Abstract

Inexpensive, portable, and easy-to-use devices for rapid detection of microbial pathogens are needed to ensure safety of water and food. In this study, a disposable polymer microfluidic chip for quantitative detection of multiple pathogens using isothermal nucleic acid amplification was developed. The chip contains an array of 15 interconnected reaction wells with dehydrated primers for loop-mediated isothermal amplification (LAMP), and requires only a single pipetting step for dispensing of sample. To improve robustness of loading and amplification, hydrophobic air vents and microvalves were monolithically integrated in the multi-layered structure of the chip using an inexpensive knife plotter. For quantification, LAMP was performed with a highly fluorescent DNA binding dye (SYTO-82) and the reactions monitored in real-time using a low-cost fluorescence imaging system previously developed by our group (Ahmad et al., Biomed. Microdevices 13(5), 929–937). Starting from genomic DNA mixtures, the chip was successfully evaluated for rapid analysis of multiple virulence and marker genes of Salmonella, Campylobacter jejuni, Shigella, and Vibrio cholerae, enabling detection and quantification of 10–100 genomes per μl in less than 20 min. It is anticipated that the microfluidic chip, along with the real-time imaging system, may be a key enabling technology for developing inexpensive and portable systems for on-site screening of multiple pathogens relevant to food and water safety.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Outbreaks of infectious diseases due to contaminated food and water continue to pose a serious threat to human health worldwide (Craun et al. 2010; Scallan et al. 2011). While treatment, disinfection, and stringent hygienic standards generally provide effective safeguards for the consumer, rapid screening of food and water for the many pathogens of concern is paramount to preventing sporadic outbreaks of disease due to delayed detection of contamination. Traditionally, microbial agents in food and water are analyzed through culturing and biochemical or serological testing; however, while being highly sensitive, this is notoriously time-consuming and also not easily applied for specific detection of a panel of pathogens. Genetic testing using multiplex PCR and microarrays is much faster and can also screen for multiple pathogens and/or virulence and marker genes (VMGs) simultaneously (Call 2005; Gehring and Tu 2011; Maynard et al. 2005; Miller et al. 2008; Severgnini et al. 2011), but requires expensive and bulky equipment that is not well suited for testing on-site or even in small-scale laboratories.

Microfluidic chips with a multitude of separate reaction wells, each containing primers for amplification of a specific pathogen and/or VMG, provide a promising platform for multiplexed detection in inexpensive, user-friendly and compact devices (McCalla and Tripathi 2011). While a myriad of such chips have been developed over the years, based on PCR and, more recently, isothermal techniques for DNA/RNA amplification (for reviews, see e.g. Asiello and Baeumner 2011; Zhang et al. 2006), robustness and simplicity-of-use have often not been given due consideration. To be suitable for deployment beyond traditional laboratory settings and operation by minimally-trained personnel, dispensing of sample should require only a single, or at most a few, steps, without using bulky off-chip equipment. In many cases, however, either manual dispensing of sample in a small number of individual wells was necessary (Fang et al. 2010; Lee et al. 2008), or peripheral equipment needed for filling of high-throughput multiwell chips (Matsubara et al. 2005; Morrison et al. 2006) and propagation of sample through an interconnecting microfluidic network (Furuberg et al. 2008; Lutz et al. 2010; Trung et al. 2010). Furthermore, fabrication of the chips often involved surface treatment of the hydrophobic polymers used as substrate for bonding, robust filling, to prevent formation of air bubbles and/or improve biocompatibility (Fang et al. 2010, 2011; Furuberg et al. 2008; Lutz et al. 2010; Morrison et al. 2006). However, this not only adds to the complexity of fabrication and cost of the chips, but also has the drawback that surfaces modified by techniques such as oxygen plasma and UV/ozone treatment remain hydrophilic for only several hours after exposure to air (Oláh et al. 2005; Tan et al. 2010).

The goal of this study was to develop an easy-to-use and robust polymer microfluidic chip for multiplexed pathogen detection that: i) entails only a single step for dispensing of sample, ii) requires no surface treatment for fabrication and/or functionality of the chips, and iii) can be rapidly and inexpensively prototyped at or near the benchtop. The utility of the chip, which was fabricated out of multiple layers of biocompatible polymer film and contained 15 interconnected reaction wells with dehydrated primers, was evaluated for parallel detection of multiple food- and waterborne pathogens using loop-mediated isothermal amplification (LAMP). The latter is relatively novel technique in which four to six specific primers are employed for amplifying DNA with high yield at a constant temperature of 60–65 °C (Notomi et al. 2000). Owing to its simplicity, robustness, and low equipment cost, LAMP has already become the preferred technique for diagnosis of infectious diseases in low-resource settings (Mori and Notomi 2009). It could also serve as a powerful tool for detection of food- and waterborne pathogens (Seyrig et al. 2011; Plutzer et al. 2010; Yamazaki et al. 2008a). For quantification, the LAMP reactions were monitored in real-time using an inexpensive light emitting diode (LED) and charge coupled device (CCD) based imaging system previously developed by our group (Ahmad et al. 2011). In the latter study, we demonstrated that by long exposure imaging the time required for identification of positive reactions using real-time LAMP with a highly fluorescent dye DNA binding (SYTO-82) could be drastically reduced compared to that of an expensive real-time PCR instrument.

2 Materials and methods

2.1 Microfluidic chip design

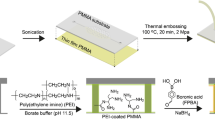

The microfluidic chip (25 mm × 65 mm) consists of an array of 15 reaction wells that are connected to a common microchannel (250 μm × 250 μm) for loading of sample from a single inlet port, and hydrophobic air vents and microvalves (Fig. 1(a)). The volume of each reaction well is roughly 1 μl and the total volume of the microchannels is 15 μl. The chip is loaded using a conventional pipettor through an access port that is designed to fit snugly around the pointed end of a 200 μl pipette tip (Fig. S1). Upon aspiration, sample is simply pushed through the distribution channel due to pressure generated by the pipettor, which results in sequential filling of the wells within seconds (Fig. 2(a)). In the process, air inside the chip escapes through hydrophobic air vents downstream of each reaction well. After loading, the inlet port and air vents are covered with tape to prevent contamination. The chip is then placed in a temperature-controlled cartridge in which each reaction well is effectively sealed using a pair of microvalves.

(a) Schematic of the microfluidic chip consisting of an array of 15 reaction wells and microchannel for sample distribution, hydrophobic air vents, and microvalves. (b) Rendering of the multi-layered structure and working principle of the chip (only four reaction wells are shown for clarity). The dotted red line marks the flow path of sample during loading of the first reaction well. During filling, air in the chip is purged out through the hydrophobic air vents, as depicted by the green line

(a) Time-lapse images showing rapid filling of the reaction wells from a single inlet port. (b) Fluorescence image of the chip after amplification demonstrating lack of cross-contamination between adjacent reaction wells. For this experiment, ipaH primers only (i) and ipaH primers plus 105 copies of Shigella gDNA (ii) were dehydrated in alternating wells throughout the chip (as shown by the dashed arrow), and the chip loaded with LAMP reagent mixture lacking primers. (c) Parallel detection of multiple pathogens using endpoint fluorogenic LAMP in the microfluidic chip. The layout of the assays (each in duplicate in neighboring wells) and composition of gDNA mixtures (105 copies/μl for each pathogen) loaded in the chips are indicated. For the amplification control, ipaH primers and 105 copies of Shigella gDNA were dehydrated in the three upper wells

To integrate the hydrophobic air vents and microvalves, the chip was constructed out of three separate layers (from bottom to top): a polymer film with shell-structured microchannels and reaction wells and two layers of patterned adhesive film (Fig. 1(b)). A microvalve consists of a discontinuation in the microchannel and a three-dimensional flow path formed by two through-holes in the middle layer and locally removed adhesive in the top layer (Fig. S2). This allows sample liquid to flow across the microchannel disconnect during filling of the chips. To close the microvalve, one of the through-holes in the middle layer is sealed by mechanically deforming the top layer. Hydrophobic air vents are formed by covering the through-holes at the end of the reaction channel with water-resistant gas-permeable membrane.

2.2 Chip fabrication

The chip was fabricated out of 100 μm thick cyclo olefin polymer (COP) film (ZeonorFilm® ZF14; Zeon Chemicals, Louisville, KY) and optical film with biocompatible adhesive (MicroAmp® Optical Adhesive Film; Applied Biosystems). Fabrication consisted of four steps: i) microstructuring of the COP film by hot embossing, ii) patterning of the adhesive films using a knife plotter, iii) dispensing and dehydrating of LAMP primers in the wells, and iv) assembly and bonding of the different layers (Fig. S3).

Microstructuring of the COP film was performed in a heated press (model 4386; Carver, Wabash, IN) by hot embossing using a sacrificial thermoplastic counter tool (acrylonitrile butadiene styrene, ABS, from K-mac Plastics, Wyoming, MI). The embossing mold was fabricated by stereolithography out of high resolution Somos® NanoTool™ (FineLine Prototyping; Raleigh, NC) and subsequently thermally cured to increase its glass transition temperature and coated with a thin layer of nickel (SLArmor) to facilitate de-embossing. To expedite fabrication, the mold contained features for four separate chips. Also, a landing shoulder was placed around the length of the mold to improve pressure build-up around the chip features by reducing lateral flow of the softened ABS tool during embossing (Yao and Kuduva-Raman-Thanumoorthy 2008), which enabled good replication with minimal optimization of the embossing conditions. The embossing process consisted of sandwiching the polymer film between the mold and ABS tool, followed by heating to 150 °C, applying a pressure of 2,000 kg for 5 min, cooling to 110 °C while maintaining the embossing pressure, and de-embossing of the mold after further cooling to room temperature. The microstructured film was then extracted from the ABS tool, cleaned with 1 % Liqui-Nox, rinsed with distilled water, soaked in isopropanol, and air-dried at 65 °C in an oven.

The adhesive films were patterned using a digital knife plotter (Craft ROBO Pro, CC5000-40-CRP; Graphtec America, Santa Ana, CA), based on the concept of xurography developed by Bartholomeusz et al. (2005). Designs to be cut were drawn using freeware available online (www.emachineshop.com) and uploaded in the ROBO Master-Pro software as DXF files, without subsequent editing. For cutting, a 0.9 mm 60° spring-loaded carbide steel blade, placed in dedicated holder for adjusting the cutting depth (both from Specialty Graphics, West Chicago, IL), was used. After cutting, unwanted film material was easily removed using tape, after which the film was cleaned with a small amount of ethanol. Features for the four chips on the embossing mold were patterned in a single film. In total, the middle layer contained 240 through-holes (diameter of 600 μm) for routing of sample liquid through the top layer, 60 through-holes for air venting (750 μm) and 4 through-holes for sample dispensing (1 mm). The top layer contained 60 through-holes for air venting, 4 through-holes for sample dispensing, and 120 regions with locally removed adhesive. Details regarding the cutting process and local removal of adhesive for constructing the microvalves are provided in the Supplemental Material.

In the next step, LAMP primers (1 μl) were manually dispensed in the reaction wells and dehydrated for 5 min at 95 °C. After cooling to room temperature, the chip was placed back in the embossed ABS tool and the two layers of patterned adhesive film and a precut piece of Durapore® hydrophobic membrane (catalog no. GVHP 09050; Millipore, Billerica, MA) visually aligned on top. The chip was then firmly bonded in the Carver press at room temperature, with a layer of 70 A silicone rubber (McMaster-Carr, Aurora, OH) placed on top to obtain a uniform and hermetic seal. Finally, a manually drilled plastic inlet port was attached to the chip with double-sided tape. The latter was designed such that the access hole for the pipette tip was located in a cavity at a level lower than the surface required for sealing (Fig. S1). This prevented wetting of the sealing surface that may occur during dispensing of the sample (Focke et al. 2010), and also allowed for backflow of a small amount of sample upon closing of the microvalves, which have a non-zero dead volume.

2.3 Experimental setup

The experimental setup consisted of two components: i) an imaging system for endpoint and real-time detection of fluorogenic LAMP, and ii) a temperature-controlled chip cartridge (Fig. S4). The former was described previously (Ahmad et al. 2011), and contained: i) an ultra-bright green Luxeon® K2 Star LED driven at 700 mA (LED Supply, Randolph, VT), dedicated L2 Wide Beam 25° lens (LED Supply), 534 ± 20 nm excitation filter (Semrock, Rochester, NY), and 50° circle pattern Engineered Diffuser™ (Thorlabs, Newton, NJ) for illumination of the chip, and ii) a 16-bit, 0.25 megapixel monochrome CCD camera (MEADE Deep Sky Imager Pro, Irvine, CA) equipped with a 572 ± 20 nm emission filter (Semrock) and 16 mm relay lens (DealExtreme) for imaging.

The chip cartridge consisted of a black ABS holder fabricated by hot embossing, to which a 2 × 6 cm2 polyimide thin film heater with a resistance of 50 Ω (Minco, Minneapolis, MN) was attached for heating. The temperature control system was composed of a 0.076 mm type-T insulated thermocouple (Omega, Stamford, CT) for temperature measurement, and a pulse-width-modulation power driver (DRV102T; Texas Instruments, Dallas, TX) for adjusting the power supplied to the heater based on a proportional-integral-derivative control mechanism implemented using a custom LabView™ application (Ahmad et al. 2011; Stedtfeld et al. 2012). For closing of the microvalves, a transparent cover with pre-aligned 1 mm plungers was fastened on top of the chip using a pair of toggle clamps.

2.4 Loop-mediated isothermal amplification

Primers for two or three VMGs of four major food- and waterborne pathogens (Salmonella, Shigella, Vibrio cholerae and Campylobacter jejuni) were used in this study (Table S1). Genomic DNA (gDNA) of Salmonella (ATCC700702), Shigella (ATCC700930), V. cholerae (ATCC39315), and C. jejuni (ATCC700819) were obtained from the American Type Culture Collection (Manassas, VA).

An appropriate amount of primers (from Integrated DNA Technologies, Coralville, IA) was dispensed and dehydrated in the reaction wells to yield 1.6 μM each of FIP and BIP primers, 800 nM each of LB and FB primers, and 200 nM each of F3 and B3 primers, after dissolution in a volume of 1 μl. Reagent mixtures for LAMP contained 800 mM of betaine (Sigma-Aldrich, St. Louis, MO), 1.4 mM of each deoxynucleotide triphosphate (Invitrogen, Carlsbad, CA), 20 mM of Tris–HCl buffer (pH 8.8), 10 mM of (NH4)2SO4, 10 mM of KCl, 8 mM of MgSO4, 0.64 units/μl of Bst DNA polymerase, large-fragment (New England Biolabs, Ipswich, MA), 8 mM of Triton® X-100 (Sigma-Aldrich), 0.2 % (v/v) of Pluronic® F-68 (Invitrogen), 1 mg/ml of bovine serum albumin (New England BioLabs), and 2 μM of SYTO-82 fluorescent dye (Invitrogen). For parallel detection, gDNA of the pathogens was added to the LAMP reagent mixtures at the desired concentration prior to dispensing in the chips. The assays were performed at 63 °C.

Real-time monitoring was accomplished by automated time-lapse imaging of the chip every 30 s using the AutoStar Suite software provided with the DSI Pro camera. Images were captured at a gain and offset of 100 and 60, respectively, and an exposure time of 5 s (Ahmad et al. 2011). For quantification, images (stored as 16-bit FTS files) were exported to ImageJ (National Institutes of Health, Bethesda, MD) for extracting signal intensities from the different wells (with a constant number of pixels per well) using a dedicated plug-in for microarray analysis (http://www.optinav.com/imagej.html). The threshold time (Tt) was defined as the interpolated time at which the baseline-subtracted signal was equal to 10 standard deviations of the baseline signal, which is equivalent to a signal-to-noise ratio (SNR) of 10, as described previously (Ahmad et al. 2011).

3 Results and discussion

3.1 Layout and operation of the microfluidic chip

The mode of sample dispensing and sealing of microfluidic chips for nucleic acid amplification are among the most important factors that determine their ease-of-use and resistance to contamination. Here, we pursued a simple method for filling of an array-type multiwell chip using solely pressure generated by a pipettor for propagating sample through the chip, without requiring peripheral equipment. To this end, the inlet port was designed to fit tightly around the pointed end of a pipette tip, such that sample liquid is simply pushed through the distribution channel upon aspiration from the pipettor (Fig. 2(a)). Air inside the chip is purged out through porous membrane that is placed at the end of each reaction channel, without sample liquid exiting the chip owing to the hydrophobic nature of the membrane. To prevent contamination among chips, which is especially crucial for LAMP due to its high yield, the inlet port and air vents are then covered with tape. To further enhance robustness and simplicity-of-use, a screw-cap type mechanism could also be used for closing of the inlet ports and sample dispensed using e.g. a syringe, both of which are being evaluated for future chip designs.

Others have also relied on pressure-driven flow for filling of similar array-type chips for LAMP, based on different strategies. In one study, Abe et al. (2011) described a glass-poly(dimethylsiloxane)(PDMS)-glass microfluidic chip that was bonded under vacuum such that dead-end channels are automatically filled within seconds upon loading of sample through a pierceable inlet port. In another study, Myers et al. (2011) exploited residual vacuum in the porous structure of degassed PDMS for automated dispensing, but this required up to 10 min to completely fill a 96-well LAMP chip due to the relatively low flow rates that are achievable using this technique. Also, use of this type of chip may require more careful coordination of the test by the user since the chip loses some of its suction power within 10 min after being released from the vacuum-sealed bag in which it is stored, which may result in incomplete filling for certain cross-sectional microchannel areas (Liang et al. 2011).

The above approaches for sample dispensing provide several benefits compared to capillary action, which was previously also explored for instrument-free filling of chips for multiplexed DNA amplification (Ramalingam et al. 2009). Most importantly, it eliminates the need for surface treatment of the hydrophobic polymers commonly used for fabrication of low-cost chips, or the use of expensive glass as hydrophilic substrate. Also, capillary action places more stringent demands on the geometry of the microchannels and wells due to the potential of abruptly expanding shapes to act as stop valves (Zimmermann et al. 2008) and/or air bubbles to become entrapped during filling (Gong et al. 2006).

After sample dispensing and sealing, the chip is placed in a dedicated cartridge in which microvalves are closed to fluidically isolate the reaction wells. This ensures highly localized and reproducible amplification in a well-defined reaction volume, and also prevents formation of air bubbles that may expel reaction mixture from the wells and/or impact signal quantification. To demonstrate the effectiveness of the microvalves, a chip was prepared in which (i) only primers (for ipaH of Shigella), and (ii) ipaH primers plus Shigella gDNA (105 copies per well) were dehydrated in alternating reaction wells. The chip was subsequently filled with LAMP reagents, sealed and placed in the chip cartridge. Imaging of the chip after 40 min of incubation at 63 °C revealed that amplicons had predominantly accumulated in the regions enclosed by microvalves, and that no carry-over of target DNA and/or amplicons had occurred between neighboring wells (Fig. 2(b)).

Based on this array-type well layout with hydrophobic air vents and microvalves, the throughput of the chips can be easily scaled up to 60 wells, for readout using a compact photodiode-based detector recently developed by our group (Stedtfeld et al. 2012). A photograph of such a higher throughput chip (fabricated using the process developed here) for simultaneous analysis of four samples, each for up to 15 pathogens and/or VMGs, is shown in Fig. S5. Importantly, due to the use of an imaging sensor for assay quantification, the system described here is highly flexible with respect to the layout and throughput of the chips, which is attractive since it allows chip to be designed based on the needs of specific users in terms of the number of samples per chip and the degree of multiplexing.

3.2 Parallel detection of multiple pathogens

To demonstrate the utility of the chips, primers for six VMGs (cj0414 and cdtA of C. jejuni, phoP and invA of Salmonella and toxR and rtxA of V. cholerae) were dispensed in duplicate in adjacent reaction wells. Three samples containing gDNA of two pathogens each, at a concentration of 105 copies/μl, and LAMP reagents were subsequently loaded in the chips and a fluorescence image recorded at the end of the reaction. For all three mixtures, the expected positive and negative signals were observed for all assays (Fig. 2(c)). This verified that the chip was suitable for simultaneous analysis of multiple pathogens, without interaction among assays.

In a subsequent experiment, primers for two VMGs of C. jejuni (cj0414 and cdtA) and Salmonella (phoP and invA), and one VMG of Shigella (ipaH) were dehydrated in triplicate in the chip. The chip was then loaded with LAMP reagents supplemented with gDNA of all three pathogens at a concentration of 105 copies/μl each, and the reactions monitored in real-time using the CCD-based imaging system. For all assays, typical sigmoidal amplification curves were obtained (Fig. 3(a)), and the Tt calculated as the time at which the SNR equaled 10 (Fig. 3(b)). When compared to our previous study in which real-time fluorogenic LAMP was performed in a multiwell COP microchip using the same imaging system (Ahmad et al. 2011), the Tt for the majority of the assays was only about 15 % higher in the microfluidic chips utilized here (with the exception of Cj-cdtA assay, which was faster in this study). Along with the good intra-chip reproducibility in terms of Tt (Fig. 3(b)), these data validated that amplification proceeded effectively in the microfluidic chips.

3.3 Detection of low abundance pathogens and quantification

To evaluate performance of the system (that is, the microfluidic chip and imaging module) for quantification and detection of pathogens at low abundance, several serially-diluted gDNA samples were analyzed. As illustrated in Fig. 4 for ipaH of Shigella and cdtA of C. jejuni, good linearity was, as expected, observed between the Tt and logarithm of the number of genome copies per reaction. Similar results were obtained for the other assays (Table S1), and further verified that amplification was reliable and that the chip could be used for quantification using traditional standard curves.

Amplification curves for a 10-fold serially diluted gDNA sample of Shigella (ipaH gene, a) and C. jejuni (cdtA gene, c). The standard curves (b and d) are determined based on the average Tt (black circles) from at least two of the replicates (empty circles represent the Tt values from each replicate that were included for calculation of the average Tt while data shown as empty diamonds were omitted)

In terms of analytical sensitivity, a lower limit of detection (LOD) of 10–100 gene copies per reaction well (or per μl) was achieved for the different assays (Table S1). While lower copy numbers were not evaluated, it is anticipated that a sensitivity of a few copies per well should be achievable using the LAMP microfluidic chip. This is because: i) detection of single copies has been reported previously using LAMP in conventional tubes (Thekisoe et al. 2010; Tsai et al. 2009; Yamazaki et al. 2008b) and also in microscale systems based on endpoint fluorescence detection (Lam et al. 2008; Gansen et al. 2012), and ii) we routinely observed that amplification efficiency of LAMP in chips fabricated out of untreated polymeric substrates (COP and polyester), is similar to that in tubes (Ahmad et al. 2011; Stedtfeld et al. 2012). As such, the microfluidic chip is expected to provide a sensitivity that is comparable to that of most molecular assays, including PCR, but with the added benefit of multiplexed detection in an inexpensive and easy-to-use format.

To allow comparison with culture-based techniques, it is useful to express pathogen abundance in terms of gene copies as well as colony forming units (CFUs). However, without direct experimental assessment, this can only be approximate because many variables determine the relationship between gene copies and CFUs. These include the frequency at which the targeted gene occurs in the pathogen’s genome, the physiological state and cultivability of the cells, and methodological aspects of both the culture- and molecular-based techniques (the range of environmental strains detected by each method, impact of sample processing on cell viability, DNA extraction efficiency, etc). Target gene frequency can be easily determined based on available whole genome sequences, and for most of the genes targeted in this study only a single copy is present per genome. The physiological state and cultivability of the cells are probably the most important factors and depend on a multitude of environmental conditions. Focusing on fecal indicator bacteria in environmental waters, recent work has indicated that while good correlations between gene copies and CFU exist (Whitman et al. 2010), their ratio is often highly variable (Converse et al. 2012). In some studies gene copy and CFU counts were comparable (Byappanahalli et al. 2010), but in others, gene abundances were up to several orders of magnitude higher than CFU densities (Converse et al. 2012; Haugland et al. 2005; Morrison et al. 2008; Khan et al. 2009), which is attributed to detection of uncultivable cells by molecular techniques. Conservatively, we can estimate that for each CFU detected, about 10 gene copies may be present in the sample, assuming a single copy per genome, and a fraction of viable cells and DNA extraction efficiency of 20 % and 50 %, respectively.

For many pathogens that are relevant to food and water safety, a LOD of a single cell per 10–25 g of food or 100–250 ml of water is necessary to meet zero-tolerance guidelines that are being promoted in several countries to minimize health risks (Gilbert et al. 2000; Barrell et al. 2000). Hence, it is clear that, even with the ability of molecular assays to reliably detect a single gene copy per reaction, meeting this requirement will depend on the availability of sample processing techniques that can effectively concentrate large-volume samples. Given the ability of the chip to screen for multiple pathogens in parallel, techniques that simultaneously concentrate viral, bacterial and protozoan pathogens will be most useful, such as ultrafiltration (Morales-Morales et al. 2003) and continuous flow centrifugation (Zuckerman and Tzipori 2006). Still, for certain applications, a DNA pre-amplification step, using e.g. isothermal whole genome amplification, may be necessary given that sample is distributed in multiple reaction wells, which reduces assay sensitivity on a copy-per-sample basis. While this may add several hours to the assay and also prevent accurate quantification, such a strategy could be justified by the much lower cost and complexity of the instrumentation required for multiplexed detection. Another option to enhance chip performance for analysis of ultra-low abundance pathogens is to load a common primer set in all reaction wells to enable accurate quantification of low copy numbers based on the fraction of positive/negative wells, as in digital PCR (Pohl and Shih 2004). The chip described here is well suited for digital LAMP, which was very recently demonstrated in an array-type glass/PDMS microfluidic chip (Gansen et al. 2012), since sample dispensing is robust and the reaction wells are effectively isolated, although the number of wells should be increased when a large dynamic range is required.

Finally, the chip could also be readily used for selective detection of viable cells by pre-treating samples with propidium or ethidium monoazide (PMA/EMA) (Nocker et al. 2007; Pan and Breidt 2007). While this technique has until now been mostly used in conjunction with PCR (e.g. Yáñez et al. 2011; Josefsen et al. 2010), successful development of EMA- and PMA-LAMP for detection of viable Salmonella cells was recently reported (Lu et al. 2009; Chen et al. 2011). Quantification of viable cells only may also improve concordance between CFUs and gene copies, which is beneficial for accelerating acceptance of molecular techniques for food and water safety monitoring.

4 Conclusions

A disposable polymer microfluidic chip for nucleic acid amplification was developed that enables parallel detection of multiple pathogens in a low-cost and easy-to-use format. Since the chip contains dehydrated primers and also requires only a single step for dispensing of sample in a multitude of independent reaction wells, it is well suited for deployment outside traditional laboratory settings and use by minimally-skilled technicians. To demonstrate the utility of the chip, LAMP was chosen because of its rapidity, robustness, and high sensitivity and specificity. The chip could however also readily accommodate other methods for isothermal DNA/RNA amplification. Furthermore, since each reaction well is effectively sealed using a pair of microvalves, the chip should also be suitable for PCR, which is typically more prone to evaporation and cross-contamination among wells due to the need for a high temperature denaturation step and thermal cycling.

For rapid detection and quantification, LAMP was performed with a highly fluorescent DNA binding dye and monitored in real-time using a low-cost CCD imaging module. The latter, together with the microfluidic chip, may form the key components of an inexpensive and robust stand-alone device for multiplexed nucleic acid amplification testing that could be combined with currently available techniques for sample processing to provide a complete system for rapid detection of water- and foodborne pathogens. Furthermore, due to robustness of LAMP, sample purity is less critical than it is for PCR, which should enable simplified sample preparation procedures that could be more easily performed on-site. Another option is to integrate sample processing on-chip using a variety of microfluidic cell lysis and nucleic acid purification techniques developed over the years (Kim et al. 2009), some of which have recently been coupled with LAMP for detection of infectious agents in clinical samples (Liu et al. 2011; Wang et al. 2011; Wu et al. 2011). Importantly, many of these techniques can also be readily integrated in inexpensive polymer chips that can be fabricated using benchtop prototyping techniques (e.g. Bhattacharyya and Klapperich 2006; Duarte et al. 2011), such as the one described here. In conclusion, with further development and validation, the microfluidic chip could find application in many areas where rapid and reliable detection of multiple microbial pathogens is required, at low-cost and without using cumbersome equipment.

References

T. Abe, Y. Segawa, H. Watanabe, T. Yotoriyama, S. Kai, A. Yasuda, N. Shimizu, N. Tojo, Point-of-care testing system enabling 30 min detection of influenza genes. Lab Chip 11(6), 1166–1167 (2011)

F. Ahmad, G. Seyrig, D.M. Tourlousse, R.D. Stedtfeld, J.M. Tiedje, S.A. Hashsham, A CCD-based fluorescence imaging system for real-time loop-mediated isothermal amplification-based rapid and sensitive detection of waterborne pathogens on microchips. Biomed. Microdevices 13(5), 929–937 (2011)

P.J. Asiello, A.J. Baeumner, Miniaturized isothermal nucleic acid amplification, a review. Lab Chip 11(8), 1420–1430 (2011)

R.A. Barrell, P.R. Hunter, G. Nichols, Microbiological standards for water and their relationship to health risk. Commun. Dis. Public Health 3(1), 8–13 (2000)

D.A. Bartholomeusz, R.W. Boutte, J.D. Andrade, Xurography: rapid prototyping of microstructures using a cutting plotter. J. MEMS 14(6), 1364–1374 (2005)

A. Bhattacharyya, C.M. Klapperich, Thermoplastic microfluidic device for on-chip purification of nucleic acids for disposable diagnostics. Anal. Chem. 78(3), 788–792 (2006)

M.N. Byappanahalli, R.L. Whitman, D.A. Shively, M.B. Nevers, Linking non-culturable (qPCR) and culturable enterococci densities with hydrometeorological conditions. Sci. Total. Environ. 408(16), 3096–3101 (2010)

D.R. Call, Challenges and opportunities for pathogen detection using DNA microarrays. Crit. Rev. Microbiol. 31(2), 91–99 (2005)

S. Chen, F. Wang, J.C. Beaulieu, R.E. Stein, B. Ge, Rapid detection of viable salmonellae in produce by coupling propidium monoazide with loop-mediated isothermal amplification. Appl. Environ. Microbiol. 77(12), 4008–4016 (2011)

R.R. Converse, J.F. Griffith, R.T. Noble, R.A. Haugland, K.C. Schiff, S.B. Weisberg, Correlation between quantitative PCR and culture-based methods for measuring Enterococcus spp. over various temporal scales at three California marine beaches. Appl. Environ. Microbiol. 78(4), 1237–1242 (2012)

G.F. Craun, J.M. Brunkard, J.S. Yoder, V.A. Roberts, J. Carpenter, T. Wade, R.L. Calderon, J.M. Roberts, M.J. Beach, S.L. Roy, Causes of outbreaks associated with drinking water in the United States from 1971 to 2006. Clin. Microbiol. Rev. 23(3), 507–528 (2010)

G.R. Duarte, C.W. Price, B.H. Augustine, E. Carrilho, J.P. Landers, Dynamic solid phase DNA extraction and PCR amplification in polyester-toner based microchip. Anal. Chem. 83(13), 5182–5189 (2011)

X. Fang, Y. Liu, J. Kong, X. Jiang, Loop-mediated isothermal amplification integrated on microfluidic chips for point-of-care quantitative detection of pathogens. Anal. Chem. 82(7), 3002–3006 (2010)

X. Fang, H. Chen, S. Yu, X. Jiang, J. Kong, Predicting viruses accurately by a multiplex microfluidic loop-mediated isothermal amplification chip. Anal. Chem. 83(3), 690–695 (2011)

M. Focke, F. Stumpf, B. Faltin, P. Reith, D. Bamarni, S. Wadle, C. Muller, H. Reinecke, J. Schrenzel, P. Francois, D. Mark, G. Roth, R. Zengerle, F. von Stetten, Microstructuring of polymer films for sensitive genotyping by real-time PCR on a centrifugal microfluidic platform. Lab Chip 10(19), 2519–2526 (2010)

L. Furuberg, M. Mielnik, A. Gulliksen, L. Solli, I.R. Johansen, J. Voitel, T. Baier, L. Riegger, F. Karlsen, RNA amplification chip with parallel microchannels and droplet positioning using capillary valves. Microsyst. Technol. 14(4–5), 673–681 (2008)

A. Gansen, A.M. Herrick, I.K. Dimov, L.P. Lee, D.T Chiu, Digital LAMP in a sample self-digitization (SD) chip. Lab Chip (2012), Advance Article doi:10.1039/C2LC21247Ab

A.G. Gehring, S.I. Tu, High-throughput biosensors for multiplexed food-borne pathogen detection. Annu. Rev. Anal. Chem. (Palo Alto Calif) 4, 151–172 (2011)

R.J. Gilbert, J. de Louvois, T. Donovan, C. Little, K. Nye, C.D. Ribeiro, J. Richards, D. Roberts, F.J. Bolton, Guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale. PHLS Advisory Committee for Food and Dairy Products. Commun. Dis. Public Health 3(3), 163–167 (2000)

H. Gong, N. Ramalingam, L. Chen, J. Che, Q. Wang, Y. Wang, X. Yang, P.H. Yap, C.H. Neo, Microfluidic handling of PCR solution and DNA amplification on a reaction chamber array biochip. Biomed. Microdevices 8(2), 167–176 (2006)

R.A. Haugland, S.C. Siefring, L.J. Wymer, K.P. Brenner, A.P. Dufour, Comparison of Enterococcus measurements in freshwater at two recreational beaches by quantitative polymerase chain reaction and membrane filter culture analysis. Water Res. 39(4), 559–568 (2005)

M.H. Josefsen, C. Löfström, T.B. Hansen, L.S. Christensen, J.E. Olsen, J. Hoorfa, Rapid quantification of viable Campylobacter bacteria on chicken carcasses, using real-time PCR and propidium monoazide treatment, as a tool for quantitative risk assessment. Appl. Environ. Microbiol. 76(15), 5097–5104 (2010)

I.U. Khan, A. Loughborough, T.A. Edge, DNA-based real-time detection and quantification of aeromonads from fresh water beaches on Lake Ontario. J. Water Health. 7(2), 312–323 (2009)

J. Kim, M. Johnson, P. Hill, B.K. Gale, Microfluidic sample preparation: cell lysis and nucleic acid purification. Integr. Biol. (Camb) 1(10), 574–586 (2009)

L. Lam, S. Sakakihara, K. Ishizuka, S. Takeuchi, H.F. Arata, H. Fujita, H. Noji, Loop-mediated isothermal amplification of a single DNA molecule in polyacrylamide gel-based microchamber. Biomed. Microdevices 10(4), 539–546 (2008)

S.Y. Lee, J.G. Huang, T.L. Chuang, J.C. Sheu, Y.K. Chuang, M. Holl, D.R. Meldrum, C.N. Lee, C.W. Lin, Compact optical diagnostic device for isothermal nucleic acids amplification. Sens. Actuat. B-Chem. 133(2), 493–501 (2008)

D.Y. Liang, A.M. Tentori, I.K. Dimov, L.P. Lee, Systematic characterization of degas-driven flow for poly(dimethylsiloxane) microfluidic devices. Biomicrofluidics 5(2), 24108 (2011)

C. Liu, E. Geva, M. Mauk, X. Qiu, W.R. Abrams, D. Malamud, K. Curtis, S.M. Owen, H.H. Bau, An isothermal amplification reactor with an integrated isolation membrane for point-of-care detection of infectious diseases. Analyst 136(10), 2069–2076 (2011)

Y. Lu, W. Yang, I. Shi, I. Li, M.J. Alam, S. Guo, S. Miyoshi, Specific detection of viable Salmonella cells by an ethidium monoazide-loop mediated isothermal amplification (EMA-LAMP) method. J. Health Sci. 55(5), 820–824 (2009)

S. Lutz, P. Weber, M. Focke, B. Faltin, J. Hoffmann, C. Müller, D. Mark, G. Roth, P. Munday, N. Armes, O. Piepenburg, R. Zengerle, F. von Stetten, Microfluidic lab-on-a-foil for nucleic acid analysis based on isothermal recombinase polymerase amplification (RPA). Lab Chip 10(7), 887–893 (2010)

Y. Matsubara, K. Kerman, M. Kobayashi, S. Yamamura, Y. Morita, E. Tamiya, Microchamber array based DNA quantification and specific sequence detection from a single copy via PCR in nanoliter volumes. Biosens. Bioelectron. 20(8), 1482–1490 (2005)

C. Maynard, F. Berthiaume, K. Lemarchand, J. Harel, P. Payment, P. Bayardelle, L. Masson, R. Brousseau, Waterborne pathogen detection by use of oligonucleotide-based microarrays. Appl. Environ. Microbiol. 71(12), 8548–8557 (2005)

S.E. McCalla, A. Tripathi, Microfluidic reactors for diagnostics applications. Annu. Rev. Biomed. Eng. 13, 321–343 (2011)

S.M. Miller, D.M. Tourlousse, R.D. Stedtfeld, S.W. Baushke, A.B. Herzog, L.M. Wick, J.-M. Rouillard, E. Gulari, J.M. Tiedje, S.A. Hashsham, In situ-synthesized virulence and marker gene biochip for detection of bacterial pathogens in water. Appl. Environ. Microbiol. 74(7), 2200–2209 (2008)

H.A. Morales-Morales, G. Vidal, J. Olszewski, C.M. Rock, D. Dasgupta, K.H. Oshima, G.B. Smith, Optimization of a reusable hollow-fiber ultrafilter for simultaneous concentration of enteric bacteria, protozoa, and viruses from water. Appl. Environ. Microbiol. 69(7), 4098–4102 (2003)

Y. Mori, T. Notomi, Loop-mediated isothermal amplification (LAMP): a rapid, accurate, and cost-effective diagnostic method for infectious diseases. J. Infect. Chemother. 15(2), 62–69 (2009)

T. Morrison, J. Hurley, J. Garcia, K. Yoder, A. Katz, D. Roberts, J. Cho, T. Kanigan, S.E. Ilyin, D. Horowitz, J.M. Dixon, C.J.H. Brenan, Nanoliter high throughput quantitative PCR. Nucleic Acids Res. 34(18), e123 (2006)

C.R. Morrison, D.S. Bachoon, K.W. Gates, Quantification of enterococci and bifidobacteria in Georgia estuaries using conventional and molecular methods. Water Res. 42(14), 4001–4009 (2008)

F.B. Myers, R.H. Henrikson, L. Xu, L.P. Lee, A point-of-care instrument for rapid multiplexed pathogen genotyping. Proceedings of the IEEE Engineering in Medicine and Biology Conference (EMBC), Boston, MA (2011)

A. Nocker, K.E. Sossa, A.K. Camper, Molecular monitoring of disinfection efficacy using propidium monoazide in combination with quantitative PCR. J. Microbiol. Methods 70(2), 252–260 (2007)

T. Notomi, H. Okayama, H. Masubuchi, T. Yonekawa, K. Watanabe, N. Amino, T. Hase, Loop-mediated isothermal amplification of DNA. Nucleic Acids Res. 28(12), e63 (2000)

A. Oláh, H. Hillborg, G.J. Vancso, Hydrophobic recovery of UV/ozone treated poly(dimethylsiloxane): adhesion studies by contact mechanics and mechanism of surface modification. Appl. Surf. Sci. 239(3–4), 410–423 (2005)

Y. Pan, F. Breidt Jr., Enumeration of viable Listeria monocytogenes cells by real-time PCR with propidium monoazide and ethidium monoazide in the presence of dead cells. Appl. Environ. Microbiol. 73(24), 8028–8031 (2007)

J. Plutzer, A. Torokne, P. Karanis, Combination of ARAD microfibre filtration and LAMP methodology for simple, rapid and cost-effective detection of human pathogenic Giardia duodenalis and Cryptosporidium spp. in drinking water. Lett. Appl. Microbiol. 50(1), 82–88 (2010)

G. Pohl, Ie-M Shih, Principle and applications of digital PCR. Expert. Rev. Mol. Diagn. 4(1), 41–47 (2004)

N. Ramalingam, H.B. Liu, C.C. Dai, Y. Jiang, H. Wang, Q. Wang, K.M. Hui, H.Q. Gong, Real-time PCR array chip with capillary-driven sample loading and reactor sealing for point-of-care applications. Biomed. Microdevices 11(5), 1007–1020 (2009)

E. Scallan, R.M. Hoekstra, F.J. Angulo, R.V. Tauxe, M.A. Widdowson, S.L. Roy, J.L. Jones, P.M. Griffin, Foodborne illness acquired in the United States-major pathogens. Emerg. Infect. Dis. 17(1), 7–15 (2011)

M. Severgnini, P. Cremonesi, C. Consolandi, G. De Bellis, B. Castiglioni, Advances in DNA microarray technology for the detection of foodborne pathogens. Food Bioprocess Technol. 4(6), 936–953 (2011)

G. Seyrig, F. Ahmad, R.D. Stedtfeld, D.M. Tourlousse, S.A. Hashsham, in Environmental Microbiology: Current Technology and Water Applications, ed. by K. Sen, N.J. Ashbolt (Academic, Caister, 2011), pp. 103–125

R.D. Stedtfeld, D.M. Tourlousse, G. Seyrig, T.M. Stedtfeld, M. Kronlein, S. Price, F. Ahmad, E. Gulari, J.M. Tiedje, S.A. Hashsham, Gene-Z: a device for point-of-care genetic testing using a smartphone. Lab Chip 12(8), 1454–1462 (2012)

S.H. Tan, N.T. Nguyen, Y.C. Chua, T.G. Kang, Oxygen plasma treatment for reducing hydrophobicity of a sealed polydimethylsiloxane microchannel. Biomicrofluidics 4(3), 32204 (2010)

O.M. Thekisoe, N.E. Rambritch, R. Nakao, R.S. Bazie, P. Mbati, B. Namangala, I. Malele, R.A. Skilton, F. Jongejan, C. Sugimoto, S. Kawazu, N. Inoue, Loop-mediated isothermal amplification (LAMP) assays for detection of Theileria parva infections targeting the PIM and p150 genes. Int. J. Parasitol. 40(1), 55–61 (2010)

N.B. Trung, M. Saito, H. Takabayashi, P.H. Viet, E. Tamiya, Y. Takamura, Multi-chamber PCR chip with simple liquid introduction utilizing the gas permeability of polydimethylsiloxane. Sens. Actuat. B-Chem. 149(1), 284–290 (2010)

S.M. Tsai, K.W. Chan, W.L. Hsu, T.J. Chang, M.L. Wong, C.Y. Wang, Development of a loop-mediated isothermal amplification for rapid detection of orf virus. J. Virol. Methods 157(2), 200–204 (2009)

C.H. Wang, K.Y. Lien, J.J. Wu, G.B. Lee, A magnetic bead-based assay for the rapid detection of methicillin-resistant Staphylococcus aureus by using a microfluidic system with integrated loop-mediated isothermal amplification. Lab Chip 11(8), 1521–1531 (2011)

R.L. Whitman, Z. Ge, M.B. Nevers, A.B. Boehm, E.C. Chern, R.A. Haugland, A.M. Lukasik, M. Molina, K. Przybyla-Kelly, D.A. Shively, E.M. White, R.G. Zepp, M.N. Byappanahalli, Relationship and variation of qPCR and culturable Enterococci estimates in ambient surface waters are predictable. Environ. Sci. Technol. 44(13), 5049–5054 (2010)

Q. Wu, W. Jin, C. Zhou, S. Han, W. Yang, Q. Zhu, Q. Jin, Y. Mu, Integrated glass microdevice for nucleic acid purification, loop-mediated isothermal amplification, and online detection. Anal. Chem. 83(9), 3336–3342 (2011)

W. Yamazaki, M. Ishibashi, R. Kawahara, K. Inoue, Development of a loop-mediated isothermal amplification assay for sensitive and rapid detection of Vibrio parahaemolyticus. BMC Microbiol. 8, 163 (2008a)

W. Yamazaki, M. Taguchi, M. Ishibashi, M. Kitazato, M. Nukina, N. Misawa, K. Inoue, Development and evaluation of a loop-mediated isothermal amplification assay for rapid and simple detection of Campylobacter jejuni and Campylobacter coli. J. Med. Microbiol. 57(4), 444–451 (2008b)

M.A. Yáñez, A. Nocker, E. Soria-Soria, R. Múrtula, L. Martínez, V. Catalán, Quantification of viable Legionella pneumophila cells using propidium monoazide combined with quantitative PCR. J. Microbiol. Methods 85(2), 124–130 (2011)

D.G. Yao, R. Kuduva-Raman-Thanumoorthy, An enlarged process window for hot embossing. J. Micromech. Microeng. 18(4), 045023 (2008)

C. Zhang, J. Xu, W. Ma, W. Zheng, PCR microfluidic devices for DNA amplification. Biotechnol. Adv. 24(3), 243–284 (2006)

M. Zimmermann, P. Hunziker, E. Delamarche, Valves for autonomous capillary systems. Microfluid. Nanofluid. 5(3), 395–402 (2008)

U. Zuckerman, S. Tzipori, Portable continuous flow centrifugation and method 1623 for monitoring of waterborne protozoa from large volumes of various water matrices. J. Appl. Microbiol. 100(6), 1220–1227 (2006)

Acknowledgments

This research was in part supported by grants from the U.S. Environmental Protection Agency (Grant Numbers: RD83301001 and EPD10016) and the Michigan Economic Development Corporation (Grant Number: 06-1-P1-0557).

Author information

Authors and Affiliations

Corresponding author

Additional information

Dieter M. Tourlousse and Farhan Ahmad contributed equally to this study

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 3567 kb)

Rights and permissions

About this article

Cite this article

Tourlousse, D.M., Ahmad, F., Stedtfeld, R.D. et al. A polymer microfluidic chip for quantitative detection of multiple water- and foodborne pathogens using real-time fluorogenic loop-mediated isothermal amplification. Biomed Microdevices 14, 769–778 (2012). https://doi.org/10.1007/s10544-012-9658-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-012-9658-3