Abstract

According to estimates issued by the Center for Disease Control and Prevention, one out of six Americans will get sick during this year due to consumption of contaminated products and there will be 50,000 related hospitalizations. To control and treat the responsible foodborne diseases, rapid and accurate detection of pathogens is extremely important. A portable device capable of performing nucleic acid amplification will enable the effective detection of infectious agents in multiple settings, leading to better enforcement of food safety regulations. This work demonstrates the multiplexed detection of food pathogens through loop-mediated isothermal amplification on a silicon chip. Silane passivation is used to prevent the adsorption of the polymerase on silicon oxide, which can severely inhibit nucleic acid amplification. We demonstrate the multiplexed screening of virulence genes of Listeria monocytogenes, Escherichia coli, and Salmonella by dehydrating the corresponding primers in oxidized silicon wells. Droplets of 30 nL with reagents for nucleic acid amplification and lysate of suspected pathogens are arrayed on micro-machined wells with an automated microinjection system. We show that dehydrated primers re-suspend when other reagents are microinjected, and the resulting mix can be used to specifically amplify the targeted gene. Results of characterization experiments demonstrate sensitivity down to a few templates per reaction, specificity that enables multiplexed screening, and robustness that allows amplification without DNA extraction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The elucidation of DNA structure, bio-molecular mechanisms of genetics, and the development of nucleic acid amplification techniques has given rise to powerful microorganism detection methods (Craw and Balachandran 2012). Through DNA amplification procedures, it is possible to detect and identify agents in complex samples within a few hours, at low cost, and with high sensitivity and specificity (Park et al. 2011). However, due to the complexity of the equipment required for traditional DNA amplification, this kind of assay is only possible to perform in well-equipped urban laboratories, limiting the number of users and scenarios where these detection methods can be applied (Holland and Kiechle 2005). With the advent of microfluidics and miniaturization techniques, several authors have advocated the convenience of a DNA-based portable diagnostic device in various fields (Park et al. 2011; Abe et al. 2011). For example, partially due to stringent requirements of equipment and facilities, each state in the U.S. has only a few (or no) laboratories accredited by the Food Safety and Inspection service (FSIS) for food analysis (USDA-FSIS 2013) limiting the speed and sample size of screening procedures. A simple, portable, and cost-effective device capable of running DNA amplification reactions would enable on-site, accurate, and rapid diagnosis of contaminants in food, enabling checkpoints in production lines or retail stores. Simple, portable, and cost-effective equipment for DNA amplification will enable detection of food pathogens at multiple stages and by multiple participants of the food production chain, improving the control of contaminated products.

There are a few commercially available devices for portable genetic testing but none that demonstrate all attributes desirable for on-site screening (Ahmad and Hashsham 2012; Seiner et al. 2012). Current systems are expensive, require reaction volumes are typically larger than 10 μL, and utilize manual pipetting of samples, which limits the number of assays that can be performed in parallel (Stedtfeld et al. 2012). New technologies promise to simplify sample loading using microfluidics and have proposed integrated solutions that minimize required instrumentation for cheap and reliable systems. For instance, simple valve-less microfluidics were developed and incorporated in DNA amplification systems to avoid pneumatic valves or pumps (Tourlousse et al. 2012; Njoroge et al. 2011), and photodiode and LED arrays have been used to monitor fluorescence in portable devices (Ahmad et al. 2011; Abe et al. 2011). These miniaturized technologies could perform the same assays as those run by current large and expensive qPCR systems used by accredited laboratories in genetic analysis for foodborne pathogen detection (e.g. 7500 fast RT-PCR by Applied Biosystems, Foster city, CA). However, none of these systems have successfully reached the commercial market. The field of portable nucleic acid testing is still waiting for a ‘silver bullet application’ that will revolutionize health care and diagnostics (Craw and Balachandran 2012).

A successful portable DNA testing system will require technologies that reduce the system’s complexity but maintain desirable characteristics of high sensitivity, specificity and multiplexed screening of current DNA-based tests (Ahmad and Hashsham 2012). There are two paths to reduce complexity in amplification systems: simplifying the required instrumentation that is used to run the reaction, and simplifying the reaction itself. Porting 60 years of semiconductor technology research into DNA amplification is the key to the miniaturization of the system to a portable device maintaining sensing capabilities. Silicon transistors can be used for the localized heating of samples, removing bulky thermo-cyclers (Salm et al. 2013). They can also be used for the electrical sensing of DNA amplification, removing the necessity of bulky and expensive optical systems that query for fluorescence or turbidity (Rothberg et al. 2011; Purushothaman et al. 2006). In addition, the semiconductor industry has developed processes for low cost and large scale production of arrays which enables the desired parallel screening and inexpensive assay and system cost. On the other hand, novel methods for DNA amplification can reduce the complexity of the standard polymerase chain reaction (PCR). The PCR protocol involves a thermal cycling of the sample, which requires precise temperature control systems that can be difficult to miniaturize (Tang et al. 2011). Isothermal amplification protocols, and in particular loop-mediated isothermal amplification (LAMP), have been proposed as simpler amplification methods ideal for portable applications. LAMP is a novel nucleic acid amplification method that employs a strand-displacing Bst DNA polymerase and a set of primers designed to fold and create dumbbell DNA structures that trigger cycling isothermal amplification (Notomi et al. 2000). LAMP primers for several targets (including multiple pathogenic microorganisms) have been developed and the reaction has been optimized with the addition of loop primers to deliver results in less than one hour (Nagamine et al. 2002).

The combination of semiconductor devices and LAMP promises to yield a simple and powerful method for nucleic acid testing that can be miniaturized for portable applications. In this study we used a microinjection system and a silicon chip with micro-machined wells to test protocols for multiplexed on-chip detection of foodborne pathogens using LAMP. After passivation of the silicon surface with Sigmacote (Sigma-Aldrich. St. Louis, MO), the microinjection system creates nano-droplet arrays on the wells where the amplification reaction takes place. Primers for amplification of virulence genes HlyA (L. monocytogenes), Stx2 (E. coli O157), and InvA (Salmonella), are dried in the silicon wells prior to the injection of a primer-less LAMP mix (Tang et al. 2011; Wang et al. 2011; Chen et al. 2011). This technique allows parallel screening of multiple pathogens in a single assay. We also performed characterization experiments to quantify sensitivity, specificity and robustness of on-chip LAMP amplification. By performing multiplexed detection of pathogens in devices fabricated with integrated circuit compatible processes, we show the viability of portable and multiplexed on-chip pathogen detection.

2 Materials and methods

2.1 Chip fabrication

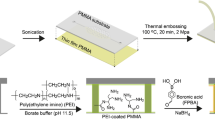

Figure 1a shows cross-sectional schematics of the fabrication of silicon wells. Undoped silicon wafers (University Wafers, South Boston, MA) are used as the substrate. After a brief piranha clean (1:1 H 2 O 2 − H 2 SO 4, 8 min) a 160 nm layer of silicon oxide is thermally grown in a furnace (Lindberg/Tempress Model 8500) at 800 °C for 20 min. Positive AZ1518 photoresist (AZ Electronic Materials, Branchburg, NJ) is spin-coated to form a 2 μm layer on the unpolished side of the wafer, followed by an 8 min soft-bake on a hotplate at 110 °C. The process is repeated on the polished side of the wafer where the photoresist is patterned using a Quintel aligner with a high resolution transparency mask (FineLine Imaging, Colorado Springs, CO) defining the wells openings. Exposed regions are then removed by developing the wafer in MIF AZ300 (AZ Electronic Materials, Branchburg, NJ) for 2 min. Uncovered silicon oxide is etched in 10:1 buffered oxide etchant (VWR, Chicago, IL) for 10 min revealing silicon. The photoresist is stripped in a Remover PG (MicroChem, Newton, MA) bath at 70 °C for 30 min, leaving a hard silicon oxide mask in the polished side of the wafer and a protective oxide layer on the bottom side. The wafer is then immersed in a TMAH bath (1:1 TMAH: DI) for 18 h to anisotropically etch a 160 μm deep inverted square pyramid. For passivation purposes, a 10 nm layer of silicon oxide is then thermally grown (2 min, 800 °C). Finally, a photoresist protective layer is spin-coated and soft-baked before the wafer is diced into 1 × 1 cm squares. Figure 1b shows a chip with four 6 × 6 arrays of silicon wells and Fig. 2c depicts a scanning electron micrograph of a well’s cross-section.

Silicon well chip and experimental protocol. a Cross sectional schematics of the fabrication flow for the silicon wells. b Photograph of 4 arrays of 6 × 6 wells ranging from 15 to 30 nL placed over a dime. Each 1 × 1 cm silicon chip has 4 arrays. c Cross-sectional SEM of silicon wells. d Schematic showing the experimental protocol in a cross section of a silicon well. Wells are prepared with a silane passivation layer and dried primers. Mineral oil is used to encapsulate LAMP reagents in wells to prevent droplet evaporation during amplification. Afterwards, a primer-less LAMP solution is microinjected. Primers will re-suspend in the LAMP solution and the chip is heated to 65 °C. Amplification is observed by measuring fluorescence of EvaGreen ® during the reaction

Amplification of stx2 gene of E.coli O157 after primer dehydration. Primers for amplification of E.coli O157 stx2 gene were dehydrated in all array positions prior to mineral oil encapsulation. The primer-less LAMP solution in the top 18 wells had no template and the bottom 18 wells had template extracted from a 109 CFU/ml, for negative and positive controls. a Fluorescence image before amplification. b Fluorescence image after 60 min of amplification. c Graph of fluorescence intensity of each well during on-chip amplification. Fluorescence was measured every minute and intensity is normalized to the first data point. The threshold for detection of amplification is defined as 1.2. d Average fluorescence increment for control and full samples. The inset shows the average time when the threshold was reached (threshold time) and the error is one standard deviation

2.2 Micro-injection operation

Experiments were performed using a microinjector IM-300 (Narishige Scientific Instrument Lab. Tokyo, JP). The microinjector was used for injection of both the primers and the primer-less LAMP solution in the silicon micro-wells. An Eppendorf VacuTip (Eppendorf. Hamburg, De) with an internal diameter of 15 μm is connected to the microinjector output and is loaded with ~1 μL of reagents. Loaded reagents are dispensed for 20 ms at 60 psi to form droplets of around 30 nL. Precise movement of the microinjector tip in the X, Y and Z directions is achieved with a 3D micromanipulator (MCL-D331) from World Precision Systems, Sarasota, FL. After the initial alignment to two reference points, a Matlab script (MatWorks, Natick, MA) controls the position system and the microinjector to fill the array of wells.

2.3 Chip preparation

Silicon and silicon-based materials have been reported to inhibit nucleic acid amplification due to the adsorption of the polymerase (Wang et al. 2006, 2012; Zhang and Xing 2010). To prevent inhibition of amplification, the silicon wells were treated with Sigmacote to create a silane layer that neutralize surface adsorption of biomolecules (Zhang and Xing 2010). Sigmacote is a solution of chlorinated organopolysiloxane in heptane; it reacts with the surface silanol groups and binds covalently to the substrate. To deposit the silane, the silicon wells chip is submerged for 5 min in Sigmacote followed by isopropanol and DI water rinses to remove any excess.

2.4 Primer-less LAMP solution preparation

For each experiment, 30 μL of primer-less LAMP solution was prepared with the following components: Betaine (800 mM), mix of dNTPs (1.4 mM), isothermal buffer (1×, New England Biolabs, Ipswich, MA), magnesium sulfate (8 mM), bacillus stearothermophilus (Bst), 2.0 WarmStart polymerase (0.64 unit/uL), Evagreen fluorescent dye (20 μM), and Template DNA (variable concentrations). Instead of wild-type Bst DNA polymerase we used Bst 2.0 WarmStart polymerase (New England Biolabs, Ipswich, MA). This is an ‘in-silico’ designed homologue of Bst DNA polymerase that was developed as a robust enzyme with higher thermal stability and salt tolerance (New England Biolabs 2012). The template for amplification is genomic DNA extracted from an E.coli O157:H7 or L. monocytogenes culture in bovine-brain heart infusion (Sigma-Aldrich. St. Louis, MO). The bacteria is incubated for 18 h to obtain concentrations of 109 CFU/ml for E.coli and 108 CFU/ml for Listeria. After incubation, 1 ml of cultured bacteria is centrifuged at 8600 RCF for 3 min to pellet the bacteria. Bacterial cells are re-suspended in nuclease-free water (Invitrogen, Grand Island, NY) and heat-lysed at 95 °C for 15 min in at 300 RPM in a Thermomixer R (Eppendorf. Hamburg, De). A final centrifugation is performed at 12,400 RCF for 10 min, which pellets undesired cell debris, leaving DNA in the supernate that is used as template.

2.5 Primer mix dehydration

The primer sequences used for amplification of virulence genes of pathogenic bacteria are listed in Table 1. The primer mix was prepared with custom DNA oligomers (Integrated DNA technologies, Coralville, IA) and mixed in the following components: FIP/BIP (19 μM), F3/B3 (2.4 μM), and LF/LB (9.6 μM). Primers are spotted in the wells after chip silanization using the microinjector with a 10 ms pulse to dispense around 15 nL. The dispensed volume quickly dries at room temperature, leaving dehydrated primers in wells prior to mineral oil encapsulation. For multiplexed screening experiments, different primers were dehydrated in the array positions.

2.6 Amplification experiments

A schematic illustrating the detection experiment sequence is presented in Fig. 1d. Silanized chips with dehydrated primers are covered with mineral oil to prevent evaporation of droplets during amplification. The microinjector is then used to fill silicon wells with 30 nL of the primer-less LAMP solution that includes the target template. Next, the chip is heated to 65 °C with an mK1000 heated stage (Instec, Bouler, CO). Fluorescence changes due to amplification are observed on a Nikon Eclipse FN-1 fluorescence microscope (Nikon Instruments inc. Melville, NY) where an automated shutter and camera setup captures images every minute.

2.7 Data analysis

Fluorescence images are analyzed in ImageJ (http://rsb.info.nih.gov/ij/). Using Raw Integrated density ‘RawIntDen’, the stack-measurement plugin, and the rectangular selection, each well’s fluorescence was individually measured. Data is imported to Matlab where data for each well is normalized to the first recorded value. A well is considered to exhibit positive amplification when its intensity increases 20 %, above the noise level observed in negative controls. The threshold time and standard deviation are calculated for groups of wells with the same template–primer combination.

3 Results and discussion

3.1 Primer rehydration and on-chip reproducibility

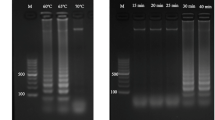

In this study we characterized DNA amplification on silicon chips after silanization and primer dehydration. Initial experiments aimed to confirm that primers re-suspend in the injected LAMP solution and then anneal to target template for amplification. In addition, we were interested in measuring intra-chip amplification efficiency variability and the rate of false negatives and positives. Figure 2 shows an experiment where primers for E. coli O157 were dehydrated in all 36 wells of the array. After mineral oil encapsulation the primer-less LAMP solution, with template extracted from a 109 CFU/ml E. Coli O157 culture, was spotted in the bottom 18 wells. The top 18 wells were spotted with a solution without template (the template was replaced with DI water) to serve as negative controls.

The initial and final fluorescence images are in Fig. 2a and b. Fluorescence intensity curves for all wells are shown in Fig. 2c. Figure 2d shows the fluorescence increase for negative and positive controls and the average threshold time (time when fluorescence increased by 20 %) for the positive control samples. The real time fluorescence data shows that amplification was observed in all wells where LAMP solution contained E. Coli O157 template. The coefficients of variation for threshold times and fluorescence increments in positive controls were 25 % and 4 % respectively. This variation is higher than the one observed in other reports using similar primer dehydration strategies (Stedtfeld et al. 2012). However, volume variability of smaller sample sizes and stronger interaction between molecules and the chip surface, may explain the higher observed intra-chip amplification variability. The false negative ratio (defined as the rate of wells where amplification was expected but not observed, over the total number of positive control wells) is cero at this concentration. Moreover, none of the negative controls presented amplification, for cero false positives and full specificity. These results indicate that primers in the prepared chip will rehydrate when LAMP reagents are injected, and participate in specific amplification for the detection of pathogens.

3.2 Sensitivity

To evaluate the detection limit of LAMP with dehydrated primers in a silicon chip, the concentration of template used in the LAMP solution was serially diluted and then spotted on the silicon wells. Figure 3 shows the threshold time and false negative ratio for experiments with multiple template concentrations of E. Coli O157 Stx2 dehydrated primers. The number of CFU per reaction is calculated from the measured CFU/ml in plating experiments and scaled to 30 nL of the reaction volume. The lowest detected concentration was 105 CFU/ml which translates to 3 CFU/reaction. The false negative ratio increases as the template concentration decreases and it approaches 50 % for experiments performed with the minimum detected template concentration. However, we observed amplification in most of the wells in experiments with low concentrations of template demonstrating a low detection limit. This agrees with other reports that show the ability of LAMP to detect single copies (Ahmad et al. 2011).

Sensitivity experiments. Threshold times and false negative ratios for experiments with multiple concentrations from serial logarithmic dilutions. The template is E.coli O157 and the targeted gene is Stx2. Thirty-six wells were sampled for each concentration (n = 36); the threshold time is defined as the time when fluorescence increases to 1.2 and the false negative percentage is the ratio of wells that did not show amplification over total number of wells with template. Error bars are one standard deviation. a Threshold time as a function of template concentration, b False negative ratio as a function of template concentration

A hypothesis for the higher number of false negatives is an incomplete surface passivation by the Sigmacote treatment. According to the Poisson distribution the probability of having at least one copy in each well at the lowest concentration of 3 CFU/reaction is 95 %, effectively assuring that each well will have at least one template for amplification. However the few copies present in the well could be adsorbed by silicon oxide areas with poor coverage of the organopolysiloxane. The probability of having all template molecules inactive during the reaction due to exposed silicon increases at lower concentrations. The Sigmacote treatment was selected for this study due to its simplicity, but further studies using different molecules and deposition methods for better coverage and uniformity may lead to single copy amplification enabling on-chip digital LAMP (Tenhaeff and Gleason 2008).

3.3 Multiplexed screening of pathogens

On-chip LAMP amplification after primer dehydration is sensitive and reproducible. However, the main advantage of this technique is that it enables multiplexed screening in one single assay when primers for multiple pathogens are dried in the same chip. There are 31 identified foodborne pathogens that cause hospitalizations in the United States (CDC 2011). In order to assure that food is not contaminated, it is necessary to screen for all those pathogens. Therefore, it is very desirable that a screening method is capable of multiplexed detection of several pathogens in a single assay to avoid labor-intensive protocols.

For experiments shown in Fig. 4 primers for Salmonella InvA, L. monocytogenes HlyA and E.coli O157 Stx2 were dehydrated in different positions of the array. In Fig. 4a the two left columns had primers for HlyA (Listeria), the middle columns for InvA (Salmonella) and the right columns for Stx2 (E.coli O157). After primer dehydration and mineral oil encapsulation, a primer-less LAMP solution with template extracted from culture of 108 CFU/ml L. monocytogenes was injected in the top 30 wells. In the bottom row, the injected primer-less solution had no template to serve as negative controls. The same experiment was executed with a different chip using a primer-less LAMP solution with template from 108 CFU/ml E.coli O157culture.

Multiplexed on-chip identification of foodborne pathogens. Primers targeting 3 pathogens were dehydrated on one chip. In a, the left columns had primers for L.monocytogenes HlyA, the middle columns had primers for Salmonella InvA and the right columns primers for E.coli O157:H7 Stx2. Sequences of each primer set are presented in Table 1 with their respective sources. The template in primer-less solution was extracted either from a Listeria (exp. 1) or E.coli (exp. 2) 108 CFU/ml culture a Fluorescence image before amplification with L. monocytogenes template. b Fluorescence image after 60 min of amplification with L. monocytogenes template. c Average increase in fluorescence for wells with common primer mix. The inset shows the average threshold time of amplification with the standard deviation for experiment 1 (L. monocytogenes template) and experiment 2 (E. coli O157 template). d Graph of quantification of fluorescence intensity of each well for experiments with L. monocytogenes template and e with E.coli template

Figure 4d and e show that the method is specific and amplification is observed only in the wells where the template and primers match. Figure 4d shows data from an experiment with listeria template. We observed that only wells with dried primers for Listeria HlyA amplified. On the other hand in Fig. 4e, experiment with E.coli template, only wells with primers for E.coli Stx2 amplified. Data from the two experiments is summarized in Fig. 4c. The plot shows the average increase in fluorescence for each group of wells with common primers in experiment 1 (with L.monocytogenes template) and experiment 2 (with E.coli template). Only the wells where primers find a complementary template increased their fluorescence intensity, demonstrating specific amplification. The difference in fluorescence increments and threshold times between E. coli O157 and L. monocytogenes experiments could be due to different primer efficiency. It has been shown previously that the LAMP reaction speed is a function of the primers length, GC content, melting temperature, free energy of hybridization, and especially 3′- and 5′-ends availability, indicating that primer design heavily affects amplification performance (Kimura et al. 2011). Given that the concentration of template and the DNA extraction protocol is the same in both experiments, the variability of threshold time and fluorescence increase can be attributed to a difference in primer activity and affinity. In conclusion, here we demonstrated that the primer dehydration technique is a multiplexed and specific screening method that enables the identification of unknown pathogens on a single chip.

3.4 Amplification with raw lysate template

As mentioned in the Section 1, successful development of portable DNA testing requires simplified systems that allow inexpensive and simple miniaturization. The DNA extraction step, done regularly in DNA amplification experiments, is performed to remove cellular components that could potentially affect the polymerase activity or the process specificity (Hedman and Radstrom 2012). However, this step involves more reagents and laboratory equipment, increasing the overall process complexity. For the experiment presented in Fig. 5, E.coli O157 Stx2 primers were dehydrated in all wells. After mineral oil encapsulation, 3 primer-less solutions were spotted. In Fig. 5a the LAMP solution injected in left columns contained extracted DNA from a 108 CFU/ml culture of E.coli. In the middle columns, the template is raw lysate (no centrifugation steps after lysis) from the same culture, and in the right columns LAMP solution has no template (as negative control). Figure 5c shows real time fluorescence intensity of each well. Figure 5d quantifies fluorescence intensity and threshold time, indicating that wells where the template is raw lysate have lower amplification efficiency. The detection times are slightly longer and fluorescence changes are smaller in the raw template samples than in the ones with extracted DNA. These results are consistent with expectations of reduced yield from raw lysate. In addition, we observed a false negative in one of the ‘raw-lysate’ wells while all wells for extracted DNA template amplified. From this experiment it is possible to conclude that amplification can be carried out without DNA extraction but with lower amplification efficiency and a slightly higher probability of false negatives. However, the use of larger arrays can mitigate this issue to keep the screening process robust. With more wells the probability of observing amplification statistically increases and compensates for possible false negatives.

Amplification without DNA extraction. Primers for E.coli O157 Stx2 were dried in all positions of the array. Primer-less LAMP solution in the left column had extracted DNA from 108 CFU/mL E. coli O157:H7. In the middle columns template is raw lysate (no DNA extraction) of the same culture and the two columns on the right are negative controls without template. a Fluorescence image before amplification. b Fluorescence image after 60 min of amplification at 65 °C. Highlighted well in position (4,4) did not show amplification c Graph of quantification of fluorescence intensity in each well. d Average threshold time and standard deviation for extracted DNA and raw lysate wells

3.5 Dehydrated primers shelf life

Spotting of primers on a microchip for multiplexed detection must be done using laboratory equipment like the microinjector or ink-jet printers (Zubritsky 2000). The multiple solutions that are dispensed (one per target pathogen) and alignment to the chip demand highly specialized equipment. Therefore, it is important to know for how long the primers can be stored after dehydration, without losing their required affinity to the complimentary sequence and their ability to generate the dumbbell structure for LAMP amplification. Primers for E.coli O157 Stx2 were dehydrated in silicon wells and then refrigerated at −20 °C for 1, 3, and 10 days. These chips were then used for E.coli O157 detection experiments using template extracted from a 108 CFU/ml culture. Once again the threshold time and the false negative ratio were recorded. Figure 6 shows that primers can be used for amplification after having been frozen for up to 10 days. However, after 10 days of refrigeration the threshold time and the false negative ratio is higher, indicating that frozen primers lose their ability to anneal with complementary sequences and create structures required for LAMP with time. Previous studies have shown a progressive degradation of dehydrated DNA. The molecule loses molecular weight and supercoil content as a function of time (Anchordoquy and Molina 2007; Molina et al. 2004) explaining the observed performance loss.

Frozen dried primers shelf life. Primers for E.coli O157 Stx2 were dried in wells and frozen at −20 °C for 1, 3 and 10 days. After defrosting at room temperature for 5 min the protocol described in Fig. 1d continued. Primer-less LAMP solution with template from DNA extraction of a 108 CFU/ml E.coli culture was microinjected in wells. a Average threshold time of wells (n = 18) where amplification was observed as a function of days the primers were frozen. Error bars are one standard deviation. b False negative ratio as a function of days of primer dehydration

4 Conclusions

Development of a portable DNA amplification system will enable on-site detection of microorganisms which could ultimately prevent the spread of infectious disease. For such portable diagnostic tools it is necessary to simplify the instrumentation that is required to perform assays to enable simple and inexpensive miniaturized detection. Isothermal amplification strategies like LAMP do not require temperature controllers needed in more traditional strategies like PCR, contributing to the assay simplification (Abe et al. 2011). In addition, semiconductor devices can be used to electrically monitor amplification reactions without the need for optics that query for fluorescence (Wong et al. 2010), locally heat samples to reaction temperatures removing bulky heaters (Salm et al. 2013), and lyse cells through electroporation to locally extract DNA (Jokilaakso et al. 2013). Therefore, it is possible to develop a simplified portable nucleic acid diagnostic system incorporating both LAMP and semiconductors.

In summary, in this study we evaluated the performance of LAMP amplification on a silicon well array. The silicon surface was passivated with a silane treatment to prevent adsorption of biomolecules, and primers were dehydrated prior to running the assay to enable multiplexed screening. We demonstrated that on-chip amplification is reproducible, sensitive down to a few copies per reaction, and specific allowing multiplexed identification of pathogens in a single assay. In addition, our experiments indicate that it is possible to perform amplification without DNA extraction protocols and that dehydrated primers can be frozen for up to 10 days for future detection experiments. Overall, our results indicate that LAMP can be reliably performed in silicon wells, enabling further integration of bio-molecular assays and semiconductor technologies for portable genetic based diagnosis.

References

T. Abe, Y. Segawa, H. Watanabe, T. Yotoriyama, S. Kai, A. Yasuda, N. Shimizu, N. Tojo, Lab Chip 11, 6 (2011)

F. Ahmad, S.A. Hashsham, Anal. Chim. Acta 733, 1–15 (2012)

F. Ahmad, G. Seyrig, D.M. Tourlousse, R.D. Stedtfeld, J.M. Tiedje, S.A. Hashsham, Biomed. Microdevices 13, 5 (2011)

T.J. Anchordoquy, M.C. Molina, Cell Preserv. Technol. 5, 4 (2007)

Centers for Disease Control and Prevention, CDC estimates of foodborne illness in the United States. http://www.cdc.gov/foodborneburden. Accessed 21 March 2013.

S. Chen, F. Wang, J.C. Beaulieu, R.E. Stein, B. Ge, Appl. Environ. Microbiol. 77, 12 (2011)

P. Craw, W. Balachandran, Lab Chip 12, 14 (2012)

J. Hedman, P. Radstrom, PCR Detection of Microbial Pathogens, 2nd edn. (Humana Press, Totowa, 2012), pp. 17–48

C. Holland, F.L. Kiechle, Curr. Opin. Microbiol. 8, 5 (2005)

N. Jokilaakso, E. Salm, A. Chen, L. Millet, C. Duarte-Guevara, B. Dorvel, B. Reddy, A.E. Karlstrom, Y. Chen, H. Ji, R. Sooryakumar, R. Bashir, Lab Chip 13, 3 (2013)

Y. Kimura, M.J.L. de Hoon, S. Aoki, Y. Ishizu, Y. Kawai, Y. Kogo, C.O. Daub, A. Lezhava, E. Arner, Y. Hayashizaki, Nucleic Acids Res. 39, 9 (2011)

M.D.C. Molina, T.K. Armstrong, Y. Zhang, M.M. Patel, Y.K. Lentz, T.J. Anchordoquy, J. Pharm. Sci. 93, 9 (2004)

K. Nagamine, T. Hase, T. Notomi, Mol. Cell. Probes 16, 3 (2002)

New England Biolabs Inc., Bst 2.0 WarmStart DNA polymerase. https://www.neb.com/products/m0538-bst-20-warmstart-dna-polymerase. Accessed 21 March 2013.

S.K. Njoroge, H. Chen, M.A. Witek, S.A. Soper, Top Curr. Chem. 304 (2011).

T. Notomi, H. Okayama, H. Masubuchi, T. Yonekawa, K. Watanabe, N. Amino, T. Hase, Nucleic Acids Res. 28, 12 (2000)

S. Park, Y. Zhang, S. Lin, T.-H. Wang, S. Yang, Biotechnol. Adv. 29, 6 (2011)

S. Purushothaman, C. Toumazou, C.-P. Ou, Sensors Actuators B Chem. 114, 2 (2006)

J.M. Rothberg, W. Hinz, T.M. Rearick, J. Schultz, W. Mileski, M. Davey et al., Nature 475, 7356 (2011)

E. Salm, C. Duarte-Guevara, P. Dak, B.R. Dorvel, B. Reddy, M.A. Alam, R. Bashir, PNAS 110, 9 (2013)

D.R. Seiner, H.A. Colburn, C. Baird, R.A. Bartholomew, T. Straub, K. Victry, J.R. Hutchison, N. Valentine, C.J. Bruckner-Lea, J. Appl. Microbiol. 114, 4 (2012)

R.D. Stedtfeld, D.M. Tourlousse, G. Seyrig, T.M. Stedtfeld, M. Kronlein, S. Price, F. Ahmad, E. Gulari, J.M. Tiedje, S.A. Hashsham, Lab Chip 12, 8 (2012)

M.J. Tang, S. Zhou, X.-Y. Zhang, J.-H. Pu, Q.-L. Ge, X.-J. Tang, Y.-S. Gao, Curr. Microbiol. 63, 6 (2011)

W.E. Tenhaeff, K.K. Gleason, Adv. Funct. Mater. 18, 7 (2008)

D.M. Tourlousse, F. Ahmad, R.D. Stedtfeld, G. Seyrig, J.M. Tiedje, S. Hashsham, Biomed. Microdevices 14, 4 (2012)

U.S. Department of Agriculture Food Safety and Inspection Service (USDA-FSIS), Accredited laboratory program. http://www.fsis.usda.gov/science/accredited_laboratories/index.asp. Accessed 21 March 2013.

W. Wang, H.-B. Wang, Z.-X. Li, Z.-Y. Guo, J. Biomed. Mater. Res. A 77, 1 (2006)

F. Wang, L. Jiang, B. Ge, J. Clin. Microbiol. 50, 1 (2011)

H. Wang, L. Wang, L. Yuan, W. Yang, J.L. Brash, H. Chen, Nanotechnology 23, 36 (2012)

W. Wong, P. Georgiou, C.-P. Ou, C. Toumazou, Electron. Lett. 46, 5 (2010)

C. Zhang, D. Xing, Chem. Rev. 110, 8 (2010)

E. Zubritsky, Anal. Chem. 72, 23 (2000)

Acknowledgments

We would like to acknowledge Jose Rivera for helping to edit the manuscript. In addition we acknowledge funding support from a cooperative agreement with Purdue University and the Agricultural Research Service of the United States Department of Agriculture, project number 1935-42000-035, and a sub-contract to the University of Illinois at Urbana-Champaign. We also acknowledge support from the National Institute of Health (NIH) Grant R01-CA20003 and the National Science Foundation (NSF) ECCS-1028549 Grant at UIUC.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary Video 1

Automated filling of micro array wells with microinjector. A silanized chip with dehydrated primers is covered in mineral oil for encapsulation. The microinjector systems automatically fills each well with around 30 nL of a primer-less LAMP solution with the target template. Including alignment steps, the full 6 × 6 array is filled in a total of about 3 min. After all wells are filled, the chip is heated to 65 °C for amplification. (MPG 41200 kb)

Rights and permissions

About this article

Cite this article

Duarte, C., Salm, E., Dorvel, B. et al. On-chip parallel detection of foodborne pathogens using loop-mediated isothermal amplification. Biomed Microdevices 15, 821–830 (2013). https://doi.org/10.1007/s10544-013-9769-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-013-9769-5