Abstract

Silver nanoparticles (AgNPs) loaded on the cotton fiber can endow the fiber with good antibacterial activity, but the AgNPs on the surface of cotton fiber will leach out with the increase of washing times, which will not only greatly reduce the antibacterial properties of cotton fiber, but also cause pollution to the environment. In this paper, carboxyl groups were introduced into cotton fiber by three methods, namely selective oxidation, butane tetracarboxylic acid (BTCA) grafting and polyacrylic acid (PAA) adsorption. The silver ions (Ag+) were adsorbed on the cotton fibers through electrostatic attraction, and after reduction, the AgNPs were loaded onto the cotton fibers, and the AgNP distribution on the fiber and its effect to the washing resistance of AgNPs were studied. The results showed that the carboxyl groups can be introduced onto the cotton fibers by all the three methods, and the reaction only occurred in the amorphous region of the fibers. The selective oxidation and the BTCA grafting can introduce carboxylic groups into the interior of cotton fibers while the PAA adsorption only imports carboxyl groups on the surface of the fiber. As a consequence, AgNPs were formed inside of the cotton fiber when the selective oxidation and the BTCA grafting were employed, while AgNPs can only be loaded on the surface of the fiber by the PAA adsorption method. AgNPs inside of the fiber have high energetic adherence, resulting in silver-cotton fabric nanocomposites with strong slow-release property and long-term antibacterial ability. The fabric nanocomposites prepared by selective oxidation and BTCA grafting exhibited high AgNP retention rate and excellent antibacterial activity even after 80 washing cycles.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cotton fiber was widely used in textile printing and dyeing industry due to its excellent water absorption and human affinity. However, cotton fibers can easily breed bacteria in a suitable environment, which not only cause color change, mechanical strength decline and odor generation, but also have a significant impact on people's life and health (Hebeish et al. 2011a, 2011b). With the concern on personal health, silver nanoparticles (AgNPs) are often loaded onto cotton fibers due to their superb bacteria inhibition and broad-spectrum antibacterial properties (Ahmad 2021; Gao et al. 2021).

There are many methods to introduce AgNPs onto cotton fibers (Bacciarelli-Ulacha et al. 2014; Nam and Condon 2014; Ravindra et al. 2010), including directly deposition (Cheng et al. 2013), padding (Lee et al. 2003), adhesive bonding disposition (Xu et al. 2016, 2017), in situ synthesis (Lee et al. 2007; Montes-Hernandez et al. 2021), heat evaporation (Smetana et al. 2005), etc. The antibacterial mechanism of AgNPs is considered to be the silver ions (Ag+) gradually release from the surface of AgNPs, which can penetrate into the cell wall and kill the surrounding bacteria (Maneerung et al. 2008). The loading of AgNPs on fibers is not permanent, which can result in poor durability against washing processing. In addition, the released AgNPs can accumulate in human tissue and organs and cause adverse effects such as cell death and DNA damage (El-Rafie et al. 2014a; van der Zande et al. 2012).Therefore, the effective immobilization of AgNPs onto the cotton fiber is crucial for its long-term antibacterial activity. Great efforts have been made by scientists to improve the stabilization of AgNPs on cotton fibers. The most studied method is the application of binders. AgNPs can be fixed onto the cotton fiber through the chelation of hydroxyl groups from the binders with the AgNPs (Pan et al. 2018). Liu et al. coated the surface of cotton fiber with polydopamine/polyethylenimine and used the catechol of dopamine to bind the AgNPs to the surface of cotton fiber, and the washing resistance and the slow-release property of AgNPs on the fiber were greatly improved (Liu et al. 2020). Coordination bonds are formed between thiol or thioether groups and Ag to enhance the affinity between AgNPs and fibers (Pan et al. 2018). Zhou et al. grafted L-cysteine and L-methionine on the surface of cotton fibers, and AgNPs were then adhered to the fiber surface through the coordination bonds formed between thioether groups and elemental silver to improve the stability of AgNPs on the surface of cotton fabric (Xu et al. 2019; Zhou et al. 2018, 2019). Kang et al. used3-mercaptopropyltrimethoxysilane (3-MPTMS) as a crosslinking agent to fix AgNPs and quaternary ammonium salts on the surface of the cotton fabric, and the stability of AgNPs on cotton fiber surface was improved (Kang et al. 2016). Amino group is also used to enhance the binding force between AgNPs and cotton fiber. Amino-substituted bis(aryldiazomethane) was synthesized and used to modify cotton fibers by carbene insertion reaction, which successfully introducing amino groups into cotton fiber, and then AgNPs were loaded on the fiber surface. It was found that the introduction of amino groups greatly enhanced the binding force of AgNPs to the fiber. In addition, AgNPs can penetrate into the multi-scale micropore of cotton fiber and be stabilized inside the fiber. Nam et al. treated cotton fibers with an alkaline solution to generate nanosized microfibrillar channels, which were then introduced with [Ag(NH3)2]+ ions and reduced to AgNPs. The AgNPs were successfully diffused into the interior of the cotton fiber, and the washing resistance of the fiber was greatly improved (Nam et al. 2020). Montes-Hernandez et al. put cotton fabrics in silver nitrate solution, and the silver ions were reduced to AgNPs. FE-SEM results of fiber cross section show that AgNPs are diffused through the interior of fiber (Montes-Hernandez et al. 2021). However, the durability of AgNPs on cotton fibers is still insufficient and the methods to improve stabilization of AgNPs on the fibers still need to be improved.

Take advantage of the multi-scale microporous structure of cotton fiber, the carboxyl groups were introduced into the fiber in this present work to slow down the leaching rate of Ag+ and enhance the stability of silver nanoparticles on the cotton fiber. To demonstrate the effect of AgNP location on the fiber on the long-term antibacterial ability of fabric, three methods for introducing carboxyl groups onto cotton fibers including selective oxidation, BTCA grafting and PAA adsorption were designed. The influence of different methods on the washing resistance of cotton fibers loading with AgNPs and the release of Ag+ were studied.

Experiment

Materials

Mercerized cotton fabrics (180.6 g/m2) were obtained from Lianfa Textile Co., Ltd (Jiangsu, China). 2,2,6,6-tetramethylpiperidine oxide (TEMPO, 99.69%)and butane tetracarboxylic acid (BTCA, 99%) were bought from Aladdin (Shanghai, China). Polyacrylic acid (Mw 80,000 g/moL, solid content 40%) was purchased from Shanghai Yingxin laboratory equipment Co., Ltd (Shanghai, China). Poly(diallyldimethylammonium chloride) (PDADMAC,Mw100,000 g/mol),peptone,agar, polybrene (94%) were purchased from Beijing Innochem Technology Co., Ltd (Beijing, China). Silver nitrate (AgNO3, 99.9%), NaBr (99%), NaOH (98%), sodium monophosphate (98%) andsodium dichloroisocyanurate (NaDCC, 96%) were purchased from Sinopharm Chemical Reagent Co.,Ltd (Shanghai, China).

Introduction of carboxyl groups onto cotton fiber

During the selective oxidation of cotton fiber, 0.047 g of TEMPO and 0.31 g of NaBr were dissolved in 300 mL of water, and 2 g of cotton fabric (CF) was then immersed in the above solution. The oxidation process was maintained at room temperature for 4 h, and the pH of the solution was kept at about 10 through the addition of 1 M NaOH during the reaction. Following, the reaction was quenchedby adding ethanol. The oxidized cotton fabric (OCF) was washed with water and then air-dried.

During the cotton fiber grafting by BTCA, 2 gof cotton fabric was immersed in 100 mL of water containing 8 g of BTCA and 3 g of sodium monophosphate, and then padded for a wet pick up of 70%. The immersed cotton fabric was dried at 80 °C for 3 min, baked at 170 °C for 3 min, cotton fabric grafted with BTCA (BCF) was washed with water at 90 °C and sufficiently dried.

During PAA adsorption method, 2 g of cotton fabric was immersed in 100 mL of water containing 4 g of PAA, and then padded for a wet pick up of 70%. The immersed cotton fabric was dried at 80 °C for 3 min, then baked at 170 °C for 3 min, cotton fabric with PAA adsorbed (PCF) was washed with water at 90 °C and sufficiently dried.

Preparation of AgNP-loaded cotton

Three kinds of treated cotton fabric samples (PCF, BCF, OCF) (2 g) and a control cotton fabric (CF) sample (2 g) were immersed in aqueous solution (100 mL) containing AgNO3 (0.17 g) and the pH was adjusted to 7.2 by adding 0.1 M NaOH solution. Then the solution was kept at 70 °C with modest stirring for 50 min. Finally, the fabric samples were separately immersed in a solution (100 mL) containing NaBH4 (0.5 g) for five min. Next, the fabric samples were washed with deionized water. The AgNP-loaded cotton fabrics (AgNP-CF, AgNP-PCF, AgNP-BCF, AgNP-OCF) were obtained after drying in the vacuum oven at 50 °C for 60 min.

Determination of carboxylate and charge contents

0.25 g of fabric sample was immersed in aqueous solution (30 mL) containing HCl (0.3 mmol) for 1 h. The sample was washed with water, then immersed in 50 mL NaOH solution (0.05 mmol/L). Then the solution was added with a drop of phenolphthalein indicator solution, then titrated with 0.05 mol/L HCl solution. The titration stopped when the color of the solution changed from red to colorless. The carboxyl content was calculated according to the following Eq. (1):

where CNaOH is the concentration of the NaOH solution (mol/L), VNaOH is the volume of the NaOH solution consumed (mL) and Ws is the weight of the sample used for titration after drying (g).

The charge content of cotton fiber was calculated by polyelectrolytes (PE) titration, which was first proposed by Lars et al. (Lars et al. 1986). Briefly, two cationic polyelectrolytes, poly(diallyldimethylammonium chloride) (PDADMAC, Mw100,000 g/mol)and Polybrene (Mw 374 g/mol) were used for the titrations.0.3 g cotton fiber was immersed in 50 mL cationic polyelectrolytes solution (0.01 meq/L) for 30 min. The fiber was washed with a large amount of water, the washing liquid was collected and then mixed with the reaction liquid and the volume was adjusted to 500 mL. 20 mL solution was titrated with potassium polyvinyl sulfate titration solution (0.0025 M) and toluidine blueindicator solution. Polybrene was used measure the total charge. PDADMAC was used to analyze the charge on the surface of the fiber. The charge content was calculated from the following Eq. (2).All results are the mean values of three measurements.

where Ccat is the charge concentration of cationic polyelectrolytes solution (mol/L), Vcat is the volume of cationic polyelectrolytes solution (mL), and WS is weight of oven-dried samples used for titration (g).

Washing experiment

To evaluate the washing resistance of AgNP-cotton, washing experiments were carried out in AATCC standard washing machine (M228, SDL Atlas) according to the AATCC Test Method 61–2006. A 150 mL washing solution containing 0.2% WOB standard detergent and 10 stainless steel balls (diameter 6 mm) were added to the stainless steel canister. The cotton fabric was cut into 5 cm × 10 cm samples and washed in the washing machine at 40 °C ± 1 °C for 45 min. This process was equivalent to 5 washing cycles, after 20, 40 and 80 washing cycles, the samples were thoroughly rinsed with water and naturally air-dried.

Characterizations

X-ray diffreaction (XRD, D/max 2500VB/PC, Rigaku), universal material tester (H10K-S, Tiniius Olsen) and fourier transform infrared spectroscopy (FTIR, Nicolet is50, Thermo) were used to test the structure and mechanical properties of the cotton fabrics. The chemical composition and bonding states were analyzed by an X-ray photo-electron spectrometer (Escalab 250Xi, Thermo).

Morphology of the AgNPs on the surface of fibers was observed by a scanning electron microscopy (SEM, TM-1000, Hitachi).Cotton yarns were put into a Hashi slicer, and then were cut into fiber sections with a blade. Morphology and distribution of AgNPs on the fiber cross-sections was observed on a field emission scanning electron microscopy (FE-SEM, S-4800, Hitachi).

In order to characterize the washing durability, the fabrics washed 0, 20, 40 and 80 cycles were characterized using an UV–vis-NIR spectrometer (UV-3600 Plus, Shimadzu). Reflection spectra in the wavelength range from 350 to 800 nm were recorded. The silver retention rate of cotton fabrics after 0,40 and 80 washing cycles were measured by an atomic emission spectrometer (Optima 2100DV, PerkinElmer)0.150 mg of cotton fabric was put into 30 mL of concentrated nitric acid for 12 h to dissolve the silver on the cotton fabric. The above solution of Ag+ was diluted to 100 mL with deionized water, in which the concentration of Ag+ in the solution was measured with ICP-AES. The content of AgNPs was calculated by the following Eq. (3):

where VAg is the volume of the solution obtained after nitrification of the fiber (mL), CAg is Ag+ concentration of the solution obtained after nitrification of the fiber (g/L) and Wt is the weight of cotton (g).

In order to characterize the release rate, AgNP-cotton (300 mg) was placed in a sealed sample bottle containing 20 mL of deionized water and kept at 37 °C. The cotton fabric was removed and then put into another sealed sample bottle containing 20 mL of deionized water every 24 h for 5 days. The concentration of Ag+ in solution was analyzed by ICP-AES.

In order to characterize the antibacterial properties, the antibacterial activity of AgNP-cotton was analyzed by shake flask method according to the GB/T 20,944.32008 (China). 5 mL of bacterial culture solution (3 × 105–4 × 105 CFU/mL) was placed in a flask containing 70 mL of PBS solution (pH = 7.2) with shaken. 0.75 g sample was cut into 0.5 cm × 0.5 cm pieces and placed in the flask mentioned above. The samples were placed in an incubator at a constant temperature of 24 °C and 150 rpm for 18 h. 10μL of solution was diluted and dropped on agar medium. All the agar medium were incubated at 37 °C for 24 h. The antibacterialrate was calculated according to the number of colonies and Eq. (4).

where B is the number of viable bacteria on the control sample, and A is the number of viable bacteria on the AgNP-cotton cultured for 18 h.

Results and discussion

In this study, three different methods were used to introduce carboxyl groups on cotton fibers, including selective oxidation, BTCA grafting and PAA adsorption. In selective oxidation (Fig. 1a), TEMPO-mediated oxidation system is used to oxidize the hydroxyl group on the 6-position of cellulose molecules to carboxyl group (Coseri et al. 2018; Isogai et al. 2011; Shinoda et al. 2012). BTCA grafting (Fig. 1b) introduces carboxyl group into cotton fabric by crosslinking BTCA and cellulose molecules through esterification reaction of carboxyl group and hydroxyl group (Hashem et al. 2020a; Lund and Brelid 2013).TEMPO and BTCA molecules can diffuse into the micropore of cotton fiber because of their small size, therefore, the carboxyl groups can be introduced into the fiber by the above two methods. PAA with Mw of 80,000 has large size, and mainly adsorb on the surface of the fiber through hydrogen bonding and van der Waals force (Li et al. 2020). In the following part, the carboxylate and charge contents of modified cotton fibers by different methods were firstly characterized by titration methods, focusing on the difference of the surface and the inner charges and structure and mechanical properties of modified cotton fabricmodified cotton. AgNPs were then in situ formed on the fibers, and the content and distribution of AgNPs on the fibers were investigated. The wash-resistance of AgNP-loaded fabrics and the antibacterial efficacy of the fabrics after 80 washings were also studied.

The effect of modification methods to the carboxylate and charge contents of cotton fabrics

The content of carboxyl group changes with the oxidant concentration, BTCA concentration, PAA concentration and reaction conditions (Isogai et al. 2018, 2011; Montazer et al. 2012a, b). In this study, the carboxyl group content on OCF kept roughly the same as BCF by adjusting the type of reagents and reaction conditions, and then the influence of different modification methods on the distribution of carboxyl group in fibers was studied. Due to the low adsorption efficiency of PAA on fibers, the content of carboxyl groups introduced into fibers by PAA adsorption method was less than that of OCF and BCF. The specific test results are shown in Table 1, there was almost no carboxyl group and charge in CF, carboxyl groups were introduced into PCF, BCF and OCF respectively. The above results showed that oxidation, BTCA grafting and PAA adsorption had successfully introduced carboxyl groups into cotton fibers, in which the internal charge of OCF accounts for 61% of the total charge. The total charge of BCF was almost the same as the surface charge. Although the carboxyl group content of BCF was the same as OCF, the test results showed that the charge of BCF was much lower than that of OCF. This is because part of the surface of untreated cotton fiber was wrapped by non-cellulose materials such as pectin and protein. Oxidation removed these non-cellulosic materials and exposed the cellulose (Fras et al. 2005). At the same time, the surface of the cotton fiber was destroyed and the surface area became larger (Baron and Coseri 2020). Therefore, the cationic polyelectrolytes can be well combined with the carboxyl group of the fiber, so the PE titrations can more accurately reflect the charge distribution of the oxidized cotton fiber. BTCA in BCF not only acted as a carrier of carboxyl groups to introduce carboxyl groups into the fiber, but also acted as a crosslinking agent to cross-link the molecular chains of cotton fibers together, blocking the voids inside the fibers, which resulted in cationic polyelectrolytes unable to enter the fibers, and non-cellulose materials on the surface of cotton fibers cannot be grafted with carboxyl groups (Hashem et al. 2020b; Ji et al. 2016; Shekarriz et al. 2003). Therefore, the test results showed that the charge of BCF was much lower than that of OCF. The total charge and surface charge of PCF were very small. This is because the molecular weight of polyacrylic acid was too large to enter the fiber and can only be adsorbed on the surface of the cotton fiber. Most of the charge was therefore concentrated on the surface of the cotton fiber.

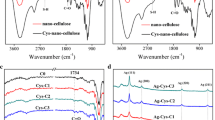

Characterization of modified cotton fabrics

ATR-FTIR spectroscopy was used to detect the functional groups of modified fabrics. Figure 2a shows that the modified fabrics have new peaks at 1726 cm−1 versus the control fabric. It corresponds to the stretching vibration of the carbon-oxygen double bond (C=O) in the carboxyl group, which indicates that the cotton fabrics are introduced with carboxyl groups by all three treatments. After the treatments, the breaking strength of cotton fabrics decreased in different degrees. As shown in Fig. 2b, the breaking strength of the cotton fabric is 986 N, and the breaking strength retention rates of PCF, BCF and OCF are 90%, 70% and 85%, respectively. In PAA adsorption and BTCA grafting methods, a large number of PAA and BTCA molecules were imported between the molecular chains of cotton fibers, so the relative movement between the molecular chains of cotton fibers was hindered, resulting in the stress concentration under the action of external forces, and the decrease of tensile strength. Especially for BTCA grafting, BTCA was covalently cross-linked with cotton fiber molecular chains, and the relative movement between cotton fiber molecular chains is greatly hindered, so the breaking strength drops seriously. Due to the inevitable breakage of a small number of molecular chains in the process of oxidation, the tensile strength of OCF was reduced to a certain extent. The XRD results are shown in Fig. 2c. The control cotton fabric and the three modified cotton fabrics have the same peaks at 2θ = 14.7°, 16.4°,22.6° and 34.3°. These peaks are the characteristic peaks of cellulose, and there is no obvious change in other positions, which means that the crystallinity and crystal type of the modified fabrics were not changed. Therefore, PAA adsorption, BTCA grafting and oxidation only occurred in the amorphous region, and have no effect on the crystalline region.

The XPS patterns of the four AgNP-loaded cotton fabrics are shown in Fig. 2d. All fabrics have C1s, O1s, Ag 3d5/2 and Ag 3d3/2 signals, and there is no significant difference. The high-resolution map of the C signal of AgNP-CF is shown in Fig. 2e, which shows a high-resolution C signal image of a typical cotton fabric. The peaks at 284.5eV, 286.1eV and 287.3eV represent C–C, C–OH and C–O–C, respectively. However, the high-resolution peak of C signal of the other three cotton fabrics with carboxyl group was significantly changed. The peak at the original position of 287.3eV was shifted to 288eV, and the peak area was much larger, which indicated that carboxyl groups were introduced in cotton fiber, the C=O double bond make the peak area and binding energylarger. XPS spectra of silver of the four fabrics (Fig. 2i) show two peaks at 374.1 eV and 368.0 eV, respectively, which are ascribed to Ag3d3/2 and Ag3d5/2. The absence of other peaks indicates that the nanoparticles are composed of silver elemental elements.

The content and distribution of AgNPs on fibers

Photographs of AgNP-loaded cotton and SEM images of their fiber surface are shown in Fig. 3. AgNPs loaded on the cotton fabric changed the color of fabric. The control cotton is white and the fiber surface is very smooth. Compared with the control cotton, the color of AgNP-CF is only slightly yellow, and the fiber surface has only a small number of nanoparticles; the colors of AgNPs-PCF, AgNP-BCF and AgNP-OCF were all obviously changed, in which the color of AgNP-BCF and AgNP-OCF became the dark brown. Because the content of AgNPs on the different fiber surfaces were different, different cotton fabrics showed different colors.

The silver contents of different AgNP-loading cotton fabrics are shown in Table 2, the silver content of CF and PCF are 1.2 mg/g and 6.1 mg/g. However, the FE-SEM images of the cross-sections of CF and PCF show that the interiors of these two fibers are not loaded with AgNPs (Fig. 4 CF and PCF). This is because the carboxyl groups exist only on the surface of PCF, so AgNPs can only be loaded on the surface of fiber, which can also be proved by the SEM images of the fiber surface (Fig. 3b, c). As shown in Table 2, the silver content of BCF and OCF were 12.8 mg/g and 12.0 mg/g respectively, much higher than that of CF and PCF. The FE-SEM images of the cross-sections of BCF and OCF proved that a large amount of AgNPs were loaded inside the two fibers (Fig. 5 BCF and OCF). The distribution of AgNPs (~ 30 nm) inside BCF and AgNPs (~ 20 nm) inside OCF were very dense and uniform. Selective oxidation and BTCA grafting introduced a large number of carboxyl groups into the interior and surface of cotton fibers. The electrostatic attraction made a large amount of Ag+ diffuse into the fiber, thus the interior of the fibers was loaded with a large number of AgNPs.

Slow-release and wash-resistance of AgNPs on fabrics

In order to evaluate the washing resistance of AgNP-cotton, four kinds of cotton fabrics were washed 0,20,40 and 80 cycles respectively according to AATCC Test Method 61–2007.Then the fabrics were characterized by UV–vis-NIR spectrometer. Figure 5 shows the reflectance spectrum of AgNP-cotton. The load of AgNPs leaded to a steep drop in reflectance between 400 and 450 nm, and the reflectance changes with the increase of washing times. Figure 5a shows that the reflectance of the AgNP-CF increased with the increase of washing cycles. As shown in Fig. 5b, the reflectance of the AgNP-PCF after 20 cycles has hardly changed, and the reflectance increased slightly after 40 cycles, while the reflectance increased significantly until 80 cycles. AgNP-BCF and AgNP-OCF had no significant change in reflectance after 20 and 40 washing cycles, and the reflectance only increased slightly after 80 washing cycles. An increase in reflectivity means a decrease in the loading capacity of silver. Therefore, the above results indicate that PAA adsorption can improve the durability of AgNPs. However, since the loading capacity of AgNPs is relatively small and distributed on the surface, increasing the number of washing will decrease the loading capacity of silver. The AgNPs of BCF and OCF are not only distributed on the surface of the fiber, but also distributed in the interior of the fiber, and the washable resistance is greatly improved. Only after 80 cycles of washing, the reflectivity is slightly increased.

In order to evaluate the stability of the AgNPs more accurately, ICP-AES was used to measure the AgNP retention rate of AgNP-cotton after 40 and 80 washing cycles. As demonstrated in Fig. 6a after the same number of washing, the durability of AgNP-OCF was the best, followed by AgNP-BCF, AgNP-PCF and AgNP-CF. The above laws reflected the washing durability of AgNPs on different cotton fabrics more accurately.

The results of OCF were compared with that of durable AgNP-cotton fabrics in other literatures, where the washing procedure was generally the same as this paper. As shown in Fig. 6b, Lee et al. reported that antibacterial cotton fabrics directly impregnated with AgNPs sol, and the silver retention rate was only 7% after 20 washing cycles (Lee et al. 2003).Reed et al. demonstrated that their AgNP-loaded T-shirts had a silver retention rate of 44% after 20 washing cycles (Reed et al. 2016). Zahran et al. used AgNP-alginate to endow cotton fabric with antibacterial properties, the silver retention rate on cotton fabrics reached 54% after 20 washing cycles (Zahran et al. 2014). The studies by El-Rafie et al. showed that the addition of adhesives can improve washing durability, the AgNP retention rate reached 65.8% after 20 washing cycles (El-Rafie et al. 2014b). Although Nam et al. (Nam et al. 2020) and Zhang et al. (Zhang et al. 2013) improved the process to improve the durability of AgNPs on cotton fabrics, silver retention rate reached 67.0% and 81.5% after 20 and 30 washes, respectively, the retention rate was still lower than that of our samples. The AgNPs loaded on our samples were wrapped inside the fiber, resulting in its strong washing resistance. Although carboxyl groups were introduced into cotton fibers through different methods, they had different results on the washing durability of silver in cotton fibers. AgNP-OCF had the best stability, because the oxidation introduces carboxyl group into the cotton fiber. The complex force of carboxyl group on Ag+ a large number of Ag+ diffuse into the fiber, thus the fiber was loaded with a large number of AgNPs. The AgNPs in the fiber were not easy to be leach out, and even after several washing cycles, the stability was still very good. AgNP-PCF had the worst stability, because the dip-rolled PAA can only introduce carboxyl group on the surface of the fiber, most of the AgNPs can only be loaded on the surface of the fiber, and it is easy to lose with the increase of washing times.

In order to study the slow-release properties of AgNP-cotton, the release rate of Ag+ from antibacterial cotton was measured by ICP-AES. As shown in Fig. 6c, the released Ag+ of AgNP-CF was the highest, which achieved 2.4% after 5 days. The released Ag+ of AgNP-PCF was 1.5%. However, the accumulative release of Ag+ from AgNP-BCF and AgNP-OCF were significantly lower than 0.9%. Hence, the introduction of carboxyl groups greatly enhanced the sustained release of silver. AgNPs on AgNP-BCF and AgNP-OCF were distributed inside the fiber and were not easy to be leached, so they have a strong sustained-release property. AgNPs on AgNP-PCF were mainly located on the fiber surface, and its slow-release property was slightly weaker than that of AgNPs of AgNP-BCF. The prepared AgNP-BCF and AgNP-OCF can provide long-term antibacterial property by continuously releasing Ag+.

Antibacterial efficacy

The antibacterial activity of AgNP-cotton was tested after 80 washing cycles by a shake flask method according to GB/T 20,944.32008 (China). The bacterial solution after cultivation for 18 h was diluted to different multiples (100,10–1,10–2), and then 10μL of the diluted bacterial solution were dropped onto the agar plates. After cultivation for 24 h, the bacterial inhibition rate was calculated. Figure 7 shows the photographs of the number of colonies after culturing for 24 h. Table 3 shows the antibacterial activities of AgNP-cotton against S. aureus and E. coli, AgNP-BCF and AgNP-OCF after 80 washing cycles inactivated all bacteria including S. aureus and E. coli. The percent reductions calculated according to Eq. (2) were both determined to 100% for S. aureus and E. coli. The percent reductions of AgNP-CF were determined to 98.6% and 94.0% for S. aureus and E. coli. The percent reductions of AgNP-PCF were determined to 97.9.% and 99.0% for S. aureus and E. coli. The results showed that after 80 washing cycles, the antibacterial properties of AgNP-BCF and AgNP-OCF did not change significantly, while the antibacterial properties of AgNP-PCF decreased significantly, and the antibacterial decline of AgNP-CF was the largest, which also proved that the introduction of carboxyl groups can enhance the stability of AgNPs on cotton fibers, resulting in long-term durable antibacterial cotton fabrics.

Conclusions

In this work, carboxyl groups were successfully introduced into the inside of cotton fiber by BTCA grafting and selective oxidation. AgNPs were well-distributed inside the cotton fiber through the electrostatic attraction of carboxyl group and Ag+. On the contrary, most of the AgNPs of AgNP-PCF were concentrated on the surface of the fiber. Internal synthesis of AgNPs within cotton fiber is an effective and reliable way to improve washing durability and sustained release of Ag+. After 40 cycles, the silver content of AgNP-BCF and AgNP-OCF were 71.2% and 92.4%, respectively. however, the AgNPs content of AgNP-CF and AgNP-PCF were only 42.9% and 61.2%. The accumulative release of Ag+ from AgNP-BCF and AgNP-OCF were significantly lower than 0.9%, which was much lower than AgNP-CF and AgNP-PCF. As expected, after 80 washing cycles, the percent reductions of AgNP-BCF and AgNP-OCF were all determined to 100% against both S. aureus and E. coli. By contrast, the percent reductions of AgNP-CF and AgNP-PCF were lower than AgNP-BCF and AgNP-OCF.

References

Ahmad H (2021) Celluloses as support materials for antibacterial agents: a review. Cellulose. https://doi.org/10.1007/s10570-021-03703-2

Bacciarelli-Ulacha A, Rybicki E, Matyjas-Zgondek E, Pawlaczyk A, Szynkowska MI (2014) A new method of finishing of cotton fabric by in situ synthesis of silver nanoparticles. Ind Eng Chem Res 53:4147–4155. https://doi.org/10.1021/ie4011113

Baron RI, Coseri S (2020) Preparation of water-soluble cellulose derivatives using TEMPO radical-mediated oxidation at extended reaction time. React Funct Polym. https://doi.org/10.1016/j.reactfunctpolym.2020.104768

Cheng F, Betts JW, Kelly SM, Schaller J, Heinze T (2013) Synthesis and antibacterial effects of aqueous colloidal solutions of silver nanoparticles using aminocellulose as a combined reducing and capping reagent. Green Chem. https://doi.org/10.1039/c3gc36831a

Coseri S, Biliuta G, Simionescu BC (2018) Selective oxidation of cellulose, mediated by N-hydroxyphthalimide, under a metal-free environment. Polym Chem 9:961–967. https://doi.org/10.1039/c7py01710c

El-Rafie MH, Ahmed HB, Zahran MK (2014a) Characterization of nanosilver coated cotton fabrics and evaluation of its antibacterial efficacy. Carbohydr Polym 107:174–181. https://doi.org/10.1016/j.carbpol.2014.02.024

El-Rafie MH, Ahmed HB, Zahran MK (2014b) Characterization of nanosilver coated cotton fabrics and evaluation of its antibacterial efficacy. Carbohyd Polym 107:174–181. https://doi.org/10.1016/j.carbpol.2014.02.024

Fras L, Johansson LS, Stenius P, Laine L, Stana-Kleinschek K, Ribitsch V (2005) Analysis of the oxidation of cellulose fibres by titration and XPS. Colloids Surf a-Physicochem Eng Aspects 260:101–108. https://doi.org/10.1016/j.colsurfa.2005.01.035

Gao DG, Li XJ, Li YJ, Lyu B, Ren JJ, Ma JZ (2021) Long-acting antibacterial activity on the cotton fabric. Cellulose 28:1221–1240. https://doi.org/10.1007/s10570-020-03560-5

Hashem A, Fletcher AJ, Younis H, Mauof H, Abou-Okeil A (2020a) Adsorption of Pb(II) ions from contaminated water by 1,2,3,4-butanetetracarboxylic acid-modified microcrystalline cellulose: isotherms, kinetics, and thermodynamic studies. Int J Biol Macromol 164:3193–3203. https://doi.org/10.1016/j.ijbiomac.2020.08.159

Hebeish A, Abdel-Mohdy FA, Fouda MMG, Elsaid Z, Essam S, Tammam GH, Drees EA (2011a) Green synthesis of easy care and antimicrobial cotton fabrics. Carbohyd Polym 86:1684–1691. https://doi.org/10.1016/j.carbpol.2011.06.086

Hebeish A, El-Naggar ME, Fouda MMG, Ramadan MA, Al-Deyab SS, El-Rafie MH (2011b) Highly effective antibacterial textiles containing green synthesized silver nanoparticles. Carbohyd Polym 86:936–940. https://doi.org/10.1016/j.carbpol.2011.05.048

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. https://doi.org/10.1039/c0nr00583e

Isogai A, Hänninen T, Fujisawa S, Saito T (2018) Review: catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions. Prog Polym Sci 86:122–148. https://doi.org/10.1016/j.progpolymsci.2018.07.007

Ji B, Yan K, Sun G (2016) Investigation on functional properties of 1,2,3,4-butanetetracarboxylic acid cross-linked fabrics impacted by molecular structures and chemical affinity of catalysts. Ind Eng Chem Res 55:5216–5222. https://doi.org/10.1021/acs.iecr.6b00159

Kang CK, Kim SS, Kim S, Lee J, Lee JH, Roh C, Lee J (2016) Antibacterial cotton fibers treated with silver nanoparticles and quaternary ammonium salts. Carbohydr Polym 151:1012–1018. https://doi.org/10.1016/j.carbpol.2016.06.043

Lars W et al (1986) Polyelectrolytes adsorbed on the surface of cellulosic materials. J Colloid Interface Sci 111:537–543

Lee HJ, Yeo SY, Jeong SH (2003) Antibacterial effect of nanosized silver colloidal solution on textile fabrics. J Mater Sci 38:2199–2204. https://doi.org/10.1023/a:1023736416361

Lee HY, Park HK, Lee YM, Kim K, Park SB (2007) A practical procedure for producing silver nanocoated fabric and its antibacterial evaluation for biomedical applications. Chem Commun. https://doi.org/10.1039/b703034g

Li L et al (2020) The oligomer polyacrylic acid effect on immobilization of silver nanoparticles onto cotton fabric to achieve a durably antibacterial function. Fiber Polym 21:1965–1974. https://doi.org/10.1007/s12221-020-1140-x

Liu G, Xiang J, Xia Q, Li K, Yan H, Yu L (2020) Fabrication of durably antibacterial cotton fabrics by robust and uniform immobilization of silver nanoparticles via mussel-inspired polydopamine/polyethyleneimine coating. Ind Eng Chem Res 59:9666–9678. https://doi.org/10.1021/acs.iecr.9b07076

Lund K, Brelid H (2013) Kinetics of cross-linking softwood kraft pulp with 1,2,3,4-butanetetracarboxylic acid. Ind Eng Chem Res 52:11502–11509. https://doi.org/10.1021/ie400849f

Maneerung T, Tokura S, Rujiravanit R (2008) Impregnation of silver nanoparticles into bacterial cellulose for antimicrobial wound dressing. Carbohyd Polym 72:43–51. https://doi.org/10.1016/j.carbpol.2007.07.025

Montazer M, Alimohammadi F, Shamei A, Rahimi MK (2012a) Durable antibacterial and cross-linking cotton with colloidal silver nanoparticles and butane tetracarboxylic acid without yellowing. Colloids Surf B-Biointerfaces 89:196–202. https://doi.org/10.1016/j.colsurfb.2011.09.015

Montazer M, Shamei A, Alimohammadi F (2012b) Stabilized nanosilver loaded nylon knitted fabric using BTCA without yellowing. Prog Org Coat 74:270–276. https://doi.org/10.1016/j.porgcoat.2012.01.003

Montes-Hernandez G, Di Girolamo M, Sarret G, Bureau S, Fernandez-Martinez A, Lelong C, Eymard Vernain E (2021) In situ formation of silver nanoparticles (Ag-NPs) onto textile fibers. ACS Omega 6:1316–1327. https://doi.org/10.1021/acsomega.0c04814

Nam S, Condon BD (2014) Internally dispersed synthesis of uniform silver nanoparticles via in situ reduction of [Ag(NH3)2]+ along natural microfibrillar substructures of cotton fiber. Cellulose 21:2963–2972. https://doi.org/10.1007/s10570-014-0270-y

Nam S, Hillyer MB, Condon BD, Lum JS, Richards MN, Zhang Q (2020) Silver nanoparticle-infused cotton fiber: durability and aqueous release of silver in laundry water. J Agric Food Chem 68:13231–13240. https://doi.org/10.1021/acs.jafc.9b07531

Pan Y, Yang P, Moloney MG, Wang L, Ma F, Wang Y (2018) Ag NP-loaded cotton fiber materials: preparation surface deposition, and antibacterial activity with different chemical structures. ACS Appl Bio Mater 2:510–517. https://doi.org/10.1021/acsabm.8b00696

Ravindra S, Murali Mohan Y, Narayana Reddy N, Mohana Raju K (2010) Fabrication of antibacterial cotton fibres loaded with silver nanoparticles via “Green Approach.” Colloids Surf A Physicochem Eng Aspects 367:31–40. https://doi.org/10.1016/j.colsurfa.2010.06.013

Reed RB et al (2016) Potential environmental impacts and antimicrobial efficacy of silver- and nanosilver-containing textiles. Environ Sci Technol 50:4018–4026. https://doi.org/10.1021/acs.est.5b06043

Shekarriz S, Cohen P, Carr CM, Mitchell R, Jones C (2003) Surface chemical analysis of 1,2,3,4-butanetetracarboxylic acid modified cotton. J Mater Sci 38:2945–2951. https://doi.org/10.1023/a:1024469410216

Shinoda R, Saito T, Okita Y, Isogai A (2012) Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils. Biomacromol 13:842–849. https://doi.org/10.1021/bm2017542

Smetana AB, Klabunde KJ, Sorensen CM (2005) Synthesis of spherical silver nanoparticles by digestive ripening, stabilization with various agents, and their 3-D and 2-D superlattice formation. J Colloid Interface Sci 284:521–526. https://doi.org/10.1016/j.jcis.2004.10.038

van der Zande M et al (2012) Distribution, elimination, and toxicity of silver nanoparticles and silver ions in rats after 28-day oral exposure. ACS Nano 6:7427–7442. https://doi.org/10.1021/nn302649p

Xu Q, Wu Y, Zhang Y, Fu F, Liu X (2016) Durable antibacterial cotton modified by silver nanoparticles and chitosan derivative binder. Fibers and Polymers 17:1782–1789. https://doi.org/10.1007/s12221-016-6609-2

Xu Q, Xie L, Diao H, Li F, Zhang Y, Fu F, Liu X (2017) Antibacterial cotton fabric with enhanced durability prepared using silver nanoparticles and carboxymethyl chitosan. Carbohyd Polym 177:187–193. https://doi.org/10.1016/j.carbpol.2017.08.129

Xu Q et al (2019) Enhancing the surface affinity with silver nano-particles for antibacterial cotton fabric by coating carboxymethyl chitosan and l-cysteine. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2019.143673

Zahran MK, Ahmed HB, El-Rafie MH (2014) Surface modification of cotton fabrics for antibacterial application by coating with AgNPs-alginate composite. Carbohydr Polym 108:145–152. https://doi.org/10.1016/j.carbpol.2014.03.005

Zhang D, Chen L, Zang C, Chen Y, Lin H (2013) Antibacterial cotton fabric grafted with silver nanoparticles and its excellent laundering durability. Carbohydr Polym 92:2088–2094. https://doi.org/10.1016/j.carbpol.2012.11.100

Zhou J, Cai D, Xu Q, Zhang Y, Fu F, Diao H, Liu X (2018) Excellent binding effect of l-methionine for immobilizing silver nanoparticles onto cotton fabrics to improve the antibacterial durability against washing RSC. Advances 8:24458–24463. https://doi.org/10.1039/c8ra04401e

Zhou J, Hu X, Zhu Y, Lyu H, Zhang L, Fu F, Liu X (2019) A hybrid binder of carboxymethyl chitosan and l-methionine enables a slight amount of Ag NPs to be durably effective on antibacterial cotton fabrics. Cellulose 26:9323–9333. https://doi.org/10.1007/s10570-019-02715-3

Acknowledgments

The authors acknowledge the financial support for this workfromtheNational Key R&D Programof China (No. 2017YFB0309603) and the Fundamental Research Funds for theCentral Universities (No. 2232021G-01).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

There are no studies involving humans or animals in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, S., Zhang, T., He, J. et al. Effect of AgNP distribution on the cotton fiber on the durability of antibacterial cotton fabrics. Cellulose 28, 9489–9504 (2021). https://doi.org/10.1007/s10570-021-04113-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-04113-0