Use of a combination of multistage hydrofracking and high-pressure air injection is proposed for developing low-permeability oil deposits of the Tyumen Suite (Upper Jurassic). An effective inert gaseous agent is formed during intrastratal transformation of the air due to oxidation of the oil. The oil autooxidation mechanism is studied. A weak dependence of the oxidation rate on the oil properties is observed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Oil reserves of the main western Siberian reservoirs are gradually being depleted. New reservoirs, usually with poorer characteristics and in difficultly accessible locations, are being developed to compensate for falling oil production. The significant oil reserves of the Tyumen suite are a promising source for the Russian petroleum industry [1, 2] although their degree of extraction is very low.

Development of Tyumen suite oil reserves is complicated by the low permeability of the reservoir because of the high content of clayey components in the rock [2]. Flooding was proposed for extraction of Tyumen suite oil. However, the problem of flooding the Tyumen suite has not been solved [3]. The recommendation to carry out massive (multistage) hydrofracking of the reservoir (MHFR) entailed the selection of an extracting agent. In our opinion, flooding must be replaced by gas extraction in the usually proposed version [1,2,3] for development of reserves in Tyumen suite low-permeability reservoirs. Mixing displacement of light oil occurs for a certain gas composition. This can completely or to a large extent suppress capillary forces that hold the oil in the reservoir. Gas poses significantly less resistance to filtration (as compared to H2O), which is also necessary to extract oil from the low-permeability Tyumen suite.

High-pressure air injection (HPAI) could be recommended as the gas method [5, 6]. An essentially similar method is called thermal gas treatment (TGT) in Russia [4] and low-temperature oxidation (LTO) in Great Britain [7]. The HPAI (TGT) method, which consists of injecting air into a light-oil reservoir, causes oxidation (but not combustion) in the liquid phase in the zone near the wellbore and simultaneous consumption of atmospheric oxygen to generate in the reservoir an inert gas agent consisting of N2 and light-oil hydrocarbons that evaporated into it.

HPAI could solve the main problem of gas methods, i.e., a shortage of gas fluids. HPAI (TGT) represents a modern method for using air in improved secondary recovery methods and for enhancing oil recovery from light-oil fields in low-permeability reservoirs. The HPAI (TGT) mechanism includes intrastratal transformation of injected air into an effective extracting agent as a result of the intrastratal low-temperature oxidative processes. HPAI (TGT) differs in principle from dry, wet, and super-wet intrastratal combustion by being a gas method and not a thermal one. TGT designs were first tested at several fields in the former USSR and USA [4]. This method was tested and proposed for implementation at many fields in the USA, China, North Sea, etc., mainly for light-oil fields with high reservoir temperatures. TGT (HPAI) is considered an oil recovery method for low-permeability reservoirs where flooding is ineffective.

HPAI (TGT) results obtained over more than 30 years at the Buffalo Field are most impressive. The work showed that 18.1 million barrels (~2.5 million tons) of additional oil was produced using TGT technology at the Buffalo Field as of Dec. 31, 2009 [8]. The cumulative volume of injected air was 262.1 billion ft3. The processing efficiency of air injection in various sections was 2,300-3,400 m3/t of additional oil, which was close to that of associated petroleum gas (APG) at light-oil fields.

Two main issues, i.e., a safety assessment and the efficiency of the gaseous extracting agent, had to be solved in order to recommend TGT for development of Tyumen suite oil reserves.

The rate of chemical oxidation of oil by air, which decreased the oxygen concentration in the gas, determined the safety of HPAI (TGT). The probability of atmospheric oxygen breaking through into producing wells could be estimated using information on the rate of oil autooxidation by atmospheric oxygen. Oils from various Tyumen suite fields differed from each other. Therefore, four samples of Jurassic oil taken from various fields and two oil samples from other reservoirs that were studied for comparison were used in the work.

The oil-extracting activity of the product from intrastratal transformation of air into an inert gaseous agent was assessed using a slim-model of the reservoir.

Fresh oil samples from the field were dehydrated by alternating centrifugation and settling. The water content in the samples used in the oxidation experiments was 0.1-0.3%. An oil sample containing <0.1% water was used for the filtration experiment.

The kinetics of oil oxidation and gaseous product formation were studied using an apparatus based on a PARR model 4842 autoclave. The experiment was carried out with stirring of the liquid phase (300 rpm) to ensure a kinetic reaction mode. Oil was oxidized in the presence of H2O, which was dispersed in the oil as fine drops simulating oil ganglia in the actual reservoir by stirring.

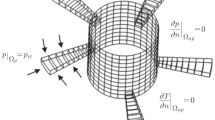

A UIK-5 modified filtration apparatus was used in the experiment. The oil-extracting properties of HPAI were tested using the slim-tube method for determining the miscibility of oil and gas [9, 10]. A slim-tube [stainless-steel tube (9.9 m × 0.8 cm) packed with coarse quartz sand and twisted into a spiral of diameter ~0.35 m] was saturated with the recombined oil model, which was expelled by APG and HPAI model gas. The experiment was performed under average reservoir conditions for the large Pri-Ob field, i.e., 27 MPa and 92°C. The experimental method was described in details before [10].

The model APG was prepared from methane, propane, butane, and isobutane and was compressed to the reservoir pressure at 80°C to ensure the gas components were completely vaporized. The HPAI (TGT) model gas prepared by metering the components into a piston column. The composition of gas formed by intrastratal transformation of air was estimated by modeling air injection and the reservoir temperature with air injection and analyzing the oil by simulated distillation. Three compositions, the driest of which was studied using the slim-tube method, were selected depending on the HPAI scenario. The HPAI gas composition was graciously supplied by A. G. Telin (Table 1).

The recombined oil model was prepared by dissolving methane, propane, butane, isobutane, and hexane in degassed and dehydrated Pri-Ob field (Jurassic) oil. The average molecular mass of the dissolved gas was the same as the average molecular mass of actual APG. The gas factor was 45 m3/m3. A propane—butane mixture from a Moscow refinery was used to model the propane—butane fraction (PBF).

Oil samples from Pervomaiskii Jurassic (Ju-1 and Ju-2), Pri-Ob (Pr), and western Salymskii (WS) fields were studied. Oil from PK reservoir of Tazovskii field (PK) and from the carbonate reservoir of Yakushkinskii field in Samara Oblast (Ya) were investigated for comparison.

Liquid-phase autooxidation of hydrocarbons by oxygen follows a radical-chain mechanism analogous to that for autooxidation of hydrocarbons and oxygen-containing compounds [11].

The kinetics of oxygen absorption during autooxidation of hydrocarbons and oxygen-containing organic compounds were typical of autocatalytic processes [11]. The initial rate of oxygen absorption was very slow and practically equal to zero (induction period). Then, it increased after the induction period and reached the maximum. The final oxidation rate slowed because oxygen was consumed or difficultly oxidized products accumulated.

Oxygen absorption during autooxidation of all oil samples began practically immediately after the reaction mixture was heated. This differentiated the autooxidation kinetics of the oil from the kinetic features of hydrocarbon autooxidation (Fig. 1). Later, the kinetic features of oil and hydrocarbon autooxidation were the same. Two reaction steps could be identified from the oxygen-absorption kinetics:

-

a fast (initial) step in the initial oxidation stages (apparently, chemisorption of oxygen by readily oxidized oil components, probably resins, without radical formation),

-

the main step where the main portion of oxygen was absorbed that was analogous to hydrocarbon autooxidation kinetics.

Figure 2 shows the generalized oxygen absorption kinetics during autooxidation of any oil sample by air. It is noteworthy that the fast reaction step was not observed for autooxidation of hydrocarbons and oxygen-containing organic compounds [3]. The fast reaction step was typical only of oil, oil-bearing rock, and shale.

Studies of atmospheric oxygen absorption kinetics in the fast reaction part showed that the reaction proceeded through a bimolecular mechanism: O2-acceptor + O2 → oxidation product.

The second main reaction step involved absorption of a large amount of O2. The main step of oil oxidation was analogous to the autooxidation kinetics of hydrocarbons and oxygen-containing organic compounds. The induction period (τ) could be determined from the oxygen absorption kinetics during oil autooxidation (Fig. 2). The reaction rate increased rapidly after the induction period was over. The oxidation occurred at an approximately constant (maximum) rate (Vmax). The fast and main reaction steps coalesced into a single common step at temperatures above 170-180°C because the induction period approached zero (Fig. 1).

The effect of temperature on oxygen absorption kinetics was studied during the main oxidation step in the range up to 180-200°C. The studies showed that the temperature dependences of τ and Vmax obeyed an Arrhenius equation (Table 2):

and

where τo and Vo are pre-exponential factors; R, universal gas constant; T, absolute temperature (K); and E1 and E2, effective activation energies (Table 2).

Figure 3 shows that the effective activation energies and pre-exponential factors were related, i.e., a compensatory effect was observed during oil autooxidation. The compensatory effect in the oil autooxidation reaction decreased the dependence of the oil oxidation rate on it composition and origin, i.e., the TGT method was rather universal. The high reservoir temperature of the Tyumen suite (up to 140°C) was responsible for the high oil autooxidation rate and complete absorption of atmospheric O2 in close proximity to the bottom.

The kinetic data (Table 2) could be used for a safety assessment of the HPAI (TGT) method. The main hazard during high-pressure air injection is breakthrough of atmospheric oxygen into producing wells. The assessment showed that the induction period during oil autooxidation was ~1-2 d at the reservoir temperatures of most western Siberian fields, i.e., TGT satisfied the safety criterion. The study demonstrated that the TGT (HPAI) method could be used successfully and safely to extract oil from fields assigned to the Tyumen suite.

The main gaseous products from oil autooxidation are CO2 and CO and small amounts of light hydrocarbons. Apparently, the main liquid products are organic acids.

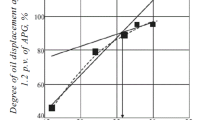

The slim-tube method was used to evaluate the oil-extracting activity of the TGT gas agent (Table 3). Experiment No. 1 tested the miscibility of oil and APG. An oil extraction coefficient of 92% was attained after passing 1 v.v. of model APG (filtration rate 12 mL/h). Thus, lipophilic APG extracted oil via multi-contact mixing displacement. Experiment No. 2 tested the TGT model gas mixture. An extraction coefficient of 84% was obtained after passing 1 v.v. of the mixture (filtration rate 12 mL/h), i.e., limited mixing displacement that was rather similar to complete miscibility of the gas and oil was observed.

Experiment No. 3 evaluated the influence of filtration rate on the oil-extracting capability of the TGT model gas mixture and used a faster filtration rate (21 cm3/h) than in Expt. No. 2. An extraction coefficient of 93% was attained if a faster injection rate was used, i.e., the increased displacement rate allowed extraction coefficients corresponding to mixed displacement of oil by gas to be obtained. Mixed and limited-mixed displacement differed little at high reservoir temperatures because of low interfacial tension (IFT) and low oil viscosity, which explained the obtained result. Thus, oil was effectively displaced by interacting with the TGT gas mixture and APG. This provided a high degree of oil extraction from the field.

Capillary forces must be suppressed, i.e., IFT must be reduced, for oil production from low-permeability reservoirs. The IFT decreases to zero if the miscibility of the gas and oil increases (in mixed displacement). The miscibility of the oil and gas could be increased if a slug of C3+ hydrocarbons was injected before the gas. A study of the influence of pretreatment with the PBF on the oil-extracting characteristics of methane (Table 3) showed that injecting a slug of the PBF could increase the miscibility from unmixed to mixed displacement for extraction of oil using PBF + methane. The mixture of light PBF-type hydrocarbons would be produced in the field because Tyumen suite oil usually has a high gas factor.

It is noteworthy that the TGT gas agent should be inert to rock. Its use to extract oil should not reduce the permeability of clayey rock, which could be observed for oil extraction by H2O.

Thus, the research found that:

-

the intrastratal transformation product of air was a highly efficient oil-extracting agent under the conditions of Jurassic reservoirs;

-

oils from different fields were oxidized at approximately equal rates, i.e., HPAI could be used at practically any light-oil field without additional research;

-

the induction period of the main oil autooxidation step was rather short for reservoir temperatures >60-70°C, which ensured safe performance of the process;

-

the miscibility of the gas could be increased to full miscibility with oil by injecting a PBF slug [or analogous broad fraction of light hydrocarbons (BFLH)];

-

a combination of horizontal drilling, MHFR, HPAI, and a BFLH slug was recommended for developing Tyumen suite oil reserves in order to increase the miscibility of the oil and gas agent.

References

V. A. Kazanenkov, Buren. Neft, No. 3, 3-11 (2016).

A. A. Sevost2yanov, K. V. Korovin, O. P. Zotova, et al., Vestn. Perm. Univ. Geol., 16, No. 1, 61-67 (2017).

A. N. Yanin, Buren. Neft, No. 11, 22-24 (2016).

A. A. Bokserman and M. F. Yambaev, in: Proceedings of the 12th European Symposium on Enhanced Oil Recovery, Kazan, 2003.

M. R. Fassihi, D. V. Yannimaras, and V. K. Kumar, SPE 28733, 1994.

M. L. Fraim, P. D. Moffitt, and D. V. Yannimaras, SPE 38905, 1997.

M. Greaves, Business Briefing: Exploration & Production: The Oil & Gas Review, 2004, pp. 108-121.

V. K. Kumar, C. Gutierrez, and C. Cantrell, SPE 133494, 2010.

A. M. Polishchuk, V. N. Khlebnikov, and V. B. Gubanov, Neftepromysl. Delo, No. 5, 19-24 (2014).

V. N. Khlebnikov, V. B. Gubanov, and A. M. Polishchuk, Neftepromysl. Delo, No. 6, 32-38 (2014).

N. M. Emmanuel, E. T. Denisov, and Z. K. Maizus, Chain Oxidation Reactions of Hydrocarbons in the Liquid Phase [in Russian], Nauka, Moscow, 1965, 375 pp.

Acknowledgments

The work was financially supported by the Ministry of Education and Science of Russia (unique project identifier RFMEFI60617X0005, contract No. 14.606.21.0005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 1, pp. 40 – 44, January – February, 2018.

Rights and permissions

About this article

Cite this article

Gushchin, P.A., Antonov, S.V., Mishin, A.S. et al. Physicochemical Mechanisms of Light Oil Oxidation During Extraction from High-Temperature Low-Permeability Oil Reservoirs. Chem Technol Fuels Oils 54, 64–71 (2018). https://doi.org/10.1007/s10553-018-0899-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-018-0899-6