Abstract

Changes in temperature and pressure conditions during the development of an oil reservoir with a high paraffin content in a limiting saturated state causes an in-situ phase transition to a solid state, and the filtering of a mixture of oil with solid paraffin particles at a temperature below the flocculation temperature causes clogging in the pore space of the reservoir in narrow places and bottle necks of pores. Thus, laboratory studies are carried out to determine the critical points and parameters of an oil — gas — paraffin mixture under various thermobaric conditions. A mathematical model is developed that describes wax deposition in the pore space of a low-temperature oil reservoir and makes it possible to calculate its permeability during development. The model parameters are adapted to their experimental values. Numerical calculations are used to determine the values of the main parameters that affect the reservoir permeability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Large oil reserves in Eastern Siberia are concentrated in hydrophobic low-temperature (12–20°C ) reservoirs with an initial pressure of 15–16 MPa. Reservoir oil is characterized by a high content of paraffins (mass fraction up to 5%) in an extremely saturated state. Technogenic impact on a reservoir (pressure drop) during its development causes the release of an oil-dissolved gas into a separate filtering phase and cools the reservoir down due to the Joule — Thomson effect. As temperature drops, the ability of oil to dissolve paraffin decreases, and, when temperature becomes equal to a temperature of oil saturation with paraffin, the crystallization process begins [1]. At this temperature, there is solid-phase nucleation whose rate can be estimated by the Zeldovich — Frenkel equation [2]. A further decrease in the temperature leads to the formation of visible paraffin crystals (solid particles). The thickness of a diffusion layer near the surface of the paraffin crystal with account for the Landau — Levich assumption about the gradual decay of turbulent pulsations is estimated at a value of the order of 1 \(\mu\)m [3], which is comparable to the characteristic pore size of the reservoir. Consequently, depending on the filtration channel size, flow rate, kinematic viscosity, and diffusion coefficient, the wax crystal and the oil flow can interact both in the entire volume of the pore and in one of its parts.

The phase transition of paraffin to a solid state is not a sufficient condition for the onset of its adsorption on the pore surface and the reservoir filtration channels. The aggregate stability of oil (ability to maintain a particle size) and kinetic stability (ability to keep solid-phase particles in suspension) play an important role in this process [4]. In the case of paraffins, a buckling point is defined as a flocculation temperature. Filtration of the resulting mixture of oil and solid paraffin particles at a temperature lower than the flocculation temperature clogs the pore space in narrow areas and pore throats and consequently reduces the reservoir permeability and productivity.

The purpose of this work is to develop a mathematical model of the wax deposition process in the pore space of a low-temperature oil reservoir during its development. This model being adapted to the experimental data can help one determine the technogenic variation of the filtration characteristics of the reservoir.

1. RESULTS OF LABORATORY STUDIES OF THE OIL — GAS — PARAFFIN SYSTEM

Paraffin phase transition in the pore space can be simulated using laboratory studies of the oil — gas — paraffin system under the conditions reproducing real conditions in the reservoir. The methods of the experimental study of deposition of asphalt-resin-paraffin substances in free volumes and in the core are described in detail in [5].

In this work, the conditions and dynamics of the deposition of solid paraffin particles are determined in the course of experimental studies of the behavior of the multiphase oil — gas — paraffin system in a free volume using ultrasonic, gravimetric, and visual methods. The following values of the oil — gas — paraffin system parameters are obtained depending on the pressure: initial reservoir pressure \(p_{in}=15.5\) MPa, initial reservoir temperature \(T_{in}~=~17.1\) °C , bubble-point pressure \(p_b=13.98\) MPa, mass fraction of paraffin in oil \(\chi=1.68{-}2.80\)%, paraffin saturation point \(T_{WAT}=0.1062p+16.6129\) at \(p>p_b\), \(T_{WAT}=18.1\) °C at \(p=p_b\), \(T_{WAT}=-0.4802p+24.8485\) at \(p<p_b\), \(T_{WAT}=18.26\) °C at \(p=p_{in}\), paraffin flocculation temperature at a cooling rate of 0.1 °C /min, \(T_{WFT}~=~16.93\) °C at \(p=p_{in}\), \(T_{WFT}=0.1359p+14.8230\) at \(p>p_{b}\), \(T_{WFT}=16.72\) °C at \(p=p_{b}\), \(T_{WFT}~=~-0.4389p+22.8443\) at \(p<p_{b}\), and the paraffin crystallization enthalpy is 1.598 J/g in a direct phase transition and 1.283 J/g in a reverse phase transition.

Thus, in the initial thermobaric conditions of the reservoir, the oil — paraffin system is in the phase transition zone. In the reservoir formation process, some of the paraffin falls out of the oil and becomes adsorbed on the rock surface, making it hydrophobic. Minimal changes in the thermobaric conditions of the reservoir (pressure and temperature drop) during the technogenic impact on the reservoir lead to the formation of solid paraffin particles in the oil. The process of flocculation of solid paraffin particles begins as soon as the temperature in the filtration zone is 0.08 °C lower than the initial reservoir temperature, which is comparable to the values of temperature anomalies arising in the reservoir due to the Joule — Thomson effect [6].

A dependence between the residual paraffin content in the separated oil and temperature in free volumes in the temperature range \(T_{in}{-}T_{WFT}\) is experimentally obtained. This paraffin filtration curve can be approximated by the linear relationship

It is shown in [7] that the temperature of oil saturation with paraffin in the pore space of the reservoir in the general case depends on its permeability and wettability. In this work, this effect is ignored because the reservoir in the phase transition zone of the oil — paraffin system is assumed to be homogeneous.

2. SYSTEM OF BASIC EQUATIONS DESCRIBING THE MATHEMATICAL MODEL

The equations of the mass conservation law for the four-phase flow in the reservoir are written in differential form [8]

Here \(m\) is the reservoir porosity; \(k\) is the reservoir permeability; \(k_{ri}\) is the permeability of phase \(i\), normalized to the reservoir permeability; \(p\) is the reservoir pressure; \(S_i\) is the reservoir saturation of phase \(i\); \(\mu_i\) is the viscosity of phase \(i\); \(B_o\) is the oil volume factor; \(R_g\) is the gas content in the oil; \(\rho_i^{STC}\) is the density of phase \(i\) under normal conditions; \(\rho_w=\rho^{STC}_w\) is the density of the water assumed to be incompressible; \(f_s\) is the volume fraction of paraffin in oil; \(a\) is the paraffin deposition rate in pores; subscripts \(o\), \(w\), \(g\), \(s\), and \(sk\) stand for oil, water, gas, solid paraffin particles, and reservoir skeleton, respectively. The following assumptions are made: the velocity of the solid particles is equal to the velocity of the oil phase flow in which they are suspended, and the paraffin phase transition affects neither the oil viscosity nor the oil phase permeability.

The paraffin volume fraction in the oil phase is determined by the equations

where \(l_s\) is the mass fraction of the paraffin particles in oil as a function of temperature. Its value is determined by Eq. (1). However, the oil phase density \(\rho_o\) and the gas phase density \(\rho_g\) are calculated by the formulas

In order to determine the gas compressibility, the relationship \(B_g(p)=p_{STC}/p\) is taken (\(p_{STC}\) is the pressure under normal conditions) [8].

The gas content and the volume factor of oil are calculated using the following relationships [9]:

Here \(\delta_g\) is the gas density relative to air and \(\delta_o\) is the oil density relative to water. The phase viscosity is assumed to be constant and independent of temperature and pressure.

The equation of mass conservation of the reservoir skeleton with account for the deposition of solid paraffin particles is written in differential form [10]

The closing equation for the fluid saturation in the pore space of the reservoir can be represented as

The paraffin deposition rate in the pore space with account for the taken assumption about the equality of the filtration rate of the suspended paraffin particles and the oil filtration rate is determined by the kinetic equation [11]

(\(\gamma\) is the deposition coefficient of the solid paraffin particles).

The open porosity of a natural reservoir is represented by flow-through and dead-end pores. According to [12], the relative concentration of dead-end pores at different values of the reservoir permeability varies in a range \(\Psi=0.1{-}0.8\). Despite the fact that no fluid is filtered through dead-end pores, a dead-end pore can serve as an additional source of mass for the fluid entering the nearest flow-through pore at a certain pressure difference between the two pores. Typically, reservoirs with a high paraffin volume fraction in oil are characterized by hydrophobic or mixed wettability. Therefore, there is no capillary blockage in a water-bound dead-end pore located in a narrow channel leading to a flow-through pore, and the mass flow between them is due to the diffusion mechanism. As the diffusion rate is significantly lower than the filtration rate, the difference in temperature and pressure conditions in dead-end and flow-through pores may be neglected at each considered time. Consequently, when the temperature and pressure conditions change, the paraffin crystals formed in dead-end pores neither penetrate into the flow-through pore system nor affect the reservoir permeability. Because of this, the porosity and the absolute permeability of the reservoir are related via the Kozeny — Carman equation [13] with a correction introduced in this work for the relative concentration of dead-end pores \(\Psi \):

(\(m_{in}\) and \(k_{in}\) are the initial porosity and permeability of the reservoir; \(n_1\) and \(n_2\) are empirical constants).

The absolute permeability tensor of the reservoir is presented in diagonal form

The heterogeneity of the reservoir permeability is set by the step function [14]

where \(\alpha\) is the degree of reduction of the reservoir permeability in the near-wellbore zone, \(r_1>r_s\) is the radius of the near-wellbore zone, \(r_s\) is the radius of the phase transition zone of the oil — paraffin system. The phase permeabilities of oil, water, and gas are set using the power-law dependences of these values on saturation with a value equal to two [15].

The value and type of the variation in the temperature field in the reservoir is determined by the following physical processes: the release (absorption) of heat during the phase transitions of reservoir fluids, the Joule — Thomson effect during the joint filtration of oil, gas, and water, the adiabatic expansion of reservoir fluids, and the convective and conductive heat transfer in the reservoir.

The heat equation is written in differential form [16]

where

the “\(\sim\)" sign denotes the effective characteristics of the flow, \(T\) is the reservoir temperature, \(c\) is the mass heat capacity of the substance, \(c_\Sigma\) is the volumetric heat capacity of the saturated porous medium, \(q_g\) is the phase transition intensity in the oil — gas system, \(\lambda\) is the thermal conductivity of the substance, \(v\) is the fluid velocity, \(\varepsilon\) is the Joule — Thomson coefficient, \(\eta\) is the adiabatic expansion (compression) coefficient of the fluid, \(L_g\) is the phase transition heat in the oil — gas system.

In the model under consideration, the following thermodynamic assumptions are made. Firstly, a change in the reservoir temperature field in the range \(T_{in}\div T_{WFT}\) has no effect on the fluid characteristics and reservoir parameters. Secondly, the temperature of the reverse phase transition of paraffin to oil significantly exceeds temperature \(T_{in}\), which allows one to ignore this effect. Thirdly, the phase transition heat in the oil — paraffin system is negligible compared to the heat in the oil — gas system and ignored in the calculations.

3. STATEMENT OF THE PROBLEM

A lateral isotropic reservoir (\(k_x=k_y\), \(k_x/k_z=\mathrm{const}\)) shaped as a cylinder (\(G=\{r_w\le r\le r_e\), \(0\le \varphi \le 2\pi\), \(0\le z\le h\}\)) is considered, and the conditions for the absence of mass and heat fluxes are set on its top \(\Omega_t\) and bottom \(\Omega_b\):

(\(r_w\) is the wellbore radius, \(r_e\) is the radius of the outer contour of the reservoir, and \(h\) is the reservoir thickness). The accepted assumption about the thermal insulation of the reservoir is due to the low thermal conductivity of the clayey rock of its top and bottom (about 0.7 W/(m\(\,\cdot\) K)) relative to the thermal conductivity of the oil-saturated part (about 4 W/(m\(\,\cdot\) K)) and to the fulfillment of the condition \(h\gg r_s\).

On the outer lateral surface \(\Omega_0\), the conditions of constant pressure, saturation, and temperature are set: \(p\big|_{\Omega_0}=p_{in}\), \(S\big|_{\Omega_0}=S_{in}\), \(T\big|_{\Omega_0}=T_{in}\).

The inner surface \(\Omega_i\) is split into a perforated surface \(\Omega_p\) (on this surface, a boundary condition for pressure \(p\big|_{\Omega_p}=p_w\) is set, and saturation and temperature are linearly interpolated due to the specificity of the equations) and an unperforated surface \(\Omega_{np}\), for which the boundary condition has the form

The initial condition is written as

Figure 1 shows the inner boundary of the reservoir, consisting of a wellbore wall and perforation channels providing hydrodynamic connection between the well and the reservoir.

4. NUMERICAL SCHEME FOR THE PROBLEM PROBLEM

System (2)–(7) is solved using a totally implicit scheme of the finite volume method with two-point flow approximation. This scheme can be written in general form

where \(u_i\) is the term describing the fluid accumulation in a cell per time step, \(T_{i\xi }\) is the conductivity between cells \(i\) and \(\xi\), \(\Gamma_\theta\) is the factor dependent on the state (pressure and saturation) of adjacent cells, subscript \(\theta\) denotes the counterflow approximation; \(\tau\) is the time step, and \(V_i\) is the cell volume.

The energy balance equation (10) is solved via the totally implicit Crank — Nicolson scheme for the conductive terms and the counterflow scheme for the convective terms:

Here \(i\equiv ijk\); \(\xi =\{i\pm 1jk\), \(ij\pm 1k\), \(ijk\pm 1\}\); \(r_i\) and \(\Delta r_i\) denote the cell coordinate and size and \(\Delta r_{i,\xi}\) is the distance between the cell centers along the corresponding axis. The problem is solved in a three-dimensional formulation in a cylindrical coordinate system using a regular numerical grid with logarithmic condensation toward the well. The perforation channels are specified using selected cells in the grid, located along the radial direction.

The schemes for the mass and heat balance equations are linearized using Newton’s method, and the solution is obtained iteratively at each step. Within the framework of the model proposed, temperature has barely affects the mass transfer, so the difference problem can be effectively split into hydrodynamic and thermodynamic parts and solved sequentially at each iteration.

The verification of numerical calculations demonstrates a high degree of their convergence with analytical dependences for a single-phase flow, which indicates the correctness of the numerical scheme used [17].

5. ADAPTATION OF THE MODEL PARAMETERS TO THEIR EXPERIMENTAL VALUES

The indefinite elements of the mathematical model are \(\gamma\), \(n_1\), and \(n_2\) in Eqs. (8) and (9), associated with the dynamics of the paraffin particle deposition in the pore space and the corresponding technogenic variation in the porosity and permeability of the real reservoir. Other parameters are determined by standard laboratory experiments.

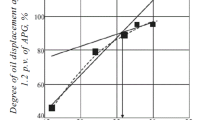

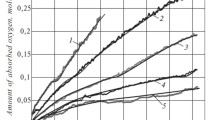

For the practical use of the constructed mathematical model, the adaptation of its parameters to the values obtained in the course of specialized nonisothermal filtration experiments in the core under the thermobaric conditions of the reservoir is carried out. At a constant pressure equal to the reservoir pressure, recombined oil whose paraffin concentration corresponds to the conditions in the real reservoir is pumped through the sample. The experiment is carried out for five temperature values of the sample, and the oil phase permeability is determined at each stage. As a result, the experimental dependence of the oil phase permeability on temperature is obtained and presented in normalized coordinates in Fig. 2.

The adaptation of the parameters of the mathematical model to their experimental values is carried out by varying the deposition coefficient of paraffin particles \(\gamma\). Figure 2 shows that it is not possible to reach complete agreement between the calculated model and the experimental dependences \(k/k_{in}=f(T/T_{in})\) due to the variation of only the deposition coefficient \(\gamma\) because of the probable deviation of the actual dependence of permeability — porosity on the dependence obtained according to the analytical Kozeny — Carman equation (9) (adopted in the model) with an increase in the fraction of deposited paraffin in the pore space of the reservoir.

The computational curve obtained at \(\gamma =0.8\) m\(^{-1}\), \(n_1=3\), \(n_2=2\), and \(\Psi=0.35\) most accurately describes the real process of technogenic reduction of the reservoir permeability. Further, numerical calculations were carried out using the model adapted.

6. COMPUTATIONAL RESULTS

Calculations of the pressure, temperature, and phase saturation field in the reservoir are carried out with the following values of the input parameters of the mathematical model: \(p_{in}=15.5\) MPa, \(T_{in}=17.1\) °C , \(p_b=15\) MPa, \(m_{in}=0.1\), \(k_{in}=0.450\) \(\mu\)m\(^2\), \(h=6.5\) m, \(k_x/k_z=10\), \(R_{gb}=200\) m\(^3\)/m\(^3\), \(\tau=8.64\cdot 10^5\) s, \(r_w=0.1\) m, \(r_e=1000\) m, \(\alpha=1\), \(S_{win}=0.02\) (water fraction in the filtration flow), \(\chi=1.68\), \(\mu_o =8.36\) mPa\(\,\cdot\,\)s, \(\mu_w=1\) mPa\(\,\cdot\,\)s, \(\mu_g=0.03\) mPa\(\,\cdot\,\)s, \(\varepsilon_o=10^{-7}\) K/Pa, \(\varepsilon_w=2\cdot 10^{-7}\) K/Pa, \(\varepsilon_g=-1.7\cdot 10^{-6}\) K/Pa, \(L_g=-150\) J/g, \(\gamma=0.8\) m\(^{-1}\), \(c_o=1.2331\) J/(g\(\,\cdot\,\)°C ), \(\eta_o=10^{-7}\) K/Pa, \(\eta_w=2\cdot 10^{-7}\) K/Pa, \(\eta_g=3.6\cdot 10^{-6}\) K/Pa, \(c_g=3.4\) J/(g\(\,\cdot\,\)°C ), \(c_w=1{,}88\) J/(g\(\,\cdot\,\)°C ), \(c_{sk}=1.8\) J/(g\(\,\cdot\,\)°C ), \(\lambda_o=\lambda_w=0.16\) W/(m\(\,\cdot\,\)K), \(\lambda_g=0.03\) W/(m\(\,\cdot\,\)K), \(\lambda_{sk}=5\) W/(m\(\,\cdot\,\)K), \(\rho^{STC}_o=855.6\) kg/m\(^3\), \(\rho^{STC}_g=1.45\) kg/m\(^3\), \(\rho_w=1000\) kg/m\(^3\), and \(\rho_{sk}= 2000\) kg/m\(^3\).

Figure 3 shows the estimated dependence of the change in the reservoir temperature \(\Delta T\) on the normalized radial coordinate \(\bar{r}=r/r_w\) at different times \(\bar{t}=t/\tau\) (\(\tau\) is the time it takes the filtration to reach the pseudo-steady-state mode) after the beginning of the wellbore operation at a constant pressure \(p_w=0.6p_{in}\). Due to the fact that \(p_w/p_b<1\), there is a sharp degassing of the oil and maximum cooling of the reservoir at the initial time \(\bar{t}=0.04\) due to the adiabatic expansion of the mixture, heat absorption during the oil — gas phase transition, and the Joule — Thomson effect during the filtering of the most mobile gas phase. As a result, a cooling zone \(\bar{r}\in (1,50)\) is formed around the well, in which the temperature decrease on the wellbore wall relative to the initial reservoir temperature \(T_{in}\) is equal to \(\Delta T\approx 0.9\) °C . As the three-phase flow (gas, oil, and water) stabilizes, the reservoir temperature is partially restored due to throttling of the liquid phases. At \(\bar{t}=36\), two characteristic temperature zones are formed in the reservoir: \(\bar{r}\in(1,10)\) is a zone cooled relative to \(T_{in}\) and \(\bar{r}\in(10,500)\) is a zone heated relatively to \(T_{in}\).

Figure 4 shows the dependence of the paraffin saturation in the reservoir pore space on the normalized radial coordinate \(S_s(\bar{r})\). Clearly, the paraffin loss occurs in the zone \(\bar{r}\in (1,100)\) zone and naturally decreases toward the depth of the reservoir, where the temperature anomaly is minimal. The radial distribution of the reservoir permeability \(k(\bar{r})/k_{in}\), caused by the clogging of the pore space with solid particles of the deposited paraffin is shown in Fig. 5. The permeability decreases in the near-wellbore zone \(\bar{r}\in(1.50)\) and naturally increases with time, thereby reducing the reservoir productivity. The main parameters of the technogenically changed zone near the borehole in the reservoir are its radius \(r_d\) (defined as the distance at which the permeability is smaller than the initial one by more than 10%) and the degree of permeability reduction near the wellbore wall \(\beta=k|_{\bar{r}=1}/k_{in}\). The dependence between \(\beta\) and time for \(\bar{t}>0.1\) can be approximated by the exponential dependence \(\beta=0.774\mathrm{e}^{-0.026\bar{t}}\) with a correlation coefficient of 0.98.

The results of the calculations carried out according to the proposed model show that \(\chi\), \(R_{gb}\), and \(\gamma\) make the greatest contribution to the technogenic change in the permeability of the near-wellbore zone of the reservoir. The table shows the approximate dependences of \(\beta\) and \(r_d/r_w\) on \(\chi\), \(R_{gb}\), and \(\gamma\), obtained via numerical calculations at \(\bar{t}=36\).

CONCLUSIONS

The mathematical model of the paraffin deposition process in the pore space of the low-temperature oil reservoir during its development is proposed on the basis of laboratory experiments. The created model makes it possible to calculate the technogenic variation of the reservoir filtration properties with account for the dynamics of the pressure and temperature fields due to the influence of the Joule — Thomson effects, adiabatic expansion, heat release (absorption) during phase transitions in the oil-dissolved gas — paraffin system. The dependences of the technogenic variation in the reservoir permeability on the main parameters are determined: paraffin concentration in oil, gas content in oil, and the coefficient of paraffin deposition on the pore walls.

REFERENCES

R. F. Sharafutdinov, “Multi–Front Phase Transitions During Nonisothermal Filtration of Live Paraffin–Base Crude," Prikl. Mekh. Tekh. Fiz. 42 (2), 111–117 (2001) [J. Appl. Mech. Tech. Phys. 42 (2), 284–289 (2001].

E. T. Klimenko and M. N. Selivestrov, “Estimation of the Thickness of a Diffusion Layer of Wax Crystals Growing from a Solution," in Methods of Applied Mathematics in Oil and Gas Industry (Moscow, 1978) [in Russian].

B. G. Levic, Physicochemical Hydrodynamics (Prentice Hall, 1962).

Z. I. Syunyaev, R. Z. Safieva, and R. Z. Syunyaev, Petroleum Dispersed Systems (Khimiya, Moscow, 1990) [in Russian].

A. A. Lobanov, Investigation of Deposition of Asphalt-Resin-Paraffin Substances During Interaction of Reservoir High-Viscosity Oil and Liquid CO 2 to Substantiate the Technology of Cyclic Exposure to Carbon Dioxide for Increasing Oil Recovery (Arkhangelsk, 2019) [in Russian].

G. F. Trebin, U. V. Kapyrin, and O. G. Liminskii, Estimating the Temperature Depression in the Critical Zone of Operating Holes (A.P. Krylov All-Russian Oil and Gas Research Institute, Moscow, 1978) [in Russian].

A. A. Zlobin, “Analysis of Paraffin Phase Transitions in the Pore Space of Reservoir Rocks," Vestn. Perm. Nats. Issled. Politekhn. Univ. Geologiya. Neftegazovoe I Gornoe Delo, No. 5, 47–55 (2012).

K. S. Basniev, I. N. Kochina, and V. M. Maksimov, Subsurface Hydromechanics (Nedra, Moscow, 1993) [in Russian].

A. I. Brusilovskii, Phase Transitions in the Development of Oil and Gas (Graal’, Moscow, 2002) [in Russian].

G. G. Tsypkin, Flows with Phase Transitions in Porous Media (Fizmatlit, Moscow, 2009) [in Russian].

J. P. Herzig, D. M. Leclerc, and P. Goff, “Flow of Suspensions Through Porous Media," Industr. Engng Chem. 62 (5), 8–35 (1970).

N. N. Mikhailov, Oil and Gas Reservoir Physics (Physics of Oil and Gas Reservoir Systems) (MAKS Press, Moscow, 2008) [in Russian].

P. C. Carman, “Permeability of Saturated Sands, Soils and Clays," J. Soc. Chem., No. 2, 57–58 (1939).

M. V. Zaitsev and N. N. Mikhailov, “Influence of a Near-Wellbore Zone on the Productivity of the Well," Neft. Khoz., No. 1, 64–66 (2004).

A. T. Corey, “The Interrelation Between Gas and Oil Relative Permeabilities," Producers Monthly, No. 5, 38–41 (1954).

E. B. Chekalyuk, Oil Revervoir Thermodynamics (Nedra, Moscow, 1965) [in Russian].

L. A. Gaidukov, A. V. Novikov, and D. V. Posvyansky, “Investigation of Thermodynamic Processes During Multiphase Fluid Filtration to the Well with Perforation Channels in Damage Reservoir for Determination of Near Wellbore Zone Properties," in Proc. of the Russ. Petroleum Technol. Conf. and Exhibition, Moscow, 24–26 Oct. 2016. DOI: 10.2118/181964-RU.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Prikladnaya Mekhanika i Tekhnicheskaya Fizika, 2021, Vol. 62, No. 6, pp. 64-73. https://doi.org/10.15372/PMTF20210608.

Rights and permissions

About this article

Cite this article

Gaidukov, L.A., Novikov, A.V. TECHNOGENIC VARIATION OF RESERVOIR PERMEABILITY DURING NONISOTHERMAL OIL — GAS — PARAFFIN FILTERING IN THE CASE OF PHASE TRANSITIONS. J Appl Mech Tech Phy 62, 943–951 (2021). https://doi.org/10.1134/S0021894421060080

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894421060080