Abstract

A brand new design of temperature sensor using ferrofluid thin film is proposed in this paper. When magnetic field parallel to the plane of the ferrofluid thin film is applied, magnetic chains form in the same direction of the magnetic field, which results in the suppressing of optical transmission. It is observed that the optical transmission is changed by the ambient temperature, so that temperature sensor can be constructed by measuring the transmission power of a laser. The physics and the sensitivity of the temperature sensor are also analyzed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Temperature sensors have important applications in the field of science and technology so that many researchers have been attracted to study on them. With the development of manufacturing techniques, temperature sensors using different materials are developed, such as CMOS (Jha et al. 2007), cholesteric liquid crystal (Moreira et al. 2004; Smith et al. 1974), optical fiber (Shenping and Chan 1998; Henry et al. 1999). But until now, there are few reports on using ferrofluid to design a temperature sensor. In this paper, the design of the temperature sensor using a novel material, ferrofluid, is presented.

Ferrofluid is a colloidal suspension of single domain ferromagnetic particles dispersed in a nonmagnetic liquid solvent which has been studied for a long time. Its magneto-optical properties have recently attracted a lot of interest of many scientists due to their potential applications (Luo et al. 1999a, b; Horng et al. 1998, 2001; Pu et al. 2005, 2006). It is indicated that the optical transmission of the ferrofluid is deeply related to its structural patterns under external fields. Yang et al. have proven that the magnetic-field-dependent optical transmission originates from the agglomeration of the magnetic particles that reduces the area of the liquid phase (Yang et al. 2001). Because the thermal agitation can suppress the ability of the agglomeration (Pu et al. 2007), the optical transmission can be tuned by changing the ambient temperature around the ferrofluid. Based on this principle, a temperature sensor is suggested by using ferrofluid thin film with a constant external magnetic filed. In this paper, the design of such a kind of temperature sensor is reported and the physics original and performance of this kind of temperature sensor is discussed.

2 Experimental

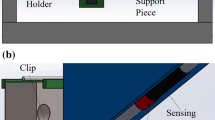

Experimental arrangement employed for realizing the temperature sensor is shown as Fig. 1. In the experimental setup, a ferrofluid thin film acted as the probe for temperature is put between a pair of solenoids which is used to apply magnetic field with its direction parallel to the plane of the film. The probe investigated here is water-based ferrofluid with an average diameter of 10 nm, and a volume concentration of 6.47% which is sealed in a 3.3 × 1.7 cm glass cell of thickness 7 μm to form a ferrofluid thin film.

The magnetic field is controlled by the combination of the signal generator which provides a square-shaped wave and the driving circuit to be on or off. The magnetic field is turned on during the high level of the square-shaped wave and on the other hand the magnetic field is turned off during the low level of the square-shaped wave. The field strength detected by teslameter is adjustable by changing the amplitude of the square-shaped wave. In the experiment, the strength of the magnetic field of 40.9 mT is used.

The laser light with the wavelength of 650 nm and the polarization direction perpendicular to the direction of the magnetic field is incident directly perpendicular to the film, in this case, the incident light is ordinary light. The transmitted intensity is detected in the direction of light propagation. A silicon photovoltaic cell is used to detect the optical signal which is shown by the oscilloscope. The electric signal of the applied magnetic field is also shown by the oscilloscope connected to the teslameter. The ambient temperature is changed by an electric heater around the ferrofluid thin film and a thermocouple is used to detect the changing temperature.

3 Results and discussions

The temperature sensor is realized through the application of the changing transmittance with the changing temperature. When the magnetic filed is not applied, the ferrofluid is isotropic and the ferrofluid shows a little absorption so that the transmitted intensity and the electrical signal shown by the oscilloscope are both in higher level. When magnetic field is applied, magnetic chains form in the ferrofluid which results in the absorption of the incident light. Thus, some of the light will not be allowed to pass through the ferrofluid thin film so that the electrical signal is shifted to the low level. When magnetic field is off, magnetic chains disappear so that the electrical signal increases again. As a result, a gap-shaped wave is observed on the oscilloscope. The results for optical transmission under external magnetic field in the temperature of 60°C (a) and 90°C (b) are shown in Fig. 2, respectively. And it is found that with the change of the temperature, the depth of the gap also changes (Fig. 2).

The transmittance of light as a function of temperature is measured as shown in Fig. 3. As is shown, the transmittance of light when a magnetic field is applied increases as the ambient temperature. The transmittance is derived by the quotient of the smallest electrical signal over the largest.

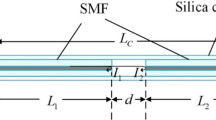

The theoretical formula describing the transmittance of the ordinary light can be described as (Taketomi et al. 1987):

where d is the thickness of the film (7 μm), λ the wavelength of the incident laser (650 nm), ϕ M the volume fraction of the ferrofluid (6.47%), σ the electric conductivity of the solute particles in the ferrofluid (2.98 × 1015esu), ω the frequency of the incident laser (2.90 × 1015 Hz), ɛ the ratio of dielectric constants of the solute particles and the solvent of the ferrofluid (0.05625), N the mean depolarizing factor in the direction of the magnetic field (0.28), C 2 the constant for normalization, δ the skin depth (4.02 × 10−8 m) and a the mean radius of the magnetic chains. The values in brackets are the parameters for the experiment.

The experimental data is verified by Eq. 1. In order to investigate the sensitivity if the sensor, exponential function are employed to fit the experimental data. It can be seen from Fig. 3 that the transmittance shows an exponential growth with the temperature which matches with Eq. 1. There are two main factors to determine the agglomeration or dispersion process of the magnetic chains, that is, magnetic attraction and thermal agitation. The former makes the magnetic particles to agglomerate while the latter makes the magnetic particles be dispersed (Pu et al. 2007). In the experiment, the amplitude of the magnetic field remains unchanged and the temperature keeps rising so that the latter factor plays a role. That is to say, the higher the temperature, the harder for the magnetic chains to be formed so that the mean radius of the magnetic chains a is in the inverse ratio of the temperature. The mean depolarizing factor in the direction of the magnetic field N reflects the shape of magnetic chains. When there is no magnetic field, all the particles disperse in the carrier liquid randomly so that N is one third which is the largest value of N. With the increase of the magnetic field strength, the particles agglomerate to form magnetic chains so that N decreases. When in a magnetic field with fixed strength, more particles will disperse into the carrier liquid with the increase of temperature which has been discussed above so that N increases. So it can be seen from Eq. 1 that the combined effect of the mean radius of the magnetic chains a and the mean depolarizing factor in the direction of the magnetic field N makes the transmittance increase with the increasing temperature. Thus, the transmittance verifies an exponential growth with the temperature which is shown in Fig. 3.

From the above experiment, the temperature sensor can be designed by investigating the changing depth of the electric signal shown by the oscilloscope with which the transmittance of the incident light can be calculated.

Because the sensitivity is a key factor for a temperature sensor, the sensitivity is obtained by calculating the differential quotients of the fitting curve in Fig. 3. The results are shown in Fig. 4.

The sensitivity is relatively small when the temperature is below 60°C while above 60°C the sensitivity is relatively large and keeps increasing to as large as 4.0%/° with the temperature. That is because when the temperature is below 60°C the effect of thermal agitation is comparable to the effect of magnetic attraction, which results in small variation of the transmittance when the temperature is increasing. On the other hand, when the temperature is above 60°C the effect of thermal agitation is dominant to the effect of magnetic attraction so that the variation of the transmittance with increasing temperature becomes larger. From the discussion above, it is found that this kind of temperature sensor designed is suitable for using in higher temperature, to say above 60°C.

4 Conclusion

The thermal agitation is enlarged with the rising temperature when the strength of the magnetic field is unchanged, which results in the suppressing of the magnetic chains to be formed while the optical transmission is enlarged. The temperature sensor can be realized by investigating the changing optical transmission with the changing temperature. After the analysis of its sensitivity, it is known that this temperature sensor designed is suitable for using in higher temperature, to say above 60°C. With further research, such kind of temperature sensor may have versatile applications in the condition that magnetic field with high intensity exists in the measuring range where dangerous for people to achieve.

References

Henry DM, Herringer JH, Djeu N (1999) Response of 1.6 μm Er:Y3Al5O12 fiber-optic temperature sensor up to 1520 K. Phys Appl Lett 74:23

Horng H-E, Hong CY, Yeung WB, Yang HC (1998) Magnetochromatic effects in magnetic fluid thin films. Appl Opt 37:2674

Horng H-E, Yang SY, Lee SL, Hong CY, Yang HC (2001) Magnetochromatics of the magnetic fluid film under a dynamic magnetic field. Appl Phys Lett 79:350

Jha CM, Bahl G, Melamud R, Chandorkar SA, Hopcroft MA, Kim B, Agarwal M, Salvia J, Mehta H, Kenny TW (2007) High resolution microresonator-based digital temperature sensor. Appl Phys Lett 91:074101

Luo W, Du T, Huang J (1999a) Novel convective instabilities in a magnetic fluid. Phys Rev Lett 82:4134

Luo W, Du T, Huang J (1999b) Field-induced instabilities in a magnetic fluid. J Magn Magn Mater 201:88

Moreira MF, Carvalho ICS, Cao W, Bailey C, Taheri B, Palffy-Muhoray P (2004) Cholesteric liquid-crystal laser as an optic fiber-based temperature sensor. Appl Phys Lett 85:14

Pu S, Chen X, Chen Y, Liao W, Chen L, Xia Y (2005) Measurement of the refractive index of a magnetic fluid by the retroreflection on the fiber-optic end face. Appl Phys Lett 86:171904

Pu S, Chen X, Chen Y, Xu Y, Liao W, Chen L, Xia Y (2006) Fiber-optic evanescent field modulator using a magnetic fluid as the cladding. J Appl Phys 99:093516

Pu S, Chen X, Di Z, Xia Y (2007) Relaxation property of the magnetic-fluid-based fiber-optic evanescent field modulator. J Appl Phys 101:053532

Shenping Li, Chan KT (1998) Optical fiber temperature sensor using a gain-switched Fabry–Perot semiconductor laser self-seeded from a linearly chirped fiber Bragg grating. Appl Phys Lett 73:23

Smith CW, Gisser DG, Young M, Powers SR Jr (1974) Laser emission at 1.065 μm from neodymium-doped anhydrous cerium trichloride at room temperature. Appl Phys Lett 24:10

Taketomi Susamu, Ukita Masakazu, Mizukami Masaki, Miyajima Hideki, Chikazumi Soshin (1987) Magnetooptical effects of magnetic fluid. Jpn J Appl Phys 56:3362

Yang SY, Chiu YP, Jeang BY, Horng HE, Hong CY, Yang HC (2001) Origin of field-dependent optical transmission of magnetic fluid films. Appl Phys Lett 79:2372

Acknowledgments

This research was supported by the National Natural Science Foundation of China (10874119); the National Basic Research Program “973” of China (No. 2007CB307000); and the Shanghai Leading Academic Discipline Project (B201).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D., Di, Z., Zou, Y. et al. Temperature sensor using ferrofluid thin film. Microfluid Nanofluid 7, 141–144 (2009). https://doi.org/10.1007/s10404-008-0371-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-008-0371-8