has been utilized extensively in a variety of applications, such as textiles, household appliances, cosmetics and medical purposes. Cellulose is characterized by good mechanical properties, radiation resistant and high stability (Almeida et al. 2018; Du et al. 2019; Fu et al. 2019; Kamel and Khattab 2020). Cotton particularly is the most common medical dressing due to its ability to adhere well to wounds as well as its high absorption capacity of wound fluids. Considering the medical applications, the enhancement of cotton antimicrobial performance is an essential requirement. Thus, several modification techniques have been developed to enhance the antimicrobial activity of cotton fabrics (Czaja et al. 2007; Wang et al. 2017). The poor binding ability of NPs to cellulose is a major problem that can be defeated by plasma-activation of cotton fabrics (Gorjanc et al. 2018; Yang et al. 2018; Nguyen-Tri et al. 2019). Plasma activation via oxidation and etching is capable to motivate new polar groups, including –O–C=O, –O–O–, C=O,–C–OH, –COOH and C–O, which facilitate stronger binding to NPs (Wang et al. 2016; Zhang et al. 2017).

Silver carbamate has been utilized recently to generate AgNPs without residual inorganic ions by a facile thermal reduction procedure. This approach enables lower reaction time, high reaction rate, enhanced reaction selectivity and rapid volumetric heating (Kwak et al. 2015a, b; Kim et al. 2018). In-situ preparation of AgNPs onto plasma-pretreated cotton fibers via thermolysis of silver N-(2-ethylhexyl) carbamate has not been reported yet. In this study, we describe for the first time, to the best of our knowledge, the in-situ and facile development of AgNPs immobilized onto plasma-pretreated cotton fibers. Different characterization methods were applied to examine if AgNPs were successfully immobilized onto plasma-activated cotton fibers. The colored cotton fibers immobilized with AgNPs offer potential multifunctionalities, including self-cleaning, antimicrobial and UV protection. Those multiple functionalities were introduced employing a facile green one pot thermal reduction technique of cotton fibers coated with organometallic silver carbamate complex. The influence of pad-dry-cure and thermal reduction on the optical and thermal properties of the treated fibers was explored. The morphology was studied by Fourier-transform infrared spectroscopy (FT-IR), transmission electron microscopy (TEM), scanning electron microscope (SEM) and energy dispersive X-ray (EDX) analysis. The thermal reduction of silver N-(2-ethylhexyl)carbamate employed for the preparation of AgNPs is an interesting method owing to its excellent selectivity, versatility and in-situ incorporation of AgNPs onto the surface of cellulose fibers. The colorfastness performance and tinctorial strength were also assessed.

Experimental

Materials and reagents

Bleached and mercerized cotton fabric was kindly supplied by Misr Helwan Spinning and Weaving Industry (Egypt). Methylene blue (MB) was obtained from Sigma-Aldrich (USA). A solution of 2-ethylhexylcarbamic acid silver(I) salt, or known by silver N-(2-ethylhexyl)carbamate, was synthesized depending on formerly reported literature procedure (Kwak et al. 2015a, b; Kim et al. 2018). The nonionic detergent, hexadecyloctaglycol, was obtained from Sigma-Aldrich (USA). 3-Triethoxysilyl-1-propanethiol (97%) was supplied by Aldrich (Germany). All materials and substrates were employed as received without any additional purification.

Oxygen plasma treatment

Low pressure oxygen plasma (13.56 MHz) equipment was utilized to activate the cotton fabric (7.5 × 15 cm) (Ahmed et al. 2020). The fabric was exposed to plasma for 3 min at a power of 400 W, gas flow rate of 200 cm3/min, and a constant pressure at 3 × 10–3 mbar. A negative charge was created on the fabric surface due to the production of O–O− and –COO− substituents by the atomic and ionized oxygen generation in the plasma cavity during activation course.

In-situ synthesis of AgNPs onto plasma-(in)activated cotton fibers

Both plasma-treated and plasma-untreated cotton fabrics (7.5 × 15 cm) were immersed in an aqueous solution of the nonionic detergent (hexadecyloctaglycol, 10 mmol), and then subjected to sonication for 30 min to get rid of oil and impurities. The fabrics were air-dried and washed with water. The samples were dipped in an acetone solution of 3-triethoxysilyl-1-propanethiol (1.0%) for 24 h to result in hydrolysis the triethoxysilanes to the corresponding silanols and to be adsorbed onto the fabric surface via forming hydrogen bonds. The fabrics were cured at 75 °C for 30 min to produce a monolayer of 3-triethoxysilyl-1-propanethiol on the fabric surface. The fabrics were rinsed with distilled water to get rid of the excessive quantities of 3-triethoxysilyl-1-propanethiol. The dried fabrics were then dipped in a range of silver carbamate solutions at some selected concentrations (0.1, 0.5, 1.0, 2.0 and 4.0 wt%; which were denoted as Cot-AgNPs-1, Cot-AgNPs-2, Cot-AgNPs-3, Cot-AgNPs-4 and Cot-AgNPs-5, respectively), and then subjected to sonication for 15 min, followed by padding. The fabrics were finally squeezed and cured in an oven at 130 °C for 5 min. For comparison, the same above described procedure was applied on plasma-untreated cotton fabrics. Figure 1 displays the molecular structures of silver N-(2-ethylhexyl)carbamate and 3-triethoxysilyl-1-propanethiol.

Analytical characterization

Fourier-transform infrared spectroscopy (FT-IR) was applied to study the functional groups on the plasma-cotton fibers using Shimadzu 8400-S spectrophotometer. The transmittance FT-IR spectrum was recorded in the spectral range of 4000–400 cm−1 with a resolution of 4.0 cm−1. Both morphology and size of the generated AgNPs was monitored using transmission electron microscopy (TEM). TEM image of the generated AgNPs was studied using JEOL-1230 (Japan) at an acceleration voltage of 100 kV. Because TEM can only be applied on a dispersed solution, the plasma treated cotton fabric (Cot-AgNPs-5) was subjected to washing and centrifuging. The fabric was removed away from the generated dispersion filtrate, which was then homogenized for 15 min. A drop of AgNPs suspension was utilized on a copper grid comprising a film of carbon. The surface morphology of the resultant cotton fabrics was explored on field emission scanning electron microscopy (FE-SEM, Quanta/FEG250, Czech Republic) connected to energy dispersive X-ray (EDX) spectroscope to investigate the elemental content at an acceleration voltage of 20 kV and a work distance of 21 mm.

Colorimetric properties

The UV–VIS absorbance spectra, tinctorial strength (K/S) and CIE Lab color space parameters were reported employing Hunter Lab spectrophotometer 600 with a pulse xenon lamp (UltraScanPro, United States) associated with a 10° viewer, d/2 geometry, D65 illuminant and a 2 mm area. All data were collected at a maximum wavelength of 375 nm for plasma-untreated fibers and 382 nm for plasma-pretreated fibers. L* is lightness from white (100) to black (0), a* is red (+) to green (−) ratio and b* is yellow (+) to blue (−) ratio.

Color fastness properties

The color fastness against light (ISO/105-B02:1988), rubbing (ISO/105-X12:1987), perspiration (ISO/105-E04:1989) and washing (ISO/105-C02:1989) were tested depending on AATCC standard ISO procedures. The fastness to light was evacuated depending on the international blue-scale (1–8), whereas the fastness to rubbing, perspiration and washing was assessed depending on the international grey-scale (1–5), with scale 1 is the poorest, and scales 8 and 5 are the best.

Photocatalysis and self-cleaning examination

The photocatalysis and self-cleaning performance of AgNPs immobilized onto cotton fibers was evaluated by examining the decomposition of MB under either visible or ultraviolet light. The visible light (λ > 410 nm) was supplied by a fluorescent light lamp (TCL/AC, 50 Hz, 18 W, 230 V) with a light intensity of 44 μW/cm2 and at a distance of 5 cm from the cotton sample. Three drops of a 50 mL of methylene blue (10 mg/L; pH ~ 6.5) were added at the middle of the cotton sample (0.5 g), which was then left in the dark for 30 min under ambient conditions to allow an adsorption/desorption equilibrium among methylene blue and cotton fibers. The fabric was then subjected to the light source (ultraviolet or visible light) at different time periods. After every given time interval, the decreased total content of methylene blue on the treated fabric was analyzed by monitoring the color change of the treated area on the fabric using Hunter Lab spectrophotometer 600 with a pulse xenon lamp (UltraScanPro, United States). The total content of methylene blue was identified depending on the changes in the maximum absorbance at 665 nm in the ultraviolet absorbance spectra versus irradiation time. The photocatalysis-based degradation of MB was identified employing Eq. (1).

where C0 is the initial total content of MB, Ct is the total content at different time intervals of irradiation, A0 is the initial absorbance and At the changeable absorbance at different time intervals of irradiation.

Photographic images of plasma-untreated or plasma-pretreated cotton fabrics immobilized with AgNPs (under and after treatment with methylene blue) were taken by Canon A710-IS camera.

Assessment of antimicrobial activity

The antimicrobial performance was studied using C. albicans as fungus, S. aureus as Gram-positive and E. coli as Gram-negative pathogenic microorganisms. The antimicrobial examination was carried out according to standard Disc agar plate approach. The tested pathogenic microorganisms were grown on nutrient agar cultures, which were diluted using sterilized distilled water to 107–108 CFUs/mL. Each culture (1 mL) was then employed to inoculate a 1 L Erlenmeyer flask enclosing a solidified agar media (250 mL). Those media (25 mL) were then placed in sterilized Petri dishes with a diameter of 10 cm. Blank and treated cotton fabrics with a diameter of 10 mm were located on the surface of inoculated Petri dishes under sterilized circumstances. The plates loaded with the tested bacteria were incubated for 24–48 h. The antimicrobial activity was reported as the inhibition zone diameter (including the disc itself), which appeared around the cotton fabric samples.

UV blocking measurements

The UV shielding character of the cotton samples was assessed by recording the ultraviolet protection factor (UPF). The UPF assessment of the cotton samples depended on AS-NZS 4399:1996. The UPF computation system of UV–visible spectrophotometer was applied using AATCC 183:2010 UVA standard transmittance test method.

Results and discussion

In-situ synthesis of AgNPs on cotton fibers

Plasma-activated cotton fabrics were activated by low pressure plasma equipment. The generated fabrics were then treated consecutively with solutions of 3-triethoxysilyl-1-propanethiol and silver N-(2-ethylhexyl)carbamate via pad dry cure process. The samples were initially thiolated by a silane coupling to produce a 3-triethoxysilyl-1-propanethiol monolayer. The plasma-treated textile substrates were dipped in an aqueous nonionic surfactant, sonicated, and dried under ambient conditions. The cotton fabrics were immersed in an aqueous 3-triethoxysilyl-1-propanethiol to perform a hydrolysis process of the triethoxysilane into the corresponding silanols (Si–OH), which can be adsorbed easily onto the cotton surface by forming hydrogen bonds. The fabrics were cured at 75 °C to generate a 3-triethoxysilyl-1-propanethiol monolayer onto the cotton surface as a result of silanol condensation with the hydroxyl terminal groups at the fabric surface. The dried samples were immersed in silver N-(2-ethylhexyl)carbamate solutions at different concentrations (0.1 (Cot-AgNPs-1), 0.5 (Cot-AgNPs-2), 1 (Cot-AgNPs-3), 2.0 (Cot-AgNPs-4), and (Cot-AgNPs-5) 4.0 wt%), sonicated, padded, and then thermally reduced at 130 °C to convert Ag+1 to Ag0. In this thermal reduction process, the organometallic silver N-(2-ethylhexyl)carbamate complex is thermally decomposed to produce metallic silver as demonstrated by Eq. (2).

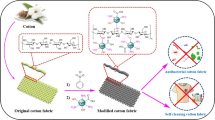

This process shows a simple reduction process of silver N-(2-ethylhexyl)carbamate to AgNPs via thermal decomposition, which is associated with releasing carbon dioxide and producing 2-ethyl-1-hexylamine. The synthesis of AgNPs immobilized onto cotton fibers via thermolysis using silver N-(2-ethylhexyl)carbamate complex is represented by schematic diagram shown in Fig. 2. The color of the reaction system was found to change from colorless to brownish-yellow for plasma-untreated fibers and from colorless to brown color for plasma-treated fibers indicating a reduction of Ag+ to metallic silver immobilized onto cotton fibers. It has been well-known that AgNPs exhibit a strong absorption band due to the effect of surface plasmon resonance due to interacting the tiny metal NPs with an electromagnetic radiation motivated by light. During the thermal decomposition, the silver N-(2-ethylhexyl)carbamate solution was monitored to gradually shift from colorless to brownish-yellow (plasma-untreated) or from colorless to brown (plasma-treated) due to the increase in the absorption peak at short wavelengths of the visible light range as a result of the plasmon effect. Additionally, the color change introduced a primary evidence of thermal metallization. For comparison, the same preparation/immobilization procedure of silver nanoparticles was performed on plasma-untreated cotton fabrics.

UV–VIS absorption spectra were explored to investigate the in-situ deposition of AgNPs on the optical properties of plasma-inactivated and plasma-activated cotton substrtaes (Fig. 3). Compared to blank fabric, the plasma-inactivated cotton samples modified with AgNPs exhibited strong absorption intensity (375 nm) in the ultraviolet electromagnetic region. Plasma-activated cotton samples modified with AgNPs displayed stronger absorbance intensity in the ultraviolet electromagnetic range at 382 nm. Thus, a little shift (7 nm) was monitored between plasma-activated (382 nm) and plasma-inactivated (375 nm) cotton samples. Increasing the concentration of the silver carbamate aqueous solution did not affect on the position of the maximum absorption wavelength; however, a little increase in the absorption intensity was monitored. This could be assigned to the surface plasmon resonance of AgNPs generated by thermal reduction of the organometallic silver carbamate complex immobilized into cotton fibers. Surface Plasmon resonance is an exciting process of electrons in the conduction band near the AgNPs surface.

Morphological characterization

The morphologies of the treated fabrics were investigated by means of scanning electron microscopy (SEM) images as displayed in Fig. 4a–j. SEM images of blank, plasma-inactivated and plasma-activated fabrics immobilized with AgNPs, which were compared to assess the immobilization of AgNPs. Figure 4a, b showed relatively smooth plasma-untreated blank fibers, while a surface engraving was detected on the surface of the plasma-treated fibers as demonstrated in Fig. 4g–j. Granular-shaped and sub-microscale structures were detected on the surface of plasma-untreated fibers, while silver nano-scaled particles were monitored for the plasma-treated fibers. The plasma modification of the fabric surface resulted in increasing the surface roughness which was much more accentuated than that of the blank cotton fabric. Plasma-inactivated cotton fabric treated with AgNPs (Fig. 4c–f) displayed a surface covered with a thin film of heterogeneous and continuous AgNPs with irregular and uneven aggregations. On the other side, plasma-pretreated cotton fabric and immobilized with AgNPs (Fig. 4g–j) displayed a surface coated with a thin film of uniform and continuous AgNPs with regular and even distribution. Due to the poor binding of AgNPs to the surface of the plasma-untreated cotton fibers, an agglomeration of AgNPs was monitored leading to the formation of microparticles. The monitored grooves and engravings on the surface of the plasma-activated cotton were monitored to be helpful for the strong binding of AgNPs onto the cotton surface through those engravings and grooves. The size distribution of the generated AgNPs onto plasma-pretreated fibers was measured by Images J software indicating an average size of 35–80 nm, which as comparatively large in diameter owing to the continuous growth of AgNPs during thermal reduction. Increasing the concentration of the silver carbamate aqueous solution did not affect on the average particle diameter; however, a higher depositing density was monitored as shown in Fig. 4i, j. AgNPs with high depositing density were accomplished onto the cotton surface even at the lower concentrations of silver carbamate.

SEM images of blank cotton (a, b), plasma-inactivated cotton at lowest concentration of AgNPs (c, d), plasma-inactivated cotton at highest concentration of AgNPs (e, f), plasma-activated cotton at lowest concentration of AgNPs (g, h) and plasma-activated cotton at highest concentration of AgNPs (i, j)

Both morphology and size distribution of the produced AgNPs onto plasma-pretreated fibers was also studied by transmission electron microscope (TEM). To generate a suspended solution of AgNPs, the plasma treated cotton fabric (Cot-AgNPs-5) was subjected to washing with distlled water and the washing water was collected and submitted for TEM evaluation. Figure 5 shows TEM of AgNPs extracted from plasma treated cotton fabric which indicates that the prepared NPs has an average size of 35–80 nm affirming that the deposited AgNPs are very small size with well distribution.

Plasma activation of cotton fabrics via oxidation and etching has been able to stimulate new polar substituents, including –O–C=O, –O–O–, C=O, –C–OH, –COOH and C–O, with the ability to facilitate better binding to AgNPs (Airoudj et al. 2015; Ahmed et al. 2020). Figure 6 displays FT-IR spectrum of plasma-activated cotton sample. The broad band monitored at 3275 cm−1 was attributed to the overlapped hydroxyl groups from the C–OH and COOH substituents. The band at 1720 cm−1 was attributed to the carbonyl groups. The absorption bands at 1414 and 1042 cm−1 were assigned to the ether bonds from C–O and –O–O–, respectively.

Determination of elemental content

The energy dispersive X-ray (EDX) analytical technique was performed to offer a comprehensive qualitative description of the prepared AgNPs/cotton samples. The changes in elemental composition of blank, plasma-untreated and plasma-treated cotton fabrics owing to the in-in-situ synthesis and immobilization of AgNPs were explored by the EDX spectra as demonstrated in Fig. 7. EDX analyses of pristine and plasma-treated fibers enclosed carbon and oxygen signals, while EDX of plasma-treated fibers incorporated with AgNPs enclosed carbon, oxygen and silver signals. The presence of silver confirmed the incorporation of AgNPs onto the fabric surface. After plasma treatment, the carbon total content decreased, whereas the oxygen total content was found to increase. This could be attributed to the plasma generated oxygen-containing polar groups, including –O–C=O, –O–O–, C=O, C–O, –COOH or –COH. These oxygen-containing substituents could be a key explanation for a hydrophilic enhancement. The improvement of the hydrophilic performance made the fabric more accessible by the pad dry cure of 3-triethoxysilyl-1-propanethiol and silver N-(2-ethylhexyl)carbamate, and consequently by the colloidal AgNPs. The oxygen total content of the plasma-untreated and AgNPs-immobilized fibers was lower than that in the plasma-pretreated and AgNPs-immobilized fibers. On the other hand, the carbon total content on the plasma-untreated and AgNPs-immobilized sample was higher than that in the plasma-pretreated and AgNPs-immobilized fibers. This could be attributed to the more generated oxygen-containing substituents on the fabric surface due to plasma treatment. Those negatively oxygen-containing substituents, such as –COO− and C–O−, were able to produce electrostatic attraction with the positively charged (Ag+). In all cases of treatment including AgNPs-immobilized plasma-untreated and plasma-pretreated fabrics, a higher depositing density was monitored upon increasing the concentration of AgNPs by increasing the concentration of silver carbamate aqueous solution. Hence, we can conclude that AgNPs was successfully synthesized and immobilized directly onto the fabric surface via facile heating approach of silver carbamate.

Antimicrobial activity

The antimicrobial properties of both plasma-untreated and plasma-treated fibrous cotton matrix and loaded with AgNPs were investigated using E. coli and S. aureus bacterial pathogens as well as C. albicans fungus as pathogenic microbes. This was performed by the standard Disc agar plate approach. The antimicrobial activity was recorded by the inhibition zone diameter (including the disc itself), which appeared around the cotton fabric sample. The aim of the current work is to develop multifunctional cotton fibers. Thus, the antimicrobial activity for the produced cotton fabrics was evaluated. Figure 8 demonstrates the antimicrobial performance of the blank cotton as well as plasma-untreated and plasma-pretreated cotton fibers at different concentrations of silver carbamate. The lowest and highest concentrations of silver carbamate (Cot-AgNPs-1 and Cot-AgNPs-5) were chosen for the assessment of antimicrobial activities. The blank cotton fabric does not show any obvious antimicrobial properties. On the other side, all cotton fabrics immobilized with AgNPs exhibited excellent antimicrobial activity against C. albicans fungus, as well as S. aureus and E. coli as pathogenic microbes. Both plasma-untreated and plasma-pretreated cotton samples (Cot-AgNPs-1 and Cot-AgNPs-5) demonstrated higher antimicrobial activity against C. albicans and E. coli compared to S. aureus. However, the plasma-pretreated cotton samples showed a better antimicrobial activity compared to plasma-untreated samples. Thus, the prepared cotton fabrics can be utilized for variety of applications, such as wound dressing, packaging, protective and hygiene textiles. The antimicrobial activity of the treated cotton confirmed the existence of AgNPs embedded into the fabric as the antimicrobial activity was significantly enhanced compared to the blank cotton. However, a better antimicrobial activity was detected for the AgNPs loaded plasma-treated fibrous cotton matrix compared to the AgNPs loaded plasma-untreated samples. This could be attributed to the better incorporation of the silver nanoparticles within the grooves and engraves generated by plasma on cotton surface. In the cases of AgNPs-immobilized plasma-pretreated fabrics, an enhanced antibacterial activity was monitored upon increasing the concentration of AgNPs by increasing the concentration of silver carbamate aqueous solution. AgNPs have been described as an antimicrobial substance for a wide spectrum of pathogens, involving fungi, bacteria and yeast as well. The realistic toxicity mechanism of AgNPs is still partly explained. However, several mechanisms have been reported for the antimicrobial performance of AgNPs as follows: (1) adhering AgNPs to the pathogen surface affects on its properties because AgNPs have been reported to degrade the molecular structure of the lipopolysaccharide which accumulated within the pathogen outer membrane by generating pits and leading to increasing the membrane permeability; (2) diffusion of AgNPs into the pathogenic cell leads to DNA damaging; (3) dissolution of AgNPs results in releasing the antimicrobial Ag+; and (4) interaction of AgNPs with the pathogenic proteins by combining the enzymatic –SH groups to result in inactivation of the pathogenic proteins.

Generally, it has been established that the increase in the surface area of AgNPs results in increasing their antimicrobial activity. Therefore, the microcidal activity can be improved by presenting more metallic silver onto the fabric surface. It has been thought that Ag0 has the same action mechanism as Ag+ by creating a redox imbalance which in turn results in an extensive death of pathogens. It has been explained that the release of metallic silver is controllable by an oxidation mechanism at the AgNPs surface preventing the loss of the AgNPs from the surface of the cotton fabric. Furthermore, the antimicrobial activity of AgNPs on the fabric surface could be assigned to the plasmon resonance effect arising from the AgNPs at ~ 382 nm. On the fabric surface, the electrons injected from AgNPs are trapped by molecular oxygen, whereas other reactive radical species including ·OH, ·OOH, and O2·− are formed. The chemical content of the bacterial cell-wall are then exposed to an oxidation process by those reactive species.

Reactions comprising electrons in the conduction band:

Reactions comprising holes in the valance band:

In addition, Ag0 can enhance the antimicrobial performance by producing reactive oxygen species:

However, exhaustive studies on the release of silver and the antimicrobial mechanism for a variety of products are still needed.

Photocatalytic properties

Methylene blue (MB) has been a suitable model for exploring the photocatalytic properties because it can be easily photo-reduced by AgNPs. It has a reduction potential (E0red) of 0.011 V (normal hydrogen electrode). The photocatalysis and self-cleaning of AgNPs immobilized onto the surface of plasma-untreated and plasma-pretreated fibers can be assessed by measuring the MB decomposition on a fabric surface under either visible or ultraviolet light (Fig. 9). The self-cleaning effectiveness was assessed by monitoring the variations in the total content of the methylene blue dye on the fabric surface as a function of UV/visible light with time. The total content of MB dye on the fabric surface was associated with the color change from blue back to brownish-yellow color for plasma-untreated fibers and brown color for plasma-pretreated fibers (Fig. 10). The changes in UV–VIS absorption spectra of methylene blue on the fabric surface were measured for Cot-AgNPs-3 under either UV or visible light for 24 h (Fig. 11). The absorbance intensity of methylene blue chromophore at 665 nm was monitored to decrease due to decreasing its concentration as a result of its decomposition. The self-cleaning effectiveness was then assessed by monitoring the variations in the total content of the methylene blue dye (C/C0) as a function of UV/visible light with time. No photocatalytic activity was monitored for the blank cotton fabric because no changes were detected in the color of the methylene blue chromophore during the irradiation process under either visible light or UV irradiation. This confirmed that the blank cotton itself exhibits no photochemical degradation ability. The inclusion of AgNPs onto plasma-untreated surface of cotton matrix introduced an improvement in the photochemical degradation process of the methylene blue dye under UV light. However, it did not show a complete photochemical degradation of MB on the surface of the cotton substrate. The inclusion of AgNPs onto plasma-untreated fibers demonstrated a negligible photochemical decomposition under visible light as only a very little decrease in the total content of MB was detected. Such little decrease in the total content of the methylene blue dye could be assigned to the adsorption and diffusion of MB into the fibrous cotton matrix. The immobilization of AgNPs onto the plasma-activated fibers stimulated a full photochemical decomposition of MB dye after exposure to either UV or visible light. No blue color was monitored on the fabric surface, which proved complete photochemical decomposition of MB. The higher photochemical decomposition of MB for the plasma-activated fibers compared to plasma-inactivated ones suggested that treatment with plasma is an efficient technique to alter the optical response from UV to visible light and to improve the visible light stimulated photocatalysis.

The photocatalytic results were also collected before and after washing under similar conditions. The photochemical decomposition rates of MB for both of AgNPs loaded plasma-inactivated and plasma-pretreated fibers were found to decrease after washing. Nonetheless, they remained much more than the blank cotton fibers. This suggests high binding between AgNPs and the fabric surface. After washing, the photochemical decomposition rate for AgNPs loaded onto plasma-treated fibers was higher than that for plasma-untreated fibers under either ultraviolet or visible light. Therefore, the treatment with plasma enhanced the self-cleaning activity of the cotton fabric. The beneficial effects of AgNPs deposition on the photocatalysis behavior of plasma-activated fibers could be assigned to the better immobilization of AgNPs onto the plasma-activated fibers bearing grooves and engravings. Depositing Ag0 is anticipated to display various effects on the photocatalysis process via different proposed mechanisms. These metallic silver species work individually or concurrently relying on the photoreaction conditions as follows: (1) enhancing the electron–hole separation by working as electron traps and transporting those electron trapping species to the adsorbed oxygen which acts as electron acceptor species; (2) improving the adsorption of MB onto the fabric surface; and (3) widening the light absorbance spectra to the visible light region and enhancing the surface electron excitation by the AgNPs plasmon resonance effect upon excitation by visible light. In addition to these roles performed by AgNPs, the photochemical decomposition on a fabric surface was found to go after different photocataysis pathway under either UV or visible light. Thus, different effects can be estimated and distinguished by AgNPs loaded onto the fabric surface by applying different mechanistic studies.

In case of photochemical decomposition of MB dye under UV, the deposited AgNPs slightly increases the photo-activity of cotton surface due to the effects of Ag0. When Ag0 is irradiated at λ < 360 nm, the electrons in the valence band were stimulated to move to the conduction band generating pairs of positively charged holes (h+) and negatively charged electrons (e−). These reactive species has an important role to commence an oxidation/reduction reaction. The generated electron–hole pairs can stimulate the production of reactive oxygen-containing species, such as hydroxyl radicals (OH·) and superoxide ions (O2−·). In the presence of those reactive oxygen-containing species, holes formed in the valence band and electrons formed in the conduction band, silver can then stimulate the degradation of MB by participating in a sequence of oxidative reactions. Hence, the charge separation on silver ions is a critical factor to influence the efficiency of the photochemical decomposition. Ag0 functions as electron traps. Once two compounds of different work functions getting in contact with each others, the Schottky barrier is produced and electrons move from the compound of lesser work function to the compound of higher work function. The photochemical decomposition of MB can be assigned to the strong oxidative effect of the reactive oxygen species. After a sequence of reactions, MB is lastly degrades into the colorless substances, including CO2, NO3−, NH4+ and SO42−. For AgNPs-immobilized plasma-pretreated fabric surface under ultraviolet irradiation, an extensively enhanced UV protection was monitored upon increasing the concentration of AgNPs by increasing the concentration of silver carbamate aqueous solution from 0.1 wt% (C/C0 variation of MB after two hours is ~ 2.09) to 4.0 wt% (C/C0 variation of MB after two hours is ~ 0.09).

The photochemical decomposition of MB on AgNPs under visible light showed that the effect of metallic silver led to increasing the photocatalytic activity of AgNPs. Metallic silver acts only as electron transport mediators. Metallic silver can be photo-excited as a result of its surface plasmon resonance. After that, the photo-created electrons are inserted into the oxygen species adsorbed onto the fabric surface. Therefore, the formation of hydroxyl and superoxide radical species in the existence of oxygen was accelerated, and accordingly participated in the enhancing the photocatalytic performance. Although the mechanisms of AgNPs as a photocatalytic agent under ultraviolet and visible light are dissimilar, the hetero-structure of silver nanoparticles is the major reason for the enhancement of the photocatalytic activity.

UV blocking properties

The ultraviolet protection factor (UPF) of the treated fabrics was measured to determine the UV-protection activity of the cotton substrates (Table 1). The UPF values of the plasma-pretreated cotton fabrics immobilized with AgNPs were much higher than that of the plasma-untreated samples. Additionally, the UPF values of both plasma-untreated and plasma-pretreated cotton samples were found to increase with increasing the concentration of the silver carbamate aqueous solution. This could be ascribed to the high ultraviolet absorbance efficiency of AgNPs.

Coloration measurements and colorfastness properties

The incorporation of AgNPs onto cotton surface afforded brownish-yellow color for the plasma-untreated substrates and brown color for the plasma-pretreated substrates. The coloration measurements, including K/S and CIE Lab (L*, a*, b*) color coordinates, were applied to explore the dyeing process of cotton fibers by AgNPs. The original color of native cotton is white with elevated L* (96.53), low negative a* (-0.07) and small positive b* (1.27). Depending on plasma treatment, AgNPs-loaded cotton displayed significantly dissimilar L*, a*, and b* values as displayed in Table 2. The highly increased color strength for plasma-pretreated substrates compared to plasma-untreated fibers indicates better K/S of plasma-pretreated cotton fibers. In both cases of plasma-pretreated and plasma-untreated fibers, a significant decrease in L* was monitored to indicate darker shade upon the generation of AgNPs onto the fiber surface. In addition, a higher change for L* was monitored for plasma-pretreated substrates compared to plasma-untreated fibers. In general, the increased a* proves redder shades, while the increased b* proves yellower shades. On the other side, the decreased a* proves a more green color, while the decreased b* proves bluer color. Accordingly, the decreased positive a* and increased positive b* values of the AgNPs-loaded plasma-untreated fibers represents an alteration in shade to a more brownish-yellow color. On the other side, the increased positive a* and decreased positive b* of AgNPs-loaded plasma-pretreated fibers represents a color shift to brown. The AgNPs-treated cotton substrates exhibited satisfactory to very good fastness to perspiration, washing, rubbing and light (Table 3). However, better colorfastness was monitored for the AgNPs-loaded plasma-pretreated fibers, which could be assigned to the better attachment of AgNPs to plasma-activated fibers as a result of the plasma generated grooves and engravings.

Conclusions

In summary, we developed a novel technique for the preparation of smart cotton fabric with multiple functional characteristics. Cotton fabric was subjected to plasma-treatment followed by coating with silver nanoparticles (AgNPs, 35–80 nm) using a facile and inexpensive in-situ pad dry cure procedure. The pad dry cure process was applied on a solution of silver carbamate complex, and then thermally reduced at 130 °C. In the current study, we report the production, characterization and utilization of cotton fabrics immobilized with AgNPs as a photocatalytic self-cleaning, UV blocking and antimicrobial agent. AgNPs was synthesized in-situ and deposited directly onto plasma-treated cotton substrates by thermolysis of silver N-(2-ethylhexyl)carbamate. The produced cotton/AgNPs displayed highly enhanced absorption in the visible light as well as high photocatalytic activity, UV blocking and antimicrobial performance compared to blank cotton. This dramatic enhancement in self-cleaning, UV blocking and antimicrobial properties could be attributed to AgNPs uniformly loaded onto the cotton surface. The consistent distribution of AgNPs on the plasma-pretreated fabric surface further enhanced the fabric properties due the plasma generated grooves and engraves allowing better attachment of silver nanoparticles to the fabric surface. Concerning the antimicrobial performance, cotton-coated with solutions of silver carbamate (0.01% or 0.1%) demonstrated slight antimicrobial activity. On the other side, cotton-coated with a solution of 0.5% silver carbamate established excellent antibacterial properties to S. aureus, E. coli and C. albicans. Cotton-coated with a solution of 0.5% silver carbamate showed excellent UV blocking in UVR spectrum compared to blank cotton. All treated fabrics displayed good tinctorial strength and colorfastness; however, the best tinctorial strength and colorfastness was detected for the plasma-pretreated samples due to the better attachment of silver nanoparticles to the fabric surface. This work presented an efficient procedure to prepare and incorporate AgNPs onto the surface of plasma-pretreated fibrous cotton matrix to impart high antimicrobial, UV protection, as well as photocatalysis-based self-cleaning activity under visible and ultraviolet light, making them potentially valuable as ideal multifunctional technical textiles for a variety of medical and protective purposes, such as wound dressings. Based on colorimetric measurements, the incorporation of silver nanoparticles onto cotton samples imparted bright brownish-yellow color for the plasma-untreated fibers and brown color for the plasma-treated fibers. Solid shades with an acceptable level and depth of shade were monitored. Moreover, the treated cotton fibers displayed a satisfactory to very good colorfastness to light, washing, perspiration and rubbing.

Change history

14 November 2022

A Correction to this paper has been published: https://doi.org/10.1007/s10570-022-04891-1

References

Abdelgawad AM, El-Naggar ME, Eissa WH, Rojas OJ (2017) Clean and high-throughput production of silver nanoparticles mediated by soy protein via solid state synthesis. J Clean Prod 144:501–510

Abdelrahman MS, Khattab TA (2019) Development of one-step water-repellent and flame-retardant finishes for cotton. ChemistrySelect 4:3811–3816

Abdelrahman MS, Nassar SH, Mashaly H et al (2020) Studies of polylactic acid and metal oxide nanoparticles-based composites for multifunctional textile prints. Coatings 10:58

Ahmed H, Khattab TA, Mashaly HM et al (2020) Plasma activation toward multi-stimuli responsive cotton fabric via in situ development of polyaniline derivatives and silver nanoparticles. Cellulose 27:2913–2926

Airoudj A, Ploux L, Roucoules V (2015) Effect of plasma duty cycle on silver nanoparticles loading of cotton fabrics for durable antibacterial properties. J Appl Polym Sci 132:41279

Almeida APC, Canejo JP, Fernandes SN et al (2018) Cellulose-based biomimetics and their applications. Adv Mater 30:1703655

Butola BS, Verma D (2019) Facile synthesis of chitosan-silver nanoparticles onto linen for antibacterial activity and free-radical scavenging textiles. Int J Biol Macromol 133:1134–1141

Czaja WK, Young DJ, Kawecki M, Brown RM (2007) The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8:1–12

Du H, Liu W, Zhang M et al (2019) Cellulose nanocrystals and cellulose nanofibrils based hydrogels for biomedical applications. Carbohydr Polym 209:130–144

El-Naggar ME, Shaarawy S, Hebeish AA (2018) Bactericidal finishing of loomstate, scoured and bleached cotton fibres via sustainable in-situ synthesis of silver nanoparticles. Int J Biol Macromol 106:1192–1202. https://doi.org/10.1016/j.ijbiomac.2017.08.127

El-Naggar ME, Al-Joufi F, Anwar M et al (2019) Curcumin-loaded PLA-PEG copolymer nanoparticles for treatment of liver inflammation in streptozotocin-induced diabetic rats. Colloids Surf B Biointerfaces 177:389–398

Elshaarawy RFM, Seif GA, El-Naggar ME et al (2019) In-situ and ex-situ synthesis of poly-(imidazolium vanillyl)-grafted chitosan/silver nanobiocomposites for safe antibacterial finishing of cotton fabrics. Eur Polym J 116:210–221

Fu L-H, Qi C, Ma M-G, Wan P (2019) Multifunctional cellulose-based hydrogels for biomedical applications. J Mater Chem B 7:1541–1562

Gorjanc M, Mozetič M, Vesel A (2018) Natural dyeing and UV protection of plasma treated cotton. Eur Phys J D 72:1–6

Haslinger S, Ye Y, Rissanen M et al (2019) Cellulose fibers for high-performance textiles functionalized with incorporated gold and silver nanoparticles. ACS Sustain Chem Eng 8:649–658

Hebeish A, El-Naggar ME, Fouda MMG et al (2011) Highly effective antibacterial textiles containing green synthesized silver nanoparticles. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2011.05.048

Hebeish A, El-Rafie MH, EL-Sheikh MA, et al (2014) Antimicrobial wound dressing and anti-inflammatory efficacy of silver nanoparticles. Int J Biol Macromol 65:509–515. https://doi.org/10.1016/j.ijbiomac.2014.01.071

Hussein J, El Naggar ME, Latif YA et al (2018) Solvent-free and one pot synthesis of silver and zinc nanoparticles: Activity toward cell membrane component and insulin signaling pathway in experimental diabetes. Colloids Surf B Biointerfaces 170:76–84. https://doi.org/10.1016/j.colsurfb.2018.05.058

Islam MS, Akter N, Rahman MM et al (2018) Mussel-inspired immobilization of silver nanoparticles toward antimicrobial cellulose paper. ACS Sustain Chem Eng 6:9178–9188

Jayathilaka WADM, Qi K, Qin Y et al (2019) Significance of nanomaterials in wearables: a review on wearable actuators and sensors. Adv Mater 31:1805921

Kamel S, Khattab TA (2020) Recent advances in cellulose-based biosensors for medical diagnosis. Biosensors 10:67

Khalil-Abad MS, Yazdanshenas ME, Nateghi MR (2009) Effect of cationization on adsorption of silver nanoparticles on cotton surfaces and its antibacterial activity. Cellulose 16:1147

Khattab TA, Mowafi S, El-Sayed H (2019) Development of mechanically durable hydrophobic lanolin/silicone rubber coating on viscose fibers. Cellulose 26:9361–9371

Kim T-S, Cha J-R, Gong M-S (2017) Preparation of silver-coated silk fabrics with antibacterial activity using silver carbamate and hydrogen reduction. Macromol Res 25:856–863

Kim T-S, Cha J-R, Gong M-S (2018) Investigation of the antimicrobial and wound healing properties of silver nanoparticle-loaded cotton prepared using silver carbamate. Text Res J 88:766–776

Kwak W-G, Oh MH, Gong M-S (2015a) Preparation of silver-coated cotton fabrics using silver carbamate via thermal reduction and their properties. Carbohydr Polym 115:317–324

Kwak W-G, Oh MH, Son S-Y, Gong M-S (2015b) Silver loading on poly (ethylene terephthalate) fabrics using silver carbamate via thermal reduction. Macromol Res 23:509–517

Kwak W-G, Cha J-R, Gong M-S (2016) Surface modification of polyester fibers by thermal reduction with silver carbamate complexes. Fibers Polym 17:1146–1153

Liu H, Lv M, Deng B et al (2014) Laundering durable antibacterial cotton fabrics grafted with pomegranate-shaped polymer wrapped in silver nanoparticle aggregations. Sci Rep 4:5920

Lund A, van der Velden NM, Persson N-K et al (2018) Electrically conducting fibres for e-textiles: an open playground for conjugated polymers and carbon nanomaterials. Mater Sci Eng R Rep 126:1–29

Magesh G, Bhoopathi G, Nithya N et al (2018) Tuning effect of polysaccharide chitosan on structural, morphological, optical and photoluminescence properties of ZnO nanoparticles. Superlattices Microstruct 117:36–45

Mitrano DM, Rimmele E, Wichser A et al (2014) Presence of nanoparticles in wash water from conventional silver and nano-silver textiles. ACS Nano 8:7208–7219

Nguyen-Tri P, Altiparmak F, Nguyen N et al (2019) Robust superhydrophobic cotton fibers prepared by simple dip-coating approach using chemical and plasma-etching pretreatments. ACS Omega 4:7829–7837

OhadiFar P, Shahidi S, Dorranian D (2020) Synthesis of silver nanoparticles and exhaustion on cotton fabric simultaneously using laser ablation method. J Nat Fibers 17:1295–1306

Perera S, Bhushan B, Bandara R et al (2013) Morphological, antimicrobial, durability, and physical properties of untreated and treated textiles using silver-nanoparticles. Colloids Surf A Physicochem Eng Asp 436:975–989

Petkova P, Francesko A, Fernandes MM et al (2014) Sonochemical coating of textiles with hybrid ZnO/chitosan antimicrobial nanoparticles. ACS Appl Mater Interfaces 6:1164–1172

Pulit-Prociak J, Chwastowski J, Kucharski A, Banach M (2016) Functionalization of textiles with silver and zinc oxide nanoparticles. Appl Surf Sci 385:543–553

Rehan M, El-Naggar ME, Mashaly HM, Wilken R (2018a) Nanocomposites based on chitosan/silver/clay for durable multi-functional properties of cotton fabrics. Carbohydr Polym 182:29–41. https://doi.org/10.1016/j.carbpol.2017.11.007

Rehan M, Khattab TA, Barohum A et al (2018b) Development of Ag/AgX (X= Cl, I) nanoparticles toward antimicrobial, UV-protected and self-cleanable viscose fibers. Carbohydr Polym 197:227–236

Rehan M, Barhoum A, Khattab TA et al (2019) Colored, photocatalytic, antimicrobial and UV-protected viscose fibers decorated with Ag/Ag2CO3 and Ag/Ag3PO4 nanoparticles. Cellulose 26:5437–5453

Revaiah RG, Kotresh TM, Kandasubramanian B (2019) Technical textiles for military applications. J Text Inst 111:273–308

Shabbir M, Mohammad F (2018) Multifunctional AgNPs@ Wool: colored, UV-protective and antioxidant functional textiles. Appl Nanosci 8:545–555

Shaheen TI, El-Naggar ME, Hussein JS et al (2016) Antidiabetic assessment; in vivo study of gold and core-shell silver-gold nanoparticles on streptozotocin-induced diabetic rats. Biomed Pharmacother 83:865–875. https://doi.org/10.1016/j.biopha.2016.07.052

Tao G, Liu L, Wang Y et al (2016) Characterization of silver nanoparticle in situ synthesis on porous sericin gel for antibacterial application. J Nanomater 2016:1–8

Textor T, Mahltig B (2010) A sol–gel based surface treatment for preparation of water repellent antistatic textiles. Appl Surf Sci 256:1668–1674

Vigneshwaran N, Arputharaj A (2020) Functional finishing of cotton textiles using nanomaterials. In: Advances in functional finishing of textiles. Springer, pp 43–56

Wang C, Lv J, Ren Y et al (2016) Cotton fabric with plasma pretreatment and ZnO/Carboxymethyl chitosan composite finishing for durable UV resistance and antibacterial property. Carbohydr Polym 138:106–113

Wang X, Yao C, Wang F, Li Z (2017) Cellulose-based nanomaterials for energy applications. Small 13:1702240

Xu Q, Xie L, Diao H et al (2017) Antibacterial cotton fabric with enhanced durability prepared using silver nanoparticles and carboxymethyl chitosan. Carbohydr Polym 177:187–193

J Yan, AM Abdelgawad, ME El-Naggar, OJ Rojas (2016) Antibacterial Activity of Silver Nanoparticles Synthesized In-situ by Solution Spraying onto Cellulose. Carbohydr Polym 147:500–508

Yang J, Pu Y, Miao D, Ning X (2018) Fabrication of durably superhydrophobic cotton fabrics by atmospheric pressure plasma treatment with a siloxane precursor. Polymers (Basel) 10:460

Yasin S, Sun D (2019) Propelling textile waste to ascend the ladder of sustainability: EOL study on probing environmental parity in technical textiles. J Clean Prod 233:1451–1464

Youssef AM, El-Naggar ME, Malhat FM, El Sharkawi HM (2019) Efficient removal of pesticides and heavy metals from wastewater and the antimicrobial activity of f-MWCNTs/PVA nanocomposite film. J Clean Prod 206:315–325

Yuranova T, Mosteo R, Bandara J et al (2006) Self-cleaning cotton textiles surfaces modified by photoactive SiO2/TiO2 coating. J Mol Catal A Chem 244:160–167

Zhang M, Pang J, Bao W et al (2017) Antimicrobial cotton textiles with robust superhydrophobicity via plasma for oily water separation. Appl Surf Sci 419:16–23

Zhou Y, Tang R-C (2018) Facile and eco-friendly fabrication of AgNPs coated silk for antibacterial and antioxidant textiles using honeysuckle extract. J Photochem Photobiol B Biol 178:463–471

Acknowledgments

The authors acknowledge King Saud University, Riyadh, Saudi Arabia, for funding this work through Researchers Supporting Project Number (RSP-2020/30), Additionally, Technical supports from National Research Centre are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Figure 5 is updated.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

El-Naggar, M.E., Khattab, T.A., Abdelrahman, M.S. et al. Development of antimicrobial, UV blocked and photocatalytic self-cleanable cotton fibers decorated with silver nanoparticles using silver carbamate and plasma activation. Cellulose 28, 1105–1121 (2021). https://doi.org/10.1007/s10570-020-03537-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03537-4