Abstract

An efficient method for covalently linking of cellulose and clay using a click chemistry based strategy is reported. Azide and alkynyl derivatives of silane were synthesized and used for silanization of cellulose and clay respectively. Functionalized cellulose and clay were then coupled using Cu(I) catalyzed azide–alkyne cycloaddition reaction, resulting in a covalent linkage between them. Successful synthesis of the silane derivates was established using Fourier transform infrared (FTIR) and nuclear magnetic resonance. Silanization of cellulose and clay with azide and alkynyl derivatives and the formation of a triazole linkage were confirmed using FTIR.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is the most abundant natural polymer (Bovey and Winslow 1981, Krassig et al. 1986). Due to its high availability, recyclability and biodegradability, cellulose is widely used in many industries, including but not limited to, paper production, pharmaceutics, food, and reinforcement in polymer composites (Okiyama et al. 1992; Bledzki and Gassan 1999; Zimmermann et al. 2004; Orts et al. 2005; Coffey et al. 2006; Czaja et al. 2006; Garcia de Rodriguez et al. 2006; Hoenich 2007; Wan et al. 2007; Maren et al. 2009; Abdul Khalil et al. 2012). Cellulose fibers are used as reinforcement to enhance mechanical properties of polymers (Bledzki and Gassan 1999; Mohanty et al. 2000, 2002; Ludvik et al. 2007). However, poor dispersion of cellulose and limited binding between cellulose and the polymer matrix is the key issue (Eichhorn et al. 2010). Cellulose fibers tend to agglomerate, which reduces their efficacy as reinforcement material. While surface functionalization of cellulose (Abdelmouleh et al. 2002, 2005; Ly et al. 2008; Xie et al. 2010), silanization for example, is used for enhanced binding between fibers and polymer matrix; addition of clay, on the other hand, is employed for better dispersion of cellulose and improved fire retardancy of the composites (White 2004; Ludvik et al. 2007; Liu et al. 2012). Although, addition of clay allow better dispersion of cellulose; mechanical properties of the composites either do not improve significantly (Thunwall et al. 2008) or even degrade (Ludvik et al. 2007). The reason for this discrepancy was attributed to the insufficient binding between clay and cellulose. Hence, for improved mechanical properties, enhanced interfacial interaction between clay and cellulose is desired.

Here we report a possible method for enhancing interfacial binding between cellulose and clay using azide–alkyne cycloaddition based click reaction. Click chemistry is considered as the best method for linking molecular species of different kind (Rostovtsev et al. 2002; Himo et al. 2005). Click reactions received great attention because of the mild reaction conditions, absence of byproducts leading to easy purification of the products and the possibility of using environmentally benign solvents or solvent free conditions. Click reactions are performed even in living system for the detailed study of biochemical reactions (Dam and Caruso 2012; Thirumurugan et al. 2013; Yang et al. 2014). Click reactions have also been used to synthesize functional materials, nanoparticles, catalysts and also in synthesis of a large number of drugs (Qin et al. 2010; Liebert et al. 2006; Binder and Sachsenhofer 2007; Fournier et al. 2007; Moses and Moorhouse 2007; Karaaslan et al. 2013). Click chemistry has found its place in material synthesis, where it has been used mainly for the incorporation of functional groups, which are otherwise difficult to achieve.

Azide and alkynyl derivatives of silane were synthesized and covalently coupled to cellulose and clay respectively. The azide and alkyne groups were then linked by Cu(I) catalyzed click reaction resulting in covalent binding between cellulose and clay.

Surface silanization of clay (Papalos 1966; Manna et al. 1999; Freeman et al. 2000) and cellulose (Abdelmouleh et al. 2002, 2005; Ly et al. 2008; Xie et al. 2010) has been reported previously. Surface functionalization of clay and covalent bonding with polymer (Wheeler et al. 2006) has been demonstrated earlier. Moreover, cellulose is also chemically crosslinked with other polymer (Chang et al. 2008). However, we could not find any literature on covalent coupling between cellulose and clay not to mention any click chemistry between the two. In this paper, click chemistry route to covalently couple cellulose and clay is demonstrated.

Materials and methods

(3-aminopropyl)triethoxysilane (APTES) and propiolic acid were purchased from Thomas Baker (chemicals) Pvt. Ltd (India), N,N’-dicyclohexylcarbodiimide (DCC), 4-dimethylaminopyridine (DMAP) were purchased from RFCL limited (India), dichloromethane (DCM), dimethylsulphoxide (DMSO), ethyl acetate, silica gel (60-120), citric acid were purchased from Thermo fisher scientific India Pvt. Ltd Mumbai (India), dimethylacetamide (DMA), petroleum ether, sodium sulfate, silica gel (100-200), sodium bicarbonate, NaCl saturated solution, N2 gas was purchased from SD fine-chem Limited Mumbai (India). 1-ethyl-3-(3-dimethyllaminopropyl)carbodiimide hydrochloride (EDC.HCl), benzotriazol-1-yl-oxytripyrrolidinophosphonium-hexafluorophosphat (PyBOP) and O-benzotriazole-N,N,N’,N’-tetramethyluronium hexafluorophosphate (HBTU) were purchased from Sigma-Aldrich (USA). Cellulose powder were supplied by Maple Biotech Private Limited Pune (India).

For the characterization of synthesized compounds, Fourier transform infrared (FTIR) (PerkinElmer, Spectrum Two, USA) and nuclear magnetic resonance (NMR) spectra (Jeol spectrometer) were recorded. 1H and 13C NMR spectra were recorded either on a Jeol spectrometer 400 MHz (100 MHz for 13C) or on a 500 MHz (125 MHz for 13C) NMR spectrometer at 25 °C. The 1H NMR signals are referenced to tetramethylsilane (δ = 0.00 ppm) and the 13C NMR peaks are referenced to residual CHCl3 signal (δ = 77.0 ppm).

Synthesis of N-(3-(triethoxysilyl)propyl)propiolamide (AMIPTES)

AMIPTES (3) was synthesised using (3-aminopropyl) triethoxysilane (1) (APTES). APTES, 1.05 mL (4.52 mmol), was dissolved in 20 mL of DCM, followed by the addition of DCC 1.12 g (5.42 mmol), DMAP 0.055 g (0.452 mmol) and 0.3 mL (4.97 mmol) of propiolic acid (2) into the 100 mL round bottom flask and stirred for 18 h at room temperature under inert atmosphere. After completion of the reaction, the mixture was poured into separating funnel and extracted with 20 mL of saturated sodium bicarbonate solution followed by 5 mL saturated solution of citric acid. The crude reaction mixture was purified via column chromatography (Scheme 1) .

Synthesis of (3-azidopropyl) triethoxysilane (AZIPTES)

The AZIPTES (5) was synthesised using (3-chloropropyl)triethoxysilane (CPTES): 4 mL (16.61 mmol) of (3-chloropropyl)triethoxysilane (4) was dissolved in 60 mL of DMA and stirred with 5.35 g (16.61 mmol) of TBAB and 1.29 g (19.93 mmol) of NaN3, and refluxed for 24 h. After the completion, the reaction mixture was extracted with diethyl ether and water. The organic layer again washed with brine followed by drying over sodium sulphate. The solvents were removed under reduced pressure and the crude reaction mixture purified through column chromatography (Scheme 2).

Silanization of microcrystalline cellulose (MCC) with AZIPTES

Preparation of NaOH treated MCC

Microcrystalline cellulose (33.00 g) was washed in 600 mL solution of 0.1 M NaOH, by ultrasonicating the mixture for 10 min followed by stirring for 30 min. After 30 min, the MCC was washed with DI water (5 cycles) to make it neutral. This step was performed to remove any impurities on cellulose.

Surface modification of MCC

MCC surface was functionalized with 1, 3, 5 and 10 % (w/w) AZIPTES. Calculated amounts of AZIPTES (1, 3, 5, 10 %, w/w with respect to MCC) were dissolved in 100 mL of 80:20, ethanol–water system separately; afterward 5.00 g of dry MCC was added into each silane solution and stirred at room temperature for 1.5 h, followed by 10 min of ultrasonication. The solution was then transferred in the petridish and kept in oven at 45 °C for 24 h to evaporate ethanol and functionalize the cellulose. After functionalizing, MCC was scratched from petridish and collected in a well stopper bottles.

Silanization of kaolinite clay by AMIPTES

To silanize clay, 10, 30 and 60 % of AMIPTES (w/w with respect to kaolinite clay) was dissolved in 200 mL of 80:20, ethanol–water system in a 250 mL round bottom flask. Dry kaolinite was added to each solution and the reaction mixture was allowed stir for 2 h. After that the mixture was ultrasonicated for 10 min. The mixture was transferred into petridish and kept in the oven at 100 °C for 24 h to dry after which, the dry modify clay was scratched with spatula and collected into well stopper bottles.

Click chemistry between kaolinite clay and MCC

A double-necked 100 mL round flask equipped with a magnetic stirrer was set and 15 mL of DMSO was added into it. Into that, 0.20 g of 30 % N-(3-(triethoxysilyl)propyl)propiolamide treated kaolinite clay and 5 % 3-azidopropyl triethoxysilane treated cellulose were added followed by 0.30 g of CuBr and the mixture was refluxed at 150 °C for 12 h. After stopping the reaction, the mixture was filtered and washed several times by ethyl acetate and water. After drying the product at 80 °C for 12 h, it was scratched from filter paper and collected for further analysis.

Results and discussion

Spectral characterization of AMIPTES

FTIR spectrum (supplementary information S1) of AMIPTES (Scheme 3i) shows absorption bands at 3257, 2952, 2883, 2823 and 2109 cm−1 that are associated with –N–H stretching in secondary amine, alkyl –C–H stretching (2952–2823 cm−1), and –C≡C stretching of alkynyl group, respectively. The spectrum shows a band at 1648 cm−1 that is associated with the stretching vibrations of the –C=O of amide group.

1 H-NMR (CDCl3, 500 MHz, Fig. 4) δ 0.58 (t, 2H), 1.17 (t, 9H), 1.61 (m, 2H), 2.77 (s, 1H), 3.24(q, 2H), 3.76 (q, 2H), 6.72 (s, 1H); 13 C-NMR (CDCl3, 100 MHz, Fig. 5), δ 7.81, 18.35, 22.44, 42.18, 58.55, 73.05, 75.19, 77.21, 152.34.

Spectral characterization of AZIPTES

FTIR spectrum (supplementary information S2) of AZIPTES (Scheme 3ii) shows absorption bands at 2977, 2926 cm−1 that are associated with –C–H stretching in alkyl groups and 2096 cm−1 that corresponds to the –N≡N stretching of nitrile group.

1 H-NMR (CDCl3, 500 MHz, Fig. 6) δ 0.67 (t, 2H), 1.19 (t, 3H), 1.23 (m, 2H), 1.66 (t, 2H), 3.79 (q, 2H); 13 C-NMR (CDCl3, 100 MHz, Fig. 7), δ 13.80, 14.18, 18.30, 53.60, 58.43.

Silanization of MCC and kaolinite

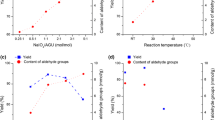

The silanization of MCC and kaolinite was achieved by using suitably functionalized silane derivatives. The halogenated silyloxy compound (4) was treated with sodium azide and TBAI to get the desired AZIPTES (5) quantitatively. MCC was functionalized with AZIPTES (3, 5, and 10 % w/w) as discussed in “Silanization of microcrystalline cellulose (MCC) with AZIPTES” section and was characterised by FTIR spectra. A stretching band at 2906 cm−1 was observed for functionalized MCC, which is the characteristic band for –N≡N group. On increasing the weight percent of AZIPTES from 1 to 10 % in MCC, the band at 2100 cm−1 became more intense (as shown in Fig. 1) suggesting successful functionalization of MCC with AZIPES.

Kaolinite was linked with alkyne derivate of silane. AMIPTES was successfully obtained by the coupling between corresponding acid (2) and amine (1) in the presence of DCC and DMAP. Attempted coupling between the same by using different coupling agents like EDC.HCl, HBTU, PyBOP gave complicated reaction mixtures. Functionalized kaolinite with varying amounts of silane was analysed by FTIR spectra. A stretching band at 2110 cm−1 was observed in all the proportion of AMIPTES in kaolinite; which is the characteristic peak for –C≡C group (as shown in Fig. 2).

Click chemistry product

After the successful functionalization of cellulose and kaolinite with azides and alkyne respectively, click chemistry was performed by using CuBr as a catalyst in DMSO at 150 °C. The obtained product was washed with organic solvents and water and characterised by FTIR. FTIR spectra (Fig. 3) exhibited the disappearance of alkyne and azide peaks confirming successful reaction. The method is an efficient route for conjugating cellulose to clay.

Discussion

The objective of the presented work was to enhance interfacial interaction between cellulose and clay. In polymer composites, cellulose is added as reinforcement while clay is used for better dispersion of cellulose. However, poor interfacial interaction between the clay and cellulose leaves us wanting for more (Ludvik, Glenn et al. 2007, Thunwall, Boldizar et al. 2008). Cellulose and clay are separately used as fillers in many polymers and both suffer from their limited interfacial interactions with the polymer matrix. Individually, cellulose and clay have been surface functionalized to enhance their interactions with polymer matrix. Clay, for example, was surface functionalized with silane to enhance its interaction with rubber (Dai and Huang 1999). Silane chemistry on cellulose is also attempted (Abdelmouleh et al. 2002, 2005; Ly et al. 2008; Xie et al. 2010). Considering the prior art in silane based chemistries on cellulose and clay, same was employed to functionalize cellulose and clay.

While functionalization results in surface groups that enhance physical interactions between the components; for enhanced mechanical properties, chemical reactions that result in covalent bond are welcomed more. Hence, instead of targeting end groups on silane that would have enhanced only physical interaction between cellulose and clay, azide and alkyne that can form covalent bonds were selected. Moreover, azide–alkyne cycloaddition reaction does not produce any by-product, making the choice of this chemistry further easier.

To realize azide–alkyne cycloaddition reaction, silane derivatives were synthesized as has been mentioned in “Synthesis of N-(3-(triethoxysilyl)propyl)propiolamide (AMIPTES)” and “Synthesis of (3-azidopropyl) triethoxysilane (AZIPTES)” sections. The products were characterized using FTIR and NMR (Figs. 4–7). While azide derivative of silane was used to functionalize cellulose, clay was functionalized with alkynyl derivative (“Silanization of microcrystalline cellulose (MCC) with AZIPTES” and “Silanization of kaolinite clay by AMIPTES” sections). FTIR confirmed the successful incorporation of the groups onto the surface of clay and cellulose. Increasing the amount of silane derivatives during functionalization resulted in sharper peaks of the corresponding functional group. For example, the azide peak at ~2100 cm−1 (Fig. 1) increasingly became stronger when the azide was increased from 1 to 10 % during functionalization of cellulose. Similar results, albeit not as strong, were also observed in alkynyl functionalization of clay (Fig. 2). A weak band could be due to low efficiency of reaction.

Following successful incorporation of azide and alkynyl derivatives of silane on cellulose and clay respectively, click reaction was performed using CuBr as acatalyst in DMSO (“Click chemistry between kaolinite clay and MCC” section). The specific stretching band at ~2055 cm−1 for azide and at ~2117 cm−1 alkyne group disappeared from the products confirming successful azide–alkyne cycloaddition reaction. The covalent interaction between cellulose and clay was hence realized. Further studies on the effect of this bond formation on mechanical properties can be performed.

The silane functionalization followed by click reaction to covalently bind two components, cellulose and clay in this case, is presented. It will be interesting to study the mechanical properties of the product. This chemistry can be incorporated in other systems as well where covalent bond between two components is desired.

Conclusion

The present study is focused to incorporate covalent linkage in functionalized MCC and kaolinite using click chemistry. For this, the AMIPTES and AZIPTES were synthesised and used to functionalize kaolinite clay and MCC, respectively. These functionalized kaolinite and MCC were characterized by their specific stretching bands at 2055 and 2117 cm−1 respectively. Finally these bands disappear in the FTIR of the conjugate obtained after the click reaction between functionalized MCC and kaolinite.

Abbreviations

- APTES:

-

(3-aminopropyl)triethoxysilane

- DCC:

-

N,N’-dicyclohexylcarbodiimide

- DMAP:

-

4-dimethylaminopyridine

- DCM:

-

Dichloromethane

- DMSO:

-

Dimethylsulphoxide

- DMA:

-

Dimethylacetamide

- EtOAc:

-

Ethyl acetate

- EDC.HCl:

-

1-Ethyl-3-(3-dimethyllaminopropyl)carbodiimide hydrochloride

- PyBOP:

-

Benzotriazol-1-yl-oxytripyrrolidinophosphonium-hexafluorophosphat PyBOP

- HBTU:

-

O-Benzotriazole-N,N,N’,N’-tetramethyl-uronium-hexafluoro-phosphate

References

Abdelmouleh M, Boufi S, ben Salah A, Belgacem MN, Gandini A (2002) Interaction of silane coupling agents with cellulose. Langmuir 18(8):3203–3208

Abdelmouleh M, Boufi S, Belgacem MN, Dufresne A, Gandini A (2005) Modification of cellulose fibers with functionalized silanes: effect of the fiber treatment on the mechanical performances of cellulose–thermoset composites. J Appl Polym Sci 98:974–984

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87(2):963–979

Binder WH, Sachsenhofer R (2007) ‘Click’ chemistry in polymer and materials science. Macromol Rapid Commun 28:15–54

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibres. Prog Polym Sci 24(2):221–274

Bovey FA, Winslow EH (1981) An introduction to polymer science. Academic press, New York

Chang C, Lue A, Zhang L (2008) Effects of crosslinking methods on structure and properties of cellulose/PVA hydrogels. Macromol Chem Phys 209(12):1266–1273

Coffey DG, Bell DA, Henderson A (2006) Food polysaccharides and their applications. Taylor and Francis, Boca Raton

Czaja WK, Young DJ, Kawecki M, Brown RM (2006) The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8(1):1–12

Dai JC, Huang JT (1999) Surface modification of clays and clay–rubber composite. Appl Clay Sci 15(1–2):51–65

Dam HH, Caruso F (2012) Modular click assembly of degradable capsules using polyrotaxanes. ACS Nano 6(6):4686–4693

Eichhorn S, Dufresne A, Aranguren M, Marcovich N, Capadona J, Rowan S, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito A, Mangalam A, Simonsen J, Benight A, Bismarck A, Berglund L, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):1–33

Fournier D, Hoogenboom R, Schubert US (2007) Clicking polymers: a straightforward approach to novel macromolecular architectures. Chem Soc Rev 36(8):1369–1380

Freeman GM, Marshall CJJ, Lackey WO, Onizawa M (2000) Silane treated clay production method, silane treated clay and composition containing same. Sanyo Trading Co., J M Huber Corporation, Tokyo, Edison

Garcia de Rodriguez NL, Thielemans W, Dufresne A (2006) Sisal cellulose whiskers reinforced polyvinyl acetate nanocomposites. Cellulose 13(3):261–270

Himo F, Lovell T, Hilgraf R, Rostovtsev VV, Noodleman L, Sharpless KB, Fokin VV (2005) Copper(I)-catalyzed synthesis of azoles. DFT study predicts unprecedented reactivity and intermediates. J Am Chem Soc 127(1):210–216

Hoenich NA (2007) Cellulose for medical applications: past, present, and future. BioResources 1(2):270–280

Karaaslan MA, Gao G, Kadla JF (2013) Nanocrystalline cellulose/Î2-casein conjugated nanoparticles prepared by click chemistry. Cellulose 20(6):2655–2665

Krassig H, Steadman RG, Schliefer K, Albrecht W (1986) Ullmann’s Encyclopedia of organic compounds. VCH, New York

Liebert T, Hansch C, Heinze T (2006) Click chemistry with polysaccharides. Macromol Rapid Commun 27(3):208–213

Liu A, Walther A, Ikkala O, Belova L, Berglund LA (2012) Clay nanopaper with tough cellulose nanofiber matrix for fire retardancy and gas barrier functions. Biomacromolecules 12(3):633–641

Ludvik C, Glenn G, Klamczynski A, Wood D (2007) Cellulose fiber/bentonite clay/biodegradable thermoplastic composites. J Polym Environ 15(4):251–257

Ly B, Thielemans W, Dufresne A, Chaussy D, Belgacem MN (2008) Surface functionalization of cellulose fibres and their incorporation in renewable polymeric matrices. Compos Sci Technol 68(15–16):3193–3201

Manna AK, Tripathy DK, De PP, De SK, Chatterjee MK, Peiffer DG (1999) Bonding between epoxidized natural rubber and clay in presence of silane coupling agent. J Appl Polym Sci 72:1895–1903

Maren R, Shuping D, Anjali H, Yong Woo L (2009) Cellulose nanocrystals for drug delivery. Polysaccharide materials: performance by design, vol 1017. American Chemical Society, Washington, pp 81–91

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibres, biodegradable polymers and biocomposites: an overview. Macromol Mater Eng 276–277(1):1–24

Mohanty AK, Misra M, Drzal LT (2002) Sustainable bio-composites from renewable resources: opportunities and challenges in the green materials world. J Polym Environ 10(1):19–26

Moses JE, Moorhouse AD (2007) The growing applications of click chemistry. Chem Soc Rev 36(8):1249–1262

Okiyama A, Motoki M, Yamanaka S (1992) Bacterial cellulose II. Processing of the gelatinous cellulose for food materials. Food Hydrocolloids 6(5):479–487

Orts WJ, Shey J, Imam SH, Glenn GM, Guttman ME, Revol J-F (2005) Application of cellulose microfibrils in polymer nanocomposites. J Polym Environ 13(4):301–306

Papalos JG (1966) Silane treated clay reinforced resin compositions. U. S. P. Office, J M. Huber Corporation, USA, Locust

Qin A, Lam JWY, Tang BZ (2010) Click polymerization: progresses, challenges, and opportunities. Macromolecules 43(21):8693–8702

Rostovtsev VV, Green LG, Fokin VV, Sharpless KB (2002) A stepwise huisgen cycloaddition process: copper(I)-catalyzed regioselective “ligation” of azides and terminal alkynes. Angew Chem Int Ed 41(14):2596–2599

Thirumurugan P, Matosiuk D, Jozwiak K (2013) Click Chemistry for drug development and diverse chemical-biology applications. Chem Rev 113(7):4905–4979

Thunwall M, Boldizar A, Rigdahl M, Banke K, Lindström T, Tufvesson H, Högman S (2008) Processing and properties of mineral-interfaced cellulose fibre composites. J Appl Polym Sci 107:918–929

Wan YZ, Huang Y, Yuan CD, Raman S, Zhu Y, Jiang HJ, He F, Gao C (2007) Biomimetic synthesis of hydroxyapatite/bacterial cellulose nanocomposites for biomedical applications. Mater Sci Eng C 27(4):855–864

Wheeler PA, Wang J, Mathias LJ (2006) Poly(methyl methacrylate)/laponite nanocomposites: exploring covalent and ionic clay modifications. Chem Mater 18(17):3937–3945

White LA (2004) Preparation and thermal analysis of cotton–clay nanocomposites. J Appl Polym Sci 92(4):2125–2131

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Silane coupling agents used for natural fiber/polymer composites: a review. Compos A Appl Sci Manuf 41(7):806–819

Yang MY, Li J, Chen PR (2014) Transition metal-mediated bioorthogonal protein chemistry in living cells. Chem Soc Rev 43(18):6511–6526

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6(9):754–761

Acknowledgments

The research was supported by Department of Science and Technology – Science and Engineering Research Board (DST-SERB), Grant number SERB/CESE/20120156. FTIR and NMR spectroscopy was done in the Chemistry department at IIT Kanpur. The authors are grateful to Prof. Amit Prashant of IIT Gandhinagar for generously donating kaolinite clay.

Conflict of interest

The authors declare no competing financial interest.

Funding Sources

This work is supported by DST-SERB (SR/S3/CE/038/2012).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yadav, P., Chacko, S., Kumar, G. et al. Click chemistry route to covalently link cellulose and clay. Cellulose 22, 1615–1624 (2015). https://doi.org/10.1007/s10570-015-0594-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0594-2