Abstract

Rhodococcus sp. CGMCC 4911 transformed 1,3-propanediol cyclic sulfate (1,3-PDS) and its derivatives into corresponding diols. Ethylene sulfate, glycol sulfide, 1,3-PDS, and 1,2-propanediol cyclic sulfate were effectively hydrolyzed with growing cells. (R)-1,2-Propanediol (>99 % e.e.) was obtained at 44 % yield with growing cells. Glycol sulfide, ethylene sulfate, and 1,3-PDS were converted into the corresponding diols at 94.6, 96.3, and 98.3 %, respectively. Optimal reaction conditions with lyophilized resting cells were 30 °C, pH 7.5, and cell dosage 17.9 mg cell dry wt/ml. 1,3-Propanediol was obtained from 50 mM 1,3-PDS at 97.2 % yield by lyophilized cells after 16 h. Lyophilized cells were entrapped in calcium alginate with a half-life of 263 h at 30 °C, and the total operational time of the immobilized biocatalysts could reach over 192 h with a high conversion rate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Short chain diols, exemplified by ethylene glycol, 1,2-propanediol (1,2-PD), 1,3-propanediol (1,3-PD), are important as platform chemicals (Metsoviti et al. 2013; Oda et al. 2013). They are widely used to synthesize polymers and other intermediates due to their structures and reaction activities. Compared to the conventional chemical method, biosynthesis can offer a highly selective reactions and environmentally benign process and is thus of great interest (Clomburg and Gonzalez 2013). Many microorganisms or enzymes can synthesize diols from the corresponding substrates (Clomburg and Gonzalez 2013; He et al. 2013).

Organic sulfate esters can be hydrolyzed into primary or secondary alkyl alcohols (Gadler and Faber 2006) by sulfatases (EC3.1.6.X). Sulfatases are a heterogenic group of enzymes that catalyze the hydrolytic cleavage of sulfate esters by liberating inorganic sulfate and the corresponding alcohol. Most of the work on alkylsulfatases has been used to transform alkyl sulfate (Toesch et al. 2014). However, there are limited data about biotransformation of cyclic sulfates into diols. Cyclic sulfates and its derivatives are a class of valuable and versatile synthons for the synthesis of important intermediates (Steinmann et al. 2001). Biotransformation of cyclic sulfates into diols is of interest owing to the desirability of conducting such conversions under mild conditions. Clearly, it is a feasible alternative to synthesize diols from the biotransformation of corresponding cyclic sulfates by sulfatase.

This is the first report that Rhodococcus sp. CCZU10-1 can convert 1,3-propanediol cyclic sulfate and its derivatives into diols.

Materials and methods

Materials

1,3-Propanediol cyclic sulfate (1,3-PDS; 1a see Table 1) was purchased from Sigma-Aldrich Co. Ltd. (USA). 1,2-Propanediol cyclic sulfate (1,2-PDS; 2a) and ethylene sulfate (ES; 3a) were obtained from Quzhou Ruierfeng Chemical Co., LTD (Zhejiang, China). Glycol sulfide (GS; 4a) was purchased from Aladdin Chemical Reagent Co. Ltd. (Shanghai, China). Other chemicals were obtained from commercial sources and were of analytical grade.

Microorganisms

Brevibacterium sp. CCZU12-1 and Rhodococcus sp. CCZU10-1, two nitrilase-producing strains, were isolated from soil (He et al. 2012, 2014b). They are preserved in our laboratory and are also deposited at China General Microbiological Culture Collection Center (CGMCC) with accession numbers of CGMCC 7042 and 4911. Using 1,3-PDS as inducer, they exhibit sulfatase activity.

Cultivation condition

Cultivation was carried out in a 250 ml flask containing 60 ml medium at 180 rpm and 30 °C. The medium had the following composition (per liter): 10 g glucose, 10 g peptone, 4.4 g KH2PO4, 1.3 g Na2HPO4·12H2O, 0.1 g MgCl2, 1 g NaCl, 2 mM 1,3-PDS, pH 7.0. Whole-cell biocatalysts were harvested after 48 h of cultivation, washed and lyophilized by vacuum-freezing.

Sulfatase assay

One unit (U) of activity is defined as the amount of cells [dry cell weight (CDW), g] required to catalyze the formation of 1 μmol diol per min under the standard condition.

Immobilization of whole-cell biocatalyst

The lyophilized cells were immobilized in calcium alginate according to the previous method (He et al. 2014c).

Analytical methods

1,3-Propanediol (1,3-PD) and its derivatives were assayed by GC according to Oda et al. (2013). The enantiomeric excess (e.e., %) of 1,2-propanediol (1,2-PD) was determined by HPLC using a chiral column (Chiralcel OD-H, Daicel Co., Japan) at 40 °C which was eluted with n-hexane/2-propanol (80:20, v/v, 1.0 ml/min) and detected at 254 nm (Oda et al. 2013).

Results and discussion

Screening of sulfatase-producing strain

To obtain the desired sulfatase-producing strain, 92 isolates were obtained using 2 mM 1,3-PDS as sole carbon and sulfur source through enrichment cultivation procedure from 480 municipal sewage samples. Sulfatase activity was found in 53 isolates. Rhodococcus sp. CCZU10-1 and Brevibacterium sp. CCZU12-1 were the best for the biotransformation of 50 mM 1,3-PDS. Three isolates [Rhodococcus sp. CCZU10-1 (CGMCC 4911), Bacillus sp. CCZU11-1 (CGMCC 9297) and Brevibacterium sp. CCZU12-1 (CGMCC 7042)] exhibited high sulfatase activity of 4.8, 1.6 and 1.3 U/g CDW, respectively. In addition, Rhodococcus sp. CCZU10-1 could transform 1,2-PDS into (R)-1,2-PD (>99 % e.e.). In the following experiments, Rhodococcus sp. CCZU10-1 was used for further investigation.

Biotransformation of 1,3-PDS and its derivatives with growing cells

There are limited data about biotransformation of cyclic sulfates. Rhodococcus sp. was cultured in growth medium supplemented with 10 mM 1,3-PDS for 72 h, and 1,3-PDS was transformed into 1,3-PD at 98.3 % yield (Fig. 1).

Biotransformation of 1,3-propanediol cyclic sulfate (1,3-PDS) with growing cells of Rhodococcus sp. CCZU10-1. Biotransformations were performed in a 250 ml flask containing 60 ml culture medium (10 g glucose, 10 g peptone, 4.4 g KH2PO4, 1.3 g Na2HPO4·12H2O, 0.1 g MgCl2, 1 g NaCl, 1,000 ml water, pH 7.0) containing 10 mM 1,3-PDS at 180 rpm and 30 °C for 72 h

Four substrates (1a–4a) were hydrolyzed with growing cells (Table 1). 1,3-PDS (1a), ES (3a) and GS (4a) were hydrolyzed with high conversions (94.6-98.3 %) over 72 h. 1,2-PDS (2a) was hydrolyzed into (R)-1,2-PD (>99 % e.e.) with a yield of 44.1 %. This is the first report that Rhodococcus sp. can transform cyclic sulfate or sulfite into diols. Platform chemicals (1,2-PD, 1,3-PD, etc.) are employed as the basic starting materials for producing chemical intermediates, building block compounds, and polymers (Clomburg and Gonzalez 2013; Lin et al. 2005; Metsoviti et al. 2013; Oda et al. 2013; Wei et al. 2014). 1,3-PD is used to synthesize polytrimethylene terephthalate (PTT). 1,2-PD is mainly used as deicer in airplane fluids, as a non-toxic replacement of ethylene glycol in automobiles and as a mist to disinfect air. Significantly, some high-value diols can thus be obtained from the hydrolysis of cheaper cyclic sulfates.

Biotransformation with lyophilized cells of Rhodococcus sp. CCZU10-1

During biotransformation, different reaction pH, reaction temperature, and cells dosage have significant effects on the catalytic activity (He et al. 2013, 2014a). In this study, the effect of temperature on the catalytic activity was examined by lyophilized cells (Fig. 2a). The catalytic activity increased with temperature, reaching a maximum at 30 °C. Above 30 °C, the catalytic activity decreased considerably, possibly due to thermal deactivation of enzymes in the resting cells during the reaction. Various pH values buffers were also tested (Fig. 2b). The catalytic activity exhibited a maximum at pH 7.5. Furthermore, the effects of different cells dosage (7.1–28.6 mg CDW/ml) on the catalytic activity were investigated. As shown in Fig. 3, the high catalytic activity was at 17.9 mg CDW/ml. When the cell concentration was over this value, the viscosity of the aqueous phase was probably too high (He et al. 2014a) and then the catalytic activity stabilized. The optimum cell concentration was therefore 17.9 mg CDW/ml.

Effects of reaction temperature and pH on the catalytic activity of lyophilized cells of Rhodococcus sp. CCZU10-1. Biotransformations of 1,3-PDS were performed at the different temperature (20–40 °C) and different pH buffer (potassium phosphate buffer, 6–8). Biotransformation of 1,3-PDS was performed for 1 h at 30 °C and 180 rpm in 10 ml potassium phosphate buffer (100 mM, pH 7.5) containing 0.143 g dry cell weight. The specific activity was 4.78 U/g CDW and was taken as 100 %

The optimum reaction temperature, reaction pH, and cells dosage were thus 30 °C, 7.5, and 17.9 mg CDW/ml, respectively. Under these conditions, 50 mM 1,2-PDS and 1,3-PDS were hydrolyzed by lyophilized cells (Fig. 4). After 16 h, (R)-1,2-PD (>99 % e.e.) and 1,3-PD were obtained with the yield of 47.8 and 97.2 %, respectively.

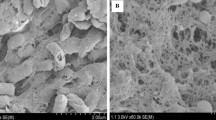

Biotransformation with immobilized cells

Immobilized whole-cell biocatalyst is an applicable and economic formulation in the biotransformation, which can avoid the need to extract and purify intracellular enzymes, facilitate recovery and reuse, improve the resistance of cells lysis, and increase the stability of the biocatalytic activity of the cells. Compared to free cells or enzymes, immobilized microbial cells have better operational stability, easier separation from the reaction media for reuse, and satisfactory biocatalytic efficiency (He et al. 2012, 2014c). In this study, calcium alginate-immobilized lyophilized cells were employed. After the immobilization, the thermal stabilities of the biocatalysts were examined and the results were shown in Fig. 5a. Considering that the optimized reaction was at 30 °C, the test of thermal stability was also performed at 30 °C. Best results were achieved using immobilized cell, which retained 85.2 % activity after 72 h at 30 °C and 180 rpm, whereas the free lyophilized cells could only maintain 8.6 % activity after 48 h. The half-life of the former (263 h) was 12.8-fold of the latter (20.5 h).

Biotransformations with free lyophilized resting cells and immobilized cells of Rhodococcus sp. CCZU10-1. a The thermal stabilities of free lyophilized cells and immobilized cells (4.92 U/g CDW cells each) were examined by assaying their residual activities at 30 °C after being incubated in Tris/HCl buffer (100 mM, pH 7.5) at 30 °C for a required period; b the reactions, consisting of 50 mM substrate (1,3-PDS and 1,2-PDS) and 5 g immobilized beads (containing 0.179 g CDW cells) or 0.179 g CDW free lyophilized cells (4.92 U/g CDW cells each) in 10 ml Tris/HCl buffer (100 mM, pH 7.5), were performed for 16 h at 30 °C and 180 rpm. After each cycle, the biocatalysts were washed with physiological saline (0.85 % NaCl) and transferred into a fresh Tris/HCl buffer (100 mM, pH 7.5)

The reusability of immobilized whole-cell biocatalysts was investigated. Each batch was performed for 16 h. At the end of each batch, the immobilized cells were collected and then reused for another batch. As shown in Fig. 5b, the immobilized cells had good stability and reusability. Using 1,3-PDS as substrate, the conversion rate was not less than 96 % after the 12th batch. Compared to the immobilized cells, free lyophilized cells could be used only 5 times with the conversion rate over 50 %. Using 1,2-PDS as substrate, similar tendency was achieved (Fig. 5b). The total operational time of the immobilized biocatalysts could reach over 192 h. Significantly, the immobilized cells had some advantages such as enhanced stability, good reusability, and easy separation from the reaction mixture (Dinamarca et al. 2014; He et al. 2014c).

Conclusion

This is the first report of the biotransformation of 1,3-PDS and its derivatives in high conversions using Rhodococcus sp. (CGMCC 4911). The optimum reaction conditions were: 30 °C, 7.5, with 17.9 mg CDW/ml. Lyophilized cells produced (R)-1,2-PD (>99 % e.e.) and 1,3-PD from the corresponding substrates over 16 h with the yields of 47.8 and 97.2 %, respectively. Lyophilized cells were entrapped in calcium alginate with a half-life of 263 h at 30 °C; operational times of the immobilized biocatalysts were over 192 h with high conversion rates. Significantly, this is an alternative to biosynthesing diols from the corresponding cyclic sulfates by using a sulfatase.

References

Clomburg JM, Gonzalez R (2013) Anaerobic fermentation of glycerol: a platform for renewable fuels and chemicals. Trends Biotechnol 31:20–28

Dinamarca MA, Orellana L, Aguirre J, Baeza P, Espinoza G, Canales C, Ojeda J (2014) Biodesulfurization of dibenzothiophene and gas oil using a bioreactor containing a catalytic bed with Rhodococcus rhodochrous immobilized on silica. Biotechnol Lett 36:1649–1652

Gadler P, Faber K (2006) New enzymes for biotransformations:microbial alkylsulfatases displaying stereo- and enantioselectivity. Trends Biotechnol 25:83–88

He YC, Zhou Q, Ma CL, Cai ZQ, Wang LQ, Zhao XY, Chen Q, Gao DZ, Zheng M, Wang XD, Sun Q (2012) Biosynthesis of benzoylformic acid from benzoyl cyanide by a newly isolated Rhodococcus sp. CCZU10-1 in toluene-water biphasic system. Biores Technol 115:88–95

He YC, Ma CL, Zhang X, Li L, Xu JH, Wu MX (2013) Highly enantioselective oxidation of racemic phenyl-1,2-ethanediol to optically pure (R)-(–)-mandelic acid by a newly isolated Brevibacterium lutescens CCZU12-1. Appl Microb Biotechnol 97:7185–7194

He YC, Tao ZC, Zhang X, Yang ZX, Xu JH (2014a) Highly efficient synthesis of ethyl (S)-4-chloro-3-hydroxybutanoate and its derivatives by a robust NADH-dependent reductase from E. coli CCZU-K14. Biores Technol 161:161–164

He YC, Pan XH, Xu XF, Wang LQ (2014b) Biosynthesis of benzoylformic acid from benzoyl cyanide with a new bacterial isolate of Brevibacterium sp. CCZU12-1. Appl Biochem Biotechnol 172:3223–3233

He YC, Wu YD, Pan XH, Ma CL (2014c) Biosynthesis of terephthalic acid, isophthalic acid and their derivatives from the corresponding dinitriles by tetrachloroterephthalonitrile-induced Rhodococcus sp. Biotechnol Lett 36:341–347

Lin R, Liu H, Hao J, Cheng K, Liu D (2005) Enhancement of 1,3-propanediol production by Klebsiella pneumoniae with fumarate addition. Biotechnol Lett 27:1755–1759

Metsoviti M, Zeng AP, Koutinas AA, Papanikolaou S (2013) Enhanced 1,3-propanediol production by a newly isolated Citrobacter freundii strain cultivated on biodiesel-derived waste glycerol through sterile and non-sterile bioprocesses. J Biotechnol 63:408–418

Oda T, Oda K, Yamamoto H, Matsuyama A, Ishii M, Igarashi Y, Nishihara H (2013) Hydrogen-driven asymmetric reduction of hydroxyacetone to (R)-1,2-propanediol by Ralstonia eutropha transformant expressing alcohol dehydrogenase from Kluyveromyces lactis. Microb Cell Factor 12:2

Steinmann JG, Phillips JH, Sanders WJ, Kiessling LL (2001) Synthesis of cyclic sulfates by halocyclization. Org Lett 3:3557–3559

Toesch M, Schober M, Faber K (2014) Microbial alkyl- and aryl-sulfatases: mechanism, occurrence, screening and stereoselectivities. Appl Microbiol Biotechnol 98:1485–1496

Wei X, Meng X, Chen Y, Wei Y, Du L, Huang R (2014) Cloning, expression, and characterization of coenzyme-B12-dependent diol dehydratase from Lactobacillus diolivorans. Biotechnol Lett 36:159–165

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 21102011), and the Natural Science Foundation of Jiangsu Province (No. BK20141172).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

He, YC., Tao, ZC., Zhang, DP. et al. Biotransformation of 1,3-propanediol cyclic sulfate and its derivatives to diols by Rhodococcus sp.. Biotechnol Lett 37, 183–188 (2015). https://doi.org/10.1007/s10529-014-1670-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-014-1670-7