Abstract

Objectives

To reduce the amount of citrulline produced by arginine-consuming bacteria in the moromi mash during soy sauce production.

Results

Bacillus amyloliquefaciens JY06, a salt-tolerant strain with high arginine consumption ability and low citrulline accumulation capacity, was isolated from moromi mash. The concentration of citrulline was decreased from 26.8 to 5.1 mM and ethyl carbamate in soy sauce, after sterilization, decreased from 97 to 17 μg kg−1 when B. amyloliquefaciens JY06 was added during fermentation. The aroma of the sauce was improved by increasing the ester content.

Conclusions

B. amyloliquefaciens JY06 is a beneficial bacterium that can be used in soy sauce fermentation to eliminate ethyl carbonate and enhance the flavor of the sauce.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soy sauce is a traditional fermentation condiment used widely as a food additive. Ethyl carbamate is a Group 2A carcinogen (Bemis et al. 2015) common in Japanese-style soy sauce (Matsudo et al. 1993). Long-term intake of foods containing ethyl carbamate might induce a variety of cancers, including liver cancer, lung cancer and lymphoma (Weber and Sharypov 2009). Ethyl carbamate is stable and therefore, the most efficient way to eliminate it is to eliminate its precursors (Zhao et al. 2013). The reaction of citrulline with ethanol, promoted by heat and acid, is the main source of ethyl carbamate in soy sauce. The equation describing the formation of ethyl carbamate by citrulline (Xue et al. 2015) is shown below. Thus, the best method to eliminate ethyl carbamate in soy sauce is to inhibit the accumulation of citrulline.

Citrulline is produced predominantly through the arginine deiminase (ADI) pathway by Pediococcus acidilactici in days 1–21 during soy sauce fermentation, the lactic acid fermentation stage (Matsudo et al. 1993; Zhang et al. 2014). The ADI pathway comprises three reaction steps (Sürken et al. 2008).

Citrulline can be used and converted to ornithine through the ADI pathway only when arginine is exhausted (de Orduña et al. 2000), suggesting citrulline accumulated during soy sauce fermentation is hard to eliminate owing to the arginine-rich environment. One strategy for reducing citrulline accumulation by soy sauce bacteria is to eliminate its precursor, arginine, and control arginine metabolism. Inhibition of the growth of lactic acid bacteria and other citrulline-producing bacteria in koji does decrease citrulline in soy sauce. However, reduction of these bacteria can result in the loss of some special flavour of soy sauce (Zhao et al. 2013). Thus, elimination of arginine without the accumulation of citrulline during soy sauce fermentation is the best way to reduce the citrulline content.

l-Arginine hydrolyzed from soybean protein is the precursor of citrulline in soy sauce. l-Arginine is usually metabolized and transformed into ornithine through the ADI pathway under anaerobic conditions, providing supplementary energy for bacterial growth (Sakanaka et al. 2015). However, citrulline can become the main end-product instead of ornithine at the optimum pH for bacteria growth (i.e. pH 5.5 for Lactobacillus fermentum IMDO 130101) or in the presence of 18 % NaCl (Vrancken et al. 2009; Zhang et al. 2014). Thus, isolation and characterization of a strain with the ability to convert all arginine to ornithine through the ADI pathway is crucial for the reduction of citrulline accumulation during soy sauce fermentation.

The aim of this study was to isolate a salt-tolerant strain with high arginine utilization ability that does not accumulate citrulline, leading to decreased citrulline in the moromi during soy sauce fermentation.

Materials and methods

Raw materials and soy sauce fermentation

The mature koji and fresh moromi mash samples were collected from a soy sauce factory in Guangdong Province, China. The mature koji was mixed 1:1.7 (w/v) with a 20 % (w/v) brine. Two kg sample of the mixed mash was loaded into a 2 l cylindrical vessel. Bacillus amyloliquefaciens JY06 was added using three different strategies (see “Results”). The mash was held at 15 ± 1 °C for 20 days. Then 107 CFU Zygosaccharomyces rouxii g−1 was added into the mash on day 21 and the temperature of the mash was raised to 30 °C. The mash samples were aerated with filtered air by an 80 W air pump for 10 min every day until day 69. The mash was then manually stirred for 10 min every week until the end of fermentation (day 90). The scheme of soy sauce fermentation process was shown as Fig. 1.

Isolation and screening of salt-tolerant bacteria with high arginine consumption capacity

Isolation and screening of salt-tolerant bacteria with high arginine consumption capacity used a medium color change cultivation method as described (Zhang et al. 2014). Arginine utilization capacity was evaluated by measuring the diameter of the purple circles surrounding target colonies. Positive isolates were stored at −80 °C. These isolates were cultivated using the koji bacteria cultivation method as described (Zhang et al. 2014). Each strain was harvested by centrifugation at 4 °C, 10,000×g for 5 min and inoculated into 50 ml modified arginine consumption broth [18 % (w/v) NaCl, no Bromcresol Purple], (Zhang et al. 2014) and cultured without mixing at 30 °C for 48 h.

Cultivation of B. amyloliquefaciens and Z. rouxii

B. amyloliquefaciens was inoculated into lysogeny broth (Rohban et al. 2009) supplemented with 10 g arginine l−1 and 10 % (w/v) NaCl (pH 5.5) then cultivated at 30 °C without mixing for 36 h. Z. rouxii was inoculated into yeast extract/malt extract broth (Difco) containing 10 % (w/v) NaCl and incubated at 30 °C for 48 h.

Analysis of moromi pH and quantification of main components in soy sauce

Concentrations of ethyl carbamate, ethanol and urea (Zhang et al. 2014) as well as total acids and nitrogen in amino acid (Cui et al. 2014) were quantified as described. Free amino acids were quantified by HPLC as described (Zhang et al. 2014); volatile compounds were analyzed using a headspace solid phase microextraction (HS-SPME) method (Zhao et al. 2011). Soy sauce samples used for volatile compounds analysis were prepared as described (Cui et al. 2014). A J&W DB-WAX quartz capillary column (30 m × 0.25 mm, internal diam. 0.25 μm) was used for the separation of volatile compounds.

Sensory evaluation

Twelve trained subjects from the Department of Research and Development Center of a soy sauce factory in Guangdong Province were selected as panelists. Two ml soy sauce was made to 20 ml with 18 % (w/v) saline for color observation. Five ml soy sauce was placed into a 150 ml tapered bottle to detect the flavor. 0.5 ml soy sauce was evaluated and described by the panelists. Finally, 2 ml soy sauce were placed into a white porcelain dish (70 mm diam.) to observe its characteristics. The quantitative descriptive analysis was done by using the double-blind method described (Feng et al. 2013). Each sample was evaluated once. Sensory evaluation was done at 25 °C, relative humidity 50 %.

DNA manipulations

Total DNA of the isolates was extracted with EZNA Genomic DNA Isolation Kits (Omega Bio-Tek, Georgia, USA). Amplification and analysis of 16S rDNA sequences and arcA sequences of isolated strains were achieved as described (Zhang et al. 2014). Primers used for the amplification of partial arcA gene were: arcAF: 5′-AATTGTCTGATTGCCGATTGAC-3′, arcAR: 5′-GACGTATCCATTCCCAAATCCA-3′. The gene was amplified using ExTaq DNA polymerase (TaKaRa): initial denaturation at 95 °C for 5 min, then 30 cycles at 95 °C for 10 s, 55 °C for 30 s and 72 °C for 90 s, finally, an extension step at 72 °C for 5 min.

Results

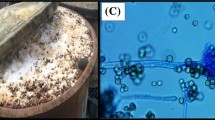

Characterization of arginine consuming strains in moromi mash

Forty-two strains with arginine consumption capacity were isolated from soy sauce moromi mash. 19 grew well in 18 % (w/v) NaCl and were subsequently tested for arginine consumption and citrulline accumulation ability. Nine strains had significant arginine consumption with 18 % (w/v) NaCl (Table 1). The arginine consumption efficiency of strain JY06 was the highest. It did not accumulate citrulline during cultivation; in addition, nearly all of the arginine used by strain JY06 was converted to ornithine. Thus, JY06 was the most suitable candidate for the elimination of arginine during soy sauce fermentation. It was identified as B. amyloliquefaciens by the phylogenetic analysis based on 16S rDNA and partial arcA gene sequences (Supplementary Fig. 1 and Supporting Information). The other isolates were identified as Bacillus subtilis, Tetragenococcus halophilus and Staphylococcus sp.

Effect of addition of B. amyloliquefaciens JY06 on accumulation of ethyl carbamate and its precursors in soy sauce

In order to determine its effect on citrulline and urea accumulation and ethyl carbamate formation during soy sauce fermentation, B. amyloliquefaciens JY06 was added into a 2 l soy sauce fermentation vessel using three different strategies: S1, addition of 3 × 107 CFU JY06 g−1 on day 1; S2, addition of 108 CFU JY06 g−1 on day 1; and S3, addition of 3 × 107 CFU JY06 g−1 on day 4 of soy sauce fermentation. Samples of the moromi mash from an individual test vessel were collected at different time points to determine the concentration of amino acids, urea and ethyl carbamate during 90 days of fermentation.

As shown in Fig. 2, there were reductions of arginine and citrulline in soy sauce induced by the addition of B. amyloliquefaciens after day 7 of fermentation. After day 90 of fermentation, arginine in the S1, S2 and S3 samples had declined by 35.5, 41.5 and 35.8 %, respectively (Fig. 2a). Citrulline in the S1, S2 and S3 samples decreased by 78.7, 80.9 and 66.3 %, respectively (Table 2). The degraded arginine was converted into ornithine through the ADI pathway by JY06 (Fig. 2c). Urea (the other ethyl carbamate precursor) in the moromi mash was also decreased by additing B. amyloliquefaciens (Table 2). Ethyl carbamate was not detected in non-sterilized soy sauce fermented with the addition of B. amyloliquefaciens JY06. After sterilization (heating at 95 °C for 30 min), ethyl carbamate formation was observed in all soy sauce samples tested. The ethyl carbamate content of samples S1, S2 and S3 were reduced by 70.7, 82.9 and 48.8 %, respectively, compared to the control. However, the concentration of ethanol (usually 2 % v/v) in the 2 l soy sauce fermentation system was lower compared to soy sauce produced in the factory. Ethanol is the other important precursor besides citrulline for ethyl carbamate formation. Thus, ethanol in all samples was made to 2 % (v/v) to investigate ethyl carbamate content after sterilization. As shown in Table 2, ethyl carbamate in S1, S2 and S3 was reduced by 76.3, 82.5 and 63.9 %, respectively. These results showed addition of B. amyloliquefaciens decreased the accumulation of citrulline and reduced ethyl carbamate formation during soy sauce sterilization.

Detection of amino acids released in the moromi during soy sauce fermentation. a Arginine; b citrulline; c ornithine; S1, addition of 3 × 107 CFU JY06 g−1 on day 1; S2, addition of 108 CFU JY06 g−1 on day 1; S3, addition of 3 × 107 CFU JY06 g−1 on day 4 of soy sauce fermentation. Error bars represent standard deviations (n = 3)

Effect of B. amyloliquefaciens addition on main components and volatile compounds in soy sauce

The concentrations of ethanol, amino acid nitrogen, NaCl, total acids and volatile compounds, and the pH of soy sauce were determined at the end of fermentation to investigate the effect of the addition of B. amyloliquefaciens on main components and aroma compounds of fresh soy sauce (unsterile). There was a decreased concentration of ethanol, a reduction of pH, and an increase of total acid concentration compared to the control. There was no significant difference in the concentration of NaCl or the amino acid nitrogen concentration of the soy sauce supplemented with B. amyloliquefaciens JY06 during fermentation compared to the control (Table 2).

The main volatile compounds in soy sauce are alcohols, acids, esters, aldehydes and ketones. With the addition of B. amyloliquefaciens JY06, the number of esters in samples S1, S2 and S3 were increased by four, three and two, respectively, and the number of ketones in samples S1, S2 and S3 were increased by three, four and two, respectively. The number of aldehydes slightly decreased compared to the control (Fig. 3a). In addition, the total amount of esters and acids was increased following the addition of B. amyloliquefaciens JY06. The amount of alcohols in volatile compounds decreased significantly with the addition of B. amyloliquefaciens (Fig. 3b). We selected S3 to perform a sensory test, which produced nearly the same amount of alcohols and acids to the control. The results showed that addition of 3 × 107 CFU JY06 g−1 on day 4 of soy sauce fermentation received a higher score on ester fragrant compared to the control (Table 3).

Comparison of volatile compounds in soy sauce produced through different procedures. a Number of volatile compounds; b amount of volatile compounds. The relative content of all samples were calculated by peak area ratio (volatile compound/2-octanol). S1, addition of 3 × 107 CFU JY06 g−1 on day 1; S2, addition of 108 CFU JY06 g−1 on day 1; S3, addition of 3 × 107 CFU JY06 g−1 on day 4 of soy sauce fermentation

Discussion

Ethyl carbamate is a harmful by-product that widely exists in foods and beverages. The elimination of ethyl carbamate is important to ensure food safety. However, there have been no studies reported on the elimination of ethyl carbamate in soy sauce. In this study, a B. amyloliquefaciens strain with high arginine consuming capacity in 18 % (w/v) NaCl was isolated from the moromi mash to reduce the accumulation of ethyl carbamate precursor citrulline during soy sauce fermentation. Arginine is the precursor of citrulline and elimination of arginine is critical for reducing the accumulation of citrulline in soy sauce. Arginine is released continuously by the hydrolysis of raw materials during the production of soy sauce. Although the raw materials and procedures are slightly different among soy sauce manufacturers, the sum of three amino acids (arginine, citrulline and ornithine) was almost constant stoichiometrically (Matsudo et al. 1993). Arginine hydrolyzed from the raw materials was consistently present from 30 to 40 mM (usually 34.5 mM) in different samples of soy sauce (Matsudo et al. 1993; Zhang et al. 2014). Thus, candidate strains for reduction of citrulline accumulation must have the ability to utilize at least 30 mM arginine within a short time during the lactic acid fermentation process. Strain with the highest arginine consumption efficiency and did not accumulate citrulline during cultivation is the best candidates.

About 70 % of total arginine is released during the lactic acid fermentation process (data unpublished). About 68 % of total citrulline is accumulated substantially through the utilization of arginine (Zhang et al. 2014). This result suggests that the lactic acid fermentation stage is the most important phase for citrulline accumulation and regulation. Thus, in this period, the faster the conversion of arginine to ornithine, the less citrulline will be accumulated. Moreover, the accumulated citrulline can be converted to ornithine through the ADI pathway by some lactic acid bacteria after the arginine in the moromi mash is completely exhausted (Liu and Pilone 1998). In this study, B. amyloliquefaciens JY06 was supplemented in the moromi mash to competitively consume arginine and converted arginine to ornithine through ADI pathway, thereby preventing the indigenous bacteria in the moromi mash converting arginine to citrulline through the ADI pathway. The optimal performance of controlling citrulline accumulation was obtained with the addition of 108 CFU g−1 at the beginning of fermentation. The accumulation of citrulline was inhibited completely because arginine was exhausted by day 13. The concentration of citrulline declined subsequently after arginine in soy sauce samples was completely exhausted. The result demonstrated the earlier and the more cells of B. amyloliquefaciens JY06 that were inoculated, the less citrulline was accumulated.

B. amyloliquefaciens is closely related to Bacillus subtilis (Priest et al. 1987) and is common in fermented foods, including Korean soybean pastes and fish sauce (Zaman et al. 2010; Nam et al. 2012). Hong et al. (2012) demonstrated the possibility of using B. amyloliquefaciens to produce a functional Korean soybean paste without a negative flavor. Salty and umami tastes are the most important characteristics of soy sauce flavor (Jeong et al. 2004). NaCl and nitrogen in amino acids are the main contributors to these flavors (Kim and Lee 2003). With the addition of B. amyloliquefaciens JY06, there was no significant difference of the concentration of NaCl or nitrogen in amino acids compared to the control. The total acids in soy sauce increased with the addition of B. amyloliquefaciens JY06 (Fig. 2b) thereby lowering the final pH. The decrease of alcohols and the increase of esters indicated that the acids produced by B. amyloliquefaciens contributed to the formation of esters. This is likely owing to the balance of different compounds through a complex interaction that contributes to the aroma and taste of soy sauce. Thus, it is very important to find an appropriate addition time and an optimal dose of B. amyloliquefaciens for both reduction of ethyl carbamate and improving the flavor of soy sauce.

Conclusion

The addition of B. amyloliquefaciens JY06 during soy sauce fermentation is efficient in controlling the citrulline content of soy sauce. This study provides the basis for the reduction of citrulline accumulation with slight changes of flavor with the addition of a B. amyloliquefaciens strain.

References

Bemis JC, Labash C, Avlasevich SL et al (2015) Rat Pig-a mutation assay responds to the genotoxic carcinogen ethyl carbamate but not the non-genotoxic carcinogen methyl carbamate. Mutagenesis 30:343–347

Cui R-Y, Zheng J, Wu C-D et al (2014) Effect of different halophilic microbial fermentation patterns on the volatile compound profiles and sensory properties of soy sauce moromi. Eur Food Res Technol 239:321–331

de Orduña RM, Liu S-Q, Patchett M et al (2000) Ethyl carbamate precursor citrulline formation from arginine degradation by malolactic wine lactic acid bacteria. FEMS Microbiol Lett 183:31–35

Feng J, Zhan X-B, Zheng Z-Y et al (2013) New model for flavour quality evaluation of soy sauce. Czech J Food Sci 31:292–305

Hong Y, Jung H-J, Kim H-Y (2012) Aroma characteristics of fermented Korean soybean paste (Doenjang) produced by Bacillus amyloliquefaciens. Food Sci Biotechnol 21:1163–1172

Jeong SY, Chung SJ, Suh DS et al (2004) Developing a descriptive analysis procedure for evaluating the sensory characteristics of soy sauce. J Food Sci 69:S319–S325

Kim S-H, Lee K-A (2003) Evaluation of taste compounds in water-soluble extract of a doenjang (soybean paste). Food Chem 83:339–342

Liu SQ, Pilone GJ (1998) A review: arginine metabolism in wine lactic acid bacteria and its practical significance. J Appl Microbiol 84:315–327

Matsudo T, Aoki T, Abe K et al (1993) Determination of ethyl carbamate in soy sauce and its possible precursor. J Agric Food Chem 41:352–356

Nam Y-D, Lee S-Y, Lim S-I (2012) Microbial community analysis of Korean soybean pastes by next-generation sequencing. Int J Food Microbiol 155:36–42

Priest F, Goodfellow M, Shute L et al (1987) Bacillus amyloliquefaciens sp. nov., nom. rev. Int J Syst Bacteriol 37:69–71

Rohban R, Amoozegar MA, Ventosa A (2009) Screening and isolation of halophilic bacteria producing extracellular hydrolyses from Howz Soltan Lake, Iran. J Ind Microbiol Biotechnol 36:333–340

Sakanaka A, Kuboniwa M, Takeuchi H et al (2015) Arginine-ornithine antiporter ArcD controls arginine metabolism and interspecies biofilm development of Streptococcus gordonii. J Biol Chem 290:21185–21198

Sürken M, Keller C, Röhker C et al (2008) Anaerobic arginine metabolism of Mycobacterium tuberculosis is mediated by arginine deiminase (arcA), but is not essential for chronic persistence in an aerogenic mouse model of infection. Int J Med Microbial 298:657–661

Vrancken G, Rimaux T, Weckx S et al (2009) Environmental pH determines citrulline and ornithine release through the arginine deiminase pathway in Lactobacillus fermentum IMDO 130101. Int J Food Microbiol 135:216–222

Weber JV, Sharypov VI (2009) Ethyl carbamate in foods and beverages-a review. In:Lichtfouse E (ed) Climate change, intercropping, pest control and beneficial microorganisms, vol 2. Springer, Netherlands, pp 429–452

Xue J, Fu F, Liang M et al (2015) Ethyl carbamate production kinetics during wine storage. S Afr J Enol Vitic 36:277–284

Zaman MZ, Bakar FA, Selamat J, Bakar J (2010) Occurrence of biogenic amines and amines degrading bacteria in fish sauce. Czech J Food Sci 28:440–449

Zhang J, Fang F, Chen J et al (2014) The arginine deiminase pathway of koji bacteria is involved in ethyl carbamate precursor production in soy sauce. FEMS Microbiol Lett 358:91–97

Zhao J, Dai X, Liu X et al (2011) Comparison of aroma compounds in naturally fermented and inoculated Chinese soybean pastes by GC-MS and GC-Olfactometry analysis. Food Control 22:1008–1013

Zhao X, Du G, Zou H et al (2013) Progress in preventing the accumulation of ethyl carbamate in alcoholic beverages. Trends Food Sci Tech 32:97–107

Acknowledgments

This work was supported by the National Natural Science Foundation of China (31371821) and the Technology Research Program of Guangdong, China (2015B020205002).

Supporting information

Supplementary Fig. 1—Identification of strain JY06 as Bacillus amyloliquefaciens by phylogenetic analysis based on 16S rDNA and partial arcA sequences.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Zhang, J., Du, G., Chen, J. et al. Characterization of a Bacillus amyloliquefaciens strain for reduction of citrulline accumulation during soy sauce fermentation. Biotechnol Lett 38, 1723–1731 (2016). https://doi.org/10.1007/s10529-016-2147-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-016-2147-7