Abstract

Safe and healthy food is the fundamental right of every citizen. Problems caused by foodborne pathogens have always raised a threat to food safety and human health. Centers for Disease Control and Prevention (CDC) estimates that around 48 million people are affected by food intoxication, and 3000 people succumb to death. Hence, it is inevitable that an approach that is efficient, reliable, sensitive, and rapid approach that can replace the conventional analytical methods such as microbiological and biochemical methods, high throughput next-generation sequence (NGS), polymerase chain reaction (PCR), and enzyme-linked immunosorbent assay (ELISA), etc. Even though the accuracy of conventional methods is high, it is tedious; increased consumption of reagents/samples, false positives, and complex operations are the drawbacks of these methods. Microfluidic devices have shown remarkable advances in all branches of science. They serve as an alternative to conventional ways to overcome the abovementioned drawbacks.

Furthermore, coupling microfluidics can improve the efficiency and accuracy of conventional methods such as surface plasma resonance, loop-mediated isothermal amplification, ELISA, and PCR. This article reviewed the progress of microfluidic devices in the last ten years in detecting foodborne pathogens. Microfluidic technology has opened the research gateway for developing low-cost, on-site, portable, and rapid assay devices. The article includes the application of microfluidic-based devices to identify critical food pathogens and briefly discusses the necessary research in this area.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Access to hygienic and wholesome food is a fundamental right for all citizens to make a healthy and efficient society. The risk of food contamination extends from farm to fork, making it imperative to maintain food safety at every level. However, the surging popularity of street foods poses a significant challenge for regulatory bodies striving to ensure food safety. Sometimes, inadvertent consumption of contaminated food happens due to human errors. Notable pathogens behind foodborne outbreaks include Staphylococcus aureus, Bacillus cereus, Salmonella spp., E. coli O157:H7, Listeria monocytogenes, and Clostridium perfringens (Paniel & Noguer 2019; Ma et al. 2020; Shang et al. 2020; Zhong et al. 2018).

Traditional culture-based methods involve growing microorganisms in various media with long turnaround times (18–24 h) (Paniel and Noguer 2019). Immunological assays offer faster detection, but false-positive concerns limit their use. Molecular diagnostic techniques like polymerase chain reaction (PCR), mass spectrometry, high throughput sequencing, etc., provide rapid and specific detection. PCR revolutionized scientific methods but has non-specific binding issues. SDS-PAGE protein profiling in proteomics faces challenges like a lack of databases and the inability to distinguish closely related species (Canciu et al. 2023; Grace 2023). Table 1 discusses the existing techniques for detecting pathogens, and Fig. 1 shows the characteristics of the conventional techniques used for pathogen detection. Microfluidics has driven the development of point-of-care (POC) devices, revolutionizing the biomedical field. Recently, there has been a surge in the use of point-of-care testing (POCT) in medical diagnostics, particularly for quickly detecting and monitoring infectious diseases. In food safety, many people prefer POCT for finding pathogens because it allows easy on-site testing, gives quick results right where the samples are taken, and is especially useful in places with limited resources (Helmy et al. 2023).

Microfluidics

Microfluidics, a cost-effective solution in scientific fields, manipulates fluid flow through micro-channels (10–9 to 10–8 L). “Lab-on-a-chip” (LOC) handles µL to pL volumes, integrating electronic and fluidic components. Microfluidic devices, distinct in structure and design from macroscale counterparts, provide fast processing, reduced reagent consumption, quick reactions, point-of-use production, point-of-care diagnostics, efficient heat transfer, and easy integration with other units. Microchannels, microvalves, and advanced fluid mechanics enable controlled sample flow, fostering on-chip sensing across various scientific branches such as chip sensing (Gileberman et al. 2019), optical sensing (Chen et al. 2022b, a), organ-on-chip (Dornhof et al. 2021), drug discovery and analysis (Ma et al. 2020), cell manipulation, single cell analysis (Willner et al. 2018), reactor technology (Narayanamurthy et al. 2020), etc. Microfluidic devices with aqueous micro-reactors support cell propagation, allowing precise monitoring of cellular responses to biochemical stimuli and weak signals. They aid cell screening by separating cells based on size, which helps distinguish microparticles from blood cells, bacteria, spores, circulating tumor cells, parasites, and nanoparticles. Though microfluidic technology has been developed academically, the significant technical challenges include usability limitations, a lack of standardization, and difficulty scaling up from a laboratory to a commercial level (Gurkan et al. 2024). Figure 2 shows the characteristics of lab-on-a-chip technology used for food pathogens.

Microfluidics integrating with different technologies

By integrating immunoassay into microfluidics, disease diagnosis is notably improved. Moreover, microfluidics transforms various aspects of drug discovery, local drug delivery, cell encapsulation, culture, and the creation of artificial organs (Shao et al. 2020). The progress in Micro Electromechanical System (MEMS) technology enables portability, miniaturization, integration, and automation. Cost-effective fabrication techniques, including laser cutting, photolithography, and polydimethylsiloxane (PDMS) printing, produce microfluidic devices from materials like paper, glass, silicon, and polymers (Tsao 2016). Fluid behavior differs at the microscale, enabling control of properties like temperature, pH, and concentration. Droplet and T-junction microfluidic devices are designed for chemical reactions. Droplet-based microfluidic devices are ideal for conducting separate reactions with minimal samples. T-junction microfluidics is employed for immiscible fluids. A typical T-junction microfluidic device for droplet generation is depicted in Fig. 3. LOC integrates various laboratory processes onto a single platform, enhancing the surface-area-to-volume ratio (Chen et al. 2022b, a; Sackmann et al. 2014).

Achieving sensitivity and precision involves integrating established techniques such as electrochemical methods, Raman spectroscopy, fluorescence microscopy, and mass spectrometry. Electrochemical techniques stand out for their insensitivity to detector miniaturization, facilitation of monitoring via digital systems, and cost-effective fabrication. Therefore, paper-based microfluidics extensively utilize electrochemical detectors (Christopher et al. 2020). The remarkable sensitivity and spatial resolution of surface-enhanced Raman scattering (SERS) are utilized in automated microfluidic devices to detect two biomarkers, enabling dynamic liquid measurements concurrently. With the use of metal nanoparticles, SERS has become renowned for its ability to multiplex detection (Zhong et al. 2018). Coupling SERS with droplet microfluidics holds promise for advancing our understanding of cellular systems, potentially lowering the detection limit to 10 pm or beyond. Willner et al. (2018) developed a SERS droplet microfluidic device to analyze single cells with 85–100% sensitivity and 90% efficiency.

With the advancement in the fabrication of microfluidics, it is now possible to make “chip calorimeters” that can assay sample volume with much smaller amounts of cells (1 × 103 cells/µL). Based on molding techniques, microfluidic fabrication is divided into three types: soft lithography (Graham et al. 2021), hot embossing (Jiang et al. 2021), and injection molding (Ma et al. 2020). These three methods offer cost-effective solutions with excellent throughput. As the name implies, soft lithography is ideal for soft polymers, organic monolayers, and gels. This technique is commonly used for PDMS microfluidic devices. Injection molding and hot embossing are closely related techniques. The melted thermoplastic is injected through the mold cavity at a specific rate, cooling the mold and removing the cast from the mold (Burklund et al. 2020). With the help of a graphic model, it is now possible to print the three-dimensional form of the device that one is intended to make. The digital model of the device is sliced into layers and reproduced using a 3D printer. Inkjet 3D printing, fused deposition molding, multi-jet molding, stereo-lithography, and two-photon polymerizations are the few technologies involved in 3D printing. However, the resolution of the 3D printers available in the market could not produce microfluidic devices as precise as the traditional lithography technique. Figure 4 shows different methods for the fabrication of microfluidic devices.

Microfluidics in the detection of food pathogens

In response to the growing global population, advanced food processing technologies have emerged to meet market demands. One-quarter of the world’s population is at risk of foodborne illness due to inadequate food inspection and the rapid growth of the economy. Microfluidics has garnered considerable attention from researchers for producing various food structures, including emulsion-based and self-assembled structures. In the dairy industry, microfluidic technology disperses stabilizers and gums in ice cream mixes or dairy-based products, ensuring adequate mixing. It can seamlessly integrate with food processing machinery to create highly concentrated nano-emulsions, nano-encapsulations, and nano-suspensions. The satiety index of food is significantly influenced by its microstructure, which additives, fibers, particles, or bubbles can control. Porous calcium alginate beads can be produced using a T-junction microfluidic device to enhance food products' energy content ratio and sample homogeneity (Burklund et al. 2020).

People are increasingly aware of health issues as the economy grows and living conditions improve. The current approach to identifying toxins such as aflatoxin and botulinum neurotoxin relies on mouse bioassays, which are slow, costly, and involve sacrificing many mice. Microfluidic-based devices offer a solution to the limitations of traditional methods. Major pathogens causing food poisoning include E. coli O157:H7, Listeria monocytogenes, Campylobacter jejuni, Bacillus cereus, and Clostridium perfringens (Tsao et al. 2016). Approximately one-quarter of the global population faces the risk of foodborne illness due to inadequate food inspection and rapid economic expansion.

Consequently, there is a need for new technologies and strategies to ensure food safety. Microfluidics is employed to achieve rapid and precise results in this regard. This review discusses the recent advancements in microfluidic technology for detecting food pathogens (Table 2). Figure 5 describes the application of microfluidics in the food industry.

Detection of Salmonella spp

Centers for Disease Control and Prevention (CDC) reports indicate that Salmonella infection is the most prevalent among foodborne illnesses in developed and developing countries. Individuals affected by this infection commonly experience symptoms such as dehydration, diarrhea, fever, and stomach cramps. Salmonellosis can manifest as either typhoid or non-typhoid salmonellosis, with the latter typically transmitted through consumption of food or water contaminated with various zoonotic serovars of Salmonella Salmonella. Among reported cases, S. enteritidis and S. typhimurium are frequently associated with severe outbreaks. The primary sources of Salmonella contamination include uncooked meat and poultry products and cross-contamination with other foods.

Almalaysha et al. (2024) introduced a disposable MEMS biosensor based on impedance for detecting S. Typhimurium in spiked raw chicken samples. By combining focusing and trapping capabilities, the device enhanced the concentration of SalmonellaSalmonella, which is available for binding with antibodies, thereby increasing sensitivity. The limit of detection (LOD) was established as 1–2 cells/mL by analyzing poultry samples with varying concentrations across a frequency range of 100 Hz to 10 MHz.

A novel colorimetric biosensor was developed using a microfluidic chip for rapid, sensitive, and on-site detection of Salmonella Salmonella. This biosensor utilizes immune gold@platinum nanoparticles (Au@Pt NPs) for specific bacterial labeling, a finger-driven mixer with two air chambers for efficient immunoreaction, and a nuclear starstruck membrane for effective bacterial isolation. This simple biosensor achieves Salmonella detection as low as 168 CFU/mL within 25 min (Jin et al. 2023a). Chen et al. (2023) developed an origami microfluidic device for rapid S. enterica detection, from sample preparation to endpoint detection, featuring nucleic acid extraction on a paper dipstick, isothermal recombinase polymerase amplification (RPA), and lateral flow assay for results. They achieved nucleic acid amplification in 20 min with 100% S. enterica specificity. The Polyethersulfone (PES) based device's LOD was 260 CFU/mL. Compared to chromatography paper, PES showed superior sensitivity, detecting S. enterica in lettuce, chicken breast, and milk at 6 CFU/g, 9 CFU/g, and 58 CFU/mL, respectively, after 6 h enrichment. PES displays excellent compatibility with isothermal nucleic acid amplification, holding promise for integrated sample-to-answer microfluidic devices in pathogen detection across various food products. A portable microfluidic bio-aptasensor, SSBP-NCMS, incorporating horseradish peroxidase as detection probes, was utilized to detect S. typhimurium. This aptasensor can detect concentrations as low as 3.7 × 101 CFU/mL, demonstrating excellent specificity and reliability (Man et al. 2023).

A novel figure-actuated microfluidic biosensor was created to sensitively detect S. Typhimurium with immunomagnetic separation, isolate the target bacteria, and combine rolling circle amplification (RCA) with CRISPR/Cas12a to enhance the detection signal. It has a 1.93 × 102 CFU/mL LOD and approximately 106% mean recovery in spiked milk samples (Xiang et al. 2023). A versatile integrated microfluidic biosensing system was developed to rapidly and sensitively detect S. typhimurium. It features a microfluidic chip with adaptable valves, RPA for nucleic acid detection, and a custom real-time fluorescence detection system. It has a LOD of 1.0 × 102 copies/µL within 30 min, aligning with results from real-time quantitative polymerase chain reaction (qPCR) tests. With its adaptable valve, this system holds promise for on-site foodborne pathogen detection (Jin et al. 2023a, b). A portable detection device was created for rapid, sensitive, and straightforward detection of viable SalmonellaSalmonella. It utilizes a finger-actuated microfluidic chip and an enhanced recombinase-aided amplification (RAA) assay. The fluorescent signal from RAA amplification is captured using a USB camera and analyzed through a mobile application for quantitative bacterial concentration determination. It has an LOD of 1.3 × 102 CFU/mL to 1.3 × 107 CFU/mL within two hours (Qi et al. 2023). A sophisticated colorimetric biosensor was developed for swift and automated detection of SalmonellaSalmonella within a sealed microfluidic chip. It quantitatively detects SalmonellaSalmonella within 30 min, with an LOD of 101 CFU/mL (Lu & Wang 2023). The VETPOD is a ready-to-use cartridge with a LAMP-based polymer chip designed to address contemporary challenges in swiftly detecting Salmonella spp. This has a LOD of 1.38 CFU/25 g, slightly surpassing the reference method by 1.17 times (Vinakaya et al. 2023).

Oliveira et al. (2018) developed an easily disposable microfluidic device (DµFD) using a non-lithographic rapid prototyping method in which multiple samples can be analyzed simultaneously. Unlike other microfluidic devices, the microchannel is made of carbon ink. Similarly, Kim et al. (2015) demonstrated the detection of SalmonellaSalmonella labeled with antibody conjugated with fluorescent Quantum Dots using a magnetic bead in a PDMS-based microfluidic device. The fluorescence that develops thus can be directly correlated with cell concentration. Interdigitated electrode arrays (IDM) are used to measure any sample in which cells are suspended. Gosh et al. (2015) developed a gold IDM array biosensor using photolithography. The impedance is directly proportional to the concentration of bacteria bound to the antibodies. The high signal-to-noise ratio, re-usability of the device, and short detection time are the salient features of the device. The developed device has a lower detection level of 3 × 103 CFU/mL and is comparable with other impedance biosensors (Wang et al. 2020; Huang et al. 2021). A microfluidic biosensor was engineered to detect SalmonellaSalmonella with a biosensor employs a metal–organic framework (MOF) known as NH2-MIL-101(Fe), which exhibits peroxidase-like activity to amplify biological signals with LOD 14 CFU/mL (Qi et al. 2021).

A microfluidic biosensor was designed for Salmonella detection, employing viscoelastic inertial microfluidics to separate magnetic bacteria from unbound magnetic nanoparticles (MNPs). It utilizes enzyme-catalytic colorimetry to amplify biological signals. This detects SalmonellaSalmonella at concentrations as low as 30 CFU/mL within one hour (Yao et al. 2020). A detection method for S. enterica using PCR on a microfluidic disc device with a fluorescent probe was developed. S. enterica was detected at concentrations as low as 5 × 104 cells/mL or higher concentrations in egg yolk within six h, including the sampling time (Kubo et al. 2020). Wang et al. (2019) developed a similar but different detection system which consists of a light source, fluorescent microscope, and smartphone. The sensitivity of this study can be improved by using brighter fluorescent material. The only limitation of this study is the video processing speed and image capturing quality of the smartphone used. The use of a higher-performance camera/smartphone can overcome it. Fronczek et al. (2013) developed a handheld microfluidic device for Mie scattering detection of S. typhimurium in meat or water from poultry packaging. The complex chicken samples can be directly pipetted to the vacuum-dried reagents device. Ng et al. (2021) developed a single-cell droplet microfluidic system to detect viable Salmonella as an alternative. The fluorescent imaging system is used to distinguish between encapsulated single cells. After droplet generation, each contains pL to nL, collected for culturing them. A noticeable change in the microdroplet's fluorescence can be observed in less than five hours. In short, this droplet microfluidics can be used for single-cell-level analysis with a LOD of 50 CFU/mL, which helped to curtail detection time from 24 to 5 h.

However, Salmonella Shigella (SS) agar can provide results within 24 h, offering a faster alternative (Dekker and Frank 2015). Furthermore, the evolution of microfluidic technology has revolutionized pathogen detection, offering miniaturized handheld devices with enhanced sensitivity. Integrating microfluidic devices with impedimetric biosensors, PCR, enables real-time monitoring and assessment of pathogens, significantly reducing time and workforce requirements.

Detection of Escherichia coli

Escherichia coli is one of the critical microorganisms of concern regarding food safety. They are gram-negative and non-spore-forming bacteria which is found in our intestines. Consumption of food contaminated with the feces of animals or infected humans is the primary source of E. coli infection. Other standard vehicles of contamination are raw milk, cross-contamination, uncooked ground meat, manure from cattle, or other animals as fertilizer.

A novel dual-mode hydrogel array biosensor was developed to quickly screen and accurately quantify virulent E. coli O157:H7 using a DNA-modified phage probe specific to E. coli. These probes are hybridized with complementary DNA (cDNA) to create double-stranded DNA fragments (phage@RCA-dsDNA), which are visually detectable through SYBR green dye fluorescence and smartphone analysis for rapid screening. Additionally, unreacted cDNA in the supernatant was quantitatively measured via microfluidic chip electrophoresis (MCE), with signal reduction correlating to bacterial concentration with LOD 6 CFU/mL. This also detects S. typhimurium using the S. typhimurium phage@RCA-DNA probe (Xu et al. 2024). Antimicrobial peptides (AMPs) are gaining popularity due to their ability to bind effectively to multiple target microorganisms due to their cationic and amphiphilic nature. Jeong et al. (2013) replaced antibodies with Magainin-1, which has superior antimicrobial properties. The device can identify E. coli concentrations of 103 cells/mL under 30 min. The non-specific binding was eliminated by converting fluorescence images into black-and-white photos and subtracting the background images. To attain rapid detection, a higher flow rate of 4 µL/mL should be applied to achieve a saturation detection level in 30 min. The detection efficiency and time required were not dependent on the bacteria concentration till 103 cells/mL (Yoo et al., 2014). Another study used an electrochemical sensing system to detect E. coli. The immunosensor biochip integrated with nanoporous alumina membranes was immobilized with antibodies using a GPMS silane monolayer. The setup consisted of upper and lower compartments with nanoporous alumina membranes in the middle. When the target bacteria enter the upper compartment, they get anchored by the antibody covering the nanopores, thus generating the electrolyte current, which the impedance spectrum can monitor. PDMS-based microfluidic devices for digital droplet PCR were used to detect E. coli O157:H7 and L. monocytogens simultaneously. Droplet digital PCR (ddPCR) amplifies the target DNA into a different droplet, which helps the user quickly quantify DNA copy numbers (Bian et al. 2015).

Plasmonic sensor technologies were explored using surface plasmonic resonance (SPR) technologies. Protein-G-based surface chemistry with anti-LPS antibodies was exploited to construct a gold-coated device that is disposable, rapid, and selective. The device is equipped with a single micro-channel and custom-made SPR platform based on the principle of Kretschmann configuration, which uses prism coupling to satisfy momentum conservation for plasmon excitation by an external light source (Tokel et al. 2015). Yang et al. 2015 detected E. coli using a Giant Magneto-Impedance (GMI) sensor in conjugation with a gold-coated open-surface microfluidic device. Magnetic beads with streptavidin monolayer covalently coupled to the hydrophilic bead surface were also incorporated. The principle was that detecting the fringe field (Hf) of the dynabeads using magnetic sensors could detect the presence, content, or absence of E. coli. This technique can detect concentrations ranging from 50 to 1000 CFU/mL with high capture efficiency. Jiang et al. (2017) used immobilized poly-(amidoamine) dendrimer on PDMS microchannels to develop a fluorescence intensity-based microfluidic detection platform. The microchannels were modified with DNA aptamers, and the fluorescence signal was enhanced up to 50 times by Rolling Circle Amplification (RCA). The LOD of the dendrimer-Aptamer-RCA system is 102 cells/mL. Zhang et al. 2017 developed a coaxial channel-based DNA extraction in conjugation with microfluidic PCR. Dastider et al. (2018) conducted another interesting study with MEMS biosensors for rapid and accurate detection of E. coli O157:H7 with a LOD value of 39 CFU/mL. The focusing area directs the flow towards the channel’s centerline using p-DEP force and fluid drag flow. The change in impedance caused due to antigen–antibody binding is measured using an impedance analyzer. This device requires no enriching step and takes approximately two hours to process.

Alternatively, the E. coli inactivation kinetics was determined using a novel microfluidic mixer via chlorine solution in the sub-second range due to the high mixing rate and the ability to control the flow rate in microfluidic chambers. The design incorporated three mixing designs: "Y” inlet junction, Dean’s vortex mixer, and chaotic mixer with three inlets for E. coli, chlorine solution, and dechlorinating agent. The contact time was quantified using the CFD model, and pathogen survival was measured using the most probable number (MPN) method (Yao et al. 2018).

A rapid and sensitive microfluidic-based electrochemical device was developed to detect Escherichia coli. It demonstrated a linear range of bacterial concentrations from 0.336 × 1012 to 40 × 1012 CFU/mL, with a LOD of 0.35 CFU/mL and a quantification limit of 1.05 CFU/mL (Fande et al. 2023). In conclusion, studies suggest that microfluidic platforms designed for detecting E. coli eliminate the need for a large and tedious experimental setup and reduce detection time from 48–72 h to 0.5–5 h. This provides a broad application not only in ensuring food safety but also in disease control.

Detection of Listeria monocytogenes

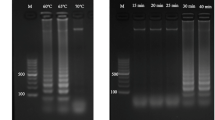

Listeria monocytogenes, a gram-positive, is the second most common foodborne disease, causing 30% fatality. The major reservoirs include unpasteurized or raw milk and their products, raw fruits and vegetables, and uncooked meat products. Immunoassays are widely used for rapid on-site detection, but their poor affinity and low detectability make them less reliable. Shang et al. 2020 developed an ultrasensitive cloth-based microfluidic device to detect L. monocytogenes using chemiluminescence methods. Coupling microfluidics with PCR has benefits like consuming fewer reagents/samples, portability, and miniaturization of the whole process, which helps in the rapid on-site detection of the pathogen. Strohmeier et al. (2014) developed a highly sensitive microfluidic single-phase continuous flow nested PCR device for the detection of food pathogens, which can amplify and detect the genomic DNA of L. monocytogenes within 42 min. Microfluidic devices helped to miniaturize the nucleic acid amplification setup, such as PCR, recombinase polymerase amplification, hybridization chain reaction (HCR), and loop-mediated amplification (LAMP), which require several days. Rodriguez et al. (2019) developed a LOC device with gold nanostars as an SERS tag to detect Listeria spp. within 100 s. The device can also distinguish between L. monocytogenes and L. innocua. Malic et al. (2015) developed a high gradient magnetic separation (HGMS) microfluidic device with immune-magnetic nanoparticles and a 3D magnetic capture chip. This capture region dramatically depends on the magnetic shell, the magnetic field’s strength, and the pillar's geometry. Within 17 min, a three-fold increase in concentration efficiency is achieved, which makes this device ideal for ensuring food safety and can be expanded as a point-of-care device.

The conventional culture method necessitates at least five days of ascertaining the absence of Listeria in food samples. If Listeria spp. or L. monocytogenes are present, an additional ten days are required to identify their presence. With the help of microfluidic-based detection devices, food safety was revolutionized by swiftly assessing the quality of food products in less than 4 h. This remarkable advancement accelerates the detection of harmful microorganisms, enhancing the monitoring process significantly.

Detection of Campylobacter jejuni

The development of antibiotic-resistant strains of Campylobacter to clinically essential drugs such as tetracycline, fluoroquinolones, and ampicillin is a daunting concern to the health sector. The increasing rate of bacterial gastroenteritis in humans is caused by Campylobacter-borne food infections. The primary sources of Campylobacter infections are contaminated poultry meat and unpasteurized milk. The standard approach has several drawbacks. A minimum of 7–9 days is required for the analysis, which is a laborious process biased towards C. jejuni.

Ma et al. (2020) developed a rapid testing polymer-based microfluidic device for Campylobacter identification using chromogenic changes. The device chamber had two primary reagents, a chromogenic medium, and antibiotics, which successfully detected multiple species of Campylobacter in 24 h. This technique finds application in complex food matrices such as milk and chicken breast with identification under 60 h. The device is also capable of identifying Campylobacter in a complex bacterial cocktail. This device is far superior to the conventional method due to its rapid detection, less sample consumption, and user intervention. In another study, a hybrid PMMA-PDMS-based multiplexed microfluidic biosensor was integrated into an array of poly-(2,7-carbazole/fullerene organic blend) heterojunction photodiodes (PHPDs) were used for the chemiluminescent detection of C. jejuni with LOD of 1 × 105 cells/mL with an assay time of 30 min.

Yunxuan et al. (2023) developed a convenient, hybrid microfluidic device incorporating paper and polymer components. This cutting-edge technology seamlessly combines paper-based DNA extraction, isothermal nucleic acid amplification, and lateral flow detection, providing a user-friendly solution for molecular analysis. The study for detecting C. jejuni using microfluidics in recent years is low; its edge over the conventional methods unfolds a rapid, convenient, and on-site detection tool.

Detection of Norovirus

Norovirus is a prevalent cause of gastroenteritis. Current detection methods involve immunoassays and RT-PCR. Conventional techniques like ELISA and nucleic acid-based assays are resource-intensive. Using 6-carboxyfluorescein aptamer and nitrocellulose, paper-based microfluidics offer cost-effective, easy-to-make alternatives to PDMS, silicon, or glass devices (Weng and Neethirajan 2017).

In another study, antibody-conjugated, submicron, fluorescent (yellow-green) polystyrene particles and the norovirus were “visualized” down to the single virus copy level on the microfluidic paper analytic devices (μPAD). The antibody-conjugated particles and norovirus could flow (capillary action), and only the aggregated particles were isolated through image processing and a smartphone-based fluorescence microscope. This rapid technique does not require washing, sample concentration, or nucleic acid amplification steps (Chung et al. 2019). Detecting norovirus in agriculture, marine, and foods is as essential as other food pathogens. Detection of viruses in any samples involves tedious sequential steps such as target concentration, cell lysis, amplification, and detection. Since norovirus is an RNA virus, only 3–30% of sample recovery is achieved in 24 h. Chung et al. (2019) developed a microfluidic device with switchable charge microbeads that can automatically perform the previously mentioned processes in separate chambers. These microbeads adsorb the norovirus particle from the sample and lyse via bead beating. The standard procedure for norovirus detection takes around 24–48 h; automation made it less than 4 h.

Thus, fabricating microfluidic devices with reduced cost of production, assay time to less than 5 min, and sensitivity to exceedingly low LOD for detection of norovirus from samples such as food, fomites, and water is essential, which can eliminate the requirement of nucleic acid amplification used in PCR methods and in-vitro cell culture to detect viruses. Figure 6 depicted different foodborne microorganisms and microfluidic technologies.

Other pathogens and toxins

S. aureus is the most common food pathogen, a gram-positive, rod-shaped bacterium. The toxin, coagulase, causes infection in both humans and livestock. Like all other food pathogens, the microbial culture method is considered the golden standard. To date, rapid detection technique for detecting and identifying bacteria includes PCR, LAMP, ELISA, quartz crystal microbalance (QCM), electrochemical impedance spectroscopy (EIS), and fluorescence microscopy. Song et al. (2020) developed a microfluidic platform immobilized with antibody-coated microspheres. It has a 1.5 × 10 CFU/µL LOD, whereas the traditional method has an LOD of 0.5 MCF. They reduced the detection time to 4 min from 18–24 h. Xiaonan et al. (2013) developed a rapid detection of S. aureus in the food sample. This device has coupled two different confocal micro-Raman spectroscopic systems to microfluidic platforms for recording the SERS spectral features of S. aureus. Azam Bagheri and Hosseini (2020) developed a paper-based microfluidic colorimetric nano biosensor device for rapid, easy, and sensitive detection of S. aureus. They use ultra-small nanoclusters (NC) using DNA as a template in a one-pot chemical process and set as a bio-receptor conjugation for the detection of whole-cell bacteria. The linear dynamic range of the colorimetric Au/Pt/NC-based optical sensor covered a range of S. aureus concentrations from 108–102 CFU/mL with a detection limit of 80 CFU/mL. A PDMS microfluidic impedance immunosensor for E. coli O157:H7 and S. aureus detection via antibody-immobilized nanoporous membrane was developed by Tan et al. (2011). The impedance spectrum was recorded for bacteria detection ranging from 1 Hz to 100 kHz. For both pathogens, the maximum impedance reported for the device was around 100 Hz. The detection time for the device is within two hours with LOD 102 CFU/mL.

C. perfringens is usually found on raw meat and poultry, in the intestines of animals, and the environment. The direct quantification of multiple pathogens has been desired for diagnostic and public health purposes for a long time. Ishi et al. (2013) applied microfluidic quantitative PCR (qPCR) technology to detect and quantify multiple food- and waterborne pathogens. They have quantified E. coli, Salmonella spp., and Campylobacter spp. Roy et al. (2017) have developed calorimetric nucleic acid detection on paper microchips using loop-mediated isothermal amplification and crystal violet dye. DNA extracted from the food sample was amplified using LAMP. Legionella pneumophila, a gram-negative human pathogen, has an outbreak rate lower than that of sporadic cases. Many Legionnaires’ disease (LD) outbreaks have been linked to various sources of contaminated water in hospitals, industrial facilities, hotels, family residences, and cruise ships. Yamaguchi et al. (2017) developed an on-site monitoring of L. pneumophila in cooling tower water using a portable microfluidic system. The LOD was 104 cells/mL with a detection time of 1.5 h. It is portable for on-site measurement and can be used to initially screen for Legionella contamination in freshwater. Foudeh et al. (2015) have developed rapid and multiplex detection of Legionella’s RNA using digital microfluidics with a limit of detection of 0.5 µM to 122 pM within 30 min. Similarly, the detection of various toxins can be determined using microfluidic devices. L-glutamate, an amino acid, is considered for food safety in consideration of the Chinese restaurant syndrome, Alzheimer and Parkinson's disease. On-chip bead-based microfluidic devices provide 91% selectivity for the determination of L-glutamate in food samples. S. aureus produces staphylococcal enterotoxin B (SEB), which is commonly associated with food poisoning. Yang et al. 2015 developed a high throughput optical carbon nanotube (CNT) based microfluidic device for detecting SEF with LOD 0.1 ng/mL. Aflatoxins, the most predominant and toxic mycotoxins, are often detected in commodities like grains, nuts, beer, and coffee. Ma et al. (2020) developed a portable visual, quantitative detection of aflatoxin B1 using a distance readout microfluidic chip with LOD 1.77 nm (0.55 ppb). Liu et al. (2013) reported a microfluidic chip-based nano-LC coupled to a triple quadrupole mass spectrometer (QqQ-MS) system for the quantitative determination of aflatoxin in food samples. The samples can be assayed in a single test with LOD 0.004 to 0.008 ng/g. Hu et al. (2013) also developed a microfluidic smectite polymer nanocomposite sensor for aflatoxin detection. Spiked corn extraction solution with aflatoxin was tested on this chip and completed in 10 min with LOD 5–80 ppb. Olcer et al. (2014) developed a real-time microfluidic electrochemical method for the detection of deoxynivalenol (DON) in wheat with a limit of detection of 6.25 ng/mL. Zhang et al. (2015) developed a PDMS microfluidic passive pumping array chip with a real-time biosensor for marine toxin detection with LOD 200 µg/L. Botulinum, the main toxin responsible for foodborne botulism, was also detected on a Forster resonance energy transfer (FRET)-based microfluidic device (Bae et al. 2015). Babrak et al. (2016) also developed a 96-well microfluidic immunoassay device with a spiral microchannel in each well to detect botulinum toxin with a detection limit of 0.9 ng/mL in less than 30 min. Wang et al. (2024) developed portable, integrated microfluidics for rapid and sensitive diagnosis of Streptococcus agalactia. It was a susceptible and specific device.

Future scope and challenges

Ensuring food safety remains a paramount concern for humanity, presenting a formidable challenge to the food industry. Conventional analytical methods for detecting food pathogens are often time-consuming and labor-intensive, underscoring the need for a more efficient, reliable, sensitive, and rapid approach. Microfluidics emerges as a transformative solution, enabling the creation of miniature laboratories on a chip. Leveraging advancements in microfabrication technology and discovering novel receptors and detectors, microfluidic-based food analysis devices are poised to revolutionize food safety practices shortly.

Microfluidics offers a compelling alternative to traditional detection methods, significantly reducing time, reagent usage, and workforce. With a focus on common foodborne pathogens like Salmonella and E. coli, microfluidic platforms enable handheld, rapid, portable, and on-site pathogen detection. These devices can be enhanced with PCR, ELISA, SPR, and LAMP techniques to enhance detection efficiency. However, successful integration with rapid detection methods necessitates careful consideration of various aspects, often overlooked in current endeavors. Smartphone integration holds promise for empowering consumers to conduct competent food examinations before consumption, contributing to enhanced food safety.

Despite recent strides in user-friendly and cost-effective fabrication methods, challenges persist in large-scale production and integration with other technologies. Parallelization emerges as a favored scale-up strategy, while advancements in three-dimensional channel design offer promising avenues for scaling up droplet microfluidics. However, obstacles such as low spatial resolution and high production costs still need to be solved. Although microfluidics holds immense potential, particularly in creating complex emulsions, it is still in its nascent stages, leaving ample room for improvements in mass production techniques. Thus, microfluidics incorporating immune-based techniques is a cornerstone in realizing the “farm-to-fork” food safety vision.

Data availability

Not applicable

Code availability

Not applicable

References

Almalaysha M, Singh A, Muhsin SA, Morey A, Zhang S, Channaiah LH, and Almasri M (2024). Microfluidic biosensor for rapid detection of Salmonella in raw chicken products. In: Proceedings of the IEEE international conference on micro electromechanical systems (MEMS), vol 14, pp 308–311. https://doi.org/10.1109/MEMS58180.2024.10439451

Babrak L, Lin A, Stanker LH, McGarvey J, Hnasko R (2016) Rapid microfluidic assay for the detection of botulinum neurotoxin in animal sera. Toxins 8:13–20. https://doi.org/10.3390/toxins8010013

Bae YM, Jin SO, Kim I, Shin KY (2015) FRET-based detection of enzymatic reaction of botulinum on microfluidic device. J Nanomater 2015:456–466. https://doi.org/10.1155/2015/126598

Bagheri pebdeni A, Hosseini M (2020) Fast and selective whole cell detection of Staphylococcus aureus bacteria in food samples by paper based colorimetric nanobiosensor using peroxidase-like catalytic activity of DNAAu/Pt bimetallic nanoclusters. Microchem J 159:105475

Bailey JS (1998) Detection of Salmonella cells within 24 to 26 hours in poultry samples with the polymerase chain reaction BAX system. J Food Prot 61(7):792–795

Bian X, Jing F, Li G, Fan X, Jia C, Zhou H, Zhao J (2015) A microfluidic droplet digital PCR for simultaneous detection of pathogenic Escherichia coli O157 and Listeria monocytogenes. Biosens Bioelectron 74:770–777. https://doi.org/10.1016/j.bios.2015.07.016

Burklund A, Tadimety A, Nie Y, Hao NJ, Zhang JX (2020) Advances in diagnostic microfluidics. Adv Clin Chem 95:1–72. https://doi.org/10.1016/bs.acc.2019.08.001

Canciu A, Cernat A, Tertis M, Graur F, Cristea C (2023) Tackling the issue of healthcare-associated infections through point-of-care devices. TrAC Trends Anal Chem 161:116983–116990. https://doi.org/10.1016/j.trac.2023.116983

Chen T, Zhu HH, Su C, Cao ZW, Li QS, Li M (2022a) A sensitivity-enhanced optical sensor is based on a multilayer-coated Fabry-Pérot interferometer. Opt Eng 61:1–10. https://doi.org/10.1117/1.OE.61.1.017102

Chen JQ, Healey S, Regan P, Laksanalamai P, Hu Z (2017) PCR-based methodologies for detection and characterization of Listeria monocytogenes and Listeria ivanovii in foods and environmental sources. Food Sci Hum Wellness 6(2):39–59

Chen Y, Hu Y, Lu X (2023) Polyethersulfone-based microfluidic device integrated with DNA extraction on paper and recombinase polymerase amplification for the detection of Salmonella enterica. ACS Sensors 8:2331–2339. https://doi.org/10.1021/acssensors.3c00387

Chen Y, Meng X, Zhu Y, Shen M, Lu Y, Cheng J, Xu Y (2018) Rapid detection of four mycotoxins in corn using a microfluidics and microarray-based immunoassay system. Talanta 186:299–305. https://doi.org/10.1016/j.talanta.2018.04.064

Chen Z, Shen L, Zhao X, Chen H, Xiao Y, Zhang Y, Yang X, Zhang J, Wei J, Hao N (2022b) Acoustofluidic micromixers: from rational design to lab-on-a-chip applications. Appl Mater Today 26:101356–101344. https://doi.org/10.1016/j.apmt.2021.101356

Christopher JV, Kensuke T, Shinjio RD, Michael VH (2020) Paper-based electrochemical sensors using paper as a scaffold to create porous carbon nanotube electrodes. ACS Appl Mater Interfaces 12:30680–30685. https://doi.org/10.1021/acsami.0c04896

Chung S, Breshears LE, Perea S, Morrison CM, Betancourt WQ, Reynolds KA, Yoon JY (2019) Smartphone-based paper microfluidic particulometry of norovirus from environmental water samples at the single copy level. ACS Omega 4:721–729. https://doi.org/10.1021/acsomega.9b00772

Chung SH, Baek C, Cong VT, Min J (2015) The microfluidic chip module for the detection of murine norovirus in oysters using charge switchable micro-bead beating. Biosens Bioelectron 67:625–633

Dastider SG, Barizuddin S, Yuksek NS, Dweik M, Almasri MF (2018) Efficient and rapid detection of E. coli using microfluidic impedance based sensing. J Sens 15:1–8. https://doi.org/10.1155/2015/293461

Deisingh AK, Thompson M (2004) Strategies for the detection of Escherichia coli O157: H7 in foods. J Appl Microbiol 96(3):419–429

Dekker JP, Frank KM (2015) Salmonella, Shigella, and Yersinia. Clin Lab Med 35:225–246. https://doi.org/10.1016/j.cll.2015.02.002

Diep B, Barretto C, Portmann AC, Fournier C, Karczmarek A, Voets G, Klijn A (2019) Salmonella serotyping; comparison of the traditional method to a microarray-based method and an in silico platform using whole genome sequencing data. Front Microbiol 10:2554

de Oliveira TR, Martucci DH, Faria RC (2018) Simple disposable microfluidic device for Salmonella typhimurium detection by magneto-immunoassay. Sens Actuators B Chem 255:684–691. https://doi.org/10.1016/j.snb.2017.08.075

Dornhof J, Kieninger J, Muralidharan H, Jochen M, Gerald AU, Andreas W (2021) Microfluidic organ-on-chip system for multianalyte monitoring of metabolite in 3D cell cultures. Lab Chip 22:225–239. https://doi.org/10.1039/D1LC00689D

Fande S, Amreen K, Sriram D, Goel S (2023) Microfluidic electrochemical device for real-time culturing and interference-free detection of Escherichia coli. Anal Chim Acta 1237:340591–340598. https://doi.org/10.1016/j.aca.2022.340591

Foudeh M, Daniel T, Maryam T (2015) Rapid and multiplex detection of Legionella’s RNA using digital microfluidics. Lab Chip 15:609–1618. https://doi.org/10.1039/C4LC01468E

Fronczek CF, You DJ, Yoon JY (2013) Single-pipetting microfluidic assay device for rapid detection of Salmonella from poultry package. Biosens Bioelectron 40:342–349. https://doi.org/10.1016/j.bios.2012.07.076

Gileberman RM, Saichon S, Michelle T, Andrea VW, Jessica ZD (2019) Inquiry-based laboratories using paper microfluidic devices. J Chem Educ 98:1946–1953. https://doi.org/10.1021/acs.jchemed.1c00214

Ghosh Dastider S, Abdullah A, Jasim I, Yuksek N S, Dweik M, Almasri M (2018) Low concentration E. coli O157: H7 bacteria sensing using microfluidic MEMS biosensor. Rev Sci Instrum 89(12)

Gosh DS, Barizuddin S, Yuksek NS, Dweik M, Almasri MF (2015) Efficient and rapid detection of Salmonella using microfluidic impedance based sensing. J Sens 4:1–8. https://doi.org/10.1155/2015/293461

Grace D (2023) The burden of foodborne disease in low-income and middle-income countries and opportunities for scaling food safety interventions. Food Secur 15:1475–1488. https://doi.org/10.1007/s12571-023-01391

Graham S, Enders A, Ackerman S, Bahnemann J, Segal E (2021) 3D-printed microfluidics integrated with optical nanostructured porous aptasensors for protein detection. Microchim Acta 188:67–76. https://doi.org/10.1007/s00604-021-04725-0

Gurkan UA, Wood DK, Carranza D, Herbertson LH, Diamond SL, Du E, Lam WA (2024) Next generation microfluidics: fulfilling the promise of lab-on-a-chip technologies. Lab Chip 24(7):1867–1874. https://doi.org/10.1039/D3LC00796K

Helmy YA, El-Adawy H, Sanad YM, Ghanem M (2023) Food safety and public health. Front Microbiol 14:9165–9171. https://doi.org/10.3389/fmicb.2023.1169139

Hou Y, Cai G, Zheng L, Lin J (2019) A microfluidic signal-off biosensor for rapid and sensitive detection of Salmonella using magnetic separation and enzymatic catalysis. Food Control 103:186–193. https://doi.org/10.1016/j.foodcont.2019.04.008

Hu H, Deng Y, Zou J (2013) Microfluidic smectite-polymer nanocomposite strip sensor for aflatoxin detection. IEEE Sens J 13:1835–1839. https://doi.org/10.1109/JSEN.2013.2242057

Huang F, Xue L, Qi W, Cai G, Liu Y, Lin J (2021) An ultrasensitive impedance biosensor for Salmonella detection based on rotating high gradient magnetic separation and cascade reaction signal amplification. Biosens Bioelectron 176:112921–112928. https://doi.org/10.1016/j.bios.2020.112921

Ishi S, Segawa T, Okabe S (2013) Simultaneous quantification of multiple food- and waterborne pathogens using microfluidic quantitative PCR. Appl Environ Microbiol 79:2891–2898. https://doi.org/10.1128/AEM.00205-13

Jeong HY, Deok HW, Mi SC, Myung SC (2013) Microfluidic-based biosensing for Escherichia coli detection by embedding antimicrobial peptide-labeled beads. Sens Actuators B Chem 191:211–218. https://doi.org/10.1016/j.snb.2013.09.105

Jiang K, Li K, Xu G, Gong F, Wu X, Diao D, Zhu L (2021) A novel and flexible processing for hot embossing of glass microfluidic channels. Ceram Int 47:1447–1455. https://doi.org/10.1016/j.ceramint.2020.09.253

Jiang Y, Shan Z, Xudong C (2017) A simple dendrimer-aptamer-based microfluidic platform for E. coli O157:H7 detection and signal intensification by rolling circle amplification. Sens Actuators B Chem 251:976–984. https://doi.org/10.1016/j.snb.2017.05.146

Jin N, Xue L, Ding Y, Liu Y, Jiang F, Liao M, Li Y, Lin J (2023a) A microfluidic biosensor based on finger-driven mixing and nuclear track membrane filtration for fast and sensitive detection of Salmonella. Biosens Bioelectron 220:114844–114852. https://doi.org/10.1016/j.bios.2022.114844

Jin Y, Wang J, Wang Z, Xiong P, Cheng J, Xu T (2023b) Integrated microfluidic biosensing system based on a versatile valve and recombinase polymerase amplification for rapid and sensitive detection of Salmonella typhimurium. Biosensors 13:790–797. https://doi.org/10.3390/bios13080790

Kim G, Moon JH, Moh CY, Lim JG (2015) A microfluidic nano-biosensor for the detection of pathogenic Salmonella. Biosens Bioelectron 67:243–247

Kubo I, Kajiya M, Aramaki N, Furutani S (2020) Detection of Salmonella enterica in egg yolk by PCR on a microfluidic disc device using immunomagnetic beads. Sensors 20:339–347. https://doi.org/10.3390/s20041060

Lee JH (2015) Protection against Salmonella typhimurium, Salmonella gallinarum, and Salmonella enteritidis infection in layer chickens conferred by a live attenuated Salmonella typhimurium strain. Immune Netw 15(1):27

Liu HY, Lin SL, Chan SA, Lin TY, Fuh MR (2013) Microfluidic chip-based nano-liquid chromatography-tandem mass spectrometry for quantification of aflatoxins in peanut products. Talanta 113:76–81. https://doi.org/10.1016/j.talanta.2013.03.053

Lu J, Wang L (2023) Multiple electromagnet synergistic control enabled fast and automatic biosensing of Salmonella in a sealed microfluidic chip. Biosens Bioelectron 237:115459–115467. https://doi.org/10.1016/j.bios.2023.115459

Ma L, Petersen M, Lu X (2020) Identification and antimicrobial susceptibility testing of campylobacter using a microfluidic lab-on-a-chip device. Appl Environ Microbiol 86:534–541. https://doi.org/10.1128/AEM.00096-20

Man Y, Ban M, Jin X, Li A, Tao J, Pan L (2023) An integrated distance-based microfluidic aptasensor for visual, quantitative detection of Salmonella with sample-in-answer-out capability. Sens Actuators B Chem 381:133480–133487. https://doi.org/10.1016/j.snb.2023.133480

Malic LX, Zhang FD, Brassard L, Clime JD, Luebbert C, Barrere A, Boutin A, Bidawid S, Farber J, Corneau N, Veres T (2015) Magnetic nanoparticle distribution in a microfluidic chip. Lab Chip 21:2658–2683. https://doi.org/10.3390/mi12070768

Narayanamurthy VK, Jeroish ZS, Bhuvaneshwari E, Samsuri F (2020) Hepatitis C virus (HCV) diagnosis: via microfluidics. Anal Methods 13:740–763. https://doi.org/10.1039/d0ay02045a

Ng HY, Lee WC, Kung CT, Li LC, Lee CT, Fu LM (2021) Recent advances in microfluidic devices for contamination detection and quality inspection of milk. Micromachines 12(5):558

Olcer Z, Esen E, Muhammad T, Ersoy A, Budak S, Uludag Y (2014) Fast and sensitive detection of mycotoxins in wheat using microfluidic-based real-time electrochemical profiling. Biosens Bioelectron 62:163–169. https://doi.org/10.1016/j.bios.2014.06.025

Paniel N, Noguer T (2019) Detection of Salmonella in food matrices, from conventional methods to recent aptamer-sensing technologies. Foods 8:371–378. https://doi.org/10.3390/foods8090371

Pires N M M, Dong T (2013) Microfluidic biosensor array with integrated poly (2, 7-carbazole)/fullerenebased photodiodes for rapid multiplexed detection of pathogens. Sensors 13(12):15898–15911

Qi W, Wang S, Wang L, Xi X, Wu S, Li Y, Liao M, Lin J (2023) A portable viable Salmonella detection device based on a microfluidic chip and recombinase-aided amplification. Chin Chem Lett 34:107360–107368. https://doi.org/10.1016/j.cclet.2022.03.083

Qi W, Zheng L, Wang S, Huang F, Liu Y, Jiang H, Lin J (2021) A microfluidic biosensor for rapid and automatic detection of Salmonella using the metal-organic framework and Raspberry Pi. Biosens Bioelectron 178:113020–113027. https://doi.org/10.1016/j.bios.2021.113020

Qiuping S, Yan S, Yi L, Wei L, Jun J, Wu H, Zhang C (2020) Ultrasensitive cloth-based microfluidic chemiluminescence detection of Listeria monocytogenes hlyA gene by hemin/G-quadruplex DNAzyme and hybridization chain reaction signal amplification. Anal Bioanal Chem 15:3787–3797. https://doi.org/10.1007/s00216-020-02633-5

Rodriguez LL, Garrido MA, Bhunia AK, Espiña B, Prado M, Diéguez L, Abalde CS (2019) Gold nanostars for the detection of foodborne pathogens via surface-enhanced raman scattering combined with microfluidics. ACS Appl Nano Mater 2:6081–6086. https://doi.org/10.1021/acsanm.9b01223

Roy E, Stewart G, Mounier M, Malic L, Peytavi R, Clime L, Madou M, Bossinot M, Bergeron MG, Veres T (2017) From cellular lysis to microarray detection, an integrated thermoplastic elastomer (TPE) point of care lab on a disc. Lab Chip 15:406–416. https://doi.org/10.1039/C4LC00947A

Sackmann EK, Fulton AL, Beebe DJ (2014) The present and future role of microfluidics in biomedical research. Nature 507:181–189. https://doi.org/10.1038/nature13118

Saravanan A., Kumar PS, Hemavathy RV, Jeevanantham S, Kamalesh R, Sneha S, Yaashikaa PR (2021) Methods of detection of food-borne pathogens: a review. Environ Chem Lett 19:189–207

Shang YS, Yi L, Wei L, Jun J, Hongyang W, Zhang C (2020) Ultrasensitive cloth-based microfluidic chemiluminescence detection of Listeria monocytogenes hlyA gene by hemin/G-quadruplex DNAzyme and hybridization chain reaction signal amplification. Anal Bioanal Chem 15:3787–3797. https://doi.org/10.1007/s00216-020-02633-5

Shao F, Yu L, Zhang Y, An C, Zhang H, Zhang Y, Xiong Y, Wang H (2020) Microfluidic encapsulation of single cells by alginate microgels using a trigger-gellified strategy. Front Bioeng Biotechnol 8:583–590. https://doi.org/10.3389/fbioe.2020.583065

Shu B, Zhang C, Xing D (2013) Highly sensitive identification of foodborne pathogenic Listeria monocytogenes using single-phase continuous-flow nested PCR microfluidics with on-line fluorescence detection. Microfluid Nanofluid 15:161–172

Smith S, Delaney M, Frey M (2020) Anti-escherichia coli functionalized silver-doped carbon nanofibers for capture of E. coli in microfluidic systems. Polymers 12(5):1117

Song B, Wang J, Yan Z, Liu Z, Pan X, Zhang Y, Zhang X (2020) Microfluidics for the rapid detection of Staphylococcus aureus using antibody-coated microspheres. Bioengineered 11:1137–1145. https://doi.org/10.1080/21655979.2020.1831362

Strohmeier NM, Daniel MA, Gunter R, Roland Z, Felix S (2014) Real-time PCR-based detection of a panel of foodborne pathogens on a centrifugal microfluidic “LabDisk” with on-disk quality controls and standards for quantification. Anal Methods 6:2038–2046. https://doi.org/10.1039/C3AY41822G

Sullivan G, Guo X, Tokman JI, Roof S, Trmcic A, Baker RC, Kovac J (2020) Extended enrichment procedures can be used to define false-negative probabilities for cultural gold standard methods for Salmonella detection, facilitating comparisons between gold standard and alternative methods. J food Prot 83(6):1030–1037

Tan F, Leung P H, Liu Z B, Zhang Y, Xiao L, Ye W, Yang M (2011) A PDMS microfluidic impedance immunosensor for E. coli O157: H7 and Staphylococcus aureus detection via antibody-immobilized nanoporous membrane. Sens Actuators B 159(1):328–335

Tegtmeyer N, Soltan Esmaeili D, Sharafutdinov I, Knorr J, Naumann M, Alter T, Backert S (2022) Importance of cortactin for efficient epithelial NF-ĸB activation by Helicobacter pylori, Salmonella enterica and Pseudomonas aeruginosa, but not Campylobacter spp. Eur J Microbiol Immunol 11(4):95–103

Terio V, Lorusso P, Mottola A, Buonavoglia C, Tantillo G, Bonerba E, Di Pinto A (2020) Norovirus detection in ready-to-eat salads by propidium monoazide real time RT-PCR assay. Appl Sci 10(15):5176

Thornval NR, Hoorfar J (2021) Progress in detection of Campylobacter in the food production chain. Current Opinion in Food Science, 39, 16-21

Tokel O, Yildiz UH, Inci F, Durmus NG, Ekiz OO, Turker B, Demirci U (2015) Portable microfluidic integrated plasmonic platform for pathogen detection. Sci Rep 5:2351–2359. https://doi.org/10.1038/srep09152

Tsao CW (2016) Polymer microfluidics: simple, low-cost fabrication process bridging academic lab research to commercialized production. Micromachines 7:225–236. https://doi.org/10.3390/mi7120225

Vinayaka AC, Huynh VN, Quyen TL, Nguyen T, Golabi M, Madsen M, Bang DD, Wolff A (2023) Validation of point-of-care device for rapid detection of Salmonella enterica in meat products. Anal Chem 95:12656–12663. https://doi.org/10.1021/acs.anarchism.3c00970

Wang L, Xue L, Guo R, Zheng L, Wang S, Yao L, Huo X, Liu N, Liao M, Li Y, Lin J (2020) Combining impedance biosensor with immunomagnetic separation for rapid screening of Salmonella in poultry supply chains. Poult Sci 99:1606–1614. https://doi.org/10.1016/j.psj.2019.12.007

Wang R, Ni Y, Xu Y, Jiang Y, Dong C, Chuan N (2019) Immuno-capture and in situ detection of Salmonella typhimurium on a novel microfluidic chip. Anal Chim Acta 853:710–717. https://doi.org/10.1016/j.aca.2014.10.042

Wang Z, Yan B, Ni Y, Cao Y, Qiu J, He R, Chang L (2024) A portable, integrated microfluidics for rapid and sensitive diagnosis of Streptococcus agalactiae in resource-limited environments. Biosens Bioelectron 247:115917

Weng X, Neethirajan S (2017) Aptamer-based fluorometric determination of norovirus using a paper-based microfluidic device. Microchim Acta 184:4545–4552. https://doi.org/10.1007/s00604-017-2467-x

Willner MR, McMillan KS, Graham D, Vikesland PJ, Zagnoni M (2018) Surface-enhanced raman scattering based microfluidics for single-cell analysis. Anal Chem 90:12004–12010. https://doi.org/10.1021/acs.analchem.8b02636

Xiaonan L, Samuelson DR, Xu Y, Zhang H, Wang S, Rasco BA, Xu J, Konkel ME (2013) Detecting and tracking nosocomial methicillin-resistant Staphylococcus aureus using a microfluidic SERS biosensor. Anal Chem 85:2320–2327. https://doi.org/10.1021/ac303279u

Xiang X, Xing G, Liu Y, Wen Q, Wei Y, Lu J, Chen Y, Ji Y, Chen S, Liu T, Shang Y (2023) Immunomagnetic separation combined with RCA-CRISPR/Cas12a for detecting Salmonella typhimurium on a figure-actuated microfluidic biosensor. J Agric Food Chem 71:13518–13526. https://doi.org/10.1021/acs.jafc.3c03799

Xu J, Yu J, Liu W, Jiang Q, Yu Z, Gan N (2024) A universal dual-mode hydrogel array based on phage-DNA probe for simultaneous rapid screening and precisely quantitative detection of Escherichia coli O157:H7 in foods using fluorescent/microfluidic chip electrophoresis methods. Anal Chim Acta 1287:3418–3424. https://doi.org/10.1016/j.aca.2023.342053

Yamaguchi N, Tokunaga Y, Goto S, Fujii Y, Banno F, Edagawa A (2017) Rapid on-site monitoring of Legionella pneumophila in cooling tower water using a portable microfluidic system. Sci Rep 7:3092–3101. https://doi.org/10.1038/s41598-017-03293-9

Yang Z, Xuecheng S, Chong L, Liu Y, Zhou Y, Lei J (2015) A giant magnetoimpedance-based biosensor for sensitive detection of Escherichia coli O157:H7. Biomed Microdevice 17:827–834. https://doi.org/10.1007/s10544-014-9925-6

Yao L, Zheng L, Cai G, Wang S, Wang L, Lin J (2020) A rapid and sensitive salmonella biosensor based on viscoelastic inertial microfluidics. Sensors 20:2738–2746. https://doi.org/10.3390/s20092738

Yao L, Lei W, Fengchun H, Gaozhe C, Xinge X, Jianhan L (2018) A microfluidic impedance biosensor based on immunomagnetic separation and urease catalysis for continuous-flow detection of E. coli O157:H7. Sens Actuators B Chem 259:1013–1021. https://doi.org/10.1016/j.snb.2017.12.110

Yoo JH, Woo DH, Chang MS, Chun MS (2014) Microfluidic based biosensing for Escherichia coli detection by embedding antimicrobial peptide-labeled beads. Sens Actuators B 191:211–218

Yunxuan C, Yaxi H, Xiaonan L (2023) An integrated paper microfluidic device based on isothermal amplification for simple sample-to-answer detection of Campylobacter jejuni. Appl Environ Microbiol 89:695–703. https://doi.org/10.1128/aem.00695-2

Zhang Y, Yan C, Hang Y, Jumping WH (2017) Rapid and selective detection of E. coli 0157:H7 combining palaeomagnetic separation with enzymatic colorimetry. Food Chem 234:332–338. https://doi.org/10.1016/j.foodchem.2017.05.013

Zhang X, Fang J, Zou Y, Zou L, Hu N, and Wang P (2015). A novel Love Wave biosensor for rapid and sensitive detection of marine toxins. Annual international conference of the IEEE engineering in medicine and biology society. pp 3181–3184. https://doi.org/10.1109/EMBC.2015.7319068

Zhong H, Huang F, Cai G, Yuntao LI, Lin J (2018) Rapid and sensitive detection of Escherichia coli O157:H7 using coaxial channel-based DNA extraction and microfluidic PCR. J Dairy Sci 101:1–11. https://doi.org/10.3168/jds.2018-14730

Funding

Funding (information that explains whether and by whom the research was supported): Department of Biotechnology, Government of India (BT/HRD/01/05/2020).

Author information

Authors and Affiliations

Contributions

Dr. Jyoti Gokhale developed the scope, concept, and the sections of the review. Lakshmi Jyotish and Sameera Kazi conducted the literature review, worked on drafting the figures, tables and major sections of the review paper. Dr. Jyoti Gokhale worked on the figures and final editing of the document. All authors have read and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declares that they have no conflict of interest.

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jyothish, L., Kazi, S. & Gokhale, J.S. Microfluidics for detection of food pathogens: recent trends and opportunities. J Food Sci Technol (2024). https://doi.org/10.1007/s13197-024-06058-1

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13197-024-06058-1