It is shown that associated petroleum gas (APG) and the product of intrastratal transformation of air (by high-pressure air injection technology) are suitable for oil displacement from low-permeability, high-temperature light oil reservoirs. It was found that APG and air are effective gaseous agents miscible with oil, which are similar in oil-displacing properties. The minimum miscibility pressure (MMP) determination data are presented for an Upper Jurassic oil-APG system. The miscibility in the oil-APG system was achieved by the multicontact mechanism of interaction between oil and enriched gas. A new method is proposed for graphical determination of MMP as a function of gas breakthrough due to pressure, and a method for enhancing gas impact efficiency and for achieving miscibility at a pressure below the MMP, which consists in injection of a liquefied gas prefringe or a wide fraction of hydrocarbons, is validated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Improving oil recovery technology, involving oil deposits in development, and raising oil recovery factor (ORF) are basic requirements for development of petroleum chemistry. All potential oil resources can be divided in terms of their applicability for producing fuels and oils as follows:

-

viscous and heavy oil;

-

residual oil of common oil deposits, including those regarded as depleted,

-

light oil of low-permeability reservoirs and source formations.

For oil refining, light oil, which yields light oil products maximally, is of the highest interest. Light oil can be refined by the existing technologies using currently operating equipment. In Russia, heavy oil refining is less developed, resulting in increased use of secondary processes, which requires investment for modernizing refineries, i.e., which is economically more expensive. Viscous and residual oils of common deposits contain heavy components, which complicate fuel cycle refining.

The problems of recovery of depleting light oil resources and attaining high ORF are pressing for future petroleum chemistry. Long-term security of oil resource base and oil refining industry in Russia is linked with low-permeability reservoirs and application of gas and water-gas technologies of oil recovery.

The procedure for investigating oil-associated petroleum gas (APG) system using "slim tube" was proposed more than 50 years ago, but in Russia it did not gain popularity because of limited application of gas methods for oil recovery and wide application of traditional method of determination of the efficiency of oil displacement by water in laboratory conditions [OST (Branch Standard) 391-958-6] using cement core models of the reservoir.

The necessity of application of gas technologies aroused interest in the 'slim tube" method, which nicely models the processes of mass exchange between the displacing gas (solvent) and the oil. Of the classical studies on the theory and practice of application of slim tube, mention may made of the studies [1,2,3]. The slim-tube method is used at VNIIneft’ (All-Russian Scientific Research Institute of Oil and Gas) [4,5,6] and RGU Neftii i Gaza im. I. M. Gubkina (I. M. Gubkin Russian State University of Oil and Gas [7,8,9]. In [10] it was shown that the OST method (in contrast to the slim-tube method) does not enable one to fully ascertain the possibility of oil displacement by applying gaseous mixing fluids and that the level of mass exchange between the oil and the gaseous fluid (solvent) is higher, the worse the OST method models the oil displacement process.

While investigating gas technologies it is important to determine the level of miscibility between the oil and the gaseous agent (miscibility, limited miscibility, or displacement without mixing). The higher the miscibility level [1,2,3], the lower the surface tension at the oil-gas (solvent) interface, the more efficient the oil displacement is, and gas breakthrough does not occur further. A knowledge of the miscibility level helps in mathematical modeling of the oil displacement processes (their calibration) [1].

The main purpose of this study was to determine the minimum oil and APG miscibility pressure in real reservoir conditions and to achieve complete miscibility of oil and gas at pressures below the minimum miscibility pressure (MMP).

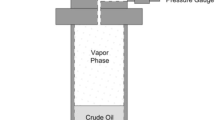

The slim tube method was used in the experiments. The displacement process was implemented in a spiraled (spiral diameter about 0.35 mm) stainless steel tube (length 9.9 m and inner diameter 0.8 cm) packed with coarse quartz sand and saturated with a recombined model of oil. The oil was displaced with gaseous fluids. The composition of the gases, including those used for preparation of the recombined oil model, is given in Table 1.

The experiments with the product of intrastratal transformation of air by high-pressure air injection (HPAI) technology and APG were conducted in reservoir conditions of the Priob’ field (pressure 27 MPa, temperature 92°C) and the MMPs for APG and for improving oil and gas miscibility were determined in conditions of Upper Jurassic reservoirs of the Sigovian (SG) suites at 27.8 MPa and 86°C. The experiments with individual gases and liquefied gas (LG) were conducted in conditions of the Severo-Mogda deposit in East Siberia (21.7 MPa, 19.2°C). The experimental procedure is described in [8, 10].

Mass exchange takes place when the HPAI gas and the oil interact: the gas components (mainly nitrogen) dissolve in the oil and the light hydrocarbons (C1-C6) of the oil evaporate [12,13,14]. Mathematical modeling of air injection by HPAI technology was used to determine the temperature in the well-adjoining zone of the reservoir of the field and the composition of the gas produced on intrastratal transformation of air was determined from the data on oil and APG composition. Depending on the HAPAI scenario, three compositions were chosen. The “driest” composition was studied using slim tube method.

Recombined models of oil No. 1 were prepared from oil of the Preob’e field (Jurassic), recombined model of oil No. 2, from the Upper Jurassic (Sigovian suite), and model No. 3, from oil of the Severo-Mogda field by dissolving the main gas components in the oil samples (Table 1). A blend of propane (60 vol. %) and n-butane (40 vol. %) was used as the model of the liquefied gas (LG No.1) or a propane-butane blend of the Moscow refinery, as the model of LG No. 2.

The experiments were performed by two methods. In the first method, a purified alcohol-benzene blend (ABB) and a dried slim tube were saturated with water and then the water was expelled with kerosene in the filtration process and the pressure in the slim tube was raised to the initial pressure of the experiment. The kerosene was replaced by an oil model at room temperature. The oil was expelled by a gas at a chosen pressure and reservoir temperature. In the second method, after saturating with kerosene, the slim tube (cleaned with ABB and dried) was saturated with recombined oil model in the filtration process at experimental pressure and room temperature. Thereafter, the oil was expelled with gaseous fluids and liquefied gas at chosen pressure and reservoir temperature.

When gas methods of oil recovery (including from low-permeability reservoirs) are employed, the first problem is gas selection. In Russian field conditions, such gaseous agents can only be APG and air. Other gases (methane, nitrogen, flue gas, etc.) are ineffective for oil displacement or are not readily available (carbon dioxide).

Utilization of APG is a national requirement. Air (HPAI technology) can be used for oil recovery from low-permeability reservoirs. The HPAI technology is safe and well-studied [12, 15,16,17,18]. Studies of oil oxidation kinetics showed that diverse oil samples are oxidized at identical temperature and close rates, i.e., the HPAI method is quite universal [12, 18,19,20]. The induction period for autooxidation of all the studied oil samples at temperatures above 60°C is short and meets the safety criterion [12].

An estimation was made of the oil displacing capacity of the APG and the product of intrastratal transformation of air by HPAI, which is expounded more fully in [10, 21]. The data in Table 2 indicate that APG and HPAI gas are close in oil displacing characteristics (in conditions of the high-temperature Priob’e field). An effective gaseous agent, which ensures a high level of miscibility between oil and gas (miscibility or limitedly miscible oil displacement conditions), is formed in the intrastratal air transformation process.

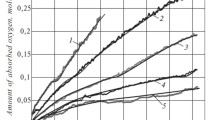

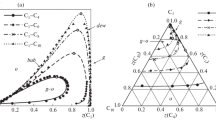

To determine the MMP for APG and oil (with reference to the deposit of the SG suite, Table 3, Figs. 1 and 2), standard method was used, i.e., the amount of oil displaced from the slim tube after injection of 1.2 pore volume (p.v.) of APG was estimated at various pressures (Fig. 1). At 162-2 MPa pressure the degree of oil displacement is 467-9%, i.e., immiscible or limitedly miscible displacement of oil by APG is realized. At higher pressures (26-30 MPa) the oil displacement efficiency is higher and miscibility of APG and oil is observed. At higher pressures (27.8-30 MPa) the oil displacement efficiency is more than 100% and gas breakthrough occurs after injection of 0.99 pore volume and more. At high pressures the multicontact miscibility is realized by the condensing gas mechanism, i.e., the miscibility zone appears at the rear of the APG fringe [2].

In the typical Slim 3 experiment at 27.8 MPa pressure, the APG breakthrough occurs at injection volume of more than 1 p.v., which is evidently impossible. APG breakthrough is detected distinctly from the fast increase in gas factor and decrease in oil shrinkage factor in the measuring vessel after degassing. After injection of 1.2 p.v. of PAG the displacement efficiency reached an unrealistic value of 111%. The reason for the observed unrealistic gas breakthrough and oil displacement efficiency values is dissolution of the APG components in the oil: condensation of the heavy components of the APG in the oil leads to increase in oil volume and decrease in gas volume in the slim tube (relative to the APG volume at the slim tube inlet). However, the scope of the experiment does not permit evaluation of this process, especially since a part of the light oil components passes into the gas phase.

The oil displacement efficiency value can be made more precise. The oil contains components that are incapable of passing into the gas phase even in miscibility conditions and that drop out from the oil upon contact with Cs- Cs hydrocarbons. These are asphaltenes, resins, and high-molecular-weight components (ARC) of the oil, a part of which may remain in the porous medium of the slim tube. A large part of the ARC will be expelled with the main mass of the oil from the slim tube before the gas breakthrough, when there will be no interaction between the ARC and the APG.

Alcohol-benzene blend (ABB) is capable of extracting ARC from the reservoir model, and after evaporation and drying of the ABB eluent the content of residual components of the oil in the slim tube was determined. The weight of the ARC residue in the Slim 3 experiment was 8.6 g. Considering that the ARC is close to 1, it can be assumed that after displacement by APG at a high pressure, only 8.6 ml of ARC, which is about 5% of the volume of the original oil, remained in the reservoir model. So, it can be assumed that the final oil displacement efficiency is 95%. In the Slim 7 experiment (30 MPa) the residue after extraction by ABB was 4.7 g. which is about 2.9% of the volume of the original oil in the reservoir model, i.e., the oil displacement efficiency in the experiment was 97%. The 95% oil displacement efficiency in the case of miscibility was used to determine MMP (Fig. 1, Table 3).

The aggregate of experimental data (Table 3, Fig. 1) indicates that "classical" dependence of the oil displacement efficiency on the pressure, which helps determine the MMP (the MMP for this system is 26 MPa) quite reliably, is observed in the miscibility study. However, the data in [22] show that the scatter (error) of oil displacement efficiency determination may be a ground for doubting the accuracy of determination of the miscibility conditions and the MMP of the oil and gas. In fact, as evident form Fig. 1, the observed dependence of the displacement efficiency on the pressure can be described by a smooth curve. For determining the MMP more precisely and easily, it is better to use the dependence of the instant of gas breakthrough on the pressure, which allows a more precise and unambiguous determination of the MMP. For the referred system, the result of MMP determination was identical (Figs. 1 and 2).

Comparison of the data in Figs. 1 and 2 and the data in [10] shows that while the gas breakthrough occurred after injection of 0.9 p.v. and more of a gaseous fluid, the oil displacement condition was miscible (Table 3). For MMP determination, more informative is the dependence of the instant of gas breakthrough on the pressure than the dependence of the degree of oil displacement on the pressure (Figs. 1 and 2). Before gas breakthrough from the slim tube, the major part of the original oil is displaced. After gas breakthrough from the reservoir model, a mixture of oil and gas is liberated whereupon mass exchange occurs between the liquid and the gas phase, which adds uncertainty to the results of measurement of the volume of displaced oil and the volume of APG injection. The invariability of the properties of the displaced oil before the gas breakthrough facilitates diminution of the influence of dynamic factors of the displacement process and mass exchange on the results.

Let us examine the possibility of achieving complete miscibility between the gas and the oil. The current or even the initial reservoir pressure at the field may be lower than the MMP. For enhancing the efficiency of the gas method of impacting, it is possible:

Elevating reservoir pressure by injecting additional volumes of APG is a complicated and costly process. Enriching APG with heavy components is quite difficult and is achieved usually by using a mixture of gases of varying composition [23, 24]. The simplest and cheapest method of enhancing efficiency of gas impact is injecting before the APG a prefringe of a liquefied gas or a WLHF generally obtained directly at the field while stripping the APG of the light oil [25].

The gas technologies are effective in low-permeability reservoir conditions for achieving complete miscibility of oil and displacing gas. Reservoir conditions and composition of gases and oils could be inadequate for the miscibility, so it is essential to find ways of achieving oil and gas miscibility. APG was chosen as the model gas and the experiment was conducted at 22 MPa, which is below the MMP (Table 4). After standard preparation for the experiment, the test of Slim-8, which is maximally close to Slim-5, was carried out. The difference between the Slim-8 and Slim-5 tests was that oil displacement occurred under the impact of a fringe of the model LG No. 1 (propane + butane) and then of APG.

Initially, 0.207 p.v. of the liquefied gas was injected into the slim tube at 22 MPa pressure. After the LG fringe, switch was made to injection of APG of usual composition for the determination of MMP (Tables 1 and 3). The LG and APG breakthroughs (perhaps LG initially) occur after injection of 1.9-1.2 p.v. of APG and the final gas breakthrough (perhaps APG) occurs after injection of 1.42 p.v. of fluids. The oil displacement efficiency (after deducting the LG injection volume) at the instant of the breakthrough exceeded 100%, which indicates that the LG and APG are soluble in the oil. Miscibility (more precisely, two miscibilities) of fluid is observed: LG displaces oil in mixing mode and APG displaces LG. Upon filtration of LG and APG fringes, low pressure drops were observed due to low viscosity of the fluids. At the end of the Slim-8 experiment, extraction with ABB and stripping of the filtrate showed that only 0.75 g of oil residues was left in the slim tube, i.e., the oil displacement efficiency in the experiment was very high (about 99.5%). Comparison of the results of Slim-5 and Slim-8 experiments (Table 4) shows that the miscibility between the oil and the APG can be improved using LG fringe. The APG components can be utilized at the same time.

The APG used in the study is quite "fat" and the pressure in the Slim-8 experiment differed little from the MMP. Therefore, the possibility of enhancing miscibility of oil and gaseous fluid was explored in the case where a "dry" gas (methane) was used for displacement. The study was carried out at the low reservoir temperature of the Severo-Mogda field (Table 5).

First a fringe of LG No. 2 in amount of 0.20 p.v. and then methane was injected into the slim tube. The value of the gas factor of production at the outlet before the gas breakthrough matched the value for the oil model. The breakthrough of gas (more precisely, components of LG No. 2) occurred after injection of 0.905 p.v. of fluids (LG No.2 + methane), which indicates miscible oil displacement. Simultaneously was observed a sudden increase in gas factor. The oil displacement efficiency stabilized at 97.1%. The obtained result was higher than in the case of oil displacement by liquid carbon dioxide (carbonic acid) (94.8%) and much higher than in the case of oil displacement by methane (38.3%) and by APG (68.3%). Thus, the proposed method of elevating the miscibility level is quite universal and is applicable for use of poorly active gaseous agents.

Change history

20 November 2018

There is an error in the article metadata on SpringerLink, the first author's name is incorrect. It should read P. A. Gushchin.

References

F. I. Stalkup, Miscible Displacement, Society of Petroleum Engineers AIME, 1984, p. 164.

L. W. Lake, Enhanced Oil Recovery, Prentice Hall Publ., Englewood Cliffs, New Jersey (1989), p 550.

W. F. Yelling and R. S. Metcalfe, J. Petrol. Technol., 32, No. 1,1601-1668 (1980).

V. B. Gubanov, Peculiarities of Oil Displacement by Carbon Dioxide in Presence of Mass Transfer Between Gases [in Russian], Candidate's dissertation, VNIIIneft, Moscow (1986).

A. M. Petrakov, Yu. A. Egorov, I. A. Lebedev, et al., Neft. khorz., No. 2, 604406 (2016).

G G. Vakhitov, V. G Skripka, A. A. Fatbilin, et al., Ntritepromyst Delo i Transport, No. 1, 131-136 (1985).

V. N. Khlebnikov, A. M. Polishchuk, and V. B. Gubanov, Nefispromyst Delo i Transport, No. 5, 192-194 (2014).

V. N. Khlebnikov, A. M. Polishchuk, and V. B. Gubanov, Nefiepromysl. Delo i Transport, No. 6, 323-328 (2014).

V. N. Khlebnikov, A. M. Polishchuk, and V. B. Gubanov,Nefiepromyst Delo i Transport, No. 9, 434-437 (2014).

M. Lyan, Physical Modeling of Oil Displacement by Gas (Solvent) Using Core Reservoir Models and Slim Tube [in Russian], Candidate's dissertation, IPNG, Moscow (2017).

I. Z. Mukhametzyanov and N. G. Glavnov, in: Abstracts ofPapers at X71 All-Russia Sci.-Tech. Conf. "Current Problems of Development of Oil-Gas Complex of Russia [in Russian], I. M. Gubkin Russian State University of Oil and Gas, Moscow (2018), P. 97.

V. N. Khlebnikov, S. V. Antonov, I. V. Khamidullina, et al., J. Petrochem. Univ., 29, No. 5, 263-267 (2016).

D. V. Yannimaras, A. H. Sufi, and M. R. Fassihi, "The case for air injection into deep light oil reservoirs," Proc. 6 th Europ. IOR Symp., Stavanger, Norway, 212-213 (1991).

R G. Barzin, S.A. Moore, M. G. Mehta, et al., SPE, 129691 (2010).

V. K. Kumar, C. Gutierrez, and C. Cantrell, "30 years of successful high-pressure air injection: performance evaluation of Buffalo field, South Dakota," SPE, 133494.

A. A. Bokserman and M. F. Yambaev, Collec. Paps. 12 th Europ. Symp. Enhancing Oil Recovery [in Russian], Kazan, Russia (2003).

M. F. Yambaev, Basic Characteristics of Thermal Gas Method of Increasing Oil Recovery with Reference to Conditions of Complexly Built Reservoirs (Based on Numerical Modeling) [in Russian], Candidate's dissertation, VNIIneft, Moscow (2006).

P. A. Guschin, S. V. Antonov, A. S. Mishin, et al., Chem. Technol. Fuels and Oils, 54, No. 1, 647-651 (2018).

V. N. Khlebnikov, P. M. Zobov, S. V. Antonov, et al., Bashkir. Khim. Zh., 18, No. 4, 879-882 (2011).

V. N. Khlebnikov, A. S. Mishin, P. M. Zobov, et al., Bashkir. Khim. Zh., 19, No. 3, 121-127 (2012).

V. N. Khlebnikov, A. S. Mishin, M. Lyan, et al., Tr. RGUNgfti i Gaza im. I. M. Gubkina, No. 1, 364-366 (2016).

M. Jamiu, Ekundaayo, G. Shawket, et al., Soc, of Petrol. Engineers, 2013.

S.-T. Lee, T. P. Moulds, R. Narayanan, et al., Soc, of Petrol. Engineers, 2001

T. P. Moulds, P. L. McGuire, G R. Jerauld, et al., Soc, of Petrol. Engineers, 2003.

I. A. Iskhakov, G. Rh. Gabitov, and K. Kh. Gainullin, Neff. Khoz., No. 4, 494-495 (2003).

This study was carried out with the Government financial support through the Ministry of Education and Science of Russia (unique identifier of works (project) RFAIEF1606177(0005, Agreement No. 14.606.21.0005).

The authors of this article express their gratitude to A. G. Tel in, Ph.D. Chem., for providing data on the composition of the gaseous fluids.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 4, pp. 42 – 47, July – August, 2018.

Rights and permissions

About this article

Cite this article

Gushchinu, P.A., Cheremisin, A.N., Glavnov, N.G. et al. Mechanisms of Mass Exchange Between Light Oiland Petroleum Gas in Low-Permeability Reservoir Development Process. Chem Technol Fuels Oils 54, 457–466 (2018). https://doi.org/10.1007/s10553-018-0947-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-018-0947-2